Midea Kitchen Appliances Division

Midea Kitchen Appliances Division

KA Company Introduction

2013.08.18

Midea Group Profile

Founded in 1968, the group is located in Shunde, Guangdong Province, China

One of the largest household appliance production bases in China. Achieved 140 billion

RMB overall sales revenues in 2011 including $6.3 billion US dollars in overseas sales

170,000 global employees, including 21,000 management professionals

Total Asset holdings equal 105.7 billion RMB, Net Asset worth 29.8 billion RMB

15 manufacturing bases consisting of 7 million square meters of operational space

As of June 2011, Midea Group donated over 500 million RMB to social welfare and educational programs

Recognized as China’s most valuable brand in 2012. Midea’s brand image has an estimated market value of 61.12 billion RMB (sixth overall)

Midea Group Structure

Board of Directors

Executive

Committee

Strategy &

Planning

Admin

&

HR

Auditing

Dept

Technology&

Quality Dept.

Finance IT Legal

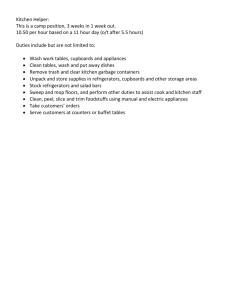

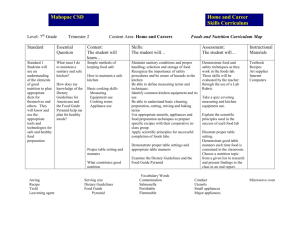

Kitchen Appliances Division Structure

Kitchen Appliances Division

Operations and

Human Resources Dept.

Financial

Management

Dept.

Midea Kitchen and Electrical Appliances Division

Structure

HR Department

Midea Cooking Appliances

Company

Finance

Department

Sales

Growth

Cooking Appliances Business growth 2008 to 2012

Overview

As a subsidiary of Midea Group Kitchen Appliances Division, the Cooking Appliances Company is a modern enterprise specializing in research & development, as well as the production of a range of ovens, hoods, gas hob, sterilizing cabinets and integrated kitchen furnishings. Midea products are sold throughout the United States, Europe, the Middle East, Australia, South America and other countries and regions. Midea has two production bases in Shunde and Wuhu China.

Midea has a research and development department as well as manufacturing and quality control system. It has an annual production capacity of producing 1.5 million ovens/ranges, 3 million hoods and 4 million gas hobs . Relying on strong marketing capabilities and Mideas positive brand reputation, the company aspires to be the world's most competitive kitchen appliances supplier.

FS cooker Hood Gas hob BI oven Induction Cooker

History

No.

Historical Memorabilia

1 Midea hoods and gas hob went public.

2

Midea hoods and gas hob awarded the title of " Guangdong Famous Brand

Product".

3

Midea hoods and gas hob awarded the "China energy-saving and environmental protection product certification".

4 Sterilizing cabinet awarded the title of " Guangdong Famous Brand Product".

5 Entered the oven industry.

6 Midea stove top ranges awarded the title of " China Famous Brand Products".

7 Imported enamel line.

8 BI oven in MP.

9 Wuhu hoods factory operation

10

Midea gas hob testing and evaluation center approved by the "National CANS laboratory".

11

Integrated ovens/range, hoods, gas hob, sterilizing cabinets and kitchen cabinet into a Cooking Appliances Company.

12 Combine electric hob into Cooking Appliances Company

Time

1999.06

2003.03

2012.09

2013.08

2004.04

2005.03

2007.04

2007.04

2007.12

2008.01

2010.09

2011.09

Information technology project -632

Operational systems (6,3), as well as two (2) portals and integrated technology platforms to push the establishment of end-to-process framework and sharing of products, materials, customers, suppliers, financial plans and other data standardization.

MIP Uniform standard platform

Marke t

R&D

Planni ng procu reme nt manu facturi ng sales servic e financ e

ERP MES CRM PLM APS

Strategic management

Financial management

Human resource management

Business support management

IT management

SRM

BI

FMS

HRMS

MDP

Integrated

Platform

Product Portfolio

Esquisite Black tempered glass kitchen unit, with dynamic light control

Six-Piece

Magic Kitchen Kit

functions. Manufactured with high-quality aluminum handles. This elegantly designed kitchen unit is the essence of quality!

Overall Combinations

Presented these as a in-house kitchen Environment

Optional

Contents of Folding

F1

Hood+Hob+Oven

Overall

Titan Suit

Kitchen Integrated Solution

F2

MWO+Oven

F3

Compact Oven +Oven

F4

Ceramic +Oven

C.M.F

Function

Old Layout | Features for reference

Industry Design

Industrial Design Company has become a professional, international team, which can complete all design aspects from “ Concept to production ”. We are committed to providing high-quality products for customers and consumers both home and abroad. Our design concepts and innovation have won various international design awards. Midea Industrial design company has gradually become one of China’s top design leaders. In the future, we will continue to innovate and develop, cutting edge products with the aim of becoming a world-class design team.

