Workmanship and Tests during Construction Phase

advertisement

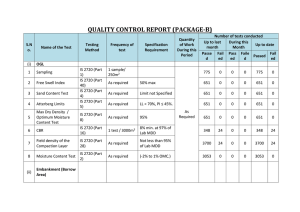

Workmanship and Tests During Construction Phase Presented by: Er. Bhagawan Shrestha Specification • Definition: A detailed description of the particulars of some projected work in building, engineering, or the like, giving the dimensions, materials, quantities etc, of the work, together with directions to be followed by builders or constructor. Back ground • Prevailing Specification approved on July 2001 and enforced to use. • Contains 31 sections including blank Section 300. DOR SPECIFICATIONS • SECTION 100 - GENERAL • SECTION 200– SITE CLEARANCE • Section 500 deals with QUALITY CONTROL • Section 600 deals with MATERIALS AND TESTING OF MATERIALS • Section 700 deals with PIPE DRAINS , PIPE CULVERTS AND CONCRETE CHANNELS • Section 900 deals with EARTHWORKS Section 500 –Quality Control contains: • • • • • • • • • • • • • • 501 502 503 504 505 506 507 508 509 510 511 SCOPE CONTRACTOR RESPONSIBLE FOR THE QUALITY OF THE WORKS QUALITY CONTROL SYSTEM QUALITY ASSURANCE PLAN TESTING PROCEDURES AND SETS OF TESTS LABORATORY TRIALS SITE TRIALS CONTROL TESTING DURING CONSTRUCTION ACCEPTANCE TESTS FOR COMPLETED WORKS OR PARTS OF THE WORKS SCHEDULE OF TESTS LABORATORY General All materials incorporated and all workmanship performed shall be strictly in conformity with the requirements of the Specifications and the Contractor shall be responsible for the quality of the works in the entire construction within the contract. Testing Procedures and Set of Tests • For ensuring quality of work, materials and workmanship be subjected to testing in accordance with procedures, sets of tests and frequencies as specified in Specifications • Specified testing frequencies are not restrictive • Engineer directs for the tests to be carried out as frequently as deemed necessary • Where no specific testing procedure mentioned in Specifications, tests be carried out as per prevalent accepted engineering practice or directions of Engineer Laboratory Trials • Laboratory trials/mixes be carried out by Contractor on materials proposed to be used in works in their natural state. • laboratory trials establish a relationship between specified requirements of end product and properties which can be determined in field for purpose of construction control. Site Trials • Materials, used for laboratory trial, composition of which meets specified requirements and is accepted by Engineer, shall then be used in site trials • Contractor shall submit the proposal for the site trials to the Engineer at least two weeks before Site Trials(contd.) • Site trials for laying and compaction shall be carried out by Contractor on all earthworks and pavement materials proposed for works using same equipment and methods proposed for use in works. Site Trials(contd.) • Site trials for concrete mixes as specified shall be carried out by Contractor to demonstrate suitability of his mixing equipment. During site trials, compliance with Specifications for weighing equipment, storage of ingredients, means of transport for concrete, placing, compaction and curing shall be checked by Engineer. During the site trial a full scale sequence including placing and compaction of concrete shall be carried out on a part of works which will represent particular difficulties due to presence of reinforcement, obstructions or others. Site Trials(contd.) Site trials demonstrates: I. suitability of materials, II. suitability of equipment for laying and compacting materials to specified density, and III. confirmation of achievement of other requirement of completed works. Site Trials(contd.) • Each site trial (for earthworks & pavement) to be at least 100 m long and to full width and to the specified depth of materials. • Site trial be carried out at least 21 days ahead of commencement of related works. Site Trials(contd.) Data to be recorded for