Corn - Maize: Feed Ingredients

advertisement

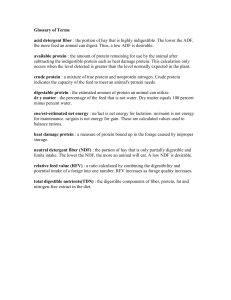

BAHAN PAKAN, DESKRIPSI DAN KANDUNGAN ZAT MAKANANNYA No. Sumber 1. Protein Deskripsi Dried Brewer’s Yeast is the dried, non-fermentative, non-extracted yeast of the botanical classification Saccharomyces resulting as a by-product from the brewing of beer and ale. Dried Brewer’s Yeast is a high-quality protein rich in B vitamins, minerals and palatability factors. It can be used to improve acceptability and is an exceptionally good source of water soluble vitamins; one of the most potent natural sources of biotin and folic acid. Guaranteed Analysis Crude Protein Crude Fat Crude Fiber Moisture 43.0% min. 0.1% min. 3.0% max. 9.0% max. Typical Analysis Amino Acids Arginine Cystine Histidine Isoleucine Leucine Lysine Vitamins 2.28% 0.61% 1.16% 1.15% 2.96% 2.41% Methionine Phenylalanine Threonine Trypotophan Valine B-1 95.00 mcg/g Inositol B-6 37.70 mcg/g Pantothenic Acid B-12 0.01 mcg/g Choline Biotin 1.17 mcg/g Folic Acid Niacin 575.40 mcg/g 0.68% 2.08% 2.26% 0.54% 1.59% 2667.60 mcg/g 81.10 mcg/g 6084.80 mcg/g 11.10 mcg/g Gambar 2. Energi Beet Pulp is the vegetable matter, which remains after sugar is extracted from sliced sugar beets. This vegetable matter is then made into pellets to improve its nutritional value and handling characteristics. It is high in fiber and unique in that its fiber is extremely digestible Typical Analysis Crude Protein Crude Fat Crude Fiber Ash Moisture TDN NEL Calcium Phosphorus 7.0% 0.5-0.6% 15.0-20.0% 4.0-5.0% 8.0-12.0% 74.0% 0.81 Mcal/lbs. 0.6% 0.1% 3. 4. Protein Protein Blood meal is produced from clean fresh animal blood, exclusive of all extraneous material such as hair, stomach contents, etc. Blood meal may be dried by several processes, but most often by spray drying. Spray dried blood meal comprises of approximately: · crude protein level of 85 percent; · crude fat, 0.5-3 percent; · crude fibre, 2.5 percent; · ash, 6 percent; · lysine, 9-11 percent, with an availability of 80-90 percent. Whole blood meal is produced by spray drying at low temperatures, the fresh whole blood from animal processing plants. The fresh blood is collected in onsite cooling tanks that utilize agitation to prevent coagulation of the fresh blood. Once delivered to the drying plants the whole blood is centrifuged to remove foreign material and then circulated through a disintegrator to rid all remaining foreign particles prior to spray drying. Typical Analysis Crude protein Crude fat Crude fiber Ruminant digestible protein 80 % 1% 1% 63.1 % Typical Amino Acid Profile Methionine Crystine Lysine Tryptophane Isoleucine Histidine Valine Leucine Arginine Glycine 1.0 % 1.4 % 6.9 % 1.0 % 0.8 % 3.05 % 5.2 % 10.3 % 2.35 % 4.4 % Storage and Handling Whole blood meal is available in bags or as bulk material. Whole blood meal is packaged in 50 pound poly-lined paper bags. 5. Bone meal is a mixture of crushed and coarsely ground bones that is used as an organic fertilizer for plants and in animal feed. As a fertilizer, bone meal is primarily used as a source of phosphorus. Bone meal once was often used as a dietary calcium supplement. Research in the 1980s found that many bone meal preparations were contaminated with lead and other toxic metals, and it is no longer recommended as a calcium source. Guaranteed Analysis Phosphorous, min. Calcium, min Fluorine, max 14 % 23 % .05 % Typical Trace Element Analysis (measured in ppm) Iron Magnesium Manganese Molybenum Copper Aluminum Vanadium Sodium Sulfates Potassium Cobalt Zinc Lead Mercury Selenium Arsenic Cadmium Chlorides Bulk Density Moisture Color Packaging 400 120 50 5 5 200 5 300 2000 20 0.5 100 2.5 25 .05 0.5 0.8 400 40 – 50 lbs./cu.ft. less than 2.0 % white Multi-wall paper bags 50 lbs. net Steamed Bone Meal is the most natural form of calcium and phosphorus available for animal health. This dried and ground product is sterilized by cooking with steam under pressure. This material is produced exclusively from bones. Standard Packaging Steamed Bone Meal is packed in 50 lb. paper bags. 2,500 lbs. are on each pallet. Pallets are to be exchanged. Steamed Bone Meal is also available in one ton super sacks. Guaranteed Analysis Calcium 23% minimum Phosphorus 13% minimum Crude Protein 6% minimum Moisture 7% maximum Particle Size:100% will pass through a 40 mesh screen with 98% through a 100 mesh screen. Pricing Steamed Bone Meal could be priced either FOB Austin, MN. in 2000 pound totes or FOB Grafton, WI in 50 lb. bags. Delivered prices to the location of your choice are available. Contracts will be accepted for shipment up to one year in advance. 6. Protein Bone Phosphate is the residue of bones that have been treated first in a caustic solution then in a hydrochloric acid solution, and thereafter precipitated with lime and dried. Typical Analysis Phosphorus Calcium Calcium Fluorine 18.5 % min 22.0 % min 25.0 % max 0.05 % max Feeding and Usage Bone Phosphate should be added to livestock rations to balance for calcium and phosphorus needs according to the specific ration. Storage and Handling Bone Phosphate is delivered in 50 lb valve-packed paper bags. It is palletized and shrink wrapped for ease of handling and should be stored in a cool, dry environment. 7. Ca Calcium sulfate is used as a source of sulfur and calcium in animal feeds. In addition to the variety of gypsum with the analysis indicated above, two other varieties are commonly available. One contains 20.3 percent calcium and 16.7 percent sulfur. The other contains 21.4 percent calcium and 17.1 percent sulfur. Typical Analysis Dry matter Crude Protein Fat Crude fiber Neutral Detergent Fiber Acid Detergent Fiber Calcium Phosphorus Sulfur Total Digestible Nutrients Net energy—Lactation 85 % 0% 0% 0% 0% 0% 26.4 % 0% 21.1 % 0% 0 Mcal/100 lbs 8. Protein Dried brewers grains is the dried extract residue of barley malt alone or in mixture with other cereal grains from the manufacture of wort or beer. It may contain pulverized dried spent hops in an amount not to exceed 3%, evenly distributed. Typical Analysis Crude Protein Fat Fiber Calcium Phosphorus Total Digestible Nutrients Net energy—Lactation 24.0% 5.0% 15.5% 0.6% 1.0% 70.0 % .72 mcal/lb. Feeding and Usage Dried brewers grains are a medium level protein feedstuff used in various animal feeds. They are an excellent source of high quality by-pass protein and digestible fiber. Dried brewers grains have a good amino acid, mineral and Bvitamin content. This feed ingredient is known for putting "milk in the pail". Suggested feeding levels are 30-40% of the ration for dairy cows. Storage and Handling Dried brewers grains are available in 50# bags or as bulk material. A sacked truckload will be approximately 22 tons while a bulk load is 16-19 tons. They will flow through normal feed or grain handling systems. Grains should be stored in a cool dry place. BREWERS YEAST, DRIED Protein Fat Ash Moisture Based on sucrose Color: Characteristics: Odor: Packaging: 40.0 - 45 % 0.2 - 1.5 % 5.0 - 10.0 % 7.0 - 10.0 % 100 - 87 % Light Brown Free flowing 98% through 100 mesh Standard Yeast odor Multi-walled bag 9. Protein Whole cottonseed is high in protein, fat, fiber and energy. This combination of nutrients in one feedstuff is unusual. Whole cottonseed with the lint still attached is white and fuzzy in appearance. It sometimes is called "fuzzy seed," and has the analysis shown below. Whole cottonseed from which the lint has been removed is called delinted seed, is black and smooth in appearance, and tends to be slightly higher in protein and fat than the fuzzy seed. Research at the Universities of California and Pennsylvania has shown that feeding whole cottonseed to milking cows can stimulate higher milk fat test and help maintain milk persistency. It should be fed at the rate of 4 to 7 pounds (1.8 to 3.1 kg) per cow per day. Mechanically delinted seed has the same effect as fuzzy seed. Whole cottonseeds do not need to be crushed or processed in any way before feeding. Typical Analysis Dry matter Crude Protein Fat Crude fiber Neutral Detergent Fiber Acid Detergent Fiber Calcium Phosphorus Total Digestible Nutrients Net energy—Lactation 93 % 21.0 % 17.0 % 24.0 % 40.9 % 30.8 % 0.14 % 0.68 % 91.0 % 94.1 Mcal/100 lbs 10. 11. Protein Fiber Cottonseed meal is the byproduct remaining after cotton is ginned and the seeds crushed and the oil extracted. The remaining meal is usually used for animal feed. However, the meal can be fed only to adult ruminants because it contains a compound called gossypol. The compound is highly toxic to monogastrics and even sometimes to calves which are really "pre-ruminants" in terms of their developing digestive systems. Cottonseed meal is produced in three protein levels. Cottonseed meals are classified as low gossypol if they contain less than 0.04 percent free gossypol. Forty-one percent cottonseed meal has a crude protein. level of 41 percent; crude fat, 2 percent; and crude fibre, 12 percent. Forty-eight percent cottonseed meal has a crude protein level of 48 percent; crude fat, 1 percent; and crude fibre, 8 percent. Although all three cottonseed meals are solvent extracted, the lower protein meals may contain some hulls. Cottonseed hulls are used mostly in the southern area of the U.S. They are low in protein, calcium, phosphorus and energy and high in fiber. Cottonseed hulls are palatable and are used as a roughage for cattle, especially in areas where good quality forages are scarce. They occasionally are included in grain mixes to increase the bulk density and crude fiber content. They can be helpful in supporting fat test in low fiber or low roughage rations. Typical Analysis 12. Protein Dry matter 91 % Crude Protein 03.7 % Fat 01.5 % Crude fiber 44.0 % Neutral Detergent Fiber 81.9 % Acid Detergent Fiber 66.4 % Calcium 00.1 % Phosphorus 00.1 % Total Digestible Nutrients 40.0 % Net energy—Lactation 40.4 Mcal/100 lbs Cottonseed meal is a high protein