70 domestic designer + 7 South Korea/USA/Italy expert

Silver Award included

R&D team

The research and development department is directly under the control of the Cooking Appliances

Company. This enables it to undertake planning and product development and establish, standards and guidelines for procurement, manufacturing and quality. R&D consists of 10 sub-sections which are directly responsible for technology, research, product development, logistics support and internal management.

R&D

Modena, Italy

R&D professionals

The R&D Centre employs more than 20 foreign technical experts, 4 domestic university professors and about 240 R & D technical specialists, including 4 national senior engineers,1 nationally registered quality engineer and 35 workers that possess masters and doctorate degrees. Furthermore, our staff is also comprised of professional dieticians .

Experience

R&D Innovation

To implement the spirit of the Division transformation, promote and encourage the spirit of technological innovation,

R&D carries out frequency conversion technology, electronic technology, energy efficiency technology, sensor technology, CFD simulation technology, finite element analysis, thermal design, materials technology, wind tunnel technology and other core technologies around the direction of the energy-saving, environmental protection, intelligence and so on, developing innovation and research constantly to achieve industry-leading level. Hightemperature steam cleaning technology has passed the national certification authority.

R&D has applied for 91 patents totally in 2012, 26 of them are appearance patents, 53 are utility model patents, the rest 12 are invention patents, the patents quantity climbs steadily within 3 years.

Efficiency

Huge air-flow

Boost burner

+10% efficiency

Intelligent control inverter control

Intelligent fire

+Move pan, fire burn down

Easy to clean high-temp self-cleaning steam wash

Information Construction

ERP leads the core information management model. It encompasses four information platforms for suppliers ( SCM ), in both domestic and foreign markets ( CRM , OSM ), it also contains manufacturing procedures ( MSS ), which run through various dimensions of information management systems. These core areas involve quality, logistics, research and development, investment and integrated office operations to provide strong support.

Order driven

ERP

Process analysis

System construction

Midea strives to keep science and technology as the driving force and believes in quality as the driving force. Midea employs numerous qualified professionals, which conduct rigorous research and development, meticulous quality control and sales service support.

Midea has been awarded various Integrated Management System Certifications (ISO90001, ISO140001, OHSAS18001,

QC080000). Our Cookers, hoods and kitchen sterilizing ccabinets have also obtained a national “Gas Appliance Production

License

” as well as a Disinfectiant hygiene certificate

Midea products have achieved domestic and international certifications (CE, CB, GS, RoHS, EMC, CCC).

The company has excellent after-sales support and is committed to providing consumers with excellent quality service.

IECQ-HSPM QC080000

ISO90001、ISO140001、OHSAS18001

Testing Center

Currently Midea is in cooperation with many certification authorities, including CCC in the domestic market and Gastec, SGS, TUV Rheinland, BV, DEKRA. As a result Midea has been awarded numerous other certificates such as CCC, CB, CE, GS, SAA. These certificates are accredited SGS gas laboratories.

On-site test On-site test On-site test On-site test On-site test

Cooking performance

Midea cooking performance lab evaluate product by using scoring card (color, temp…) to ensure product meet market demand during new product development. And also develop new menus for new products.

Standard we are using:

EN50304-EN60350-2009

Gas performance

Midea gas lab can evaluate thermal load, burning status (including: flame stability, yellow flame, analysis of carbon, carbon monoxide, nitrogen oxides, etc.), electric ignition performance, safety devices performance, performance and other professional testing laboratory.

Major equipment: gas leakage detectors, flue gas analyzer (Siemens, TESTO, Germany), wet gas meter

(Shinagawa, Japan), data logger, etc.

Standard we are using:

EN 30-1-1 2008/BS EN 30-2-1/BS EN

30-2-2

NAG312

NBR 13723-1

NTE INEN22590

NCH 927- 1

Wet gas meter Flue gas analyzer

Gas life test

The domestic largest life test lab for gas product with capacity-90 units products test at the same time. To evaluate reliability of Midea gas products.

For components For finished goods

Gas distribution station

Midea gas distribution stations equipped with automatic continuous control of gas distribution system to prepare a variety of test gas mixtures. Simultaneous preparation of two different gas mixtures, which has a high accuracy gas distribution, gas distribution variety, ease of operation, output pressure stability, high degree of automation. Its Wobbe index meet the national standard CB/T13611, European standard EN437 standard requirements.

Source mixture: G110; G112; G21; G222; G23; G24; G25; G26; G27; G231; G1.250; G1.251; G1.252; G271;

G25.1; G26.1; G27.1; G2.411; G2.412; G2.350; G2.351; G2.352; G2.300; G2.301; G2.302

automatic continuous control system

Electric performance

To evaluate safety and functions of oven and hood, mainly concern temp rise, air/smoke isolation efficiency, energy efficiency, abnormal test etc…

Major equipment: data collection instrument (USA Agilent), temperature logging devices (Yokogawa), energy efficiency brick, ERP tester.

