IEReport/QUALITY CONTROL August-2014 NH

advertisement

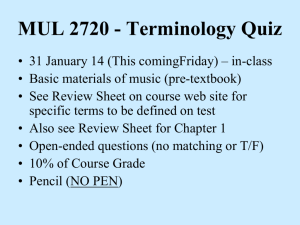

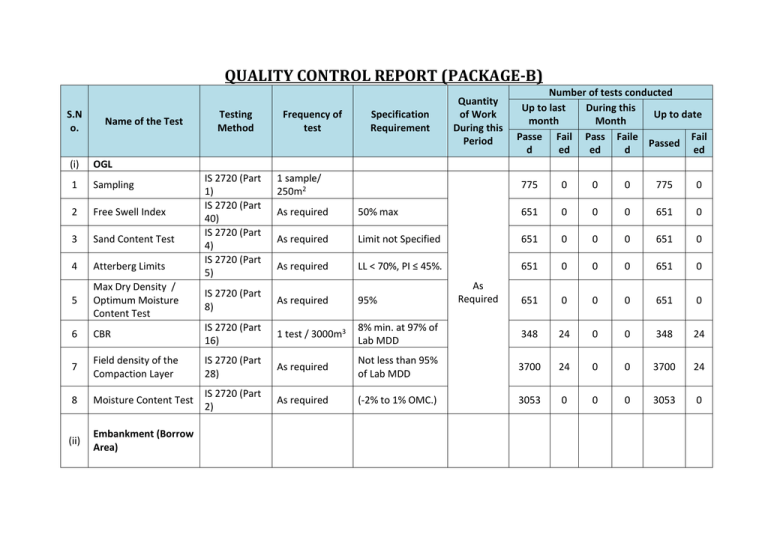

QUALITY CONTROL REPORT (PACKAGE-B) S.N o. Name of the Test Testing Method Frequency of test Specification Requirement (i) OGL 1 Sampling 2 Free Swell Index 3 Sand Content Test 4 Atterberg Limits 5 Max Dry Density / Optimum Moisture Content Test IS 2720 (Part 8) As required 95% 6 CBR IS 2720 (Part 16) 1 test / 3000m3 7 Field density of the Compaction Layer IS 2720 (Part 28) 8 Moisture Content Test IS 2720 (Part 2) (ii) Embankment (Borrow Area) IS 2720 (Part 1) IS 2720 (Part 40) IS 2720 (Part 4) IS 2720 (Part 5) Quantity of Work During this Period 1 sample/ 250m2 Number of tests conducted Up to last During this Up to date month Month Passe Fail Pass Faile Fail Passed d ed ed d ed 775 0 0 0 775 0 As required 50% max 651 0 0 0 651 0 As required Limit not Specified 651 0 0 0 651 0 As required LL < 70%, PI ≤ 45%. 651 0 0 0 651 0 651 0 0 0 651 0 8% min. at 97% of Lab MDD 348 24 0 0 348 24 As required Not less than 95% of Lab MDD 3700 24 0 0 3700 24 As required (-2% to 1% OMC.) 3053 0 0 0 3053 0 As Required IS 2720 (Part 1) IS 2720 (Part 40)20 1 Sampling 2 Free Swell Index 3 Sand Content Test IS 272 (Part 4) 4 Atterberg Limits IS 2720 (Part 5) 2 tests / 3000m3 2 tests / 3000m3 5 Max Dry Density / Optimum Moisture Content Test IS 2720 (Part 8) 2 tests / 3000m3 6 CBR IS 2720 (Part 16) 1 test / 3000m3 iii Test on Existing Shoulder material & Excavated Material 1 Sampling 2 Free Swell Index 3 Sand Content Test IS 272 (Part 4) 4 Atterberg Limits IS 2720 (Part 5) 2 tests / 3000m3 2 tests / 3000m3 IS 2720 (Part 8) 2 tests / 3000m3 As per MorT&H cl.302. IS 2720 (Part 16) 1 test / 3000m3 As per MorT&H cl.302. 5 6 Max Dry Density / Optimum Moisture Content Test CBR IS 2720 (Part 1) IS 2720 (Part 40)20 As required 25 mc/c 1430 0 0 0 1430 0 As required 50% Max. 1267 00 0 0 1267 0 00 0 0 0 0 0 1267 Limit not Specified L.L < 70%, P.I ≤ 45%. Up to 3m ht 1.52 g/cc & more than 3m ht 1.6 g/cc. 8% min. at 97% of Lab MDD As required 25 mc/c As required 50% Max. Limit not Specified L.L < 70%, P.I ≤ 45%. As Required 1267 1267 1267 1267 0 0 1267 0 0 0 559 0 0 0 559 0 494 0 1 0 495 0 0 1 0 0 1 0 0 1 0 494 494 494 494 438 0 495 495 495 0 0 0 495 0 1 0 0 1 0 0 439 0 (ii) Embankment 1 Sampling 2 Free Swell Index 3 Sand Content Test 4 Atterberg Limits 5 6 7 (iii) 1 Max Dry Density / Optimum Moisture Content Test Field density of the Compaction Layer Moisture Content Test As required IS 2720 (Part 40) IS 2720 (Part 4) IS 2720 (Part 5) IS 2720 (Part 8) IS 2720 (Part 28) IS 2720 (Part 2) Sub grade Sampling 2 Free Swell Index 3 Sand Content Test 4 Atterberg Limits As required 2 tests / 3000m3 2 tests / 3000m3 2 tests / 3000m3 1 test / 1000m2 1 test / 250m3 2134 2134 50% Max. Limit not Specified L.L < 70%, P.I ≤ 45%. Up to 3m ht 1.52 g/cc & more than 3m ht 1.6 g/cc. Not less than 95% of Lab MDD 3925.0 Cu-m 19625 Sq-m 1 test / Source (-2% to 1% OMC) 2 tests / 3000m3 2 tests / 3000m3 50% Max. Limit not Specified L.L < 70%, P.I ≤ 45%. 