Final Presentation

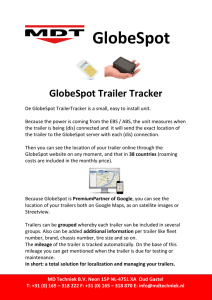

advertisement

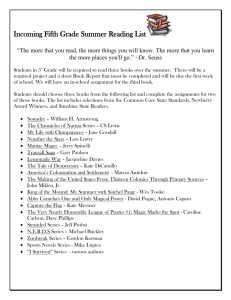

Retractable Tractor Trailer Boat Tail Tim Slattery 11/15/12 Background • Typical full tractor trailer will get about 6 mpg & travels 120,000 miles per year • $80,000 annual fuel cost • Rear of trailer contributes ~25% of total aerodynamic drag Description • Goal • To decrease drag on rear of trailer while still allowing easy access to cargo • Device must retract to allow doors to fully open Description • Hinged metal plates form shape • Device is unlocked from deployed position • Pivot arm is rotated, pushing panels down the side of the trailer • When in place, the device is locked into position and the doors can be opened • Device is deployed by reversing this procedure Customer Needs Allows use of current dock Improves fuel economy Device does not obscure any tail lights Device must lock in deployed and retracted positions Pays for itself in 1 year 7000 6000 Annual Fuel Savings ($) • • • • • 5000 4000 3000 2000 1000 0 0 2 4 6 8 10 12 14 Percent Drag Coefficient Reduction 16 18 20 Main Specifications • Reduces aerodynamic drag by >7% • Annual fuel savings of $2,200 • Trailer doors are free to open at least 250° • Extends off back of truck 5 feet or less • Department of Transportation (DOT) Constraint • Does not extend past width and height of trailer • DOT Constraint • Deploy or retract device in less than 30s • Deploy or retract in 5 steps or less Scope & Deliverables • Scope • Design that allows full access to trailer doors • Reduce drag by 7-9% • Focus on retractable design mainly • Deliverables 1. 2. Small scale trailer model to prove drag reduction One half scale prototype to demonstrate retractable function Customer • Aerodynamic Trailer Systems, LLC • • • • • Jim Domo Design products to improve trailer efficiency Makers of the SmartTail® 4-7% fuel savings Only deploys at highway speeds • Faculty Consultants • Dr. Gomes • Mechanical Design, Mechanics • Dr. Wellin • Testing, Aerodynamics, Fluid Mechanics • Dr. Venkataraman • Fluid Mechanics, CFD, Wind Tunnel Team Staffing & Equipment • 4-5 ME Students • • • • • • CFD Analysis Fluid Dynamics Aerodynamics Stress Analysis Fatigue Analysis Mechanical Design • RIT Drag Tank • RIT Wind Tunnel • RIT Machine Shop • MSD lab Budget Estimate • • • • Budget $750.00 High investment yields high long term savings 7-9% drag reduction = $2205.59-$2835.76 annual fuel savings Consumer cost <$2000.00 provides net savings in under one year Item 6061 Aluminum Sheet (51” x 24” x 1/16”) Miscellaneous 6061 Aluminum Square Tubing (8 ft) 1:24 Scale Truck Plywood (4’ x 8’ x 0.5”) 2x4 boards (8 ft) Source Cost Each ($) www.metalsupermarkets.com ~60 Quantity 16 Total ($) ~480 www.onlinemetals.com 7.00 4 150.00 28.00 www.3000toys.com www.lowes.com 29.00 ~9 1 3 29.00 ~27 www.lowes.com ~4 7 Total ~28 ~$750.00 Future Projects • Optimize tail geometry • Improve fuel savings • Up to 16% fuel savings • Saves $12,000 annually • Fully automated design • Minimize operator interaction • Full scale prototype testing References • Aerodynamic Trailer Systems, LLC • www.ats-green.com • Tractor Trailer Tail: Final Report • http://www.seniord.aere.iastate.edu • PRP • http://edge.rit.edu/edge/R13902/public/HW_Deliverables/Indivi dual%20Submissions/Tim%20Slattery/PRP%20Drafts/PRPFinal.pdf