T2B) Anticorrosive Zn Free Pigments

advertisement

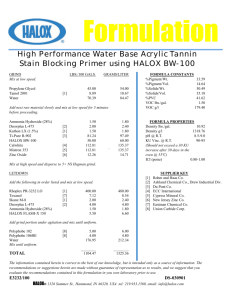

Anticorrosive Zn Free Pigments: Their Performance PNWSCT 2014 Agenda Historical Evolution of Anticorrosive Pigments Corrosion Protection Zn free pigments Case Study Accelerated cyclic electrochemical test Analytical experiments Additional systems tested Summary HISTORICAL EVOLUTION OF ANTICORROSIVE PIGMENTS Anticorrosive Zn Free Pigments: their performance Dr. Ricard March, Nubiola Historical evolution of anticorrosive pigments TRADITIONAL ANTICORROSIVE PIGMENTS Chromate based pigments ALTERNATIVE NON CLASSIFIED AS HAZARDOUS ANTICORROSIVE PIGMENTS ZINC BASED PIGMENTS • Zinc Phosphate ZINC FREE PIGMENT Calcium strontium phosphosilicate • Modified Zinc Phosphates Zinc Chromate Zinc Tetraoxychromate Strontium Chromate Barium Chromate Red lead Un/Modified with organic surface treatment CORROSION CORROSION What the corrosion is? Corrosion is a gradual spontaneous process as a result of a chemical reaction with the environment that damages the original metal, typically iron. + O2 / + H2O Spontaneous !! Non spontaneous !! Entropy: Order Disorder Corrosion Process: description 1 Anodic reaction: Fe Fe2+ + 2 e- Cathodic reaction: O2 + 2 H2O + 4 e- 4 OH- 2 e- 3 O2 Fe2+ Fe(OH)2 4 H2O delamination 5 blistering OH- e- Protective coating OHFe OH- ee- Metallic substrate (Fe) Corrosion Process: reactions Redox reaction: Anodic reaction (oxidation): Fe Fe2+ + 2 e- Cathodic reaction (reduction): O2 + 2 H2O + 4 e- 4 OHGlobally: 2 Fe + O2 + 2 H2O + 4 e- 2 Fe2+ + 4 OH- + 4 e- Formation of rust: Fe2+ + 2 OH- Fe(OH)2 4 Fe(OH)2 + O2 4 FeOOH + 2 H2O 2 FeOOH Fe2O3 + H2O Corrosion Process Other compounds can accelerate the reaction: •H3O+ (or changes in the pH) •SO2 (industrial environment) •NaCl (marine environment) •Other contaminants: NH4+, SO42-, Mg2+, COO-, etc •Also: temperature PROTECTION How to Slow the Corrosion Process 1 e- flowing O2 Fe2+ H2O delamination blistering OHe- Protective coating OHFe OH- ee- Metallic substrate (Fe) It is impossible to interrupt the electron flowing (metal) How to Slow the Corrosion Process 2 H2O / O2 in the interface O2 Fe2+ H2O delamination blistering OHe- Protective coating OHFe OH- ee- Metallic substrate (Fe) It is possible to reduce water and oxygen flow through barrier effect How to Slow the Corrosion Process Cathodic reaction: O2 + 2 H2O + 4 e- 4 OH- 3 High pH (OH-) displaces the reaction to the left and helps hydroxides precipitation Cathodic inhibition by metallic hydroxides and oxides precipitation OH- generation in the cathode O2 Fe2+ H2O delamination blistering OH- e- Protective coating OHFe OH- ee- Metallic substrate (Fe) How to Slow the Corrosion Process Anodic reaction: Fe Fe2+ + 2 eAnodic passivation by metal and iron complexes (phosphates, silicates, …) precipitation O2 4 Fe2+ generation in the anode Fe2+ H2O delamination blistering OH- e- Protective coating OHFe OH- ee- Metallic substrate (Fe) How to Slow the Corrosion Process Anodic reaction: Fe Fe2+ + 2 e- Cathodic reaction: O2 + 2 H2O + 4 e- 4 OH- Compounds precipitated in the cathode and the anode also avoid the ionic mobility Fe2+ Fe(OH)2 O2 H2O Ionic mobility delamination 5 blistering OH- e- Protective coating OHFe OH- ee- Metallic substrate (Fe) Zn FREE PIGMENTS Zn free pigments Calcium Strontium Phosphosilicates: aM*. bP2O5 . cSiO2 . xH2O, for M = Ca, Sr • Low particle size •Special particle shape combination (acicular + spherical) •Elemental particles <1µ forming aggregates and agglomerates up to <10µ % 10 100 D(v,0.5)=1.15µ % 10 100 90 N301 STD 5'-3 90 Nubirox 301 80 N 20 030829009 0'-1 80 70 70 60 60 50 50 40 40 0 0.01 30 30 20 20 10 10 0 0.1 1.0 10.0 100.0 Particle Diameter (µm.) 1000.0 0 0.01 0 0.1 1.0 10.0 100.0 1000.0 Particle Diameter (µm.) Zn free pigments • Higher specific surface area 21 m2/g vs 1 m2/g (std zinc phosphate) • Minimizes moisture, oxygen and ionic species diffusion. • Microscopical reinforcing action • Better adhesion to the metal surface • Better dispersion capability • More active surface (allows lower pigment dosage) • Better performance in thin film systems • Low effect on gloss SEM (scanning electron microscopy) 10000X Zn free