Standard we are using:

BI oven: IEC/EN60335-1; IEC/EN60335-2-6; EN60350

Hoods

:

IEC/EN60335-1; IEC/EN60335-2-31; IEC60591

Remark: EN for European products and IEC for SA products

Electric life test

To evaluate liability of Midea electric products and spare parts by thousands circles test.

For components

For finished goods

Environment Lab

The equipment can reach temp range 85 ℃ --- -30 ℃

, humidity 95% to evaluate products performance in various environment.

Packaging

To evaluate packaging protection through vibration/stack/drop test

Mold manufacturing

With advanced international hardware and software facilities, high speed precision CNC machine centers, wire cutting and mirror computer spark machines; the company retains a full set of nearly one hundred advanced modeling and testing equipment. Such machine technology has enabled Midea the ability to manufacture continuous large-scale mold and high-end plastic injection molds . Such machine integration has enable Midea to convert industrial design, R&D and design appeal into producing high quality products.

Shunde Base

Metal Processing Factory

Shunde sheet metal processing factory has 180 employees, mainly producing core component for oven, hobs and hoods by using punching, welding and CNC etc. core technologies.

It has industry-leading equipment and technology machines with more than 50 imported punching machines with 60-600 ton capacity, domestic advanced CNC (1 CNC punching machine, 1 CNC shearing machine, 7 CNC bending and 2 CNC rough shape cutting lines), production equipment, 2 semiautomatic cavity welding production lines and advanced cavity curling technology. The capacity is 2 million units per year.

Shunde Base

Painting Factory

Shunde painting factory produce enamel and powder painting processes .

It has industry-leading equipment and technology: including two importer enamel lines and one Germany imported spray line . The Spray line has a powder room designed by Germany’s Wagenaer. The enamel line has a pre-treatment line designed in the United States

KMI and the dry powder line are designed by

Nordson, USA. Another enamel line has robot cavity automatic spraying line capabilities designed by

Germany Lyike and the firing furnace designed in

Turkey. Annual output is 2 million units.

Shunde Base

Assembly Factory

Shunde factory assembly factory has 1000 employees , mainly specializing in assembling ovens, ranges and hoods.

It has industry-leading equipment and technology: Including 12 push-pull production lines and 1 CKD/SKD line, automatic dispensing lines, automatic marking machines, automatic stacking machine etc.The average single-shift output of ovens is about 800 units, the anual output is about 1,000,000 units . The average single-shift capacity of gas hob is about 1500 units, the anual production capacity is about 2 million units.

Wuhu Base

Metal sheet factory

362 employees, mainly producing hoods.

It has industry-leading equipment and technology: with more than 50 imported units capable of holding 60-600 tons.

It also has domestic advanced CNC (1 CNC shearing machine,

2 CNC bending and 1 CNC rough shape cutting line )production equipment, 1 automatic production line, 2 industry-leading storage welding box production lines. Additionally it also has the industry’s leading automatic laser welding production line(German KUKA robot + Han’s laser ), a pulsed laser automatic welding spray line designed in the United States.

Moreover, the workshop also owns imported equipment from

Nordson Corporation and automatic spray gun as well as a spray paint line designed in France and imported equipment designed by Purcell.

Wuhu Base

Assembly shop

One of the final output models in Wuhu’s factory cooker and kitchen exhaust hood assembly shop. This shop epitomizes the key manufacturing sector yielding on-site quality, and efficiency . The shop mainly produces cookers and hoods. This is in addition to manufacturing Chinese cookers and kitchen exhaust hoods, European style cookers and kitchen exhaust hoods.

The assembly and manufacturing workshop has industryleading automated production lines and automatic conveyor belts, part assembly lines, automatic code printers and 2 viscose lines. The average single shift output is 5000 units, and the annual output is 1.8 million units.

The management business model mainly consists of institutionalized production principles which adhere to lean logistics concepts in addition to high-end production assembly.

Logistics

The Cooking Appliances Company logistic plans are guided by a pull production concept in which the delivery distance is shortened . This is accomplished by reducing on-site materials management issues through logistics simplification and container standardization . Additionally, logistics response will be enhanced through the use of automated transportation solutions. Thus, reducing transport distance by just-in-time production and layout optimization so that it can minimize personnel intervention.

Track

Inspect

Organize

Store

Select

Transport Manufacture

Ship

Internal overall management serves for production!

Warehouse

The Cooking Appliances Company warehouse supplies frontend materials while utilizing just-in-time logistics concepts. Thus, reducing occupied areas and raw material inventory to to achieve lean objectives. Concurrently, finished products warehousing integrates foreign an domestic sales market demands while centrally allocating three industrial zones to achieve minimum inventory and maximum transportation requirements.

Energy saving

Midea Cooking Appliances Company has successively used LED lighting throughout various offices and production lines. It has resulted in energy consumption savings of 210000 KW and approximately in 30,000

USD savings each year.

Production line using

LED lights (11W)

Employee

Stable employee, stable quality

Midea Culture Club is an employee organization that is devoted to worker’s well being. Throughout these years, various company functions are organized to promote employee wellness, moral and overall sense of belonging. Such activities include sports and other social functions.

T h an You