each site trial: i. Composition and grading of material before site trial, ii. Composition and grading of material including bitumen content, iii. Moisture content at compaction and Optimum Moisture content for that specified compaction, Site Trials(contd.) iv. Equipment details like type, size and tyre pressures, frequency of vibration and number of passes made by compaction equipment, v. Maximum dry density measured on sample before site trials (Lab. Test), vi. Density achieved, vii. Compacted thickness of the layer Site Trials(contd.) • Contractor conducts 8 sets of tests on each 100m length of trial section for each level of compaction effort. • If all eight sets of results meet specified requirements for material and workmanship, site trial be deemed successful. • Data recorded in trial becomes agreed basis on which particular material be provided and processed to achieve specified requirements. CONTROL TESTING DURING CONSTRUCTION • All earthworks, pavement layers, and backfill to drainage and other structures shall be subject to control testing (process control) including, if required, testing by the Engineer in accordance with the Conditions of Contract and Clause 503. • The tests to be carried out and their frequency for the quality control of the works are detailed in the relevant Sections of these Specifications Testing Schedule (Example) PART OR Section/Clause COMPONENT No of TESTS FREQUENCY OF THE Specification WORKS 700 PIPE DRAINS, PIPE CULVERTS AND CONCRETE CHANNELS MATERIALS 701 Identification : As specified FOR RE-FILLING Gradation, or required by THE TRENCHES Plasticity the Engineer Index, CBR In-Situ Density (95% MDD) Testing Schedule (Example) EARTHWORKS FILL MATERIAL COMPACTION 900 1. Material 1. For each Identificati new source on, MDD, and in OMC, every 1500 CBR m3 2. MC 2. For each new source and in every 250 m3 3. Field 3. One test Density per 250m2 of each Acceptance testing • Contractor requests, in writing for Engineer's approval for each layer of each section of earthwork, pavement construction and backfill • Such request be accompanied by tests results required by Specifications. • Engineer inspects section for any visible defects including, heaving material (visible during compaction), segregation, and for uniformity of mixing and compaction Acceptance testing (contd.) • If visual aspects satisfactory Engineer tests Section of works submitted and informs Contractor in writing of results of tests specifying acceptance or rejection of section or layer concerned • Work on a layer in no circumstances commences until preceding layer been approved and accepted by Engineer in writing. Acceptance testing (contd.) • Contractor fully responsible for protecting and maintaining condition of work submitted for approval. • any layer left unprotected for more than 24 hours subsequent to approval shall again be subject to construction control testing, and tolerance checks. • Contractor responsible for making good any subsequent damage due to traffic, ingress of water or any other reason Section 600 contains • 601 SCOPE • 602 QUALITY OF MATERIALS • 603 SOURCES OF MATERIALS • 604 INSPECTION AND ACCEPTANCE OF MATERIALS • 605 MATERIALS AND MANUFACTURED ARTICLES • 606 DEFECTIVE MATERIALS Section 600 Table 6.3 : Classes of Material Quality MATERIAL LAA AIV CLASSES % SSS Degradabilit Flakiness Crushin y g Test Test Index Ratio % % % <12 <5 <20 100 <12 <5 <25 100 <12 <5 <25 80 A B C1 <25 <30 <35 ACV % <20 <20 <25 C2* D1 <30 <40 <20 <30 <12 <12 <5 <5 <25 <30 60 D2* E1 E2 E3 <35 >35 & <50 >40 & <50 >50 <20 <25 <30 <30 <12 <18 <18 <18 <5 <10 <10 - <30 - - C D E Table 6.4: Tests Procedures Applicable to Disturbed/Undistributed Samples of Soils and Gravels Tests Test procedure Determination of : i) Moisture Content IS 2720 Part 2 (Oven-drying method) ii) Liquid Limit IS 2720 Part 5 (Cone Penetrometer or by Casagrande Apparatus) ApparatusaP iii) Plastic Limit IS 2720 