Kein Folientitel - Utah Biodiesel Supply

advertisement

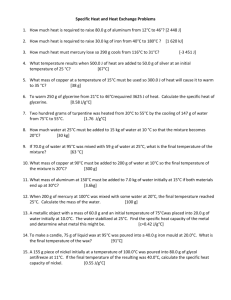

Lewatit® Ion Exchange Resins Tailor-made solutions for biodiesel production 1 Biodiesel production with Lewatit® ion exchange resins Lewatit® iex resins Pure Biodiesel 2 Biodiesel purification with Lewatit® K 2567 • Lewatit K 2567 has specifically been developed for biodiesel purification and is used to remove glycerine, soaps, salts and to a certain extent, monoglycerides. • It can replace the conventional water-wash, eliminate costly water stripping to dry the biodiesel and thereby reduce operating and investment costs. Biodiesel 3 Advantages of using Lewatit® K2567 • Biodiesel purified with Lewatit K 2567 fulfills the stringent specification requirements of the European and American fuel industries. • Lewatit K 2567 is a macroporous cation exchange resin with monodisperse bead sizing, to optimize break-through and pressure drop performance in packed beds. 4 • One liter of K 2567 will purify 11-14 tons biodiesel / year • It can be reused many times, thus minimizing resin disposal costs. • Resin lifetimes up to 7 years have been obtained. • Therefore only relatively small beds are necessary for cycle times of 7–10 days • It can be retrofitted into existing plants. • All biodiesel qualities irrespective of the triglyceride source can be treated. • It is currently used in plants ranging widely in size, from 10,000 350,000 to/a. • It is the most cost-effective ion exchange resin based purification system in the market. • Lewatit K 2567 has been used for biodiesel production in Europe since 1997. Biodiesel quality standards ASTM 5 Property ASTM Flash point 93 Lim its 100 min. Units °C Water sediment 2709 0.05 max. vol. % Carbon residue 4530 0.050 max. w t. % Kin. viscosity 40°C 445 1.9 - 6.0 Sulfur 5453 0.05 max. Cetane 613 40 min. Cloud point 2500 by customer Copper corrosion 130 No 3 max. Acid number 664 0.08 max. Sulfated ash 874 0.020 m ax. w t. % Free glycerine 6584 0.020 m ax. w t. % Total glycerine 6584 0.240 max. w t. % mm²/sec. w t. % °C mg KOH/g Biodiesel quality standards Europe: EN 14214 * Property Limits Flash point > 101 Water content Units °C ISO CD 3679e 500 mg/kg EN ISO 12937 Alkali metals 5 max. mg/kg pr EN 14108 Viscosity 40°C 3.5 - 5.0 mm²/sec. EN ISO 3104 Sulfur 10 max. mg/kg Cetane 51 min. Methanol content 0.2 max. Copper corrosion Class1 Acid number 0.5 max. mg KOH/g pr EN 14104 Sulfated ash 0.02 m ax. % (m /m ) ISO 3987 Free glycerine 0.02 m ax. %(m /m ) pr EN 14105 Total glycerine 0.25 max. w t. % pr EN 14105 EN ISO 5165 %(m/m) pr EN 141101 EN ISO 2160 * As specified for BD from rape seed oil (not all specs. listed) 6 Test method Raw oil sources Oil types Palm Rape seed Soyabean Sunflower Canola Coconut Jatropha Used cooking Animal fats High viscosity Poor combustion 7 Conversion Biodiesel Low viscosity Good combustion Raw oils chemical composition O Triglycerides O > 95% O O Fatty-Acids: OH 0.1- 5% Others: < 1% 8 Micelles, phospholipids, proteins, mineral salts Triglyceride transesterification Purified Triglycerides O O > 95% O NaOCH3* CH3OH O Top Layer Biodiesel phase OCH3 Glycerine phase OH HO Bottom Layer OH * The catalyst Na-methoxide is also a drying agent and should be used instead of NaOH to suppress the formation of soap. 9 Transesterification byproduct soap O Free fatty acid (FFA) < 5% OH + NaOCH3 O Soap ONa + Methanol CH3OH The FFA content of the triglycerides should be maintained below 0.5% to minimize soap formation and maximize BD selectivity, i.e. FFA´s should be esterified to Me-esters before transesterification. FFA´s can be esterified with H2SO4 or Lewatit K 2621 as catalysts. 