2134 0 0 0 2134 11 11 11 11 250.0 Cum 1497 Sq-m 0 0 0 0 2145 2145 2145 2145 0 0 0 0 2145 11 0 As required IS 2720 (Part 40) IS 2720 (Part 4) IS 2720 (Part 5) 2134 0 0 0 20638 216 120 14 20758 230 20638 176 120 14 20758 190 1273 1273 0 2 0 0 0 2 0 1275 1275 0 2 0 0 2 0 1273 1273 1275 1275 0 0 0 5 Max. Dry Density / Optimum Moisture Content Test 6 CBR 7 Field density of the Compaction Layer Moisture Content Test (iv) 1 Granular Sub Base Max Dry Density / Optimum Moisture Content Test IS 2720 (Part 8) IS 2720 (Part 16) IS 2720 (Part 28) IS 2720 (Part 2) 2 tests / 3000m3 1 test / 3000m3 1 test / 500m2 1269 Not less than 1.75 g/cc. 8% min. at 97% of Lab MDD Not less than 97% of Lab MDD 1 test / 250m3 (-2% to 1% OMC) IS 2720 (Part 8) 1 test / Source MORT&H-900 0 2 0 0 1011 0 2 0 1013 0 18037 147 20 4 18057 151 18037 93 20 4 18057 97 35 0 0 0 35 0 2128 5 2 0 2130 5 2128 75 2 0 2130 75 8 0 0 0 8 0 4 0 0 0 4 0 39 0 2 0 41 0 2 Gradation IS 2386 (Part 1) 1 test / 200m3 3 Atterberg Limits IS 2720 (Part 5) 1 test / 200m3 4 CBR IS 2720 (Part 16) As required 30% Minimum 5 Water Absorption IS 2386 (Part 3) 1 test / Source > 2% then Soundness test need to conduct 6 10% Fine value 1 test / Source 50KN Min. 7 Moisture Content Test 1 test / 250m2 (-2% to 1% OMC) 6247 62 10 2 6257 64 8 Field density of the Compaction Layer 1 test / 500m2 Not less than 98% of Lab MDD 6247 92 10 2 6257 94 BS 812 (Part 111) IS 2720 (Part 2) IS 2720 (Part 28) As per MORT&H Table 400-1. LL not more than 25 and PI not more than 6 1271 66.6 Cum 333.0 sq-m (v) 1 WMM Max Dry Density / Optimum Moisture Content Test IS 2720 (Part 8) Aggregate Impact Value Combined Flakiness & Elongation IS 2386 (Part 1) IS 2720 (Part 5) IS 2386 (Part 4) IS 2386 (Part 1) 6 Field density of the Compaction Layer 7 Moisture Content Test 8 Sand Equivalemt Value Test 2 Gradation 3 Atterberg Limits 4 5 (vi) 1 test / Source 1 test / 100m3 1 test / 100m3 MORT&H-900 As per MORT&H Table 400-11 PI not more than 6 1 test / 200m3 30% max 1 test / 200m3 30% max IS 2720 (Part 28) 1 test / 500m2 Not less than 98% of Lab MDD IS 2720 (Part 2) As required (-2% to 1% OMC.) 1 test / 200m3 Limit not Specified 32 0 0 0 32 0 4318 0 18 0 4336 0 0 18 0 4318 1331.2 Cum 8875 sq-m 4336 0 2515 0 9 0 2524 0 2515 0 9 0 2524 0 9380 118 60 9 9440 127 9380 78 60 9 9440 87 3207 0 0 0 3207 0 Cement & Concrete 0 1 Consistency Test IS 4031 (Part 4) 1 Test / Consignment Not Less than 28 2 Setting Time IS 4031 (Part 5) 1 Test / Consignment 3 Fineness Test IS 4031 (Part 3) 1 Test / Consignment Cement4.0 lot 370 0 4 0 374 0 Initial not < 30 min Final not > 600 min 370 0 4 0 374 0 Not > 10% 370 0 4 0 374 0 4 4.A 5 6 7 8 9 10 11 Compressive Test IS 4031 (Part 6) 1 Test / Consignment Soundness test IS 4031 (Part 6) 1 Test / Consignment IS 383 As required Coarse Aggregate Gradation Fine Aggregate Gradation Specific Gravity and Water Absorption Aggregate Impact Value Flakiness / Elongation Test Workability / Slump Comp. Strength of Concrete Comp. Strength of Concrete IS 2386 (Part1) IS 2386 (Part3) IS 2386 (Part4) IS 2386 (Part1) As required As required As required (1 test / day min.) As required (1 test / day min.) 3/7/28 days 2052 0 21 0 2073 0 370 0 4 0 374 0 5896 0 108 0 6004 0 5896 0 108 0 6004 0 Max. 2% 39 0 0 0 39 0 30% max. 3132 0 54 0 3186 0 35 % max. 3132 0 54 0 3186 0 Cum As per design requirement As per design requirement IS 1199 As required Mix Design/Site 4148/ 37469 0 0/ 168 0 4148/ 37637 0 IS 516 7 days/28 days Mix Design 2230 0 0 0 2230 0 IS 516 7 days 15325 0 0 00 15325 0 24639 0 0 0 24639 0 5964 453 0 0 74 105 0 0 6038 558 0 0 28 days Site Site Concrete PCC M-15 (Cum) PCC M-20 (Cum) IS 516 IS 516 7 /28 days 7 /28 days Site Site Total 1091.69 cu-m 74.69 107.78 PCC M-25 (Cum) PCC M-30 (Cum) IS 516 Site 25.00 5952 0 5 0 5957 0 IS 516 7 /28 days 7 /28 days Site 0.0 718 0 0 0 718 0 PCC M-35 (Cum) PCC M-40 (Cum) PSC/RCC M-45 (Cum) PSC/RCC M-50 (Cum) DLC (CUM) PQC (Cum) KERB (Cum) (vii) Bitumen Tests VG-30 IS 516 IS 516 IS 516 IS 516 IS 516 IS 516 IS 516 7 /28 days 7 /28 days 7 /28 days 7 /28 days 7 /28 days 7 /28 days 7 days/28 days Site Site Site Site Site Site Site 63.50 439.30 259.50 0.0 0.0Cum 0.0 121.92 17628 2032 2725 46 670 1200 3673 0 0 0 0 0 0 0 57 25 025 0 0 0 33 0 0 0 0 0 0 0 17685 2057 2750 46 670 1200 3706 0 0 0 0 0 0 0 IS 1203 IS 1208 IS 1205 1 sample/ lot 2 samples/ lot 2 samples/ lot 60 - 70 mm 75 cm 45⁰C to 55⁰C 2197 2197 2197 IS 1202 As required 0.99 min 0 0 0 00 4.0- lot 1 2 3 4 1 2 3 4 5 1 Penetration Absolute Viscosity Softening Point Specific gravity @ 27⁰C CRMB - 60 Penetration IS 1203 IRC - SP-53 AElastic recovery 1 / ASTM D 5976 Softening Point IS 1205 Specific gravity @ IS 1202 27⁰C Separation TFOT on CRMB - 60 Penetration IS 1203 14 8 8 8 0 0 0 0 0 2205 2205 2205 14 0 0 0 0 0.0lot 1 test / 10 t Less than 50 750 0 0 0 750 0 1 test / 10 t 50 min 750 0 0 0 750 0 1 test / 10 t 750 0 0 0 750 0 11 0 0 0 11 0 As required 60⁰C As per Grade & Requirements 4 max. 725 0 0 0 725 0 1 test / 10 t 60 % min of 19 0 0 0 19 0 As required original 2 3 IRC - SP-53 AElastic recovery 1 / ASTM D 5976 Softening Point IS 1205 19 1 test / 10 t 35 min 1 test / 10 t 5⁰C max. 19 19 0 0 0 0 0 0 0 19 0 1.0- lot Emulsion(css-2)&(RS-1) 1 2 Viscosity IS 1206 Residue by vaporation 1 sample/ lot As required 30 - 150 60% min 273 269 0 0 1 1 0 0 274 270 0 0 3 Penetration IS 1203 1 sample/ lot 60 - 120 269 00 1 0 270 0 1 sample/ lot 50 cm min 151 00 1 0 152 0 23 23 0 0 23 23 7 7 0 0 7 7 4 1 2 4 1 2 3 Ductility is 1208 MSS Type -A &Type-B IS 2386 Individual Gradation (Part1) IS 2386 Mix Gradation (Part1) Extraction & Sieve ASTM-D-2192 analysis Aggregate Impact IS 2386 Value (Part4) DBM Aggregate Impact IS 2386 Value (Part4) IS 2386 Flakiness & Elongation (Part1) IS 2386 Individual grading (Part1) IS 2386 Combined grading (Part1) 2 Tests/Day 2 Tests/Day As per table 50026 As per table 50026 2 Tests/Day MORT&H-500 6 6 0 0 6 6 1 test/50m3 Max 30% 7 7 0 0 7 7 1 test/50m3 27% max 3386 0 22 0 3408 0 1 test/50m3 30% max 2 Tests/Day 2 Tests/Day As Table MORT&H 500-10 As Table MORT&H 500-10 986.6 Cum 3386 0 22 0 3408 0 8113 0 80 0 8193 0 1775 0 16 0 1791 0 1 test per 400 t Extraction with ASTM-D-2192 or 2 tests / Gradation day00 OBC + 0.3, -0.3% 1793 0 16 0 1809 0 5 Stability of Mix ASTM D-1075 2 SETS /day i) Stability - 9.0 kN Min ii) Flow 2-4 iii) AV 3-6% iv) VMA: Morth Table 500-12 v) VFB 65-75% 1350 0 18 0 1368 0 6 Water sensitivity of ASTM D-1283 Mix As required 80% 14 0 0 0 14 0 2 Tests /day Not less than 50 1490 0 1 test/250m2 0.98 4 7 Sand Equivalent Value IS 2720 (Part 37) 9 Density Of Comp. layer Theoritical sp.gravity 10 Tack coat (Emulsion) IS 1203 1 test/500m2 2 to 3kg / 10m2 11 Prime coat (Emulsion) IS 1203 1 test/500m2 2 to 3kg / 10m2 8 2 IS 2386 (Part1) IS 2386 Mix Gradation (Part1) Individual Grading 13154.7 sq-m 2 tests/day min Bituminous Concrete Grade 1 1 1490 21230 3369.5 0 0 0 11480 0 69 0 11549 0 1796 0 16 0 1812 0 6898 0 46 0 6944 0 2644 0 30 0 2674 0 1730 0 0 16 1746 0 452 0 0 4 456 0 401.50 Cum 2 Tests /day 2 Tests /day As per MORT&H table 500-18 As per MORT&H table 500-189 3 4 5 6 7 8 9 10 11 12 13 14 15 1 2 3 Extraction & Sieve ASTM-D-2192 2 Tests /day analysis Flakiness & Elongation IS 2386 1 test/50m3 Index (Part1) IS 2386 AIV 1 test/50m3 (Part4) IS 2720 (Part Sand Equivalent Value 2 Tests /day 37) Theoritical sp.gravity Plasticity Index MORT&H-500 1 test/day ASTM -DMarshall Stability Min 6 