by-product from the extraction of oil from whole cottonseed. There are two different processing methods used to extract the oil from the cottonseed, and they differ in the amount of oil (fat) they leave in the meal. The amount of oil left in the meal affects its energy value. Cottonseed meal is palatable and commonly is used in cattle rations in the southern and western U.S. Solvent extracted cottonseed meal is the more common of the two types and has about 89 percent of the energy value of 44 percent protein soybean meal. Cottonseed meal contains gossypol. Under typical conditions, though, even high-producing cows will not consume enough cottonseed meal to suffer from gossypoltoxicity. Cottonseed meal is used as a protein supplement and can replace all of the soybean meal in the ration. Typical Analysis Dry matter Crude Protein Fat Crude fiber Neutral Detergent Fiber Acid Detergent Fiber Calcium Phosphorus TDN Net energy—Lactation Expeller process: Solvent process: 94 % 92 % 41.0 % 41.5 % 04.5 % 01.5 % 12.5 % 12.5 % 26.3 % 23.9 % 18.8 % 17.5 % 0.15 % 0.15 % 1.10 % 1.10 % 72.0 % 70.0 % 76.3 Mcal/100 lbs 72.6 Mcal/100 lbs 13. Fiber Soybean hulls are a by-product of soybean processing for oil and meal production. Soybean hulls have urease activity, which can be a problem in rations containing urea. Heat treatment destroys the urease activity. Soybean hulls which have been heat treated are referred to as soybean mill run. Soybean mill run is a palatable feedstuff for cows and calves. It contains a high level of very digestible fiber. It has slightly more TDN than beet pulp and oats, 93 percent of the TDN value of barley, and 88 percent of the TDN value of corn. Soybean mill run may be included in the grain mixture at a rate of up to 14 pounds (6.5 kg) per cow per day. Because of its bulky texture, caution should be taken when feeding over 12 pounds (5.5 Kg) per cow per day. 14. Typical Analysis Dry matter 91 % Crude Protein 10.0 % Fat 02.0 % Crude fiber 36.0 % Neutral Detergent Fiber 61.1 % Acid Detergent Fiber 45.5 % Calcium 0.45 % Phosphorus 0.16 % Total Digestible Nutrients 71.0 % Net energy—Lactation 73.8 Mcal/100 lbs Soybean meal is the product remaining after extracting most of the oil from whole soybeans. The oil may be removed by solvent extraction or by an expeller process in which the beans are heated and squeezed. The nutrient composition of the oil extracted soybean meal 48 is shown in the table below. Soybean meal is high in protein and energy and is one of the most commonly used protein supplements in North America. It is a palatable feedstuff and may be used as the major protein supplement in rations for dairy cattle. Typical Analysis (Solvent extracted soybean meal 48) Dry matter 89 % Crude Protein 48.0 % Fat 01.0 % Crude fiber 03.0 % Neutral Detergent Fiber 07.1 % Acid Detergent Fiber Calcium Phosphorus Total Digestible Nutrients 15. 05.3 % 00.2 % 0.65 % 78.0 % 81.1 Mcal/100 Net energy—Lactation lbs Corn gluten feed is a by-product from the manufacture of cornstarch and corn syrup. It is a medium protein feed, which contains almost the same Total Digestible Nutrients level as barley. The protein in corn gluten feed is degraded relatively rapidly in the rumen. Corn gluten feed has medium palatability and may be included in the grain mixture up to a level of 50 percent or fed to cows at a rate of up to 12 pounds (5.4 kg) per cow per day. Typical Analysis Dry matter Crude Protein Fat Crude fiber Neutral Detergent Fiber Acid Detergent Fiber Calcium Phosphorus Total Digestible Nutrients Net energy—Lactation TDN: Beef TDN: Dairy Fat Ash Magnesium Potassium Sulfur Crude Fat Lysine Tryptophan Methionine 90 % 18.0 % 03.5 % 08.0 % 45.0 % 13.0 % 00.3 % 1.00 % 83.0 % .87 Mcal 88.0% 87.0% 3.5% 7.2% 0.5% 1.5% 0.3% 3.5% 0.6% 0.2% 0.5% Cystine 0.4% Applications Corn Gluten Feed is commonly used as a medium level protein and energy source. It may be used in ruminant feeds, pet foods, poultry (replacement chicks, layer and breeder), turkey and swine. 16. Corn gluten meal is a by-product from the manufacture of corn starch and corn syrup. It is very high in protein supplement in feeds for livestock, poultry and pets. It contains slightly more TDN than corn. The protein in corn gluten is degraded relatively slowly in the rumen. A variety of corn gluten meal with 41 percent protein is available in some areas. It is higher in crude fiber (5 percent) and lower in TDN (78 percent) than the variety with 60 percent protein. Corn gluten meal usually is not included in mixtures at levels greater than 15 percent or fed at a rate greater than 15 percent or fed at a rate greater than 5 pounds (2 ¼ kg) per cow per day due to poor palatability above these levels. Typical Analysis Dry matter Crude Protein Fat Crude fiber Neutral Detergent Fiber Acid Detergent Fiber Calcium Phosphorus Total Digestible Nutrients Net energy—Lactation 90 % 60.0 % 02.5 % 02.0 % 12.6 % 06.2 % 04.5 % 00.5 % 83.0 % 84.1 Mcal/100 lbs Guaranteed Analysis Crude Protein Crude Fat Crude Fiber 60.0% minimum 1.0% minimum 3.0% maximum Appearance Color Golden Yellow Texture Fine Granular Typical Analysis Xanthophyll Metabolize Energy Methionine Digestible Protein 100 to 225 mg./lb.; varies seasonally 1,756 calories/lb. 1.6% 98% Advantages -Permits the manufacture of higher nutrient density broiler, layer, and turkey feeds -Xanthophyll and protein analysis certificate on each load 17. Hominy Corn. Hominy feed is a by-product from the manufacture of pearl hominy, hominy grits or table meal from corn. It is similar in appearance to ground corn, has slightly more energy and protein, and has similar feeding characteristics. Hominy should be analyzed for its fat content, which can vary considerably due to the type of manufacturing process. As fat content drops, so does TDN. For example, hominy containing 1.5 percent fat will have 82 percent TDN. Hominy is a palatable feedstuff. It is safe to feed in large quantities and can be included in the grain mixture at high levels. Typical Analysis Dry matter Crude Protein Fat Crude fiber Neutral Detergent Fiber Acid Detergent Fiber Calcium Phosphorus 90 % 10.0 % 05.0 % 05.6 % 49.5 % 11.7 % 0.05 % 00.5% 18. Total Digestible Nutrients 84.0 % Net energy—Lactation 86.1 Mcal/100 lbs Citrus Pulp is the dried residue of peel, pulp and seeds of oranges, grapefruit and other citrus fruit. As with most feeds, citrus pulp is dried to a moisture content of approximately 10%. Dried Citrus Pulp is second only to corn as a source of concentrated feed nutrients for dairy and beef cattle, and sheep. It is a good source of calcium, but very low in phosphorus and carotene. Based on these data, dried or pelleted citrus pulp is one of the most desirable energy feeds and can be considered in feeding programs as being: 1. A dry carbohydrate concentrate with high total digestible nutrient (TDN) content averaging about 74 % 2. A bulk energy feed with a high degree of water absorption 3. Having an above-average palatability for cattle. As a general rule, 40 – 45 % of the ground snapped corn in a dairy ration can be replaced by dried citrus pulp or pellets. Typical Analysis 19. Protein % Fat Crude Fiber Ash Moisture Canola Meal Range Average 5.0 – 9.3 1.3 – 9.1 6.4 – 16.8 3.1 – 8.4 3.5 – 13.7 Dry Matter Crude Protein Ether Extract Crude Fiber Ash 6.16 3.74 12.28 4.68 8.58 91.5% 36.0% 3.5% 11.7% 6.8% Amino Acids Avg. Crude Protein Methionine Std. Dev. % CV 36.0 1.09 3.0 0.74 0.03 4.1 Cystine TSAA Lysine Tryptophan Threonine Arginine Isoleucine 20. 0.91 1.65 2.10 0.46 1.61 2.12 1.38 0.05 0.08 0.05 0.02 0.05 0.09 0.05 5.5 4.8 2.5 4.3 3.1 4.2 3.6 Minerals Major Trace mg/lb mg/lb Calcium 0.66% Copper 4.7 10.4 Phosphorus 1.14% Iron 72.2 159.2 Sodium 0.03% Iodine 0.36 0.8 Chloride 0.02% Manganese 24.5 53.9 Potassium 1.29% Selenium 0.45 1.0 Magnesium 0.64% Zinc 32.4 71.4 Cassava is used as animal feed extensively in Asia, South America, Africa, and Europe. Especially in places such as Thailand, China, Nigeria, Brazil, etc. Cassava hay, is hay which is produced at a young growth stage, 3-4 months and being harvested about 30-45 cm above ground, sun-dried for 1-2 days until having final dry matter of at least 85%. The cassava hay contains high protein content, 20-27% CP and condensed tannins, 1.5-4%. 21. It is used as a good roughage source for dairy, beef, buffalo, goats, sheep by either directing feeding or as a protein source in the concentrate mixtures. Copra is the dried meat, or kernel, of the coconut. The name copra is derived from the Malayalam word kopra (ക ൊപ്ര) for dried coconut. Copra meal is also used as fodder for horses and cattle. Its high oil levels and protein are very fattening for stock and it is popular among horse enthusiasts. The Philippines is the world's largest coconut producer and supplies much of the demand of copra meal around the globe. For example, copra meal exports totalled 586,173 mt in 1994 with 96% being exported to Europe, mainly to the Netherlands, Germany, United Kingdom, and Italy. An additional 23,700 mt of unmilled copra (equivalent to around 7,347 mt of copra meal) was also exported mainly to Korea. The volume of copra meal utilized locally for feeds is estimated to be at least 600,000 mt per year. 22. Corn - Maize: Feed Ingredients Corn also known as Maize is a cereal grain that was domesticated in Mesoamerica and then spread throughout the American continents. In the United States and Canada, the primary use for maize is as a feed for livestock, forage, silage or grain. Silage is made by fermentation of chopped green cornstalks 23. Corn Distillers Dried Grain with Solubles This product is obtained by removal of ethyl alcohol by distillation from the yeast fermentation of corn or corn mixture by condensing and drying at least 75 percent of the solids of the resultant whole stillage. Corn distillers dried grain with solubles has a crude protein level of 26-27 percent; crude fat, 7-8 percent; and crude fibre, 