10 Free fatty acids removal with Lewatit® K 2621 K 2621 11 Design for an 8,000 to/a esterification unit for Reduction of free fatty acids (FFA´s) from triglycerides with Lewatit K 2621 Feed Triglycerides with FFA´s Resin volume: 3.0 m3 Diameter: 1.0 m Bed depth: 4.0 m Throughput 1 m3/h (upflow) Temperature: 90 °C MeOH conc: 20 – 50 wt% FFA content influent 1 – 5 wt% FFA content outlet < 0.2% Classical biodiesel production process Low-acid triglycerides MeOH MeONa HCl Antioxidant Water Water strip Methyl ester phase Water strip Esterification Water wash Transesterification Separation Glycerine phase Glycerine purification 12 MeOH Strip Raw oils with free fatty acids MeOH + Gly. + salts Water + Glycerine + Salts Glycerine + Salts Pure methyl esters (Biodiesel) Purification with Lewatit® K 2567 Low-acid triglycerides MeOH MeONa Methyl ester phase Separation Glycerine phase Lewatit MDS 1368 13 MeOH Strip Glycerine purification MeOH + glycerine Glyc. adsorption desorption Esterification Transesterification Raw oils with free fatty acids Antioxidant HCl Lewatit K 2567 Glycerine + Salts Pure methyl esters (biodiesel) Lewatit® K 2567 vs water wash Purification with Lewatit® K 2567 Purification with water wash Water Glyc. adsorption desorption 14 Water strip Water + glycerine + salts Water strip Water wash One column of resin completely replaces the water washing system!! Lewatit® K 2567 vs water wash Purification with water wash Many biodiesel plants already use NaOCH3 for transesterification, i.e. the streams are already very dry. Water efficiently removes impurities but needs to be stripped down down to <500 ppm in the purified biodiesel. In classical biodiesel plants, dry streams are wetted and redried at subtantial cost. 15 Purification with Lewatit K 2567 With K 2567, dry biodiesel streams remain dry. Only methanol is required as a washing agent to regenerate the resin. The washing effluent is recycled to the transesterification. Mechanism of glycerine adsorption Dry Lewatit K 2567 is hygrosopic and strongly hydrogen-bonds to alcohols and water. HO HO Glycerine is a polar tri-alcohol and is very efficiently removed from low polarity biodiesel esters. OH Glycerine HO O K 2567 S O O Hydrogen bonding HO HO 16 HO Na+ HO OH Solvation with glycerine MeOH-washed, dry resin HO OH Glycerine-solvated resin OH HO SO3- Na+ K 2567 SO3- Na+ OH K 2567 OH 17 Mechanism of salts and soaps adsorption Glycerine layer Ionic impurities + soaps dissolve in the glycerine layer Mg++ Cl- K+ -O2C SO3-Na+ K2567 -O2C Na+ SO42- 18 Ca++ Impurities adsorption in glycerine Transesterification phase separation Capture of ionic impurities on glycerine phase of K 2567 Biodiesel phase + Biodiesel phase Small concentrations of ionic impurities + soaps clean K 2567 + Glycerine phase Glycerine phase + High concentrations of ionic impurities + soaps 19 + High concentrations of ionic impurities + soaps Structure of Lewatit® K 2567 Monodisperse bead sizing, hexagonal closest packing K 2567 “sponge-structure“ 20 Application mode of Lewatit® K2567 Alternate loading and washing Washing with dry MeOH Biodiesel + glycerine Lewatit K 2567 Transesterification Purified biodiesel 21 MeOH + glycerine Regeneration / cleaning with methanol Raw oils MeOH Methanol + glycerine + salts & soaps K 2567 + glycerine + salts & soaps Transesterification K 2567 clean Methanol 22 Operating conditions Preconditioning Biodiesel from phase separation glycerine: 600 – 4000 ppm soap: 10 – 500 ppm • Fresh K 2567 is first preconditioned by drying with 3-4 bed volumes MeOH at 2BV/h. The MeOH is then drained and the biodiesel passed into the reactor. Before the MeOH wash, the biodiesel is also drained. • After preconditioning, K 2567 is only subjected to alternate MeOH / biodiesel treatments and never washed with water. • 100% bed volume water-wet, shrinks to 95% in MeOH, further shrinks to 90% in biodiesel + glycerine Lewatit® K2567 Operating parameters: Temperature:30°C – 40°C LHSV: Bed height: Freeboard: Operating capacity: Regeneration: Regeneration volume: Resin life: 1.5 – 2 (BV* biodiesel/hr) 1 – 2 m** 20% 250 g glycerine/liter MeOH @ 20-35°C 5-10 BV to transesterification 4-5 years (average) *BV = bed volumes ** Please refer to us for specific design details Refined biodiesel: glycerine <10 ppm, soap: < 5 ppm 23 Plant configuration • Depending on the the amount