PowerPoint-Präsentation

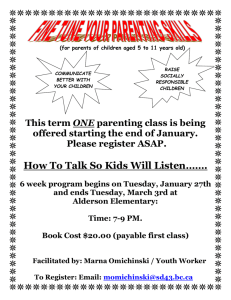

advertisement

The transfer of serious games to business research An example of knowledge transfer between management theory, a serious game, and practice 1st GaLA Alignment School, 20-24th June, Edinburgh, UK Christian Schneider, ETH Zürich, cschneider@ethz.ch The transfer between theory, SG, and practice Practice Theory Tuesday 21 June 2011 ? SG 2 The aim of the analysis is to do better than that… Tuesday 21 June 2011 3 Content Introduction to the logistics game Theoretical background Results Conclusions and practical implications Tuesday 21 June 2011 4 Basic facts about the logistics game Given Between 11 and 16 players 3 instructors Approx. 2 hours A box full of raw material Goal Produce the right amount of goods in the right quality at the right time at minimal costs*. * costs are determined by costs for personnel, stock, late deliveries and bad quality Tuesday 21 June 2011 5 Impressions from playing the logistics game WP 3 Shipping WP 1 Sales Stock Rework Customer QC Direct Internal Transport External Transport Tuesday 21 June 2011 WP 2 WP 4 6 Playing the game taking measures Start Round 1 measuring performance Tuesday 21 June 2011 taking measures Round 2 measuring performance taking measures Round 3 measuring performance Round 4 Stop measuring performance 7 Content Introduction to the logistics game Theoretical background Results Conclusions and practical implications Tuesday 21 June 2011 8 Theoretical background (1/2) The sand cone model by Ferdows and de Meyer defines a chronological order in which different manufacturing capabilities should be tackled in order to achieve lasting improvements in manufacturing. Question: Can this model be verified in the logistics game? Tuesday 21 June 2011 9 Theoretical background (2/2) Instead of specifying the exact parameters of the learning curve, Adler and Clark model how learning effects emerge by differentiating between firstand second-order learning. direct labor hours per unit First-order learning Production activity Secondorder learning Productivity improvement cumulative unit number Question: Does this model help explain the outcome of the logistic games? Tuesday 21 June 2011 10 Content Introduction to the logistics game Theoretical background Results Conclusions and practical implications Tuesday 21 June 2011 11 120% 120% 35% 35% 80% 60% 100% 80% 60% Share of bad parts, Round 2 100% Share of bad parts, Round 2 Share of bad parts, Round 1 Share of bad parts, Round 1 Results: quality performance and costs 30% 25% 20% 15% 30% 25% 20% 15% Question: Does a sound performance in quality imply that the financial result is good as well? 40% 20% 40% 20% 0% 0% 1 10 10% 5% 100 10 10000 1000 100 100001000 100000 100000 10 1 1 Costs perRound good part, Round 1 Costs per good part, 1 0% 1 40% 20% 0% 10 25% 20% 15% 10% 5% 100 10 1000 100000 10000 1000 100 10000 100000 % % % 8% 1 4% 2% 100 1000 8% 6% 4% 2% 0% 1 1000 10000 6% 5% 4% 7% 6% 6% r = 0.06 5% 5% 4% 3% 2% 1% 10 100 1001000 Round 3 4% 2% 3% 2% 1% 1000 4% 3% 2% 1% 1 1 10 10 100 1001000 Costs perRound good part, Round Costs per good part, 4 Round 4 Costs per good part 6% 5% 4% 10 100 1001000 Costs perRound good part, Round 3 Costs per good part, 3 Tuesday 21 June 2011 1000 3% 2% 1% 0% 0% 1 10 1 1 10 10 100 1001000 1000 10000 0% 0% 1 10 10000 100 1000 Finding: While costs correlate with quality in the first two rounds, this correlation weakens in round three and disappears in round four. 6% 0% % Share of bad parts, Round 4 % 6% 0% 10 100 7% 7% 10% 8% 10% Round 2 Share of bad parts, Round 4 Share of bad parts, Round 3 % 5% 10% r = 0.17 Costs perRound good part, Round 2 per good Costs perRound good part, Round 3 Costs part, 3 Costs per good part, 2 14% 12% 10% 101 Round 1 % 15% 1 Costs perRound good part, Round 1 Costs per good part, 1 % 20% 0% 0% 1 25% 12% 7% Share of bad parts, Round 4 0% 60% r = 0.32 12% Share of bad parts, Round 4 0% 80% 30% Share of bad parts, Round 3 0% r = 0.28 100% 30% 10 100 Costs perRound good part, Round Costs per good part, 2 14% 14% Share of bad parts, Round 3 0% 35% 35% Share of bad