Service Operations Management

advertisement

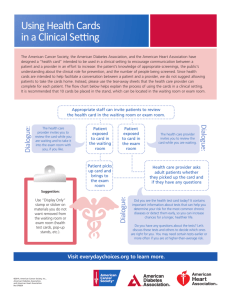

Service Operations Management Fundamentally, there are no differences between service and manufacturing operations! Both are concerned with: • Efficiency • Effectiveness • Quality • Cost Effectiveness • Right prescription • Right advice • Service availability Efficiency • No. of servers • Use of resources Cost • Inventory management • Tradeoffs • Purchasing Quality • Training • Error prevention • Continuous Improvement Service Operations Management Selected Issues • • • • • • • • New service development Managing service experiences Front-office/Back-office Analyzing processes Service quality Yield management Inventory management Waiting time management New Service Development • Service Blueprinting Focus on moments of truth • Servicescapes • Utility-based Service Design Perceived utility to customer • Relative importance of Dimensions of Service Quality Service Blueprinting Source: Metters, King-Metters, Pullman, & Walton, p. 84 Utility-based Service Design Source: Metters, King-Metters, Pullman, & Walton, p. 88 Dimensions of Service Quality • • • • • Reliability Responsiveness Assurance Empathy Tangibles ACSI Site: http://www.theacsi.org/index.php?option=com_content&task=view&id=15&Itemid=172 Parasuraman, et al., 1985 Managing Service Experiences • Customer Engagement • Context • Time • Service Blueprinting Focus on moments of truth Front-office/Back-office • Front-office work requires customer presence. • Back-office work does not require customer presence. • Decoupling: separating work into highcontact/low-contact jobs. Ultimate = outsourcing/offshoring Analyzing Processes • Process flow diagrams (flow charts) – Process communication – Focusing mgt. attention on customer – Determining what to work on • Process Simulation Service Quality • Defining service quality is more difficult than defining manufacturing quality. – Expectation vs Perception – Expectation vs Performance Gaps in Service Quality Source: Metters, King-Metters, Pullman, & Walton, p. 186 Developing a Culture of Service Quality • • • • • Hire the right people. Educate and train them well. Allow them to fix anything. Recognize and reward them regularly. Tell them everything, every day. Service Recovery • • • • • • • Measure the costs Listen closely for complaints Anticipate needs for recovery Act fast Train employees Empower front line Close the loop Yield Management Purpose is to sell the right capacity to the right customer at the right price. • Overbooking • Differential pricing • Capacity allocation Inventory Management Service vs Manufacturing • • • • • • • Setup/Ordering costs high Number of products higher Limited shelf space Lost sales vs backorders Product substitution Demand variance higher Information accuracy (complication of customers) Waiting Time Management • Waiting lines are pervasive in services • The problem is important • Lack of management intuition about waiting lines 15/30 Waiting Time Rule in hospital ER References Fitzsimmons & Fitzsimmons (1998). Service Management 2ed., Irwin/McGraw-Hill. Metters, King-Metters, Pullman, Walton (2006). Successful Service Operations Management 2ed., Thomson. Nelson. (2005). “Baldrige—Just What the Doctor Ordered.” Quality Progress. Sower, Duffy, Kohers, et al. (2001). “The Dimensions of Service Quality for Hospitals…” Health Care Management Review. MGT 568 Service Management & Marketing MGT 568 is a team-taught course available as a graduate elective.