no./day 1559 Retained Stability MORT&H-900 Min 3 no./day Swell test MORT&H-900 1 test/day OBC + 0.3, -0.3% 452 0 0 4 456 0 30% Max. 876 0 0 8 884 0 24% Max. 876 0 0 8 884 0 Not less than 50 201 0 0 0 201 0 2 tests/day min Not more than 4 486 53 0 00 0 0 4 0 490 53 0 0 9 kN min. @ 60⁰C 3685 0 0 12 3697 0 Limit not Specified Limit not Specified 21 0 0 0 0 0 0 0 21 0 0 0 4332 0 0 0 4372 0 0 0 0 0 0 0 2462 0 0 0 2462 0 60 0 0 0 60 0 12 0 0 0 12 0 12 0 0 0 12 0 8030.0 sq-m Field Density a)Core Cutting MORT&H-500 1 test/250m2 b)Nuclear Density MORT&H-500 1 test/250m2 Gauge Tack coat (Emulsion) IS 1203 1 test/500m2 Bituminous Concrete Grade 2 IS 2386 Individual Grading 2 Tests /day (Part1) IS 2386 Mix Gradation 2 Tests /day (Part1) Extraction & Sieve ASTM-D-2192 2 Tests /day analysis 98% of lab Marshal density 98% of lab Marshal density 2 to 3kg / 10m2 0.0 As per MORT&H table 500-18 As per MORT&H table 500-18 OBC + 0.3, -0.3% 4 5 6 7 8 Flakiness & Elongation IS 2386 Index (Part1) IS 2386 AIV (Part4) IS 2720 (Part Sand Equivalent Value 37) IS 2720 (Part Plasticity Index 5) ASTM -DMarshall Stability 1559 1 test/50m3 30% max 12 0 0 0 12 0 1 test/50m3 24% max 12 0 0 0 12 0 2 Tests /day Not less than 50 4 0 0 0 4 0 1 test/day Not more than 4 0 0 0 0 0 0 Min 6 no./day 9 kN min @ 60⁰C 28 0 0 0 28 0 9 Retained Stability MORT&H-900 Min. 3nos./day Limit not Specified 3 0 0 0 3 0 10 11 Swell test MORT&H-900 1 test/day Field Density Limit not Specified 0 0 0 0 0 0 0 0 0 0 0 0 30 0 0 0 30 0 0 0 0 0 0 0 12 0 0 0 12 0 0 0 0 0 0 0 Max 30% 0 0 0 0 0 0 Max 30% 0 0 0 0 0 0 2644 6898 0 0 30 46 0 0 2674 6944 0 0 12 13 14 1 2 3 1 a)Core Cutting MORT&H-500 1 test/250m2 b)Nuclear Density MORT&H-500 1 test/250m2 Gauge Theoritical sp.gravity Mastic Asphalt (sqm) Extraction & Sieve ASTM-D-2192 2 test/day analysis IS 2386 AIV 2 test/day (Part4) Flakiness & Elongation IS 2386 2 test/day Index (Part1) Prime Coat (sqm) Rate of Spreading MORT&H-500 1 test/500m2 Tack Coat MORT&H-500 1 test/500m2 98% of lab Marshal density 98% of lab Marshal density 2 tests/day min Table-500-1 Table-500-2 3369.5 21230 Steel 1 Tensile strength IS 1786 2 Elongation IS 1786 3 Bend-rebend test IS 1599 4 Re-Bend test IS 1786 Carbon Sulpher 5 Chemical test Phosphrous Sulpher & Phosphrous 1 test/consignme nt 1 test/consignme nt 1 test/consignme nt 1 test/consignme nt 1 test/consignme nt 1 test/consignme nt 1 test/consignme nt 1 test/consignme nt As per IS 1786 Table 3 420 0 0 0 420 0 As per IS 1786 Table 3 420 0 0 0 420 0 As per IS 1786 Table 4 420 0 0 0 420 0 As per IS 1786 Table 4.1 420 0 0 0 420 0 As per IS 1786 Table 4 141 0 0 0 141 0 As per IS 1786 Table 4 141 0 0 0 141 0 As per IS 1786 Table 4 414 0 0 0 414 0 As per IS 1786 Table 4 141 0 0 0 141 0 0.0 lots Hume pipes 900 dia (LM) 1200 dia (LM) Water 1 2 3 0.0 0.0 Chlorides IS 3025 (Part 18) IS 3025 (Part 11) IS 3025 (Part Suspended 17) PH value Chloride contenet Admixture Dry Material Content Ash content Density DLC (cu-m) PQC (cu-m) Compressive strength Compressive strength 7 days Flexural strength 7 2145 3075 0 0 0 0 0 0 0 0 0 2145 3075 0 0 1 test/Source 2000 mg/l for PCC and 500 mg/l for RCC 1 test/Source Not less than 6 28 0 0 0 28 0 1 test/Source 2000 mg/l 28 0 0 0 28 0 46 0 0 0 46 0 46 0 0 0 46 0 46 0 0 0 46 0 425 0 0 0 425 0 670 0 0 0 670 0 656 0 0 0 656 0 0 0 0 318 0 1 test/consignme nt 1 test/consignme nt 1 test/consignme nt 3 density holes each 2000 sq-m 3 sample 1000 sq-m 1 set of cubes and 1 set of beams per 150 cu-m & IRC-152002 28 0.0 cu-m 