Operations Improvement chapter * 18

advertisement

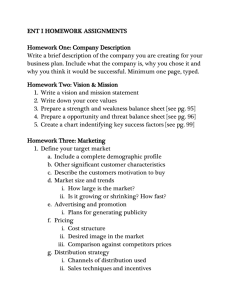

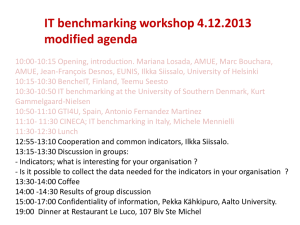

Operations Improvement chapter – 18 Operations improvement is the 6th step in quality planning and control. There is always a scope for improvement in business operations, that’s why making improvement is considered as the main responsibility of operational managers. I. Measuring and Improving Performance(how can operations measure their performance in terms of the five performance objectives?) The first step for improving performing improvement is to know how good the operation at the moment. Or identify the worth of operation. Performance measurement means the activity of measuring or assessing the various aspects of a process. • So, performance measurement identifies if an operation is good or bad. • Three aspects of performance measurement is as follows: • What factors to include as performance measures? • Which are the most important performance measures? • What detailed measures to use? a. What factors to include as performance measures? It is not possible to take a single factor to measure the performance of an operation, instead we have to take a bindle of factors from performance objectives. Performance measures at different levels of aggregation Broad strategic measures Overall strategic objectives Composite performance measures Generic operations performance measures Operations strategic objectives Market strategic objectives Functional strategic measures Customer satisfaction Quality Defects per unit Some detailed Level of performance customer measures complaints Scrap level Agility Dependability Mean time between failures Lateness complaints Financial strategic objectives Speed Resilience Flexibility Customer query time Order lead time Throughput time Time to market Product range Cost Transaction costs Labour productivity Machine efficiency Performance measures at different levels of aggregation Broad strategic measures High strategic relevance and aggregation Functional strategic measures Composite performance measures Generic operations performance measures Detailed performance measures High diagnostic power and frequency of measurement b. What are the most important performance measures? 1.Operations overall strategy. 2.Detailed measures. C. What are the detailed measures to use? Five performance objectives of operation are used. Five performance objectives should be broken down into individual factors. Page 585 fig 18.1 Balanced scorecard approach • This approach presents an overall picture of organizational performance in a single report. The measures used in the balanced scorecard Financial performance measures To achieve strategic impact, how should we be viewed by shareholders? Internal process performance measures To achieve strategic impact, what aspects of performance should business process excel at? Overall strategic objectives Learning and growth performance measures To achieve strategic impact, how will we build capabilities over time? Customer performance measures To achieve strategic impact, how should we be viewed by customers? Setting target performance Performance measures can only be set, once the performance target is known. There are four approaches to set performance targets as follows: 1. Historically based targets- this type of targets compare the current performance against the previous. 2. Strategic Targets – the targets set to show the appropriate level of performance to achieve the strategic objectives of an organization. 3. External performance based targets- targets set to show the performance level according to similar, competitor’s or external operators performance. 4. Absolute performance targets- targets set on upper limit of performance Benchmarking Benchmarking means a process of learning from others. It is comparing ones own performance or methods against others. Benchmarking in operations is about stimulating creativity in improvement. Types of benchmarking • Internal benchmarking – comparing operations within an organization. For example an automobile company having many factories for business, where one factory can benchmark the other. • External benchmarking – benchmarking with another organization. • Non-competitive benchmarking – benchmarking with organizations who do not perform the same business. • Competitive benchmarking – benchmarking against competitors . • Performance benchmarking – comparison between achieved levels of performance in different operations. For example an organization compare the five performance objectives against other organizations performance. •Practice benchmarking- comparing one operation practice to another. II. Improvement priorities (howcan operational managers prioritize improvement of performance objectives) Improvement priorities are based on two major influences: 1. Needs and performances of customers. 2. The performance and activities of competitors. The needs and preferences of customers are known as ‘importance’ of operations objective. The performance and priorities of competitors are known as ‘performance’ of operations objective. Prioritizing process objectives Priorities should be determined by … The Your IMPORTANCE PERFORMANCE of each competitive objective in each competitive objective IMPROVEMENT PRIORITIES Judging the ‘importance’ factor to customer • Order winning competitive factors- the factors that directly win the business for an operation. • Qualifying competitive factors- factors that may not win business, but a fall in performance leads to lose of business. • Less important factors – unimportant competitive factors. Order-winning objectives Qualifying objectives +ve neutral –ve High Low Achieved performance neutral –ve Qualifying level Low High Competitive benefit +ve Competitive benefit Competitive benefit +ve Less important objectives neutral –ve Low High Achieved Achieved performance performance 9-point importance scale For this product or service, does this performance objective … Order-winning objectives 1 …provide a crucial advantage with customers? 2 …provide an important advantage with most customers? 3 …provide a useful advantage with most customers? 4 …need to be up to good industry standard? Qualifying objectives 5 …need to be around median industry standard? 6 …need to be within close range of the rest of the industry? Less important objectives 7 …rate as not usually important but could become more so in future? 8 …very rarely rate as being important? 