Cycle Time Reduction - CQI-TECH

advertisement

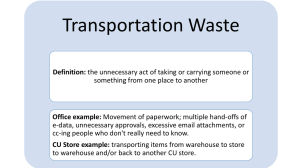

Cycle Time Reduction Gulay Litchfield For CQI-TECH PLC Introduction Many companies waste thousands of pounds on unnecessary procedures and processes that add no value to operations and slow response times. Customers are five times more likely to switch to another supplier because of poor service than because of poor quality or lower price. Cycle Time Reduction, a technique to reengineer business and production processes for speed and maximum company performance, is critical maximising profit. Cycle Time Reduction provides specific, proven techniques that are absolutely guaranteed to cut costs and dramatically improve the overall company efficiency. Some Important Facts Statistics consistently show at least a 40 to 1 return on every pound invested in cycle time reduction Cycle time reduction can reduce overhead by as much as 50% As many as 75% of the steps in each business process are non-value added New product development can be reduced from over two years to under one year (and sometimes much less) with significantly fewer resource Response to special customer requests can be reduced from 3 months turn-around to a mere 3 weeks or less Outlines Definition of ‘Cycle Time’ Definition and Methodology of ‘Cycle Time Reduction’ as a Management Tool Advantages Critical Success Factors Key Stages Success Stories Conclusion References Definition of Cycle Time Cycle time is defined as the total time for a unit to go from raw materials to finished goods and is a key performance measure in an industry with short product lives and rapid price erosion. Definition of Cycle Time Reduction Cycle Time Reduction is a management tool used for fundamentally redesigning the way work processes are carried out to ensure they meet the needs of clients in the most efficient and effective manner possible Methodology Fundamentally redesign the Process Effectively meet client’s needs Efficiently meet client’s needs Review key activities in value chain crossovers Reduce conception to delivery lead times Main Application Areas New Product Development Use of cross-sectional teams to shrink the time required taking a product from conception to market Operations Cycle Time Reduction minimises complexity, streamlines processes and decreases run lengths. Delivery and Logistics Eliminating unnecessary work and speeding up decision-making can decrease the time required to fill the orders. Advantages of Cycle Time Reduction Increase productivity and employee effectiveness Increase profit margins by lowering production costs Eliminate bottlenecks,identify and protect the CCR, and reduce inventory. Effectively meet changing customer needs through shortened product development cycles Supports more product changes over a shorter period of time What This Means Cycle Time Reduction will give a company a major competitive advantage in terms of improved costs, quality, service and customer satisfaction Critical Requirements for Success General recognition and acceptance of the ‘NEED’ by management and staff Senior Management’s commitment to change Empowerment of team participants Commitment to implementation Appropriate representation of key staff in team Consultation at all stages Key Stages 1 Preparation Identification of the CCR (Capacity Constraint Resource) Obtaining the support of senior management Quality office co-ordination and assistance Identification of appropriate team members Briefing participants, supplying documentation, setting venue Identifying ‘ how we do things now’ Identifying the way the process currently operates Identifying current problems and concerns, consultation! Key Stages 1 Preparation continued… Identifying ‘how we should be doing things’ Identifying the possibilities for fundamentally changing the process Creating a new process Identifying the actions required for implementing the new process Assigning the responsibility Assigning a Team Leader for the next phase (Implementation and Evaluation) Key Stages 2 Implementation and Evaluation Regular assessment of action plan progress Reassessment of priorities when necessary Reporting tangible improvements Evaluating the redesigned process A few success stories Using cycle time reduction techniques, IBM Brazil eliminated 50 unnecessary procedures, 450 different forms and 2.5 million documents a year A major computer chip company estimated a 30% increase in productivity with a savings of over $60 million. A major aerospace firm provided the same volume of product in 1992 as in 1991, while at the same time accelerating throughput and improving on-time delivery with one less shift, no increase in standard hours, and $800,000 less overtime. An expense report process at a major U.S. manufacturing plant went from 3 weeks to I day and required 5 fewer people. Conclusion Cycle Time Reduction isn't just the latest management technique. It's a proven strategy to reengineer your core business processes through SPEED, eliminating waste and maintaining maximum efficiency (productivity) and effectiveness (quality). References Achievement Dynamics Curtin University of Technology Brunel University The Goal (Goldratt 1992) Domaschkle, Brown, Robinson and Leibl Bain & Company Management Tools John Stark.com I Holland Ltd - Implementing The Goal