Part 5 iv) Plasticity Index IS 2720 Part 5 v) Linear Shrinkage IS 2720 Part 20 vi) Specific Gravity of Particles IS 2720 Part 3 vii) Particle Size Distribution IS 2720 Part 4 viii) Organic Matter Content IS 2720 Part 22 ix ) Total Sulphate Content IS 2720 Part 27 x) pH Value IS 2720 Part 26 (Electrometric Method) xi) Mica Content xii) Density-Moisture Content relationship (2.5 kg rammer) - Manual mineralogical counting IS 2720 Part 7 xiii) Density-Moisture Content relationship IS 2720 (4.9 kg rammer) Part 8 xiv) California Bearing Ratio IS 2720 Part 16 xv) Sand Equivalent IS 2720 Part 37 (Mechanical Shaker or Manual Shaker method) xvi) Field Dry Density IS 2720 Part 28/Part 29 xvii) Unconfined compression test IS2720 Part 10 xviii) Consolidation test IS2720 Part 15 xix) Direct shear test IS2720 Part 13 xx) Triaxial test IS2720 Part 11,12 xxi) Hydrometer analysis IS 2720 Part 4 xxii) Vane shear test IS 2720 Part 30 Table 6.5 : Tests Procedures Applicable to Stone Aggregate and Fillers Tests Test Procedure Determination of: i) Particle Size Distribution IS 2386 Part 1 IS 2386 Part 2 iii) Flakiness Index IS 2386 Part 1 iv) Specific Gravity IS 2386 Part 3 v) Moisture Content IS 2386 Part 3 vi) Bulk Density,Voids & Bulking IS 2386 Part 3 vii) Soluble Chloride Content BS 812 Part 117 (Gradation) ii) Clay, Silt, Dust in Aggregates viii) Mica Content Manual mineralogical counting ix) Water Absorption 1S 2386 x) Crushing Ratio Manual counting & weighing xi) Los Angeles Abrasion IS 2386 Part 4 xii) AIV - ACV IS 2386 Part 4 xiii) Polished Stone Value IS 2386 Part 4 xiv) Degradability Test NFP 94 - 067 xv) Sodium Sulphate Soundness IS 2386 Part 5 xvi) Alkali Aggregate Reactivity Test IS 2386 Part 7 xvii) Bitumen Adhesiveness (Vialit NFP-98-274-1 Part 3 Test) xviii) Deleterious Substances IS 2386 Part 2 xix) Sand Equivalent IS 2720 Part 37 Table 6.11: Tests Procedure Applicable to Straight run Bitumen Tests Determination of : i) Penetration ii) Softening point (Ring and Ball) iii) Flash and fire points ( open cup) iv) Loss on heating v) Ductility vi) Water Content vii) Solubility in Trichloroethylene viii) Specific gravity ix) Penetration of residue from loss on heating Test Procedure ASTM D 5 ASTM D 36 ASTM D 92 ASTM D 6/D1754 ASTM D 113 ASTM D1461/D95 ASTM D 2042 ASTM D70 ASTM D5 Table 6.12: Tests Procedure Applicable to cutback Bitumen Tests Test Procedure Determination of : i) Kinematic viscosity ii) (a) Flash point (Tag open cup) (RC-MC) (b) Flash point ( open cup) (SC) iii) Penetration iv) Specific gravity by hydrometer method v) Asphalt residue of 100 pen (SC) vi) Water content vii) Distillation viii) Penetration of residue from distillation ix) Ductility of residue from distillation x) Solubility of residue from distillation ASTM D 2170 ASTM D 3143 ASTM D 92 ASTM D 5 ASTM D 3142 ASTM D 243 ASTM D 95 ASTM D 402 ASTM D 5 ASTM D 113 ASTM D 2042 Table 6.13: Tests Procedure Applicable to Bitumen Emulsion Test Determination of : (i) Residue on 0.710 mm sieve (ii) Residue on 0.150 mm sieve (iii) Stability to mixing with coarse (iv) aggregate (v) Stability to mixing with cement (vi) Binder content (vii) Engler viscosity (viii) Redwood II viscosity (ix) Storage stability (short period) (x) Storage stability (long period) Particle charge Test Procedures BS 434 Part I, Appendix C1 " " " C2 " " " D1 " " " D2 " " " E " " " F1 " " " F2 " " " H1 " " " H2 " " " J Table 6.6: Requirements on the Physical Characteristics of Cement S.N. Physical characteristics i) Fineness, m2/kg: (by Blaine's Air Permeability method) ii) Setting Time : OPC / PSC HSPC Test Procedure 225 225 (a) Minimum Initial Setting Time (minutes) 45 45 (b) Maximum Final Setting Time (minutes) 600 600 10 10 iii) Soundness by Lechatelier method, mm, maximum IS-4031 Part 2 IS 4031 Part 5 IS 4031 Part 3 iv) Compressive Strength : Minimum Average Compressive Strength of three mortar cube(N/mm²) (a) 3 days 16 27 (b) 7 days 22 