8.5-9.5 percent. Feather meal a poultry by-product has been used as an ingredient in the manufacture of feeds. Feather meal contains about 80-85 percent protein and is a relatively good source of sulphur-containing amino acids. Whether these amino acids are completely available has not been demonstrated. Good results have been reported when it is used in catfish diets at the 15 percent level. Poultry by-products are lower in lysine than fishmeal, and trout diets containing over 75 percent poultry by-products would be deficient in the amino acid. 24. That some of the sulphur-containing amino acids in hydrolyzed feather meal are available to salmonids was recently demonstrated in feeding tests at the University of Washington. In these experiements, trout grew much better on mixes of feather meal and yeast SCP than when either of these commodities was used as the sole source of protein. Egg Dried Pasteurized, spray- dried whole- egg solids, produced from eggs that do not meet the USDA standards for human consumption. Eggs are denatured with a small quantity of certified caramel coloring that imparts a light- brown shade to the finished product. Product Standards: Chemical Protein Fat Fiber Ash 46.0% minimum 33.0% minimum .1% maximum 6.0% maximum Moisture Physical Particle Size Color Microbiological Packaging Storage 6.0% maximum 100% through #16 USBS Screen Light Brown Salmonella: Negative by approved method This product is packed in 50 lb.net weight polycoated bags. Bulk packaging is also available Store in a cool dry place. 25. Inedible eggs are which the USDA has stated cannot be used in human foods due to broken shells or eggs which do not meet human standards in terms of blood spots, etc. These eggs are centrifuged and the resulting liquid is pasteurized, spray dried, and packaged in our own facility. Ingredients Inedible eggs (can be denatured with edible FD&C approved green dye or without, at the customer’s request.) Specifications Moisture Protein Fat Standard Plate Count Salmonella Free Packaging 5 % or less 50 – 58 % 25 – 30 % less than 100,000 total All product is tested for salmonella in our USDA supervised lab and a certificate is available upon request. 50 lb bags or 50 lb boxes 26. Fish Meal. Menhaden is the major source of fish meal produced in the U.S. The fish are taken in Atlantic coastal waters from Maine to Florida and in the Gulf of Mexico. Menhaden are not used for human food but for oil used in paints, soaps, and lubricants and as an ingredient in margarine in Europe. The fish are ground, cooked and processed to yield three products: presscake, fish solubles and oil. The final fish meal product may be simple presscake meal, full meal (all the soluble are added back into the presscake), or some combination of presscake and soluble. Fish meal used for animal feed should be stabilized with an antioxidant such as ethoxquin to prevent the fish oil from becoming rancid. The protein in fish meal has a high rumen bypass value. The bypass protein itself is high in quality because it is rich in the essential amino acids lysine and methionine. For this reason, it makes a good combination with alfalfa or earlycut grass silage, which tend to be higher in rumen degradable protein. Feeding Fish meal should be introduced into the ration gradually to avoid feed refusal. Since the greatest benefit from feeding fish meal comes during the first half of lactation when protein requirements are highest, it is useful to start adapting the cows to it during the latter part of the dry period. Fish meal can be fed to milking cows at a rate that supplies up to a maximum of 100 grams (3.5 ounces) of fish oil (fat) per cow per day. Higher levels of fish oil tend to lower fat test. The fat content of fish meal varies among suppliers. Therefore, it is important to know the fat content of the fish meal being used. A practical guideline is to feed it at a rate of up to 1 ½ pounds (0.7 kg) per cow per day. Typical Analysis Dry matter Crude Protein Fat Crude fiber Neutral Detergent Fiber Acid Detergent Fiber Calcium Phosphorus Total Digestible Nutrients Net energy—Lactation 92 % 62.0 % 09.8 % 01.0 % 00.0 % 00.0 % 05.0 % 03.0 % 71.0 % 70.0 Mcal/100 lbs. Others: Herring, Anchovy, Redfish, and Whitefish meal Herring and anchovies also are oil-type fish and are processed similarly. Redfish meal is the filleting waste from ocean perch. Ocean perch are not an oil fish. They are caught for human food off the eastern coast of Canada and the U.S. After the fillets are removed, the heads and racks are ground, cooked and dried to produce redfish meal. The term whitefish refers to cod, haddock, hake, flounder and pollack. Like ocean perch, these also are caught for human food. After the fillets are removed, the heads and racks are ground, cooked and dried to produce whitefish meal. Low Ash Menhaden meal differs from conventional commodity fishmeal by the additional process developed to remove a large amount of the bone. The resulting meal has a significantly reduced ash content, and a corresponding increase in protein. This meal is ideal in situations where a lower mineral content is needed. This process results in a meal with a much smaller particle size. Proximate Composition Micro and Macro Minerals Typical Guaranteed Crude Protein 70.0 68 min Calcium % Fat 9.0 Phosphorus % Moisture 9.7 Potassium % Ash 13.0 Magnesium % Digestibility (0.2%) 97.8 Sodium % Digestibility 91.1 90 min Manganese- PPM (0.0002%) TVN 0.16 0.18 max Iron- PPM Boron- PPM Copper-PPM Amino Acids % of Sample Zinc- PPM Aspartic Acid 6.4 Chromium- PPM Threonine 3.0 Selenium- PPM Serine 2.7 Strontium- PPM Glutamic Acid 9.2 Barium- PPM Proline 3.5 Aluminum- PPM 3.4 2.2 1.0 0.2 0.7 45.2 924.0 4.5 7.8 94.8 4.0 2.0 66.2 14.3 774.4 Glycine Alanine Cystine Valine Methionine Isoleucine Leucine Tyrosine Phenylalanine 5.4 4.6 0.7 3.5 2.3 3.0 5.1 2.2 2.8 Histidine 2.0 Lysine 5.6 Arginine 4.4 Tryptophan 0.7 Taurine 0.6 Hydroxyproline 1.3 Vitamins- MG/LB- Literature Values Botin Choline Folic Acid Niacin Pantothenic Acid Vitamin B1Thiamine Vitamin B2Riboflavin Vitamin B6Pyridoxine Vitamin B12 a- Tocopherol (IU/#) 0.1 1360.0 0.1 25.0 4.0 0.3 2.2 2.7 0.1 9.5 27. Fish silage is a liquid product made from whole fish or parts of fish that are liquefied by the action of enzymes in the fish in the presence of an added acid. The enzymes break down fish proteins into smaller soluble units, and the acid helps to speed up their activity while preventing bacterial spoilage. Silage made from white fish offal that does not contain much oil, but when it is made from fatty fish like herring it may be necessary to remove the oil at some stage. The composition of fish silage is very similar to that of the material from which it is made. A typical analysis of white fish offal is: · 80 per cent water, · 15 per cent protein, · 4.5 per cent ash · 0.5 per cent fat, and the composition of silage from offal is virtually the same. Whole fatty fish like sprats and sand eels have a higher protein and fat content, and correspondingly lower water and ash content. Production of fish silage is a viable alternative to fish meal, especially in location where small amount of fishery waste or by-catch is produced It has been shown that by-catch or fish wastes, whole, chopped or ground, preserved in molasses or as fermented or acid silage, in the form of a paste or block, can replace more conventional sources of protein for pigs, ducks, sheep, cows, beef cattle and even camels! While the technology for the preparation offish silage exists. Its commercial application will depend on extension to producers and on its opportunity cost versus that of other conventional protein sources, as well as on the existence of other means of processing to meet environmental regulations. At the moment it is not commericially available on a widescale. 28. 29. Meat meal is only available where offal is not valued for human food; may be contaminated and spoiled before use; may also contain animals condemned as unfit for human consumption. Meat scraps and trimmings after fat removed are dried into meat meal. This is inferior to fish meal or soybean meal and is prone to damage (evidenced by low available lysine) by poor processing. If refrigeration is available or the waste can be collected daily both it and blood are potential moist feed ingredients. Meat and bone meal is prepared from the wastes materials associated with slaughtering operations (carcass trimmings, condemned carcasses, condemned livers, inedible offal (lungs) and bones) and also from the rendering of dead animals. There can be a wide variation between plants and batches in what goes into the meat and bone meal that is being prepared. If the ash content is high, this indicates that it contains a higher amount of bones and is referred to as meat and bone meal. If the ash content is lower it is referred to as meat meal. Typically when the phosphorus content is above 4.5 % P, then it is called meat and bone meal and when it is below that level it is referred to as meat meal or some other term. In addition to the protein (amino acids) meat and bone meal is an excellent source of calcium and phosphorus and some other minerals (K, Mg, Na, etc.). The ash content of the meat and bone meal normally ranges from 28 to 36 %; calcium is 7 to 10 % and phosphorus 4.5 to 6 %. When using meat and bone meal as the primary supplemental protein source the mineral levels may limit its use in some diet formulations. Meat and bone meal like with other animal products is a good source of Vitamin B-12. Like other animal protein sources meat and bone meal has a good amino acid profile. Digestibility of the protein fraction is normally quite high, ranging from 81 to 87 % (Kellems, 2000). Its protein quality is lower than fish meal or soybean meal for applications in feeding swine or poultry when used to supplement CP in cereal based diets. In ruminant it can readily be used to replace most