28 0 cu-m 318 318 days Compressive strength 28 days Flexural strength 28 days 1 set of cubes and 1 set of beams per 150 cu-m & IRC-152002 Workability /slump IS-1199 AS REQUIRED 318 0 0 0 0 344 0 0 0 344 0 344 0 0 344 0 37057 0 0 37057 0 QUALITY CONTROL REPORT OF ISOLUX (PACKAGE-A) :S.No. Name of the Test (i) Testing Method Frequency of test Specification Requirement Quantity of Work During this Period Number of tests conducted Up to last During this Month month Passed Failed Passed Failed Up to date Passed Failed OGL 1 Sampling 2 Free Swell Index 3 Sand Content Test 4 Atterberg Limits IS 2720 (Part 1) IS 2720 (Part 40) IS 2720 (Part 4) IS 2720 (Part 5) 1 sample/ 250m2 As required As required As required Max Dry Density / 5 Optimum Moisture Content Test IS 2720 (Part 8) As required 6 CBR IS 2720 (Part 16) 1 test / 3000m3 Field density of the Compaction Layer IS 2720 (Part 28) As required 8 Moisture Content Test IS 2720 (Part 2) As required 7 50% max Limit not Specified LL < 70%, PI ≤ 45%. 95% 673 38 0 0 673 38 540 34 0 0 540 34 563 0 0 0 563 0 465 1 0 0 465 1 571 0 0 0 571 0 190 4 0 0 190 4 7992 26 0 0 7992 26 7992 32 0 0 7992 32 As Required 8% min. at 97% of Lab MDD Not less than 95% of Lab MDD (-2% to 1% OMC.) (ii) Embankment (Borrow Area) 1 Sampling 2 Free Swell Index 3 Sand Content Test 4 Atterberg Limits (ii) IS 2720 (Part 1) IS 2720 (Part 40) IS 2720 (Part 4) IS 2720 (Part 5) As required 25 mc/c 447 22 0 0 447 22 As required 50% Max. 431 30 0 0 431 30 423 0 0 0 423 0 419 0 0 0 419 0 438 0 0 0 438 0 126 40 0 0 126 40 453 0 0 0 453 0 449 0 0 0 449 0 449 0 0 0 449 0 449 0 00 00 449 0 2 tests / 3000m3 2 tests / 3000m3 Max Dry Density / 5 Optimum Moisture Content Test IS 2720 (Part 8) 2 tests / 3000m3 6 CBR IS 2720 (Part 16) 1 test / 3000m3 Limit not Specified L.L < 70%, P.I ≤ 45%. Up to 3m ht 1.52 g/cc & more than 3m ht 1.6 g/cc. 8% min. at 97% of Lab MDD As Required Embankment 1 Free Swell Index 2 Sand Content Test 3 Atterberg Limits Max Dry Density / 4 Optimum Moisture Content Test IS 2720 (Part 40) IS 2720 (Part 4) IS 2720 (Part 5) IS 2720 (Part 8) As required 2 tests / 3000m3 2 tests / 3000m3 2 tests / 3000m3 50% Max. Limit not Specified0 L.L < 700%, P.I ≤ 45%.0 Up to 3m ht 1.52 g/cc & more than 3m ht 1.6 g/cc. 0.0 cum (iii) Field density of the 5 Compaction Layer IS 2720 (Part 28) 1 test / 6 Moisture Content Test IS 2720 (Part 2) 1 test / 250m3 7 CBR IS 2720 (Part 16) 1 test / 3000m3 Not less than 95% of Lab MDD (-2% to 1% OMC) 8% min. at 97% of Lab MDD 0.0 Sqm 23335 14 0 0 23335 14 23335 14 0 0 23335 14 14 0 0 00 14 0 471 0 0 0 471 0 471 0 0 0 471 0 471 0 0 0 471 0 471 0 0 0 471 0 263 40 0 0 263 40 33988 407 0 0 33988 407 33988 407 0 0 33988 407 Sub grade 1 Free Swell Index 2 Sand Content Test 3 Atterberg Limits IS 2720 (Part 40) IS 2720 (Part 4) IS 2720 (Part 5) Max. Dry Density / 4 Optimum Moisture Content Test IS 2720 (Part 8) 5 CBR IS 2720 (Part 16) Field density of the 6 Compaction Layer IS 2720 (Part 28) 7 Moisture Content Test IS 2720 (Part 2) Granular Sub Base (iv) 1000m2 1 test / Source 2 tests / 3000m3 2 tests / 3000m3 2 tests / 3000m3 1 test / 3000m3 1 test / 500m2 1 test / 250m3 50% Max. Limit not Specified L.L < 70%, P.I ≤ 45%. Not less than 1.75 g/cc. 0.00Cum 8% min. at 97% of Lab MDD Not less than 97% of Lab MDD (-2% to 1% OMC) 0.0 Sqm Max Dry Density / 1 Optimum Moisture Content Test IS 2720 (Part 8) 1 test / Source 2 Gradation IS 2386 (Part 1) 1 test / 200m3 3 Atterberg Limits IS 2720 (Part 5) 1 test / 200m3 IS 2720 (Part 