Scaffolder

advertisement

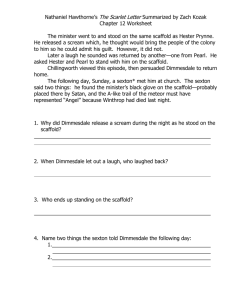

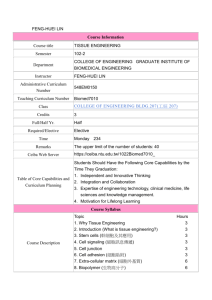

SAFE SCAFFOLDING PRESENTATION BY: Bechtel Scaffolding Department., Habshan 3 Project, Abu Dhabi. 1 INTRODUCTION Scaffold is an integral part of any major or minor construction process, where activity at elevated locations is required. Well constructed scaffold provides a stable platform from which the work may be undertaken safely and with confidence. Construction of scaffold involves principals of engineering that must be complied with to obtain the required safe work location. Poorly constructed scaffold provides opportunity for disasters resulting in serious injury or death. Falls from height can kill. This program aims to introduce you to the basic principals applied to the construction of safe scaffold work platforms on which your workmates DEPEND for their LIFE. 2 TERMINOLOGIES THE A to Z OF GOOD SAFE SCAFFOLD 3 TERMINOLOGIES Adjustable Base Plate – a mild steel plate of at least 150 x 150 x 6mm thick with a threaded spindle and adjusting nut. The maximum extension permitted on the spindle shall be 600mm provided 150mm is located inside the tube. Base plate – a mild steel plate with an area of at least 0.0225 m sq. x 6 mm thick. Bay – the rectangular space enclosed by 4 adjacent standards for the full height of the scaffold or the equivalent space when applied to a putlog scaffold Brace – a tube incorporated diagonally across 2 members in a scaffold and fixed to them to afford stability. 4 TERMINOLOGIES Heavy Duty Scaffold – a scaffold designed for heavy duty work with a safe working load of 625 kg. Independent Scaffold – a scaffold consisting of 2 rows of standards connected together longitudinally with ledgers and braces, and transversely with transoms and putlogs. Ledger – a tube fixed horizontally to the standards to tie the scaffold longitudinally that may support the putlogs. Lift – a height from the ground or floor to the lowest ledger, or the vertical distance between ledgers. 5 TERMINOLOGIES Light Duty Scaffold – scaffold that is normally erected for use by electricians, painters, or general light duty maintenance workers. SWL 180 kg. Light Duty Suspended Stage - a working platform suspended from overhead supports, including the means of lowering or raising the stage, whether those means are operated by hand or are power driven; The overhead supports, attachments and tracks; and the means of suspension. (usually a needle) Medium Duty Scaffold – a scaffold that is normally erected for use by carpenters, plasterers, and glaziers or similar trades. SWL 430 kg. 6 TERMINOLOGIES Puncheon – a vertical member that is not supported from the ground or base of the scaffold. Putlog – a member fixed horizontally across ledgers or across a ledger to an adjacent wall to support a working platform. Safety Fitting – an additional right angle or swivel coupler provided adjacent to the right angle coupler on a tube such as a strut, tie, puncheon or cantilever. Designed to increase the friction grip at that point. Scaffolder – a person who, by direction of the employer, erects, dismantles or modifies scaffold as defined herein. A person who has been assessed by the employer as being competent to do so. 7 TERMINOLOGIES Scaffolding – any platform of metal poles and wooden boards, made into a framework supporting persons working at height. Span – the distance measured along a member, between the centre lines of adjacent supports of that member. Standard – a vertical support. Tie – a member used to secure the scaffold to a structure. Transom - a transverse horizontal member, clamped to the standards or ledgers by right angle couplers. 