other supplemental protein sources. The CP is less ruminally degradable, and will pass thorough the rumen without being degraded when compared to many other supplemental protein sources. Processing temperature will also effect the availability of the protein fraction. Often pepsin digestibility of the protein fraction is used as a means of determining the extent of processing and availability of the protein fraction. Excessive heating during processing can reduce the digestibility of the CP. Meat and bone meal is the dried and rendered product from mammal tissues. It does not contain horn, hair, hide trimmings, manure, stomach contents, added blood meal or poultry by-product. The calcium content should not be more than 2.2 times the phosphorus content. A calcium content higher than this indicates additional calcium from a source other than bone. The protein in meat and bone meal is degraded relatively slowly in rumen. Meat bone meal can be fed as a protein source. It may be included in the grain mix at a rate of up to 5 percent or fed at up to 1 ½ pounds (0.68 kg) per cow per day. It is not very palatable and should be introduced into the ration gradually. Typical Analysis Dry matter Crude Protein Fat Crude fiber Neutral Detergent Fiber Acid Detergent Fiber Calcium Phosphorus Total Digestible Nutrients Net energy—Lactation 92 % 50.0 % 09.5 % 02.5 % --- % --- % 10.1 % 04.8 % 65.3 % 68.1 Mcal/100 lbs 30. Liver Meal is a high protein specialty product manufactured from whole livers. These materials are processed under controlled time and temperature conditions and then dried to provide a fine meal product. The protein and fat content of this product provide for an exceptional source of energy and a real liver flavor for specialty pet food formulas. Usage Liver Meal performs as an excellent ingredient in pet food formulas, as well as aquaculture feeds. Suggested usage levels of 1 to 3% will provide significant palatability increase when applied externally if mixed with fat prior to joint application. Internal application can also result in increased palatability at usage levels of 3 to 6%. Typical Analysis Protein Moisture Fat Ash Amino Acid Profile Aspartic Acid Serine Hydroxyproline Proline Alanine Valine Isoleucine Tyrosine Hydroxylysine Arginine Storage and Handling Standard Packaging 62.0% min. 10.0% max. 20.0% max. 7.0% max. 5.60% Tryptophan 0.93% 3.09% Threonine 3.08% 0.01% Glutamic Acid 10.28% 3.29% Glycine 3.79% 3.48% Cystine 0.91% 3.75% Methionine 1.23% 2.04% Leucine 5.41% 2.22% Phenylalanine 2.08% 0.01% Histidine 2.17% 4.41% Lysine- Total 4.34% Storage in unopened containers may be indefinite. However to maintain full nutritional value recommended storage at room temperature is three months. Liver Meal is packaged in 50 lb. poly- lined double wall paper bags. Other packaging arrangements are negotiable. 31. Palm oil milling is a major industry in countries in SE Asia. The industry, besides producing palm oil, also produces by-products usable as animal feed. These are palm kernel cake, palm oil sludge (POS) and palm pressed fibre (PPF). The most useful is palm kernel cake, which is the solid residue left behind after the extraction of oil from the kernels of the palm fruits. It is now well entrenched as a major feed ingredient in beef and dairy feed in theese producing countries. The palm kernel cake is obtained out from two stages of oil extraction from the palm fruit. The first stage is the primary extraction of palm oil from the pericarp portion of the fruit, which also produces the kernel and by-products palm oil sludge and palm pressed fibre. The extraction of oil from crushed kernel then results in the production of palm kernel cake as by-product. Two methods are used for the extraction of oil from the crushed kernels. These are the conventional mechanical screwpress method that results in the expeller pressed palm kernel cake and the solvent (usually hexane) extraction method that results in the solvent extracted type. Although palm kernel cake supplies both protein and energy, it is looked upon more as a source of protein. palm kernel cake by itself is a medium grade protein feed and with its high fibre content it is often consider as suitable for feeding of ruminants. palm kernel cake was ranked a little higher than copra cake but lower than fish meal and groundnut cake especially in its protein value. Suitability of palm kernel cake as feed for cattle has been much proven. Invariably, it has become the basic feed in most rations for fattening cattle in feedlots in SE Asia. It is also the primary constituent supplementary feed for dairy cattle, mixed together with other ingredients such as ground maize and soybean meal. PKC is a reasonably good economic feed for cattle, both for fattening and supplementary feeding. It is an agro-industrial by-product that is being produced locally and within the Southeast Asian region in sizeable quantity and should thus be exploited fully. 32. Peanut meal is obtained by grinding the cake, chips or flakes obtained by removal of most of the oil from peanut kernels by a mechanical or solvent extraction process. Peanut meal will have a crude protein level of about 46 percent; crude fat, 1-7 percent; and crude fibre, 10-13 percent. 33. Feather Meal Hydrolyzed poultry feathers or feather meal is produced by hydrolyzing clean, undecomposed feathers from slaughtered poultry. The most important factor affecting the quality of hydrolyzed poultry feathers is the extent of hydrolyzation. If less than 75 percent of the crude protein content is digestible by the pepsin digestibility method, then hydrolyzation was incomplete and protein quality is reduced. The protein in feather meal is degraded slowly in the rumen compared to most other protein sources. In research at Purdue University, a combination of feather meal and urea produced average daily gains in growing beef cattle similar to that achieved with soybean meal. There is very little experience with feather meal in dairy cattle rations. It is not very palatable and should be introduced into the ration gradually. It may be fed to milking cows at an average rate of up to 1 ½ pounds (0.7 kg) per cow per day. Typical Analysis Dry matter Crude Protein Fat Crude fiber Neutral Detergent Fiber Acid Detergent Fiber Calcium Phosphorus Total Digestible Nutrients Net energy—Lactation 92 % 85.0% 03.0 % 03.0 % --- % 16.2 % 0.45 % 0.31 % 63.0 % 64.0 Mcal/100 lbs 34. Poultry by-products of slaughter - such as feet, head and undeveloped eggs can be processed in the same way as other slaughterhouse waste if the quantities are large enough. Gizzards and intestines can be used as well if the contents are removed. The dry- rendering method is usually preferred for processing poultry by- products. Poultry tankage and meat meal are about equal in value to the same byproducts from larger animals. They can be used as the only protein component in growing and finishing rations for swine with good results. Poultry byproduct meal is remarkably rich in the vitamin choline and is often included up to 5% in poultry diets. Poultry byproducts are primarily used by the pet food industry. They appear to be excellent protein and lipid sources containing: · 69 percent crude protein, · 10-21 percent lipid · and about 10 percent ash. Poultry by-products are lower in lysine than fishmeal, and trout diets containing over 75 percent poultry by-products would be deficient in the amino acid. 35. Rapeseed oilcake The cultivated varieties of rape are mainly varieties of B. Maps and B. campestris. Both may be grown as annuals or biennials, depending on the variety and time of sowing. The plants are from 0.6 to 1 m high and have thick succulent stems and leaves, although the leaves of B. campestris are thinner, less succulent and greener or less glaucous. The seed contains about 40% semi-drying oil. The oil is used as salad and cooking oil or in the manufacture of margarine. Rapeseed oilcake contains compounds that are potentially toxic to certain age groups or classes of livestock and poultry, but experiments in recent years have indicated numerous ways in which the meal can be used without detriment to animals. The toxic factors derive in part from glucosides, which yield toxic substances when hydrolysed enzymatically. One of these substances inhibits the uptake of iodine by the thyroid and thus causes goitre. Rapeseed may also be contaminated with mustard seeds so that the press cake will contain residual mustard oil that may be harmful. B. campestris meals contain a considerably smaller amount of the glucoside than B. napus meals. One detoxification method involves moistening the ground seed and allowing the enzyme to hydrolyse the glucosides. After the oil has been extracted, the cake is steamed, This treatment removes most toxic factors, but the substance causing goitre remains in the cake. Other methods involve extraction of the toxic factors from the cake with hot water or ethyl alcohol. The safest method of avoiding the total effect of the toxic factors is to limit use of the oilcake. An almost glucoside-free variety has been developed (Brassica napus L. cv. Bronowski); the growth responses to the oilcake of this variety are reported to be equal to the results from soybean oilcake. The content of toxic constituents differs greatly between varieties and may also depend on the processing method. Feeding trials with cattle and sheep have shown that ruminants are less susceptible than other classes of livestock to the toxic effects of rapeseed meal. Adult cattle can be given from 1 to 1.5 kg a day without detrimental effects on feed consumption, growth or milk flavour. Young or pregnant animals should be given less. Rapeseed meal is not very palatable to sheep and therefore should not exceed 20% of their total ration. Solvent-extracted meal can constitute up to 4% of the total ration for young pigs (up to 20 kg) and up to 10% of the total ration for market pigs (20-90 kg). It should not be used in rations for breeding stock during reproduction and lactation. Rapeseed meal should not be used in starter rations for poultry, but it may be used to fatten birds or layers, for which the maximum desirable level is about 10% of the total ration. It should be noted that oilcakes produced by the expeller process may be low in lysine. Poultry fed rapeseed oil meal are likely to have enlarged thyroid glands; however, this condition will usually be of no economic importance if a stabilized iodine is incorporated in the diet. Some strains of layers may produce eggs with a fishy taste when they are fed rapeseed meal. 36. 