MSOM 5806 syllabus - The Astro Home Page

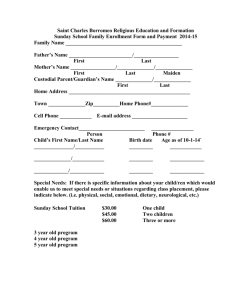

advertisement

TEMPLE UNIVERSITY MSOM 5806: Operations Management (3 credit hours) May/June 2012 Executive MBA Program Course Syllabus Instructor: Dr. Edward C. Rosenthal Office: Alter Hall, room 526. Phone: (215) 204-8177. Fax: (215) 204-6237 E -mail: edward.rosenthal@temple.edu Textbook: Operations Management, Jay Heizer and Barry Render. Tenth Edition, Prentice Hall, 2011. Software: POM-QM for Windows, Howard J. Weiss. Download at: http://astro.temple.edu/~hweiss/pomsoftware . MSOM 5806 is an introductory, survey course in operations management in the Fox Executive MBA program. The course will be taught in a compressed format according to the following schedule: Tuesday, May 8: 2 hour WebEx session (8 PM – 10 PM) Friday, May 18: Saturday, May 19: Sunday, May 20: 4 hour class session (1 PM – 5 PM at the Desmond conference center) 4 hour class session (1 PM – 5 PM at the Desmond) 4 hour class session (1 PM – 5 PM at the Desmond) Tuesday, June 12: 2 hour WebEx session (8 PM – 10 PM) Friday, June 15: Saturday, June 16: Sunday, June 17: 4 hour class session (1 PM – 5 PM at the Desmond) 4 hour class session (1 PM – 5 PM at the Desmond) 4 hour class session (1 PM – 5 PM at the Desmond) Below you will find more details, including what the course is about what will be expected of you, and a detailed class schedule. Overview: The operations function is integral to any organization. Essentially, one can think of this function as the subsystem of the organization that converts inputs into goods and services. This course will discuss the efficient design and control of this subsystem. Much of the analysis involved is quantitative, and therefore much of the work will be aimed at mathematical formulation and (computer) solution of the problems typically encountered. The course will be an introduction to and survey of the field. In the survey spirit, students will be exposed to many different ideas and techniques in both the manufacturing and service sectors. However, to keep the course from being too scattershot, some of the material supply chain management, in particular will be studied in more depth. Objectives: Students are expected to leave the course with a basic familiarity with the different models used to analyze the various operations functions. Also important to grasp is how these sometimes disparate functions are integrated, not only among themselves but with other functional areas in the organization. Finally, everyone will have ample opportunity in the group project to use various methods from the course in a real work environment. Grading: Midterm Exam (done individually at home): 35% of grade Group homework assignment: 10% Group Project: 20% Final Exam (done individually at home): 35%. Homework (HW): In addition to the group HW assignment listed above, there will be other, “regular” homework assignments. Some of these assignments will be carried out in class as group exercises; the remainder of these assignments will be done at home and reviewed both at home (with solutions posted on the Blackboard site) and, to a lesser degree, in class. These “regular” HW assignments will not be collected or graded. Group Projects: As listed above, there will be one group homework assignment and one group project. The group HW assignment will be distributed right after the May 20 session and it will be due on Friday, June 15. This assignment will involve problems that are somewhat more in-depth than the class examples and textbook problems. Some of this material will require “self-study” at home using materials posted on Blackboard as well as readings in the textbook. It is meant to be carried out in your already established teams. The group project will also be done in your established teams. Each team will write up a short paper describing their project and will make a 15 minute (or so) presentation on Sunday, June 17 (our last class meeting). The project will involve an application of operations management techniques or methodology to a significant problem that one person in the group is involved with directly or indirectly at work. You will find more description of this project below. Class Schedule: We will have six face-to-face (F2F) sessions and two WebEx sessions. Please note that for each session I have given a rough estimate of how long we will spend on each activity or topic. Each WebEx session will include one short break about halfway along, and each 4 hour F2F session will include two breaks at appropriate intervals. Time allocated for breaks is included in the estimates below. Tuesday, May 8: 2-hour WebEx session (8:00 - 10:00 PM) Friday, May 18: 4-hour F2F session, (1:00 – 5:00 PM) Saturday, May 19: Quality/statistical process control (1 hour) Capacity planning (2.5 hrs.): Decision trees (including team exercise) Break-even analysis Capacity utilization and strategy Learning curves Team exercise on SPC problems (0.5 hr.) 4-hour F2F session (1:00 – 5:00 PM) Sunday, May 20: Introduction (less than 1 hour) Total Quality Management (TQM, about 40 min.) Discussion/initiation of team project Facility location (2 hrs.): Transportation-based approach Center-of-gravity approach Factor rating method Facility layout: process analysis (1.5 hrs) Team exercise (0.5 hr.) 4-hour F2F session (1:00 – 5:00 PM) Facility layout: office, retail, warehousing (1 hr.) Queueing (1.5 hrs.) Review and HW solutions (1.5 hrs.) At the