Cabinet Design & Construction

advertisement

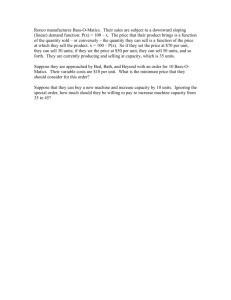

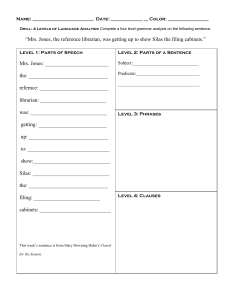

Cabinets kitchen cabinets are typically modular, standardized, and available in different quality levels & prices 'shop drawings' • when a project calls for custom millwork, or for specialized cabinetry and installation, the designer sends design drawings to the fabricator, who in turn, makes 'shop drawings'. • the shop drawings are the fabricator's interpretation of what the design drawings have proposed. • the shop drawings communicate the precise, dimensioned, and specific material character of the item. • the designer then checks the shop drawings to be sure that they are an accurate interpretation of the design drawings. • the fabricator will begin making the item after receiving the approved shop drawings back from the designer. each individual cabinet is identified with a number dimensions are coordinated with the interior designer a typical design drawing of a kitchen cabinet layout a typical shop drawing cabinet drawers: material, operability & joint construction = quality level types of drawer joints general criteria in selecting cabinets • The box of the cabinet should look and feel sturdy. The drawer is a good indication of the quality of construction used in cabinets. • Corner of wall and base should be braced with corner blocks. • Where there is stress or a major joint, the stiles and rails (the vertical and horizontal framing) should be joined with mortise and tenon or dowel joints. • Tops and bottoms should be dadoed into the sides. • Hinges should be strong, swing freely, and operate silently. • Hardware should be conveniently located and be comfortable to the hand, e.g. D- or U-shaped handle. • In addition to quality, if undercabinet lighting is being considered, select wall cabinets with an apron or recessed lower shelf large enough to cover the light. drawer selection criteria • Drawers should be removable, have an automatic stop, and be of sturdy construction. • The easiest sliding drawers have double metal tracking on sides or bottom of the drawer with nylon and ballbearing rollers or aluminum glides with nylon rollers. Over time, drawers that slide directly on wood will not slide as well. • The sturdiest drawers have dovetail or mortise and tenon joints in all four corners and have a separate drawer head attached to the drawer box which is made of 1/2 inch thick wood for the sides and back and 1/2 inch thick plywood or particle board bottom. • Tongue and groove joints are sturdy; rabbeted and butt joints are the least sturdy. • Plastic is easy to clean and can have molded plastic compartments which are useful. However, light-weight plastic can break if heavy objects are dropped on it. shelving criteria • Cabinets wider than three feet should have a shelf support in the center. • Wall cabinet shelves should be removable and adjustable, attached with clips or grooves. • In base cabinets, pull-out shelves are more usable and convenient than stationary shelves and may be vertically adjustable. • Open metal racks and shelving are available in base or wall cabinets and allow easy viewing. • Roll-out or tilt-out bins are options to standard drawers. • Lazy susans or blind corner swing-out shelves make corner space more accessible. cabinet materials • Wood – Wood is the most popular material for cabinets. It is available in softwood and hardwood. Softwood scratches and dents more easily. Wood grain of higher priced cabinets match vertically and horizontally. Plywood and particle board are more often used than solid wood for large areas since large wood pieces may warp. Exposed surface may be a veneer over plywood or particle board. Wood cabinets with stainless steel drawer and door pulls. Reclaimed wood cabinets dovetail joints used in the drawer construction, metal ‘glides allow smooth open and close operation. Cabinets made using reclaimed wood • High pressure decorative laminates – The 1/32 inch thick decorative laminate, e.g. Formica®, on a rigid material is highly suitable for kitchen cabinets. Decorative laminate cabinet doors need a backing sheet to prevent warping. Laminate is by far the most popular kitchen counter top. It's easy to clean, resists stains, comes in many colors and can imitate the look of marble and granite, wood, and stainless steel. It is also one of the less expensive kitchen counter materials. Some suppliers of High Pressure Laminate are Formica®, Wilsonart®, Nevamar®, and Pionite® Plastic laminate multiple layers of resin soaked kraft paper, topped by a patterned sheet of melamine (plastic) that’s subjected to heat and pressure. The resulting 1/16-in. laminate