37. Rice groats are the ground rice kernel, without the bran. Rice groats contain approximately a crude protein level of 8.6 percent; crude fat, 1.2 percent; and crude fibre, 1.0 percent. Rice bran with germ is primarily the pericarp or bran layer and the germ portions of the rice kernel. · crude protein level is approximately 13.3 percent; · crude fat, 15.0 percent; · crude fibre, 11.0 percent. Description Rice bran is a by-product of the milling of rice. It consists mostly of the bran layer and germ of the rice with some fragments of hull and broken rice. The calcium level in rice bran will vary with the amount of added calcium carbonate. When the amount of added calcium carbonate exceeds 3 percent (total calcium exceeds 1.2 percent), then the percentage of calcium carbonate must be stated in the product name. Rice bran is similar to oats in crude protein, fat, fiber and energy. It is a palatable feedstuff, which can be included in the grain mixture at a rate of up to 25 percent or fed at a rate of up to 8 pounds (3.6 kg) per cow per day. Typical Analysis Dry matter Crude Protein Fat Crude fiber Neutral Detergent Fiber Acid Detergent Fiber Calcium Phosphorus Total Digestible Nutrients 38. 90 % 13.0 % 13.0 % 13.0 % 29.7 % 16.2 % 1.00 % 1.54 % 68.0 % 70.0 Net energy—Lactation Mcal/100 lbs. Rice polishings are the outer portions of the rice kernel produced by the process used in producing polished white rice. Rice polishings have: · crude protein level of 11.8 percent; · crude fat, 13.2 percent; · crude fibre, 3.0 percent. 39. Sesame Cake: After extraction of the oil from the seeds, the resulting oilcake is a valuable high- protein feed. Combined with groundnut meal it provides a well-balanced protein supplement. Mixed with an equal amount of cottonseed meal, it has been included up to 15% in chick rations. Supplemented with blood meal and energy this feed has been quite successful. The oilcake is palatable to all classes of livestock and has a mildly laxative effect. If it forms too large a part of the ruminant or swine ration, it will produce soft butter and pork. It is recommended that dairy animals be given no more than 3 kg of sesame cake per day, as larger amounts will give the milk a disagreeable taste. It should not be wetted when fed, as the meat will acquire an unpleasant taste. Sesame meal is frequently used as the principal protein in both growing and fattening rations for swine, constituting up to 30% when 5% of the ration is a lysine-rich ingredient, such as meat meal. Excessive use of sesame meal may produce soft pork. As sesame cake is rich in methionine and arginine, it has great potential as a poultry feed when mixed with lysine-rich materials. It has a high content of phytic acid and appears to bind calcium; hence the amount of calcium in diets containing sesame meal should be increased. The cake will become rancid if stored for any length of time. 40. Shrimp meal can be made from either cull shrimp that are being processed before freezing or from whole shrimp that is not of suitable quality for human consumption. A dried meal similar to fish meal, made from the waste heads and shells of large prawns or shrimps, or from whole small shrimps or crustacea of no human food value. Its true protein value is only about 50-70% (depending on the proportion of heads to shells in the original material) of the apparent, or 'crude' protein content. This is because much of it derives from an indigestible (nitrogen containing) polysaccharide, chitin. However, it is an important source of this chitin for shrimp feeds, it is high in choline and it is used for pigmentation as it contains important carotenoids. Both shrimp and fish meals, unless finely ground, give poor stability to aquaculture feeds. Again, as with fish meals, it is important to know the source of the material and to analyse it. Some meals are nearly all shells, with little value. Waste shrimp heads and shells can, if available fresh or refrigerated, be used as excellent ingredients in moist aquaculture feeds, especially for shrimp. 41. Milk contains almost all nutrients required by animals. Although milk products are excellent feeds, their cost prohibits extensive use for all but young animals. Skim milk is milk from which most of the fat has been removed but in which all the protein remains. The protein has a high biological value and is very digestible. Skim milk is a good source of Water Soluble Vitamins, whereas the Fat Soluble Vitamins (A and D) are removed with the fat. Various viable options are available for using skim milk in feeding systems for calves (bucket, cooling, formic acid treatment, etc.) and swine. Skim milk is an excellent feed for swine and would be a viable feed ingredient when the price is competitive or when there is an excess supply. Gains in growing swine were increased when skim milk was fed . Normally it is more economical to feed liquid skim milk than dried skim milk and the normal bacterial acidification was found to be the cheapest method of stabilization. Liquid skim milk that had been stabilized with formic acid was found to be more palatable in swine feeding applications as compared to hydrochloric acid stabilized skim milk . Formaldehyde stabilization of skim milk fed to calves has been evaluated and shown to increase gains. 42. Sorghums are grown for grain and also for forage in areas with inadequate rainfall for satisfactory maize cropping. There are two general types: the sweet sorghums, which have stems filled with a sweet juice, and the grain sorghums, which usually have pithy stems. Sweet sorghums are grown for forage rather than grain. There are many varieties of grain sorghum, but the composition of their grain does not differ enough to affect significantly their feed qualities. All varieties are annual maizelike gasses more than 2 m high. Sorghum requires similar soil conditions to maize but can grow in drier climates. When properly supplemented, sorghum grains are excellent for all classes of livestock. The grains have to be processed before being fed to cattle, else a large proportion of the grains will be swallowed whole and the waxy bran covering the grain will make digestion difficult. Grinding is the simplest, least expensive method of preparing sorghum grain for cattle; other methods include dry-rolling, steam-rolling, flaking and popping. All methods produce end products with different degrees of digestibility. Sheep can be given whole sorghum grains as they masticate them more thoroughly. Whole grain can also be fed to pigs and poultry, but cracked or ground grain gives somewhat better feed efficiency especially with small-seeded varieties or very dry grains. For best results the grain must be ground only moderately fine, as too finely ground grain decreases consumption. When sorghum grain is replacing maize, it must be borne in mind that sorghum lacks carotene and should therefore be supplemented with about 3% dried green feed. Sorghum has the disadvantage of tending to cause constipation. 43. Squid Meal if available, this is an excellent ingredient for shrimp feeds, but expensive. It appears to have growth promoting properties. Fresh squid can also be used in moist diets. In a growth trial (1 to 48-days) with chicks squid meal based diet was found to out perform fish meal and meat and bone meal based diets. Squid meal was found to be a good source of supplemental protein for prawns . When shrimp were fed diets containing squid meal feed conversion and gain was increased. In trials with gilthead seabream squid meal was found to be an excellent supplemental protein source. While the benefit sof using squid meal are very good, the high expensive of this ingredient could prhobot it's use. 44. Sunflower Meal: The composition of the oil meal varies with the quality of the original seed and the method of processing. A wide variety of products are available on the market, ranging from low-quality strawlike meals to highquality flours. The use of high-fibre sunflowerseed oilcakes is restricted to the feeding of adult ruminants, whereas the decorticated cake is a digestible high-protein feed that can be used freely in balanced mixtures for all livestock. As the cakes are hard, they are best fed ground and incorporated in compounds. Meals with a high fat content tend to produce soft pork if fed in large amounts. If limited to about one third of the protein supplement, the meal gives good results in pigs, especially those weighing over 45 kg. The oilcake does not keep well. Supplementary lysine will be necessary if large amounts are to be fed to nonruminants, and for poultry a rich source of energy has to be added. 