8 CREW The size of an individual work crew shall not exceed seven (7) persons including supervision. The crew shall consist of six scaffolder and a foreman or supervisor. The supervisor or foreman shall be provided with the following work tools as a minimum. Safety Harness & Lanyard Magnetic Spirit Level Five (5) Meter Tape measure Adjustable wrench or Scaffold Key (with rope) Hammer (with rope) Tool Belt The work crew are to be provided with the following as a minimum Safety Harness & Lanyard Adjustable wrench or Scaffold Key (with rope) Hammer (with rope) Tool Belt 9 GENERAL ERECTION PROCEDURES There are many types of scaffolding that may be erected on a site, some of which are documented in this Guideline. The physical environment of the work area will determine the type of scaffold to be erected. However, there are safety precautions and recommended work practices common to all scaffolding. The design of the scaffold must be based on sound engineering. Foundations or supporting structures are to be solid and adequate to support the scaffold. Sufficient suitable material to erect the scaffold must be available. Scaffold shall tied and braced for support and rigidity Each scaffold must be provided with adequate clear access. Each scaffold shall be provided with the correctly designed working platforms, Working platforms provide clear work areas, and the provision for materials. Working platforms shall be fully planked with kickboards, hand rails and if necessary, mid rails. All scaffold shall be inspected and all access shall befitted with SCAFFTAG Safe to Use or Do Not Use Scaffold 10 GENERAL ERECTION PROCEDURES Each scaffold shall be provided with safe, secure access free from obstruction, scaffold of twenty (20) meters or longer shall be provided with two (2) access/egress points. A Safety harness shall be worn for all scaffold erection and dismantling work at or over two (2) meters in height. Scaffold of two (2) meters or more in height, shall have guardrails at NLT and NMT one (1) meter, and a mid rail at NLT and NMT point five (0.5) of a meter, from the working platform positioned immediately below. At all times scaffold must be fitted with Safe to Use or if under construction Do Not Use Scaffold SCAFFTAG signs 11 Line Drawings & Pictures of SAFE SCAFFOLD USE THESE PICTORIALS TO HELP YOU TO IDENTIFY THE PRICIPALS OF SAFE SCAFFOLD AND WORK PLATFORMS AS DESCRIBED IN THE PRESENTATION. 12 Material Inspection 13 Material Inspection 14 Girder Couplers/Bolted Spigot 15 Scaffold Component 16 Mobile Scaffold Caster 17 Scaffold Component 18 Scaffold Platform units/Plane view of column box 19 Ties 20 Unsafe Foundation 21 Ground Support 22 Foundations 23 Plum of Scaffold 24 Support Spacing for Planks 25 Securing Planks 26 Gin Wheel 27 Scaffold Lifts 28 Scaffold Measurements 29 Transverse Bracing 30 Transverse “zigzag” bracing 31 Longitudinal face Bracing 32 Typical Bracing 33 Scaffold Joints 34 Raker 35 External Ladder Access 36 Scaffold Terminology 37 Scaffold Terminology 38 Typical Tube and Coupler Scaffold 39 A Typical “Independent Run" Scaffold 40 Under hung Scaffold 41 Tower Scaffold 42 Bracket Scaffold 43 Typical System Scaffold 44 Scaffold Work Platform 45 Access 46 Mobile Scaffold 47 Spur Scaffold 48 Beam Cantilever Scaffold 49 Spurred Needle for Suspended Scaffold 50 Drop Scaffold 51 Stair towers Stair towers when used must have: A stair rail consisting of a toprail and a midrail on each side of the stairway. A toprail of each stair rail system capable of serving as a handrail, unless a separate handrail is provided. Sufficient space on handrails, and toprails serving as handrails, for employees grasping them to avoid falling. Stair rails and handrails surfaced to prevent punctures or lacerations to employees, and to prevent snagging of clothing. Ends of stair rails and handrails constructed so that they do not constitute a projection hazard. A space of at least 3 inches between handrails, or stair rails used as handrails, and other objects. A distance of no less than 28 inches and no more than 37 inches from the upper surface of the stair rail to the forward edge of the tread, in line with the face of the riser. 52 End of Scaffold Presentation 53