sheet can be glued to several different sub-strates, such as plywood, mdf (medium density fiber board), particle board, et cetera. • Plastics – Polystyrene, a heavy, durable plastic is sometimes used to imitate wood. Rigid vinyls in sheet or roll, and low pressure decorative laminates are laminated to a substrate or corestock, i.e. particle board, but are not as durable as the high pressure decorative laminates. Dupont Corian • more than 30 years ago, DuPont discovered a way to blend natural minerals with pure acrylic resin to create a product they call Corian®. • Corian is a solid surfacing material that can be cut, routed, drilled, sculpted, bent, or worked like a fine wood. It is currently available in more than 100 colors. The solid color of Corian® goes all the way through the material. • Corian solid surfacing material Corian used to make outdoor furniture Nature-inspired design by Avanzini The Leaf line of outdoor furniture was created by architect Giancarlo Zema with folding, leaf-like forms that are soft to the touch Bowls made of Corian • Steel – Steel cabinets are durable, washable, and retain no odor. – Low quality steel cabinets are less expensive and may be noisy to use. Stainless steel kitchen cabinets Stainless steel doors with pulls a sequence of design drawings that explore the design of a kitchen: this is the work of a student named Joseph Londt, Spring 2000 • This project began when Professor Rod Underwood delivered the assignment to me: design and execute drawings that detail a theoretical kitchen. • With little more information than this, I set out to design a space for the preparation and cleanup of food in a small space, much like the apartment where I currently live. • • I took basic ideas in space economy and filtered them through the ideals that I hold about the use of kitchen, and applied the understanding I've recently acquired in my technical classes at Ball State University to create the following drawings. vertical section/elevation • This one (previous sketch) shows the relationship of a six foot tall person and the counter spaces, which eventually evolved to be 36 inches high, as well as the wall mounted cabinets that are placed 60 inches off the floor plane, to accommodate a wide range of users, from short to tall. Exploration of lighting and the spatial requirements of the aisle was also a component. • This diagram shows spatial relationships of most of the surfaces of the kitchen space, and highlights the placement of many of the systems that will make the space work. • One component of the HVAC system is the ceiling mounted cook top exhaust hood, and some of the electrical and plumbing devices are shown in their preliminary locations. Rough dimensions also explain the space. • The floor plan shows door swings for cabinets and appliances, indicating worst case scenarios for available walkways, as well as distances from sink to stove to refrigerator. Standard kitchen cabinet units are both about manufacturing efficiency, and about human dimension. Anthropometrics is the study of human body measurements usually done along side ergonomics as a component of human factors engineering . Standard sizes of wall mounted cabinets Poggenpohl • “Our goal is to improve the kitchen.” • • This was cabinet maker Friedemir Poggenpohl's mission when he founded the company in 1892 - a company which today has become one of the most well-known kitchen brands in the world. Poggenpohl cabinets beautifully made Danish cabinets are very expensive. Cabinet Design and Consruction • In framed cabinetry, wood joinery holds the parts together. This American-style cabinet attaches a 1 ½” wide x ¾” thick frame to the front of the cabinet box. Horizontal rails and vertical stiles secure the door to the box. Hinges attach the door to the face frame. In frameless cabinetry, thicker side panels keep the cabinet rigid without the use of a front frame. Special hardware fittings secure the door directly to the side or end panels of the cabinet. Due to the lack of face frame, the cabinet doors lie flush with each other, forming a tight reveal of 1/8” or less. • Box materials typically contain wood chips, other wood by-products, and synthetic additives to make them especially strong and warp resistant. Your options typically include particle board, plywood, and • mdf (medium density fiberboard) • According to the National Kitchen & Bath Association, standard cabinet dimensions are as follows: base cabinets, which are set on the floor, are 24” deep and 34 ½” high, including a 4” toekick. wall cabinets, which are affixed to the wall with screws, are 12” deep. Standard height is 30”, but other common heights include 24”, 33”, and 