45. Sweet potato is a creeping plant with perennial vines and adventitious roots, some of which produce swollen tubers. It is an ancient food plant from tropical America and the Pacific islands, and several varieties of sweet potato are now extensively cultivated in many parts of the world. The major producing countries are Japan, Indonesia, Brazil, Korea, China, India and Uganda, with their production ranging between one and four million tons per year. Substantial quantities are also produced by the Philippines, the USA, Malaysia and several other countries. Chemical composition: Low protein, fat and fibre were found in the roots, but the high nitrogen-free extract fraction in this tuber is indicative of its potential value, mainly as an energy source. The vines have a lower carbohydrate content but higher in fibre and protein and their principal nutritive value is as a source of vitamins and protein. Carbohydrates generally make up between 80 to 90 % of the dry weight of sweet potato roots but the uncooked starch of the sweet potato is very resistant to the hydrolisis by - amylase. When cooked, their susceptibility to the enzyme increases. Thus, after cooking, the easily hydrolysable starch fraction of sweet potato increases from 4 % to 55 %. The content of trypsin inhibitors of the raw sweet potato roots could decrease the protein digestibility in mixed feed. The vines will not produce this effect because they do not contain them in great quantities. This trypsin inhibitor could be destroyed or lowered by preheating raw sweet potato roots. Roots: Cooking sweet potato increased pig live-weight gain when compared with raw sweet potato and Pigs grazing sweet potatoes require 500 g protein concentrate per pig per day for optimal growth. Several results have confirmed that the performance of pigs fed diets containing dried sweet potato chips was not comparable to that of pigs fed corn but daily gain and feed/gain ratio were acceptable when the pigs were fed diets where sweet potato chip substituted half of the corn or at levels near 40 % in the diet. However, cooked and mashed sweet potatoes may totally replace maize for fattening pigs provided an adequate protein supplementation is used. Sweet potato root meal can be included up to 50 % in poultry feeds with good results if properly supplemented with protein. The fresh tubers are palatable for cattle and sweet potato meal was found to be 90 % efficient as a feed for lactating cows when compared to corn meal feed. Foliage: The vines serve as a nutritive and relished green feed for cattle. The feeding value of vines is close to that of alfalfa. Fresh sweet potato vines are palatable to cattle and a cow of 400-500 kg can consume 50-70 kg daily. An increased proportion of fresh sweet potato vines produced more milk. The supplementation of sweet potato-forage improves feed intake and weight gain of young bulls fed sugar cane stalks. Sweet potato vine meal can be used in poultry rations both as a source of protein or xantophyll pigment. The xantophyll of sweet potato vines is a good pigmentation agent for egg yolks and broiler skins. Sweet potato fresh foliage has been used for weaned piglets substituting 10 % of the cereal concentrate with satisfactory animal performance both from the point of view of weight gain and feed conversion and also related to mortality and herd culling. The supplementation of standard diets with sweet potato foliage did not improve the performance of pigs. The use of fresh foliage, substituting 25 and 50 % of soybean meal as a protein source in sweet potato roots-soybean diets, decreased the intake of dry matter probably due to the bulkiness of this feed. Nevertheless, with the low level of substitution of soybean, meal, feed conversion was similar to that obtained using sweet potato-soybean diets. 46. Dried Potatoes are composed of potato by-products from a food processing plant. The main component is potato skins that have been steam extracted without the use of chemicals or artificial aids. Other components could be misshapen pieces as well as limited amounts of fryer skimmings. The product is mixed, dried, and cooled. Uncooled dry material is used as feedstock for the wet products going into the dryer. Typical Analysis Crude Protein Crude Fat Crude Fiber Moisture Calcium Phosphorus Potassiuim Magnesium TDN 9.0% minimum 3.5% minimum 4.0% maximum 12.0% maximum 0.20% 0.40% 2.50% 0.29% 80.0% Usage Dried Potato product is equal to corn in energy value while having 1 ½ times the protein value. The heat treatment of the product greatly increases the bioavailability of the nutrients. Specific use recommendations depend on the species and size of animal being fed. 47. Oil Cake is the solid residue that can be removed from various types of oily seeds. The residue is usually extracted by being pressed, removing the oil. Oil cake is valued for being rich in minerals and protein. Their most common use is in animal feed. Among the kinds of seeds that oil cake is obtained from are soybeans, peanuts, linseed, cottonseed, coconuts, and sunflower seeds. However, some specific kinds may be toxic, and are rather used as fertilizer. Even cottonseed contains a toxic pigment, gossypol, that must be removed before processing. The major oil-bearing seeds contribute large quantities of by-products which are used in animal feeds, all of which have potential as aquaculture feed ingredients. The following is a list of the major plants contributing products to this category of ingredients: Common Name Of Oilcake Or Meal Groundnut (Peanut) Mustard) Rape) Coconut (Poonac) Oil Palm Soybean Cotton Sunflower Safflower Para Rubber Flax (Linseed) Sesame (Gingelly) Special Characteristics methionine deficient; prone to aflatoxin development; extensively used in carp diets. also used in carp diets but need great care, as non-detoxified meals contain a range of toxins. prone to rancidity; absorbs water, thus water unstable feeds; low in protein; high in fibre. kernel high in protein; fats saturated; (African oil palm). high protein; low lipid; generally good source of EAA's including lysine but methionine deficient; contains a trypsin inhibitor and urease but these are destroyed during processing; with EAA supplementation it is a potential partial replacement for fish meal. screw-press cake contains high level of free gossypol which is toxic; high in fibre; potentially valuable but knowledge of effect of gossypol on fish not adequately known (see ADCP, 1983). richer in methionine and cystine than soybean; lysine deficient; no toxins. poorer in the EAA's lysine and methionine than sunflower. must be de-toxified to remove prussic acid; suitability probably similar to coconut. like para rubber, contains an enzyme and a glucoside that produces prussic acid but normal processing destroys the enzyme; not known whether its additional toxicity to poultry (which can be eliminated by supplementary vitamin B6) affects fish or not. rich in methionine but deficient in lysine; would be good ingredient in conjunction with soybean; value for Indian carps has been demonstrated. 48. Oats rank around sixth in the world cereal production statistics following wheat, maize rice, barley and sorghum. Oat grain has always been an important form of livestock feed. They are a good source of protein, fibre, and minerals but world oat grain declined as farm mechanisation increased between 1930 to 1950. Oats remain an important grain crop for people in marginal ecologies throughout the developing world, and in developed economies for specialist uses. In many parts of the world oats are grown for use as grain as well as for forage and fodder, straw for bedding, hay, haylage, silage and chaff. Livestock grain feed is still the primary use of oat crops, accounting for an average of around 74% of the world's total usage in 1991 to 1992 Russia, countries of the former Soviet Union, the US, Canada, Germany and Poland account for about 75% of the worlds supply of grain oats, seed and industrial grade oats. Since the 1960s the proportion of oats used for feed has declined in the US and Canada, remained unchanged in the former Soviet Union countries and Poland, and increased slightly in Germany. Oats consumed as feed in the US are becoming a specialty feed for race horses, hobby farmers and breeding stock. The leading exporters of oat grain are Canada, Finland, Sweden Australia, and Argentina. The US, Japan, the former Soviet Union, Switzerland and the European Union are the principal importers of oat grains. A significant proportion of the oat grains and forages produced on smaller more remote farms around the world, including in the Himalayan region, are consumed on the farm and never enter the commercial market place. Oats are grown for use as grain as well as forage and fodder, straw for bedding, hay, haylage, silage and chaff. Food uses for oats include oatmeal, oat flour, oat ban and oat flakes for use as breakfast cereals and ingredients in other food stuffs. Oats are one of the most nutritious grain cereals, high in protein and fibre. The protein of rolled (flakes) oats is generally greater than that found in other cereal grains. Many of the vitamins and minerals found in oats are combined in the bran and germ. Most oat food products use the entire groat, making it a nutritious cereal grain. Oats normally have almost 90 percent of the energy value of barley and contain more fiber than barley of corn. They can vary considerably in protein, fiber and energy. Oats are a palatable feedstuff and may be safely included at high levels in the grain ration. They should be fed rolled or ground for maximum utilization. In grain mixtures where a high level of energy is required, such as for highproducing cows, oats should not be the major ingredient due to their lower energy value relative to corn and barley. In this case, they should make up no more than 33 percent of the grain mix. Calves can digest whole oats effectively because they chew their feed more thoroughly than cows. 49. Typical Analysis Dry matter 89 % Crude Protein 12.0 % Fat 04.5 % Crude fiber 12.0 % Neutral Detergent Fiber 28.5 % Acid Detergent Fiber 14.2 % Calcium 0.07 % Phosphorus 0.35 % Total Digestible Nutrients 68.0 % Net energy—Lactation 70.2 Mcal/100 lbs Oat groats are made by dehulling oats and removing all fines and broken kernels. Moisture Protein Fat Total Dietary Fiber Ash Unhulled Oats Hulls Brokens Enzyme Activity FFA 50. Max 12.0 % Min 12.0 % 6.0 % +/- 1.0 % 10.0 % +/- 1.0 % 2.0 % +/- 0.5 % Max 7 Oats/100g Max 10 Hulls/100g Max 5 % through US #10 