of biodiesel produced and manufacturing site infrastructure, any of the configurations A-C can be used. • Greatest flexibility is obtained with the classical lead-lag setup, whereby the freshly MeOHregenerated reactor is switched to the lag-position. A: Single unit 24 B: 1x in operation, 1x in standby C: 2 units in series: lead-lag Operating data Adsorption of glycerine & soaps from rape seed biodiesel with Lewatit K 2567 at 2 BV/h and 28°C 800 glycerine inlet soaps inlet glycerine outlet soaps outlet 700 600 ppm 500 400 300 200 100 0 5 25 10 15 20 25 Bed volumes biodiesel from rape seed oil 30 35 Basic design Capacity 100,000 to/a* 30 mio. gal/a Annual operation Throughput 8,000 h 12.5 to/h 15,600 l/h 69 gal./min. LHSV 2 bed vols/h Bed volume 7,800 liter K2567 Bed height 2 meter Pressure drop Glycerine capacity 0.4 bar 150-250 g/liter resin** Glycerine conc 800 ppm Cycle time 156 h Resin lifetime 5 years * This basic design can be scaled linearly for plant sizing ranging from 1,000 300,000 to/a. bed depth should be kept in the range 1.5 meters (1,000 to/a) to 3 meters (300,000 to/a) **Variable, depending on the influent glycerine concentration. 26 Competitive technologies and resin cost of operation Competitive ion exchange resin-based biodiesel purification processes are also available involving once-only use of disposable resin without regeneration. A comparison of the two approaches is summarised in the following tables: Lewatit K 2567 Competitor resins dry Resin disposal every 5 years Resin disposal every 2-4 weeks Clean, smooth operation Regular opening of reactor & waste handling No regular BD loss Regular BD loss in resin during dispoal No swelling relative to delivery form Resin swelling of 100-200% 80-90% utilization of reactor volume 20-30% utilization of reactor volume Competitor resins dry (one way application) 0.007500 €/l 0.0350 $/gal Lewatit K 2567 (lifetime 5 years) 0.000043 €/l 0.0002 $/gal Competitor : Lewatit 27 175 cost factor Glycerine salts-removal with Lewatit® MDS 1368 Design for a 2000 to/a glycerine purification unit via Ion Exclusion Chromatography with Lewatit MDS 1368-Na 350µ MDS 1368-Na 350µ 28 Feed Glycerine from BD transesterification Resin volume: 8.0 m3 Diameter: 1.4 m Bed depth: 5.0 m Loading / cycle 1 to. glycerine in 0.8 to water Salts conc. in raw glycerine: 5-7 wt% Temperature: 85 °C LHSV: 0.25 (1.2 m/h) Effluent conc: 1 to. glycerine in 6 to. water [ø] Glycerine purification with Lewatit® MDS 1368 Salts [*100 µS/cm] MDS 1368-Na 350µ 60 60 50 50 40 40 30 30 20 20 10 10 0 0 0,2 0,4 0,6 Filtered bed volume 29 0,8 )%( Glycerine Separation of salts from transesterification-glycerine Glycerine polishing with Lewatit® S 2528 / S 4268 MDS 1368-Na 350µ S 2528 Strongly acidic, monodisperse gel-type cation exchange resin Strongly acidic, heterodisperse macroporous cation exchange resin S 4268 Raw glycerine from transesterification 30 Intermediate-basic monodisperse macroporous anion exchange resin Refined glycerine Biodiesel and glycerine purification with Lewatit® iex resins Transesterification K 2567 Biodiesel phase Glycerine phase 31 MDSS1368 2568 S 2568 Additional information at www. lewatit.com 32 Legal note This information and our technical advice - whether verbal, in writing or by way of trials - are given in good faith but without warranty, and this also applies where proprietary rights of third parties are involved. Our advice does not release you from the obligation to verify the information currently provided (especially that contained in our safety data and technical information sheets) and to test our products as to their suitability for the intended processes and uses. The application, use and processing of our products and the products manufactured by you on the basis of our technical advice are beyond our control and, therefore, entirely your own responsibility. Our products are sold and our advisory service is given in accordance with the current version of our General Conditions of Sale and Delivery. 33