37 33 53 (c) 28 days IS 4031 Part 6 CONCRETE The minimum frequency of sampling of concrete of each grade shall be as following: For 1-5 m3 quantity of work - 1 no. of sample For 5-20 m3 quantity of work - 2 no. of sample For 20 m3 and more quantity of work - 3 no. of sample plus one additional for each 20m3 or part thereof. At least one sample shall be taken from each shifts of work. Table 6.14: Specification for Straight run Bitumen S.N. Specifications Penetration Grade 60/70 80/100 180/200 i) Penetration, at 25°C (100g-5s), in 0.1 mm 60-70 80-100 180-200 ii) Softening point (Ring and Ball), °C 44-54 41-51 33-42 iii) Flash point ( open cup), °C (min) 250 225 200 iv) Ductility at 25°C, cm (min) 100 100 100 v) Loss on heating (5 h at 163°C) % (max) 0.2 0.5 0.5 vi) vii) Penetration of residue from loss on heating at 25°C (100 -5s) % of initial pen 80 80 80 (min) Specific Gravity at 25°C 1.01-1.06 1.00-1.05 1.00-1.05 viii) Water, % by weight (max) 0.2 0.2 0.2 ix) Solubility in tricloroethylene, % by weight (min) 99.0 99.5 99.5 The number of tests and criteria for conformity shall be as per IS 73. Table 6.15: Tests Procedure Applicable to Bituminous Mixtures Tests Test Procedure Determination of : i) Moisture and volatile distillates ASTM D 1461 ii) Quantitative extraction of bitumen ASTM D 2172 iii) Specific gravity of compacted mixture ASTM D 1188 & D 2726 iv) Recovery of bitumen from solution ASTM D 1856 v) Coating and stripping ASTM D 1664 vi) Degree of particle coating ASTM D 2489 vii) Maximum specific gravity ASTM D 2041 viii) Degree of pavement compaction AASHTO T230 ix) stability ASTM D1559 2401 GABIONS • Gabions shall consist of steel wire mesh crates. Steel wire shall be mild steel wire complying with NS 169-2045. • Weight of deposition of zinc shall be in accordance with NS 163-2045. Zinc coating shall be uniform and be able to withstand minimum number of dips and adhesion test specified as per NS 163-2045 • Wire shall be woven into hexagonal mesh with minimum of 3 twists 2401 GABIONS (Contd.) • Selvedge wire at least 3 gauges heavier than mesh wire • Gabion wire shall be tested for mass, uniformity and adhesion of zinc coating and tensile strength of the wire itself. Section 1200 (Contd.) • 1201 MECHANICALLY STABLE SUBBASE CONTAINS: 1. Scope 2. Sources of Materials 3. 4. Material Requirements- (a) Gravel , (b) Sand, Silty and Clayey Sands, (c ) All Materials Compaction Trials 5. Laying and Compaction Section 1200 (Contd.) 6. Proof Rolling 7. Setting out and Tolerances 8. Drainage of Subgrade and Subbase 9. Testing – (a) Process Control, (b) Routine Inspection and Testing 10. Measurement 11. Payment Mechanically Stable Sub base (Example) Table 12 .2 : Minimum Testing Frequency Tests Materials: Gradation Plasticity Index Maximum Dry Density and Optimum Moisture Content Workmanship: Field Density and Moisture Content Construction Tolerances: Surface Levels Thickness Width One test in every 200 m3 or part of it and change in source " " " " 1000 m3 " " " Min. no of tests per section 2 2 2 500 m2 2 10 m 25 m 200 m - Construction & Workmanship Tests • Earthwork in cutting/Sugrade a) Detern of Insitu MC b) Detern of Insitu Density c) Horizontal Alignment d) Surface Level e) Surface regularity Construction & Workmanship Tests • Granular Sub base a) Gradation of In situ materials b) LL/PL –PI of In situ materials c) AIV of In situ materials d) Detern of In situ MC e) Detern of In situ Density f) Compacted thickness g) Horizontal Alignment h) Surface Level i) Surface regularity • Construction Control Testing/Process Control Testing Unless otherwise directed, values given in these Specifications are minimum values for the properties of materials and the workmanship. They shall be considered satisfactory, if all results of the tests, taken at the frequencies specified, are at least equal to the values given in the relevant Section of these Specifications THE END THANK YOU