42”. tall pantry or utility cabinets are generally 84” or 96” high Doors • How the cabinet door fits over the cabinet box determines its basic type Your options for cabinet door type include: Inset doors sit within the rails and stiles and lay flush with the front edges of the cabinet box. Truly inset doors are only available with framed construction, but designers can achieve the same look using vertical pilasters on frameless cabinets. Note: wood may expand and contract because of humidity, causing rubbing between the door and stiles. • Lipped doors are routed with a slight wooden groove to fit over the face frame. • Partial overlay doors conceal just some of the face frame - there is usually a ½” to 1” space between closed doors, allowing you to see much of the face frame. Because partial overlay doors are smaller than full overlay doors, they require less material, so this choice could slightly reduce your cabinetry’s total cost. • Full overlay doors have less than one-eighth of an inch between them - in effect, they fully lay over the cabinet. By definition, all frameless cabinets have full overlay doors. Manufacturers can attach full overlay doors to framed cabinets as well, however, creating a similar look. You can tell for sure whether a cabinet is framed or frameless by opening a door and checking for rails and stiles. doors and drawers: inset, slab, raised panel, recessed panel Drawers • The drawers will likely be made of solid wood or medium-density fiberboard (MDF); have framed or flat slab fronts; and be held together with either dovetail, mortise-and-tenon, or butt joints Drawer Slides • • • • • • Options for drawer slides include: Full extension・ Ball bearing Track and roller Wood Self closing • Full-extension slides attach to the bottom or the sides of the drawer and provide full access to the drawer interior. Their ball-bearing system adds stability and strength. Stronger versions can be used to store heavier items, such as files or cookware. Ball-bearing slides attach to the bottom of the drawer sides. Usually standard on high-end cabinets, they offer smooth, quiet operation. Their concealed runners mounted to the bottom of the drawer donユt get as dirty as those mounted on the side. They allow for a wider drawer box with a more usable interior space. • Track-and-roller slides attach to the drawer sides. Their epoxy-coated steel tracks and nylon rollers offer quiet operation but are less stable than ball-bearing ones Wooden slides work as slots in the drawer sides or bottoms and move the drawer along a wood runner. This option has fallen out of favor because the drawers tend to stick as the wood expands and contracts. • • • • • Stock cabinets are constructed prior to purchase. The manufacturer does not build them to individually requested specifications, so all sizes meet industry standards. Stock cabinetry widths begin at 9 inches and increase in 3” increments to 48”, the largest standard stock size available. Some stock companies also offer half-sized cabinets (13½”, 19½”, etc.). A kitchen's dimensions may not correspond exactly to the available increments. To accommodate sizes outside of the 3-inch increments, filler strips are used to close any gaps between the cabinet and walls or appliances. SEMI-CUSTOM CABINETRY • • • • • Partly stock, partly custom. Includes all of the offerings of stock cabinetry and fewer limitations. A step up from stock, semi-custom cabinets also typically come in 3” increments but have the ability to incorporate certain custom features, such as increased and reduced depths. Semi-custom cabinets have a wider range of door, finish, and wood selections than stock. Construction begins when order is finalized, so modifications can be made as the cabinets are somewhat built to suit. Expect to wait at least one month for delivery. CUSTOM CABINETRY • Custom cabinets are restricted by only one thing - the amount of money one is willing to spend! • There tend to be two kinds of custom cabinets: those made by a custom manufacturer (such as William Ohs) and those made by a local ‘custom’ woodworking shop. • Local cabinetmakers produce the box, frame, and drawers in their shop. They will either fabricate the doors or order them from a company. • You may want to ask your local cabinetmaker how much of it is done in-house. Surface Materials for Cabinets • • • • • • Typical Surface Materials Include: Wood Wood Veneer Plastic Laminate Stainless Steel Glass Poggenpohl Cabinets • Web page with links to many cbinet makers: • http://www.angelfire.com/tx2/tillmill/cabinets.html Pedini Italian Kitchens Pedini Italian Kitchens Typical Kitchen Layouts: Linear, ‘Railroad’, Peninsula, Corner, Horseshoe