16) As required 4 CBR 5 Water Absorption 6 10% Fine value 7 Moisture Content Test Field density of the 8 Compaction Layer (v) WMM Max Dry Density / 1 Optimum Moisture Content Test 2 Gradation IS 2386 (Part 3) BS 812 (Part 111) IS 2720 (Part 2) 49 0 0 0 49 0 1363 24 0 0 1363 24 1360 0 0 0 1360 0 30% Minimum 42 0 0 0 42 0 1 test / Source > 2% then Soundness test need to conduct 2 0 0 0 2 0 1 test / Source 50KN Min. 41 0 0 0 41 0 5677 34 0 0 5677 34 5677 34 0 0 5677 34 0 0 0 7 0 0 1 test / 250m2 MORT&H-900 As per MORT&H Table 400-1. LL not more than 25 and PI not more than 6 (-2% to 1% OMC) Not less than 98% of Lab MDD IS 2720 (Part 28) 1 test / 500m2 IS 2720 (Part 8) 1 test / Source MORT&H-900 IS 2386 (Part 1) 1 test / 100m3 As per MORT&H 0.00 cum 0.0 Sqm 0.0 Cu-m 40 2846 40 2846 0 7 Table 400-111 3 Atterberg Limits IS 2720 (Part 5) 1 test / 100m3 PI not more than 6 2832 .0 0 0 2832 .0 4 Aggregate Impact Value IS 2386 (Part 4) 1 test / 200m3 30% max 1725 0 0 0 1725 0 IS 2386 (Part 1) 1 test / 200m3 30% max 1722 0 0 0 1722 0 Field density of the 6 Compaction Layer IS 2720 (Part 28) 1 test / 500m2 7060 58 0 0 7060 58 7 Moisture Content Test IS 2720 (Part 2) As required 7060s 58 0 0 7060s 58 IS 4031 (Part 4) 1 Test / Consignment 227 0 0 0 227 0 IS 4031 (Part 5) 1 Test / Consignment 227 0 0 0 227 0 IS 4031 (Part 3) IS 4031 (Part 6) 1 Test / Consignment 1 Test / Consignment 202 0 0 0 202 0 3 days 250 0 1 0 251 00 7 days 28 days As per design 242 242 2555 0 0 0 1 3 4 0 0 0 243 245 2559 0 0 0 5 (vi) Combined Flakiness & Elongation Not less than 98% of Lab MDD (-2% to 1% OMC.) 0.0 Sq-m Cement & Concrete 1 Consistency Test 020 setting Time 3 Fineness Test 4 Compressive Test 5 Coarse Aggregate IS 383 As required Not Less than 28 Initial not < 30 min Final not > 600 min Not > 10% Cement-00consignment Gradation 6 Fine Aggregate Gradation 7 Specific Gravity and Water Absorption 8 Aggregate Impact Value Flakiness / Elongation Test 10 Workability / Slump Comp. Strength of 11 Concrete 9 IS 2386 (Part1) IS 2386 (Part3) IS 2386 (Part4) IS 2386 (Part1) IS 1199 IS 516 M-10 IS 516 M-15 IS 516 M-20 M-25 IS 516 IS 516 M-30 IS 516 M-35 IS 516 M-40 M-45 IS 516 IS 516 As required As required As required (1 test / day min.) As required (1 test / day min.) As required requirement As per design 0requirement 1736 0 2 0 1738 0 Max. 2% 24 0 0 0 24 0 30% max. 226 0 0 0 226 0 35 % max. 227 0 0 0 227 0 28104 0 9 0 28113 0 As per design 3 days Mix Design 104 0 0 0 104 0 7 days 28 days 7 days 28 days 7 days 28 days 7 days 28 days 7 days 28 days 7 days 28 days 7 days 28 days 7 days 28 days 7 days Mix Design Mix Design Site Site Site Site Site Site Site Site Site Site Site Site Site Site Site 268 779 47 168 1086 1927 1367 2889 863 1690 896 1597 2664 6883 701 1639 516 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 268 779 47 168 1086 1928 1368 2914 869 1723 896 1602 2664 6883 701 1639 517 0 0 0 0 0 00 0 0 0 0 0 0 0 1 0 0 0 0.00 0.0 Cum 6.0 Cum 42.0 Cum 0.0 Cum 0.0Cum 0.0 1 1 25 6 33 0 5 0 0 0 0 1 Site 0.0Cum 28 days (vii) 1 2 3 4 5 1156 0 9 0 1165 0 M-50 IS 516 7 days 28 days Site Site 0 0.0 Cum 386 1122 0 0 0 0 0 0 386 1122 0 0 Bitumen Tests VG - 30 Penetration Ductility Softening Point Specific gravity @ 27⁰C IS 1203 IS 1208 IS 1205 IS 1202 1 sample/ lot 2 samples/ lot 2 samples/ lot As required 60 - 70 mm 75 cm 45⁰C to 55⁰C 0.99 min Min 2400 poise Lot-0 MT-0.0 1086 0 1086 4 0 0 0 0 0 0 0 0 0 0 0 0 1086 0 1086 4 0 0 0 0 369 0 0 0 369 0 Absolute Viscosity at 60⁰C CRMB - 55 1 