conclusion of the Sunday (May 20) session, a take-home exam will be distributed, which will be due in one week, and a HW project will be distributed, due on June 15. Tuesday, June 12: 2-hour WebEx session (8:00 – 10:00 PM) Go over exam solutions Discuss group projects Friday, June 15: 4-hour F2F session (1:00 – 5:00 PM) Saturday, June 16: 4-hour F2F session (1:00 – 5:00 PM) Sunday, June 17: Scheduling: sequencing tasks (45 min.) Project management (1.5 hours) Inventory management (1 hour) Team exercise (45 min.) Inventory management (1 hour) JIT and “lean” (45 min.) MRP and lot-sizing (45 min.) Supply chain management (45 min.) Team exercise (45 min.) 4-hour F2F session (1:00 – 5:00 PM) Group project presentations (75-90 minutes) Topics in supply chain management (2 hours) Conclusion (0.5 hr.) At the conclusion of the Sunday (June 17) session, a take-home exam will be distributed, which will be due by the following weekend. Note: We will be actively using our laptops for all of the sessions. Group Project: My objective for this part of the course is for each of you to discover and begin to tackle “real” applications of the course material in your current work environment. Each team will pick out a problem or issue in one member’s current work environment that is amenable to a solution based on one or more techniques from this course. Specifically, this would involve using our management science techniques to improve some aspect of operations that you are familiar with. Here’s what I’d like you to aim for with the presentation: Spend some time documenting what is wrong (or can be improved) with the particular process; Spend some time trying to “model” the particular problem with one or more of the techniques or applications from our course; and Map out how you would go about your analysis. Begin to carry out your modeling and analysis (collect data, run some models, etc.) I am not asking you to perform a complete analysis (e.g., collect data, interview people, crunch numbers, develop a recommendation, implement your solution, etc.). My goal for you is to use this opportunity to build the foundation for such an analysis and then start to carry this analysis out. Therefore, your presentation – in 15 minutes – would describe to us what the problem is that you want to tackle, how you would go about attacking it, what you have found out thus far, and further work and what you would expect to find. Finally, in addition to the presentation, I would like to receive a short written synopsis (say, 4 – 6 pages) that describes the work you have carried out. One concern about the project in the early going of the course has to do with generating a suitable topic. Below I list a number of projects from past years. Each is tagged with a topic name (in italics) so as to identify its relation to the course coverage. Project scheduling: computer system installation. PERT/CPM. Staffing/physician assignment in hospital medical department. LP (STAT 5802). Production facility re-design with cellular manufacturing. Facility layout, JIT. Inventory policy design for home-visit health care provider. Inventory. Scheduling/workflow improvement in dentist's office. Queueing/simulation. Salesforce support -- phone line staffing study. Queueing/simulation. Facility location: product distribution for large pharmaceutical corporation. Facility location. (Another) production facility layout/line balancing improvement. Facility layout. Analysis of parts shipments. Transportation, queueing. Analysis of walk-in health care clinic. Queueing. Yield improvement in manufacturing process. Statistical process control. Customer service improvement: phone line staffing. Queueing, simulation. Book publishing cycle time improvement: process analysis. TQM. Pension fund deposit cycle time improvement. TQM. Cost analysis for bottle production capacity expansion. SPC. Facility aggregation and location. Facility location. Data entry performance evaluation. Statistical process control. I expect each group to come up with a suitable problem for study (every group in the past has done so!). Accomplishing this requires not only identifying a candidate problem but also surmising whether the application of one or more operations methods would be relevant and tractable within the limited time available. Often a successful project is merely a pilot analysis for a more involved future study. My goal for each presentation is for our peers to learn about the original problem under investigation, to learn what methods can be used to model the problem, and how the solutions obtained would lead toward a resolution of the problem. Finally, there are two other items that need to be stated: Disability Statement: This course is open to all students who meet the academic requirements for participation. Any student who has a need for accommodation based on the impact of a disability should contact the instructor privately to discuss the specific situation as soon as possible. Contact Disability Resources and Services at 215-204-1280 in 100 Ritter Annex to coordinate reasonable accommodations for students with documented disabilities. Statement on Academic Freedom: Freedom to teach and freedom to learn are inseparable facets of academic freedom. The University has adopted a policy on Student and Faculty Academic Rights and Responsibilities (Policy # 03.70.02) which can be accessed through the following link: http://policies.temple.edu/getdoc.asp?policy_no=03.70.02.