parts, Round 2 0% 120% Share of bad parts, Round 2 Share of bad parts, Round 1 Share of bad parts 0% 5% 0% 0% 1 10% 1000 Costs perRound good part, Round 4 Costs per good part, 4 12 Results: quality performance and costs 120% 100% 80% 60% r = 0.24 40% 20% 0% 0 50 100 150 200 250 300 Costs per good part, Round 3 350 Share of bad parts, Round 1 Share of bad parts, Round 1 Question: Do groups that have good quality performance in the beginning outperform other groups in round four? 120% 100% 80% 60% r = -0.03 40% 20% 0% 0 50 100 150 200 Costs per good part, Round 4 Finding: Good quality performance in the beginning has no correlation with the financial result in the last round. Tuesday 21 June 2011 13 Results: quality performance and measures taking measures Start Round 1 Round 2 measuring performance Round 3 Round 4 Stop measuring performance best performers evaluate delta worst performers Tuesday 21 June 2011 14 Results: quality performance and measures Question: Do the measures taken by the best performers differ from the measures taken by the worst performers? 14 # times chosen 12 Performance change between round 1 and 2 in number of bad parts: 10 8 6 Best performers 4 Worst performers 2 0 Layout Lot size Training Removal int. transp. Q-Training Finding: The measures taken by the two groups are practically the same. Tuesday 21 June 2011 15 Results: quality performance and measures Question: Does the measure “quality training” improve quality more than other measures? Average number of bad parts Average costs per good part With Q-Training Total With Q-Training Total Round 1 10.86 11.69 4874.00 2443.22 Round 2 3.57 3.21 256.71 109.31 Delta 7.29 8.48 4617.29 2333.91 Finding: Groups choosing “quality training” as a measure improve quality less than the total average. Tuesday 21 June 2011 16 Results: quality performance & learning Players‘ progress in producing the part in the right quality. First-order learning: based on repetition and learning-by-doing Production activity Productivity improvement Second-order learning: based on managerial or engineering actions purposely improving the manufacturing capabilities Measures aimed at improving the production capabilities. Tuesday 21 June 2011 17 Content Introduction to the logistics game Theoretical background Results Conclusions and practical implications Tuesday 21 June 2011 18 Conclusions Costs only correlate with quality performance in the first two rounds. Good quality performance in the beginning does not assure a superior financial result in the end. Measures taken between round one and two have no influence on quality. Quality training does not improve quality more than other measures. The sand cone model can be confirmed inasmuch as quality improves early on. The learning process helps to explain why quality performance improves independently of measures taken. Tuesday 21 June 2011 19 Practical implications In manufacturing, improving quality helps to bring down costs early on. Improving quality is not necessarily a matter of managerial or engineering actions, some aspects might improve simply as a function of the cumulated units produced. Tuesday 21 June 2011 20 What have we seen? Practice ? Theory SG WP 3 Shipping WP 1 Sales Stock First-order learning Production activity Tuesday 21 June 2011 Secondorder learning Rework Productivity improvement Customer QC Direct Internal Transport External Transport WP 2 WP 4 21 THANK YOU! Tuesday 21 June 2011 22 BACKUP Tuesday 21 June 2011 23 Results: quality performance and measures 12 # times chosen 10 8 6 4 2 0 Layout / Training Tuesday 21 June 2011 Layout / Removal int. transp. Layout / Lot size Lot size / Training Lot size / QTraining Training / Training Training / QTraining 24 Results: quality performance & learning Plateuing in round three and four Improvements of costs base on more sources of learning than improvements in quality. 14 2500 Costs 2000 Quality 12 10 8 1500 6 # Qabs Costs 3000 1000 4 500 2 0 0 1 2 3 4 Round Tuesday 21 June 2011 25 Data sources Played for the last 16 years Results of 81 games Played with students (70%) and practitioners (30%) Tuesday 21 June 2011 26