Penetration 2 Elastic recovery 3 Softening Point 4 Viscosity TFOT on CRMB - 60 1 Penetration 2 Elastic recovery 3 Softening Point Emulsion(RS-1) IS 1206 IS 1203 IRC - SP-53 A1 / ASTM D 5976 IS 1205 IS 1206 1978 IS 1203 IRC - SP-53 A1 / ASTM D 5976 IS 1205 As required 1 test / 10 t Less than 50 1 0 0 0 1 0 1 test / 10 t 50 min 2 0 0 0 2 0 1 test / 10 t 60⁰C As per Grade & Requirements 2 0 0 0 2 0 2 0 0 0 2 0 1 test / 10 t 50 - 70 0 0 0 0 0 0 1 test / 10 t 40 min 0 0 0 0 0 0 1 test / 10 t 50⁰C 0 0 0 0 0 0 As required LOT-0, 0.0 MT 1 Viscosity 2 Residue by evaporation 3 Penetration 4 Ductility IS 1206 1 sample/ lot 30 - 150 34 0 0 0 34 0 IS 1203 is 1208 As required 1 sample/ lot 1 sample/ lot 60% min 60 - 120 50 cm min 34 34 34 0 0 0 0 0 0 0 0 0 34 34 34 0 0 0 26 26 26 26 0 0 0 0 0 0 0 0 0 0 0 0 26 26 26 26 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 Emulsion(css-2) 1 2 3 4 Viscosity Residue by evaporation Penetration Ductility MSS Type -A &Type-B 1 Individual Gradation 2 Mix Gradation Extraction & Sieve analysis 4 Aggregate Impact Value LOT-00, 0.0 MT IS 1206 IS 1203 is 1208 IS 2386 (Part1) IS 2386 (Part1) 1 sample/ lot As required 1 sample/ lot 1 sample/ lot 2 Tests/Day 2 Tests/Day 30 - 150 60% min 60 - 120 50 cm min As per table 500-26 As per table 500-26 ASTM-D-2192 2 Tests/Day MORT&H-500 0 0 0 0 0 0 IS 2386 (Part4) Max 30% 0 0 0 0 0 0 1 test/50m3 DBM 0 1 Aggregate Impact Value 2 Flakiness & Elongation IS 2386 (Part4) IS 2386 (Part1) 1 test/50m3 27% max 2881 0 0 0 2881 0 1 test/50m3 30% max 2881 0 0 0 2881 0 3778 0 00 00 3778 0 00 0 0 1286 0 0 0 1286 0 0 0 0 0 0 0 As per Asphalt Institute Manual MS-2 1220 0 0 0 1220 0 0.98 16408 0 0 0 16408 0 153 0 0 0 153 0 153 0 0 0 153 0 Individual & Combined 3 grading IS 2386 (Part1) 2 Tests/Day 4 Extraction with Gradation ASTM-D-2192 1 test per 400 t or 2 tests / day 5 Stability of Mix ASTM D-1075 2 SETS /day 6 Water sensitivity of Mix ASTM D-1283 As required 2 Tests 1 test per 10T on Individual & Mixed grade 1 test per 400 t Binder Content & Grading 7 Mix 8 ASTM 2172 Density Of Comp. layer(NDG) BM 1 AIV 2 Flakiness & Elongation Index As Table MORT&H 500100 OBC + 0.3, 0.3% i) Stability - 9.0 kN Min ii) Flow 2-4 0.0 cu-m & iii) AV 3-6% 0.0 iv) VMA: Sq.-m Morth Table 500-12 v) VFB 65-75% 80% 1 test/250m2 IS 2386 (Part4) IS 2386 (Part1) 1 test/50m3 27% Max. 1 test/50m3 30% Max. 0.0 CU-M 1220 1220 00 3 Individual & Combined grading IS 2386 (Part1) 2 Tests/Day 4 Extraction with Gradation ASTM-D-2192 1 test per 400 t or 2 tests / day Density Of Comp. layer(NDG) Bituminous Concrete Grade 1 5 1 test/250m2 1 Individual Grading 2 Tests /day 2 Mix Gradation IS 2386 (Part1) 2 Tests /day Extraction & Sieve analysis Flakiness & Elongation 4 Index 5 AIV 6 Sand Equivalent Value 7 Plasticity Index 8 Marshall Stability 9 Retained Stability 10 Swell test 280 0 0 0 280 0 60 0 0 0 60 0 948 0 0 0 948 0 1767 0 0 0 1767 0 495 0 0 0 495 0 495 0 0 0 495 0 0.0 Cu-m IS 2386 (Part1) 3 As Table MORT&H 50010 OBC + 0.3, 0.3% ASTM-D-2192 2 Tests /day IS 2386 (Part1) IS 2386 (Part4) IS 2720 (Part 37) MORT&H500 ASTM -D1559 MORT&H900 MORT&H- As per MORT&H table 500-18 As per MORT&H table 500-18 OBC + 0.3, 0.3% 1 test/50m3 30% Max. 1141 0 0 0 1141 0 1 test/50m3 24% Max. 1141 0 0 0 1141 0 0 0 0 0 0 0 0 0 0 0 0 0 500 0 0 0 500 0 000 0 00 0 000 0 0 0 00 0 0 0 2 Tests /day 1 test/day Min 6 no./day Min 3 no./day 1 test/day Not less than 50 Not more than 4 9 kN min. @ 60⁰C Limit not Specified Limit not 900 Specified 0.0 Sq-m 11 Field Density 