Production Process Overview

advertisement

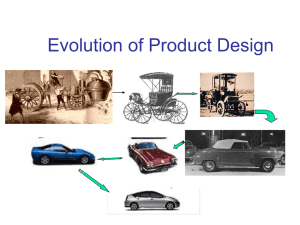

The word “design” is often used as a generic term that refers to anything that was made by a conscious human effort. Design is also a process that is used to solve problems. A design process is a strategy used to develop solutions to solve human needs or wants. 1. Identify problem(s) 2. Investigate and research options 3. Generate alternative solutions 4. Choose a solution 5. Developmental work 6. Model and/or prototype 7. Test and evaluate 8. Redesign and improve Individual parts of products Simple ▪ Wire Complicated ▪ Engine parts When assembly operations begin, all of the necessary parts must be available in the right quantities. Sometimes assembly work is completed by hand. Sometimes automatic assembly machines are used. In the past all machines were controlled by operators. Now CNC is commonly used. The numerical directions are contained in a computer program. Not only can the computer give directions to machines, it can also receive feedback. ▪ For example, it a cutting tool is broken, the computer is sent this information. The machine will then stop. For many years, cutting had to be done using a saw, knife blade, or cutter. Thanks to new technology, new processes are being developed. Waterjet Cutting is the process of using a highly pressurized jet of water to cut a material. ▪ Squirting water at a rate of 50,000 PSI turns the water into a knife blade. ▪ The waterjet follows a path guided by a computer program. Laser Cutting is the process of using a concentrated, high energy beam of light to cut materials. ▪ Laser cutting is used to engrave the molds used to make CDs. ▪ Like Waterjet Cutting, laser cutting is computercontrolled. Quality Assurance means making sure the product is produced according to plans and meets all specifications. Prevention involves doing everything possible to prevent variation in materials or processes before parts are made. Detection means inspecting to find variations in parts or products after they have been produced. Why do we change products? Who impacts these changes? Manufacturer Consumer Designer When do changes take place? Where do these changes come from? What advantages and disadvantages are associated with these changes? Room Key MIT Invention Index at the Massachusetts Institute of Technology, asked which of five inventions Americans could not live without. “The toothbrush emerged as the undisputed champ, beating out the car, the personal computer, the cell phone, and the microwave, in that order, as the most prized innovation.” Some records indicate a version of the toothbrush dates back as far as 5000 years ago. Babylonians rubbed a “chew stick” on their teeth and mouth to keep them clean. Companies in the U.S. started mass producing the toothbrush around 1885. Most Americans did not brush their teeth until Army soldiers in World War II were taught the habit of tooth brushing and brought their enforced habit back home after the War. Natural bristles were used in toothbrushes until nylon was discovered. In 1938, nylon, invented by Dupont, replaced the natural bristle. One of the first nylon toothbrushes to commercialize the industry was called Doctor West’s Miracle toothbrush. In 1960 the first commercialized electric toothbrush was marketed in the United States. The technology was developed in Switzerland in 1939. vs. Toothbrush designs now include electronics. The Radius™ toothbrush has a built-in timer that blinks light or plays music to let you know how long to brush.