Dyeing & Printing

advertisement

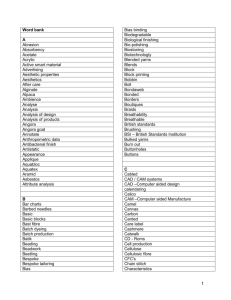

FASH 15 textiles dyeing & printing dyeing & printing color is one of the most significant factors in the appeal & marketability of textile products manner in which color is added to a textile and the chemical nature of the colorant contribute to product’s • appearance • performance • rate of response to fashion change • quality • cost color theory complex phenomenon that combines • the physics of light • chemistry of colored objects • biology of the eye • behavioral sciences—social & cultural meaning of color • aesthetics colorants—pigments insoluble color particles held on surface of a fabric by a binding agent • application is quick, simple & economical • more than 80% of printed fabrics colored with pigments • fewer sustainability issues compared to dyes • lower color strength—uses more pigment • washdown can be a problem (losing color) • used on short-run prints such as university logos, professional sports teams, event t-shirts, etc… colorants—dyes complex organic compounds used to add color to materials by binding to them • molecules dissolved in in water or some other carrier that allows them to penetrate the fiber— stage added affects penetration • chemical additives used to regulate penetration • great color strength • small amount of dye colors large quantities of fabric • used in either solutions or pastes (used for printing) • thermoplastic fibers difficult to dye http://www.youtube.com/watch?v=SB N3hDIz88Y stages of dyeing fiber stage— • added to fibers before yarn spinning—slightly irregular color (heathered or mottled) • mass pigmentation (solution-dyed)—adding colored pigments or dyes to spinning solution before fiber is formed • stock or fiber dyeing is expensive stages of dyeing yarn stage— can be done with • yarn in skeins— skein dyeing • yarns wrapped on cones or packages— package dyeing • yarn wound on beams— beam dyeing yarn-dyed fabrics more expensive to produce— • larger inventories of yarn needed • threading loom considered to be better quality fabrics http://www.youtube.com/watch?v=_wfagh_MZRw&feature=related participation activity: yarn dyeing wool & kapok samples …using the wool & kapok samples created in the yarn spinning activity from a previous class, select a color of kool-aid dye to experiment with …put both samples in the same color for comparison purposes …leave in dye for duration of class stages of dyeing piece/fabric stage piece dyeing— when bolt or roll of fabric dyed • usually produces solid-color fabrics • generally costs less to dye • color decisions can be delayed cross dyeing— piece dyeing of fabrics (sometimes yarns) made of different generic fibers • each fiber type bonds with a different dye class union dyeing— another type of piece dyeing that uses dyes suited to each fiber type, mixed to produce same hue stages of dyeing product stage— after fabric is cut & sewn into finished product • great care must be taken in handling materials & dyeing to produce level, uniform color • button, thread, trim may be different color because of differences in dye absorption • important due to quick response to retail & consumer demands methods of dyeing batch dyeing— AKA exhaust dyeing—textile circulated through dye bath, can be used in any stage of production beck (reel or winch) dyeing— • fabric (in loose rope) lifted in and out of dye bath by a reel jig dyeing— • uses stationary dye bath with two rolls above bath—fabric carried around rolls & rolled back and forth pad dyeing— • fabric run through dye bath in open width then between squeeze rollers to force dye into fabric with pressure methods of dyeing package dyeing— dye bath forced through textile during yarn stage— wound on core and placed on perforated spindle in pressurized machine methods of dyeing combination dyeing— both textile & dye bath are circulated jet dyeing— • similar to beck dyeing—fabric processed as continuous loop paddle machines, rotary drums or tumblers— • used primarily for product dyeing continuous machines— • used for large fabric lots—include compartments for wetting-out, dyeing, aftertreatment, washing, rinsing methods of dyeing resist dyeing— block color absorption during yarn or fabric dyeing batik— • generally hand process using hot wax applied to fabric in given design tie dye— • hand process in which areas of yarn or fabric are wrapped with thread or string ikat— • ancient form of resist in which yarn is tied, dyed & woven—requires great skill to determine placement of design in finished fabric http://www.youtube.com/watch?v=KkFc0JNsmO0 printing • used to add color to localized areas only • allows for greater design flexibility and relatively inexpensive patterned fabric • wet prints use a thick, liquid paste • dry prints use a powder • foam prints use a colorant dispersed in foam http://www.youtube.com/watch?v=6iVicNDx-00&feature=related printing methods direct printing— color is applied directly to fabric in pattern & location desired in finished fabric block printing— • hand process; oldest technique—expensive & slow http://www.youtube.com/watch?v=LZ4_0shRurE warp printing— • warp yarn printed before weaving printing methods discharge printing— • piece-dyed fabrics in which design is made by removing color from selected fabric areas • usually done on dark backgrounds http://www.youtube.com/watch?v=91Y59-gSBi8&NR=1&feature=fvwp screen printing • incredibly versatile, simple process • separate mesh screens used for each color http://www.youtube.com/watch?v=NQpmFFarsZA&feature=related printing methods digital printing— • ink-jet printing heat-transfer printing • design transferred to fabric from specially printed paper by heat & pressure electrostatic printing • prepared screen covered with powdered dye; passes through electric field & pulled onto material foil printing • adhesive applied to fabric, foil heated on heat transfer press & bonds to adhesive pattern stencil printing • separate pattern cut for each color, color is applied in thick paste or sprayed on with air gun participation activity: yarn dyeing wool & kapok samples …remove your yarn samples from the dye—please be careful not to spill or dribble dye, clean up after yourself …rinse and wring out yarn samples well …compare the two samples and answer the following questions: • • • • • how well did the wool take the dye? how well did the kapok take the dye? what differences between the two samples are readily identifiable? which one do you like better? anything else you would like to add? …lay out samples to dry in resource room—I will collect & grade them later