Wire Mesh Screen Negative Max 0.5 % Oat hulls are a high-fiber, low energy, low-protein feedstuff. Because of their high fiber content, oat hulls can be used as a roughage extender during times when forages are in short supply. Typical Analysis Dry matter Crude Protein Fat 90 % 03.5 % 01.6 % 51. Crude fiber 30.0 % Neutral Detergent Fiber 70.2 % Acid Detergent Fiber 37.8 % Calcium 0.14 % Phosphorus 0.14 % Total Digestible Nutrients 31.5 % Net energy—Lactation 30.2 Mcal/100 lbs Oatmill by-product is a mixture of coarsely ground oat midds, hulls, and thin oats from human consumption oat plants. It is mainly used as an oat substitute due to its nutritional characteristics and price competitiveness with whole oats. Typical Analysis Crude Protein Fat Fiber Calcium Phosphorus Energy Carbohydrates Moisture 9 – 10 % 3–4% 20 % 0.16 % 0.25 % 61 – 65 % 73 % 10 % Feeding and Usage Oatmill by-product can be included in dairy, beef, and hog rations at the same level as whole oats. It works extremely well in dry cow and heifer rations due to its bulkiness and energy level. It is often economically advantageous to market whole oats as cash grain and replace it with oatmill by-product for feeding. However, it is not recommended for use in calf starter rations. Storage and Handling Oatmill by-product is available in meal or pellet form, bulk or 50 lb. bags. Bulk material is delivered in hopper, dump or live bottom trailers in 23 – 25 ton loads. It can be handled with any normal moving equipment used in the feed or grain industry. Bagged loads are 22 – 23 tons and are delivered in van trailers. 52. Linseed (Linum usitatissimum) meal is the by-product of extracting the seed for oil. The meal contains 350-380 g/kg CP that is low in protein quality, being deficient in lysine. It has been a favourite protein source for horses and ruminants in the past. Today, soya meal is preferred as it is cheaper and of higher protein quality. The meal fed in large amounts is laxative, and excess amounts in rations have undesirable softening effects on butterfat and give milk a rancid taste. The recommended maximum intake for cattle is 3 kg per day. Because of this softening property of the oil, linseed cake is unsatisfactory as a main ingredient in pig feeds. Up to 1 kg per day has been used with good results, but not more than 8 percent linseed meal is commonly included in rations. For young pigs and brood sows a maximum of 5 percent linseed meal in the ration is usually recommended. Linseed meal is toxic to poultry except in very small proportions (under 3 percent). Larger amounts depress growth. The toxicity can largely be eliminated by soaking the meal in water for twenty-four hours or by adding pyridoxin, one of the B-vitamins to the diet. Linseed meal is the byproduct of extracting the oil from flaxseed. It is used as a protein supplement and contains somewhat less TDN than soybean meal. A good source of selenium, it averages 1.0 ppm. Linseed meal is very palatable. It may be included in the grain mix at a level of up to 25 percent of feed to milking herds at a rate of up to 9 pounds (4kg) per head per day. Typical Analysis Solvent: Dry matter Crude Protein Fat Crude fiber Neutral Detergent Fiber Acid Detergent Fiber Calcium Phosphorus Total Digestible Nutrients Net energy—Lactation 91 % 34.0 % 01.5 % 09.3 % 22.7 % 17.3 % 00.4 % 00.9 % 70.0 % 71.8 Mcal/100 lbs. 53. Barley is a cereal grain, which serves as a major animal feed crop, with smaller amounts used for malting and in health food. It is a member of the grass family Poaceae. In 2005, barley ranked fourth in quantity produced and in area of cultivation of cereal crops in the world (560,000 km²). Its germination time is anywhere from 1 to 3 days. Half of the world's barley production is used as an animal feed. A large part of the remainder used for malting and is a key ingredient in beer and whiskey production. Two-row barley is traditionally used in German and English beers, and six-row barley in American beers. Non-alcoholic drinks such as barley water and mugicha are also made from unhulled barley. A small amount is used in healthfoods. 54. 55. Limestone is sometimes added as a supplement in animal feeds, as a source of calcium. Mineral elements have a great diversity of uses within the animal body. The following mineral elements are recognized as essential for body functions in fish: calcium, phosphorus, sodium, molybdenum, chlorine, magnesium, iron, selenium, iodine, manganese, copper, cobalt and zinc. To these may be added fluorine and chromium which have also been shown to be essential for land animals. The prominence of each mineral element in body tissues is closely related to its functional role. As constituents of bones and teeth, minerals provide strength and rigidity to skeletal structures. In their ionic states in body fluids they are indispensable for the maintenance of acid-base equilibrium and osmotic relationship with the aquatic environment, and for integration activities involving the nervous and endocrine systems. As components of blood pigments, enzymes and organic compounds in tissues and organs they are indispensable for essential metabolic processes involving gas exchange and energy transactions. Calcium Phosphorus Iron Zinc Manganese Copper Cobalt Iodine Selenium 56. Alfalfa dehy is produced from standing alfalfa, which is mowed and chopped in the field, delivered to the dehydrating plant still containing a minimum of 60 percent moisture, artificially dried, ground and pelleted. Dehy can replace a portion of both the grain and the forage in rations for milking cows. It can replace up to 50 percent of the conventional forage dry matter in the ration, but at this level the ration should contain no more than 50 percent grain, on a dry matter basis. Research at the University of Nebraska has shown that the protein in dehy tends to be degraded in the rumen to a lesser extent than the protein in alfalfa hay, alfalfa silage or soybean meal. This is the basis of dehy’s reputation as a source of "by-pass" protein. Typical Analysis Dry matter Crude Protein Fat Crude fiber Neutral Detergent Fiber Acid Detergent Fiber Calcium Phosphorus TDN NE/L 92 % 17.0 % 02.9 % 25.5 % 40.9 % 32.2 % 1.39 % 0.23% 56.1% 57.6 Mcal/100 lbs. When managed correctly, alfalfa is very palatable forage for dairy cattle and a good source of protein, vitamins, calcium and potassium. It also tends to be higher in energy than many other forages. Suncured alfalfa pellets are produced from alfalfa hay, which has been ground and pelleted. The meal is produced by regrinding the pellets. If the hay is chopped instead of ground, the product is called suncured chopped alfalfa or chopped alfalfa hay. In addition to the 13 percent crude protein product, a 15 percent crude protein product also is commonly available on the market. Suncured alfalfa is used as a forage source in dairy rations. Because its small particle size tends to alter rumen fermentation patterns and possibly depress fat test, suncured alfalfa (pellets, meal, or chopped) should not make up more than 50 percent of the ration’s forage dry matter. Typical Analysis Dry matter Crude Protein Fat Crude fiber Neutral Detergent Fiber Acid Detergent Fiber Calcium Phosphorus Total Digestible Nutrients Net energy—Lactation 92 % 13.0 % 01.8 % 30.0 % 48.7 % 35.9 % 01.2 % 00.2 % 47.8 % 48.0 Mcal/100 lbs 57. Barley Flour is produced from barley after malting and removal of sugar and starch by hot water extraction. The extracted barley is dried by indirect steam, milled and sifted to obtain a flour which 100% passes a US 40 mesh screen and 90% is retained by a US 120 mesh screen. Typical Analysis Protein Crude Fat Total Dietary Fiber Ash Moisture 18.5 % 06.8 % 65.0 %* 04.6 % 07.0 % *AACC Method 32 – 05/ AOAC/ Prosky Method Physical Characteristics Density (lbs./cu. Ft.) Color Uniform Aroma Flavor Granulation 58. 32 Tan Mild roasted grain Bland Through US # 40 – 100 % Packed in 50 lb. multiwall paper bags. Packaging Also available for bulk delivery. Best stored at dry and cool conditions (32 Storage – 40 degrees F). Barley grain has about 95 percent of the energy of corn and is higher in fiber. Barley should be ground or rolled for maximum utilization by dairy cows. Barley can vary greatly in feed value depending on its source and growing conditions. Protein may vary from 7 to 13 percent. Lightweight or immature barley tends to be higher in fiber, less digestible and lower in energy than heavy weight barley. Barley is very palatable and safe to feed in large quantities. It may be included in the grain mix at high levels. Typical Analysis Dry matter Crude Protein Fat 89 % 11.6 % 02.0 % 59. Crude fiber 06.0 % Neutral Detergent Fiber 16.9 % Acid Detergent Fiber 06.2 % Calcium 0.07 % Phosphorus 0.36 % Total Digestible Nutrients 76.0 % Net energy—Lactation 78.3 Mcal/100 lbs. Saccharomyces cerevisiae yeast 100% pure Saccharomyces cerevisiae yeast cultured on sugar cane molasses under carefully controlled and sanitary conditions. After fermentation, the yeast is collected and dried using special spray dryers, which preserve the full and unaltered protein, mineral and vitamin content of pure yeast. Typical Analysis: Protein Protein Carbohydrates Moisture Fat Ash Fiber 40.0 % min. 40.0-43.0 % typical 44.0 % average 8.0 % maximum 4.0 % maximum 4.0 % maximum 2.0 % maximum Microbiological: Total plate count Coliform Salmonella E Coli Typical Amino Acid: Alanine Cystine Isoleucine Phenylalanine Valine Glutamic Acid Leucine Proline less than 50000 g less than 1000 g negative negative 2.71 0.32 1.92 2.13 2.28 4.76 3.02 1.51 Arginine Glycine Lysine Serine Aspartic Acid Histidine Methionine Tyrosine 1.73 1.79 total 3.18 1.73 4.31 1.13 0.81 0.94 Threonine Vitamin: 2.47 Tryptophan .0.45 B1 1.29 mg/kg B2 B6 Folic Acid 8.67 mg/kg <0.11 mg/kg B12 Biotin (H) Choline 685.0 mg/kg Inositol 22.51 mg/kg 0.01 mg/kg 2.02 mg/kg 300.0 mg/kg Physical Properties Aroma Typical for yeast Taste Typical for yeast- soft and mild- not bitter Color Light Cream Packing: 50 pound net- multiwalled paper bags with pre liner. 