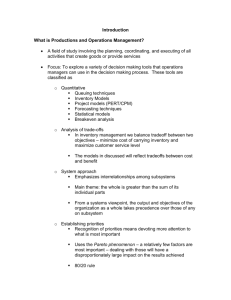

Introduction to Operations Management

advertisement

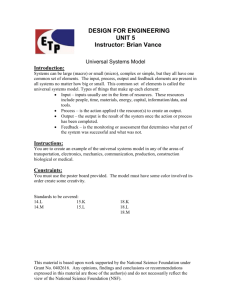

Introduction to Operations Management Operations Management Session 1 1 Objectives The student will be able to: – Define Operations Management – Describe the nature and role of the operations function – Construct and use transformation models – Appreciate that operations produce both products and services – Understand the difference between micro and macro operations – Understand the importance of internal suppliercustomer chains – Build a Typology of Operations based on the Four V’s – Appreciate how operations fit in with Operations Strategy 2 Topics • What is Operations? • What do Operations Managers do? • Operations Management in Goods and Services • Transformation Model • Business Process Analysis • Typology of Operations • Missions and Strategies 3 Definition • Operations Management (OM) management of activities that lead to the creation of goods and services through the transformation of inputs to outputs 4 Functions - Airline Marketing Operations Flight Ground Facility Operations Support Maintenance Finance/ Accounting Catering 5 OM - Critical Decisions 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Managing quality Design of goods and services Process and capacity design Layout design Human resources Location strategies Supply-chain management Inventory management Scheduling Maintenance 6 The Critical Decisions - 1 • Quality management – Who is responsible for quality? – How do we define quality? • Goods and services design – What product or service should we offer? – How should we design these products and services? 7 The Critical Decisions - 2 • Process and Capacity design – What processes will these products require and in what order? – What equipment and technology is necessary for these processes? 8 The Critical Decisions - 3 • Layout design – How should we arrange the facility? – How large a facility is required? • Human resources and job design – How do we provide a reasonable work environment? – How much can we expect our employees to produce? 9 The Critical Decisions - 4 • Supply chain management and JIT “Just-in-time” Inventory, Material Requirements Planning – Should we make or buy this item? – Who are our good suppliers and how many should we have? – How much inventory of each item should we have? – When do we re-order? 10 The Critical Decisions - 5 • Immediate, short term, and project scheduling – – Is subcontracting production a good idea? Are we better off keeping people on the payroll during slowdowns? • Maintenance – Who is responsible for maintenance? • Location – – Where should we put the facility On what criteria should we base this location decision? 11 Output of most Operations a Mixture of Goods and Services PSYCHOTHERAPY CLINIC MANAGEMENT CONSULTANCY COMPUTER SYSTEMS SERVICES Tangible Can be stored Production precedes consumption Low customer contact Can be transported Quality is evident RESTAURANT SPECIALIST MACHINE TOOL MANUFACTURER ALUMINIUM SMELTING CRUDE OIL PRODUCTION PURE GOODS Intangible Cannot be stored Production and consumption are simultaneous High customer contact Cannot be transported Quality difficult to judge PURE SERVICES 12 Goods Versus Services - 1 Good Can be resold Can be inventoried Some aspects of quality measurable Selling is distinct from production Service Reselling unusual Difficult to inventory Quality difficult to measure Selling is part of service 13 Goods Versus Services - 2 Good • Product is transportable • Site of facility important for cost • Often easy to automate • Revenue generated primarily from tangible product Service • Provider, not product is transportable • Site of facility important for customer contact • Often difficult to automate • Revenue generated primarily from intangible service. 14 The Transformation Model Input Resources Output Services + Products Input Transformed Resources Materials Information Customers Transformation Process Customers Input Transforming Resources Facilities Staff 15 Economic System Transforms Inputs to Outputs Inputs Land, Labour, Capital, Management Process Economic system transforms inputs to outputs at about an annual 1% increase in productivity: - capital 1/6 of 1% - labour 1/6 of 1% - management 2/3 of 1% Outputs Goods and Services Feedback Loop 16 Macro and Micro Operations • Micro – An operation or process that can not be split up into smaller operations and processes • Macro – An operation or process that can be split up into smaller operations and processes • All Macro operations are made up of many Micro operations 17 Internal Customer Concept • To treat internal suppliers and customers as if they were independent external organisations • Each micro-operation should identify its internal customers and internal suppliers • Discuss with them what they need and what they can offer • Related to Business Process Re-engineering (BPR) 18 The Four V’s • Volume of demand – How many the organisation makes – Service vs. Mass Production • Variety in operations – The ability to adapt the transformation process to meet needs of the customer – Taxi vs. Train • Variation in demand – Adapting to changing demand • Visibility of transformation – How much of the operations functions are visible to the customer – Some operations have mixed high/low visibility eg Restaurant Front and Kitchen Often they are in conflict 19 A Typology of Operations Electricity generator factory Gourmet restaurant Pioneering surgery Taxi service Bespoke tailor University tutorials Corporate tax advice Department store Electricity utility Financial audits Emergency service London underground Health care "Cook at your table" restaurant Dentist Music teacher Low High High High Volume Variety Variation in Demand Visibility High Low Low Low Television plant Fast food restaurant Routine surgery Mass rapid transport Off-the-peg suit plant University lectures Financial audits Jeans shop Bread bakery Consultancy advice Shopping mall security Trucking operation Most manufacturing Prepackaged sandwich maker Dental technicians Distance learning 20 The Most Important Conflict Volume vs Variety Project Job Unique aspect to each product Batch Mass Continuous Made to order Made to stock Commodity Product Unique Volume Very low Very low to low Low to med High Very high Variety Infinite Very high to high Medium to high Low Very low 21 Project Job Batch Variety High Process Types - Products Mass Low Continuous Low Volume High 22 High Process Types - Services Professional Variety Service (e.g shops) Low Mass Services Low Volume High 23 Organisation Mission Statement • Mission – the purpose or rationale for an organisation’s existence • Example Mission Statement – “To manufacture and service a growing and profitable worldwide microwave communications business that exceeds our customers’ expectations” 24 Operations Management Mission Statement • General – To produce products consistent with the company’s mission as the worldwide low-cost manufacturer • Specific – To attain the exceptional value that is consistent with our company mission and marketing objectives by close attention to design, procurement, production and field service opportunities 25 Strategies • Strategy – How an organisation expects to achieve its missions and goals • Generic Strategies – – Competing on price – Competing on differentiation – Competing on response 26