9 …never come into consideration? Temperature-controlled – overnight service IMPORTANCE to customers 1 2 3 4 5 PRICE 7 8 9 X SERVQUAL (DISN.) X SERVQUAL (ORDER TAKE) X ENQUIRY LEAD-TIME X DROP QUOTE X WINDOW QUOTE DELIVERY PERFORMANCE 6 X X X DELIVERY FLEXIBILITY VOLUME FLEXIBILITY X DOC. SERVICE X 1 2 3 4 5 6 7 8 9 9-point performance scale For this product or service, is the achieved performance … Better than competitors 1 …consistently considerably better than our nearest competitor’s? 2 …consistently clearly better than our nearest competitor’s? 3 …consistently marginally better than our nearest competitor’s? Same as competitors 4 …often marginally better than that of most competitors? 5 …about the same as that of most competitors? 6 …often close to that of our main competitors? Worse than competitors 7 …usually marginally worse than that of our main competitors? 8 …usually worse than that of most competitors? 9 …consistently worse than that of most competitors? Nine-point scale for judging importance and performance Diagram 18.6 page 590 The Sandcone Theory According to sandcone theory, the obejectives should be prioritized in an order. Sandcone theory considers quality as first priority, then dependability, speed, flexibility and cost. The sandcone model of improvement Cost Flexibility Speed Dependability Quality Quality Quality + dependability Quality + dependability + speed Quality + dependability + speed + flexibility Quality + dependability + speed + flexibility + cost III. Approaches/methods to improvement (what are the broad approaches to managing the rate of improvement) Once the priority improvement is fixed, the next step if to consider the approach or strategy to take the improvement. There are two strategies for improvement process: 1. Breakthrough improvement (innovationbased improvement) 2. Continuous improvement These two approaches can be compared to a Sprint and Marathon. Breakthrough improvement This approach assumes that main method of improvement is major or dramatic changes in the operations. Or changing the operations absolutely for improvement. Examples for breakthrough improvement: New machine in a factory Computer-based reservation system in a hotel. These improvements are always costly, sudden and disturbing the ongoing working of operations. Continuous improvement • This is also known as Kaizen in Japan. It means improvement step-by-step. Or small improvements instead of drastic ones. Continuous improvement is small level of improvements in an operation. How to build a continuous improvement capability ? Continuous improvement comes with specific abilities, behaviors and actions. These are known as: Organizational abilities – the capacity adopt a particular approach to continuous improvement. Continuous behaviors – the routine behavior of staff. Enablers – the techniques used to progress the continuous improvement effort. Difference between breakthrough and continuous improvement Breakthrough improvement Continuous improvement Places high value on creativity Less ambitious Encourages free thinking and individualism Stresses adaptability Does not accept constraints stresses teamwork Stresses attention to detail Depends on the wealth of experience within the organization. Improvement cycle Improvement is a never-ending process, this repeated nature is known as improvement cycle. There are two main improvement methods :: 1. PDCA – plan, do, check, and act. 2. DMAIC – SIX SIGMA PDCA It starts with ‘p’ (plan) stage which examines the current method. The next step is ‘do’ stage, here the plan is implemented. Next stage is ‘C’ where the implemented solution is checked. The last stage is ‘A’ (act) where the change is standardized, if it has been successful. DMAIC CYCLE The plan–do–check–act (or ‘Deming’) improvement cycle, and the define–measure–analyze–improve–control (or DMAIC) ‘six sigma’ improvement cycle Define Plan Do Control Act Check Improve Measure Analyze The DMAIC cycle Define – identify the problem, define requirements and set the goal Control – establish performance standards and deal with any problems Measure – gather data, refine problem and measure inputs and outputs Analyze – develop Improve – develop improvement ideas, problem hypotheses, identify ‘root causes’ and test, establish validate hypotheses solution, and measure results BPR or Business process Reengineering approach This is the same way of breakthrough approach. It promotes business process re-engineering approach. BPR is a mix of many ideas. For example Just-in-time, flow charting, critical examination study, operations network management e.t.c BPR Means redesign the process to fulfill customer needs. BPR advocates reorganizing (reengineering) processes to reflect the natural processes that fulfil customer needs Functionally based processes Function 1 Function 2 Function 3 Function 4 End-to-end process 3 Customer needs fulfilled End-to-end process 2 Business processes Customer needs End-to-end process 1 Principles of BPR A. Organize business process around the output of process, i.e customers. B. Try for dramatic improvement. C. Have those who use the output from a process to perform the process. Or check if all internal customers can be their own suppliers. D. Put decision points where the work is performed. IV. The techniques of improvement Some common techniques for process improvement Input/output analysis Flowcharts Scatter diagrams x Input Output x x Cause–effect diagrams Pareto diagrams x x x x x x x x ‘Why-why’ analysis Why? Why? Why? 1.Scatter diagrams It’s a graphical representation technique. This method provides easy solution for identifying whether there is evidence of a connection between two sets of data. For example the time you start work and how long the journey to work takes. This method only identifies the relationship. 2.Process maps or flow charts Describes how the activities within the process relate to each other. It records each stages of process. It clarifies improvement opportunities. 3. Cause –Effect diagrams A technique that finding out the root cause problems. This method is done by questioning technique such as what, when, where, how and why. It provides way for brainstorming sessions. 4. Pareto diagrams This technique identifies what is important and what is not. 5. Why-Why Analysis This technique starts by asking why the problem occurred, again once the reasons are found, each reasons are taken individually and questioned ‘why’. This process continues.