60. Yeast, Active Guaranteed Analysis 15% Crude Protein minimum Crude Fat 3% minimum 7% Crude Fiber maximum Ingredients: Saccharomyces cerevisiae yeast, ground yellow corn, hominy feed, corn gluten, wheat middlings, soybean meal, cane molasses, brewers dried yeast and brewers dried grains Feeding Directions For general feeding purposes, yeast should be mixed with ground grains and/ or commercial feeds and mashes, for all livestock and poultry, and fed dry in the usual way. General recommended amounts of yeast for optimum results: Swine: Mix 50 lbs. of yeast per ton of sow gestation feed and 25 lbs. per ton in sow lactation rations. In pig starters, use 50 lbs. of yeast per ton and 25 lbs. in grower and finisher rations. Dairy: Feed yeast at a rate of 4 ounces per head per day. Normally 25 lbs. per ton of grain mixture or 15 lbs. per complete feed will meet this level. Beef Cattle: Feed 2-4 ounces of yeast per head per day mixed with the complete ration or supplement. Sheep: Feed 1-2 ounces of yeast per head per day or mix 25 lbs. per ton of complete feed. Poultry: In layer and breeder feeds, mix 25 lbs. of yeast per ton of complete feed. For broilers and growing turkeys, use 50 lbs. per ton in the starter ration and 10-25 lbs. per ton in grower and finisher feeds. Horse: Feed 2-4 ounces of yeast per head per day by top dressing the daily feed or mix 50 lbs. per ton of grain mix. Dogs and Mink: Mix 50 lbs. of yeast per ton of complete dog food. Mix 50 lbs. of yeast per ton for dry grain mix for mink. These recommendations are based on complete feed and grain mixtures. Supplements and concentrates require larger quantities of yeast as they are only a portion of the total feed intake. The amount of yeast should, therefore, be calculated proportionately. 61. Whey is the liquid portion of milk, which separates from the curd during cheesemaking. Sweet whey comes from the manufacture of Cheddar and mozzarella cheese. The pH of sweet whey is 6.0, which is higher than that of fresh acid whey. Whey is corrosive. Suitable materials for equipment used in handling whey include plastic, stainless steel, glass, fiberglass and wood. Whey should be delivered fresh daily. Whey that is not fresh (over 36 hours old) has a low pH, is not consumed as readily as fresh whey, and tends to cause tooth erosion and sore gums, especially in young stock. Cows require a period of up to four weeks to become accustomed to liquid whey. It may be necessary to limit water during this period. Once a herd adapts to liquid whey, water should be freely available. In general, cows will drink about two-thirds of their liquid as whey and one-third as water. On a dry matter basis, whey is similar in TDN to corn and contains almost one-third more protein. When offered liquid whey free-choice, cows will drink up to 200 pounds (91 kg) or 25 gallons daily. One hundred pounds (45 kg) of liquid whey is equivalent to 7 ½ pounds (3.4 kg) of a 12-percent-protein grain mixture. Cattle drinking liquid whey free-choice will increase their urine output considerably and will require more bedding. Reducing the moisture content of liquid whey to 0 percent gives a product called whey concentrate. Typical Analysis Dry matter Crude Protein Fat Crude fiber Neutral Detergent Fiber Acid Detergent Fiber Calcium Phosphorus Total Digestible Nutrients Net energy—Lactation 6.5 % 0.90 % 0.07 % 0.00 % 0.00 % 0.00 % 0.06 % 0.07 % 5.70 % 6.00 Mcal/100 lbs 62. Wheat grain. In general, wheat is higher in protein than corn or barley and about equal to corn in energy. Because several varieties of wheat are commonly grown, the protein content can vary from 9 to 15 percent and TDN from 74 to 82 percent. Wheat is a palatable grain and should be fed coarsely ground or crushed for best results. It should not be fed whole or ground finely. Finely ground wheat is powdery and unpalatable. Wheat should not make up more than 50 percent of the grain mix (a maximum of 33 percent is common) nor be fed at a rate greater than 12 pounds (5.5 kg) per cow per day. Unseasonably rainy weather occasionally will cause wheat to sprout after it has been cut and is lying in the swath or even while still standing. Sprouted wheat is an acceptable feed, although it is somewhat damaged wheat. Rolled sprouted wheat should be prepared every two days to avoid spoilage. 63. Typical Analysis Dry matter 89 % Crude Protein 11.0 % Fat 01.7 % Crude fiber 02.5 % Neutral Detergent Fiber 16.5 % Acid Detergent Fiber 05.2 % Calcium 0.05 % Phosphorus 0.32 % Total Digestible Nutrients 79.0 % Net energy—Lactation 82.4 Mcal/100 lbs Wheat Mill (Pollard) These byproducts of milling wheat for flour consist of varying amounts of bran, germ and flour. They are highly palatable, low in calcium and tend to be higher in phosphorus than most other grains and processed grain by-products. Wheat bran is highest in fiber and phosphorus and lowest in energy of the five. It can be included in the grain mix up to a level of 25 percent or fed at a rate of up to 7 pounds (3.2 kg) per cow per day. Wheat middlings (also called midds) is a very common ingredient in cattle feeds. Midds are a by-product of the flour milling industry comprising several grades of granular particles containing different proportions of endosperm, bran and germ. It has 96 percent of the energy value of barley and 91 percent of the energy value of corn. Midds are palatable feedstuffs and can be included in the grain mixture at high levels. Wheat middlings can be maintained in good condition for up to three years if stored in a dry environment. Bulk material can be handled in normal equipment used in the feed or grain industry. Typical Analysis Dry matter Crude Protein Fat Crude fiber Neutral Detergent Fiber Acid Detergent Fiber Calcium Phosphorus Total Digestible Nutrients Net energy—Lactation Wheat Bran 89 % 15.5 % 03.5 % 11.0 % 45.4 % 13.4 % 00.1 % 1.10 % Wheat Midds 89 % 16.5 % 04.5 % 07.5 % 32.0 % 09.9 % 00.1 % 0.80 % 62.0 % 72.8 % 64.6 Mcal/100 lbs 83.8 Mcal/100 lbs 64. Urea is a synthetic compound with a high level of nitrogen. It is not a natural protein. In high-energy rations, it can serve as a source of nitrogen for the synthesis of protein by rumen microbes. This is why it is said to have an equivalent crude protein value from nonprotein nitrogen. Feed grade urea usually is 42 to 46 percent nitrogen, equivalent to 262 to 287 percent crude protein from nonprotein nitrogen, respectively. Feed grade urea comes in the form of small beadlets coated with a clay solution. Feeding Urea can be fed to milking cows up to a maximum rate of ½ pound (0.22 kg) per cow per day. One-fourth to one-third pound (0.11 to 0.15 kg) of urea per cow per day is a more common rate of feeding. This is equal to about 1 to 2 percent urea in the total grain ration or about 2.8 to 5.6 percent crude protein equivalent from nonprotein nitrogen in the total grain ration. Levels of urea in the feed much higher than recommended can be toxic. Urea should not be used in the same ration with raw soybeans or raw soybean hulls. These feeds contain an enzyme, which breaks down urea to ammonia, causing poor palatability. The enzyme is destroyed when the soybeans are heated. Urea can be mixed with corn silage at ensiling to raise the crude protein value. Urea should not be fed to calves less than three months old. Typical Analysis Dry matter 99 % ECPNPN* 287 % or 262 % Fat 0.00 % Crude fiber 0.00 % Neutral Detergent Fiber 0.00 % Acid Detergent Fiber 0.00 % Calcium 0.00 % Phosphorus 0.00 % Total Digestible Nutrients 0.00 % Net energy—Lactation 0.00 Mcal/100 lbs * Equivalent crude protein from nonprotein nitrogen 65. Dried tomato pomace is the dried mixture of tomato skins, pulp and crushed seeds that remain after the processing of tomatoes for juice, soup, or ketchup. It is a middle protein, a good source of B Vitamins and a fair source of Vitamin A. It is commonly used in pet foods as a source of dietary fiber, to produce firm stools. Tomato pomace also increases the palatability of cat diets. Typical Analysis Crude Protein Crude Fat Crude Fiber Ash Moisture 20.0 - 24.0 % 15.0 - 18.0 % 26.0 - 35.0 % 3.0 - 5.0 % 6.0 - 10.0 % 66. Malt sprouts are obtained from malted barley by the removal of the sprouts, which may include some of the malt hulls, other parts of the malt and foreign material unavoidably present. Description Malt sprouts consist of dried sprouts and rootlets produced during the malting (germination of sprouting) of barley for brewing. Sprouts should contain at least 24 percent crude protein. Malt sprouts with less than 24 percent crude protein are sometimes referred to as No. 2 malt sprouts. They are a medium protein, medium energy, high fiber feedstuff with about 82 percent of the TDN value of corn. They may be included in the grain mix as needed. Avoid including them as more than 20 percent of the ration due to their lower energy value. Typical Analysis Dry matter Crude Protein Fat Crude fiber Neutral Detergent Fiber Acid Detergent Fiber Calcium Phosphorus Total Digestible Nutrients Net energy—Lactation 94 % 26.0 % 01.4 % 15.0 % 43.2 % 16.9 % 0.25 % 00.7 % 66.0 % 68.2 Mcal/100 lbs Feeding and Usage Malt sprouts are an inexpensive source of protein, which also supplies adequate fiber for normal rumen function and fat test. Sprouts are about as bulky as dried brewers grains and supply slightly less total digestible nutrients. They are somewhat bitter and thus should be mixed with other feedstuffs for palatability. It is recommended not to exceed a level of 15% malt sprouts in a concentrate mixture for dairy cows for other stock. Storage and Handling Malt sprouts are available in bulk and may be delivered in a hopper, dump or live bottom trailers. A trailer load is approximately 16 to 20 tons Malt sprouts can be handled with augers, belts, or other feeding systems.