12 a)Core Cutting MORT&H500 1 test/250m2 13 b)Nuclear Density Gauge MORT&H500 1 test/250m2 14 Tack coat (Emulsion) IS 1203 1 test/500m2 98% of lab Marshal density 98% of lab Marshal density 2 to 3kg / 10m2 3 0 0 0 3 00 9369 0 0 0 9369 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 Bituminous Concrete Grade 2 1 Individual Grading IS 2386 (Part1) 2 Tests /day 2 Mix Gradation IS 2386 (Part1) 2 Tests /day Extraction & Sieve analysis Flakiness & Elongation 4 Index 3 5 AIV 6 Sand Equivalent Value 7 Plasticity Index 8 Marshall Stability ASTM-D-2192 2 Tests /day IS 2386 (Part1) IS 2386 (Part4) IS 2720 (Part 37) IS 2720 (Part 5) ASTM -D- As per MORT&H table 500-18 As per MORT&H table 500-18 OBC + 0.3, 0.3% 1 test/50m3 30% max 0 0 0 0 0 0 1 test/50m3 24% max 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 2 Tests /day 1 test/day Min 6 no./day Not less than 50 Not more than 4 9 kN min @ 9 Retained Stability 10 Swell test 1559 MORT&H900 MORT&H900 Min. 3nos./day 1 test/day 60⁰C Limit not Specified Limit not Specified 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 11 Field Density 12 a)Core Cutting MORT&H500 1 13 b)Nuclear Density Gauge MORT&H500 1 test/250m2 Mastic Asphalt (sqm) Extraction & Sieve 1 analysis 2 AIV 3 Flakiness & Elongation Index Rate of Spreading (sqm) 1 Prime Coat Tack Coat Steel test/250m2 98% of lab Marshal density 98% of lab Marshal density ASTM-D-2192 2 test/day IS 2386 (Part4) IS 2386 (Part1) MORT&H500 MORT&H500 2 test/day Max 30% 0 0 0 0 0 0 2 test/day Max 30% 0 0 0 0 0 0 1 test/500m2 Table-500-1 2582 0 0 0 2582 0 1 test/500m2 Table-500-2 5802 0 00 00 5802 0 0.0 sq-m 0.0 sq-m 0.0- MT, 0.0-Lot 1 Tensile strength IS 1786 2 Elongation IS 1786 3 Bend test IS 1599 4 Re-Bend test IS 1786 5 Chemical Test IS 1786 1 test/consignment 1 test/consignment 1 test/consignment 1 test/consignment 1 test/consignment As per IS 1786 Table 3 As per IS 1786 Table 3 As per IS0 1786 Table 40 As per IS 1786 Table 4.1 359 0 0 0 359 0 359 0 0 0 359 0 359 0 0 0 359 0 359 0 0 0 359 0 190 0 0 0 190 0 0 0 0 14 0 0 0 14 0 6 0 0 0 6 0 14 0 0 0 14 0 6 0 0 0 6 0 6 0 0 0 6 0 53 0 0 0 53 0 Water 1 Chlorides 2 PH value 3 Suspended IS 3025 (Part 18) IS 3025 (Part 11) IS 3025 (Part 17) 4 Sulphates(so4) 5 Inorganic Marrer(TDS) organic Marrer(TDS) 6 IS 3025 (Part 18) IS 3025 (Part 17) 1 test/Source 2000 mg/l for PCC and 500 mg/l for RCC 1 test/Source Not less than 6 1 test/Source 1 test/Source 1 test/Source 1 test/Source 2000 mg/l Max. 400 mg/l Max. 3000mg/l Max. 200 mg/l Max. 14 0 0.00MT Lot-0.0 Admixter 1 Chloride Content 14 IS 9103 1 test/Consignment 2 Dry Material Content 3 Ash Content Hume pipes(900,1000,1200 mm) Dimensional Tolerance 3-edge Bearing test Hydrostatic test IS 9103 IS 9103 1 test/Consignment 1 test/Consignment 53 0 0 0 53 0 53 0 0 0 53 0 0 0 0 0 0 0 0 0 0 271 0 0 0 274 0 295 0 0 0 295 0 60 0 0 0 60 0 130 0 0 0 130 0 Cu-m 130 0 0 0 130 0 Cu-m 130 0 00 0 130 0 IS 458-1991 IS 458-1991 IS 458-1991 0.0 NOS. 464 123 122 464 123 122 0 0 0 DLC Strength of concrete IS:516 In situ density Mix gradation PQC IS:516 Compressive Strength 7 days Compressive Strength 28 days Flexural Strength 7 days 3 sample per 1000 sq.m 3 desity holes each 2000 sq-m. 1 Test/day 1 set of cube and 1 set of beam per 150 cu-m 1 set of cube and 1 set of beam per 150 cu-m 1 set of cube and 1 set of beam per 150 cu-m 0.0 0.0 00 Cu-m 0.0 Flexural Strength 28 days 1 set of cube and 1 set of beam per 150 cu-m Cu-m As required 0 0 0 130 0 1532 0 0 0 1532 0 0.0 Nos. Slump test 130