pigments: Calcium Strontium Phosphosilicates O2 + 2 H2O + 4 e- 4 OH- Cathodic reaction displacement Barrier effect aM*.bP2O5.cSiO2.xH2O M= Ca, Sr Anodic passivation: Ca/Sr/Fe phosphates&silicates complexes Cathodic inhibition: Ca/Sr hydroxides Metallic substrate (Fe) CASE STUDY DOE •WB Styrene Acrylic •Substrate: CRS, S-46 •60 - 90 •240 - 1170 h Neutral Salt Spray ASTM B117 •Formulated at same: •Anticorrosive Pigment Volume Content (3% - 6%) •PVC/CPVC ratio (same free binder volume, 0,47) •DOE: Full factorial experiment 24 (16 runs of 1 replica in one block): •Pigment (qualitative): zinc phosphate – zinc free •Dose (quantitative): 3% - 6% •Thickness (quantitative): 60 - 90 •Exposure time (quantitative): 240 h – 1170 h •Exit parameters: •Oxidation at scribe •Oxidation on the panel •Adhesion at the scribe Panel Evaluation Blistering ISO 4628-2 “Cross cut” adhesion ASTM D3359 Adhesion at the scribe ASTM D1654 B Oxidation at the scribe ASTM D1654 A Oxidation on the panel ASTM D610 DOE: Pareto Plots Thickness Dose DOE: interaction plot for oxidation at scribe DOE: interaction plot for oxidation on the panel Faster activity and higher efficiency of Zn free Zn free 3% 60 240 h Zn phosphate 6% 60 240 h Zn free 6% 90 1170 h Zn phosphate 6% 90 1170 h ACET ACET: The need Accelerated Cyclic Electrochemical Technique (ACET) 24 h 100 10.000 h 4.400 – 25.000 h UNE 48315-1 ASTM B117 ACET: Steps ACET: Information |Z|max(Ω) |Z|min(Ω) ∆Z (Ω) Emax (V) Emin (V) ∆E (V) Bode Graph Definition Effect Maximum impedance value Minimum Impedance Value Impedance variation Maximum Free Corrosion Potential Minimum Free Corrosion Potential Free Corrosion Potential Variation Erelax vs trelax Initial quality of the Coating Coating Porosity Coating Porosity & Adhesion Coating Porosity & Adhesion Coating Porosity & Adhesion Activity in the Interface Activity in the Interface, Adhesion & Porosity ACET: Equivalent circuit Equivalent circuit used to model EIS & ACET Coating properties Interface Rpo Cc Rp Cdl Rs Definition Effect Pore Resistance Coating Capacitance Polarization Resistance Double Layer Capacitance Degradation due to porosity increasing Water Absorption Corrosion in the Interface Delamination Electrolyte resistance Panel Evaluation: Standard (SSC) Blistering ISO 4628-2 “Cross cut” adhesion ASTM D3359 Adhesion at the scribe ASTM D1654 B Oxidation at the scribe ASTM D1654 A Oxidation on the panel ASTM D610 Panel Evaluation: ACET Impedance values: Emax, Emin, ∆E and Bode graph Equivalent circuit parameters: Rp and Cdl Impedance values: |Z|max, |Z|min and ∆Z Equivalent circuit parameters: Rpo and Cc ACET: ANN Blank std ZnPh Zn-free CPV (%) 0 3 4,5 6 8 3 4,5 6 8 |Z|max(Ω) 1,45E+08 1,06E+08 1,55E+07 1,47E+08 9,81E+07 1,22E+08 8,39E+07 1,02E+08 6,92E+07 |Z|min(Ω) 1,49E+04 2,57E+04 4,63E+03 2,38E+04 1,53E+04 9,26E+07 1,93E+07 2,67E+07 6,08E+07 Emax (V) 0,25 0,24 0,18 0,17 0,11 0,2 0,16 0,21 0,19 Emin (V) -0,16 0,03 -0,13 0,02 -0,02 -0,33 -0,37 -0,35 -0,32 ∆E (V) 0,41 0,21 0,31 0,16 0,13 0,52 0,54 0,55 0,51 Use of this methodology in the industry? Electrochemical Models? Artificial Neural Networks (ANN) ACET: correlation ANALYTICAL EXPERIMENTS SEM: panel observation SEM: mapping SEM: cross-section observation Blank Zn Phosphate Zn free •Water Based Styrene Acrylic •Substrate: CRS, S-46 •70 •450 h Neutral Salt Spray ASTM B117 •Formulated at same: •Anticorrosive Pigment Volume Content (6%) •PVC/CPVC ratio (same free binder volume) SEM: cross-section observation Blank Oxidation Zinc phosphate Zn free The finest particle distribution SEM: cross-section observation Zinc phosphate: Energy Distribution Spectroscopy Element Mapping (EDS element mapping) Fe O P Si Coating Zn Panel SEM: cross-section observation Zinc free pigment: Energy Distribution Spectroscopy Element Mapping (EDS element mapping) Fe O P Si Coating Panel Sr Ca Smaller particle size allows the pigment to have a more direct interaction with the metal surface. SEM: cross-section observation Energy Distribution Spectroscopy Linescan (EDS Linescan) Blank Panel Coating Zn free (line 2) Zn free (line 1) Panel Coating Panel Coating SEM: cross-section observation Energy Distribution Spectroscopy Linescan (EDS Linescan) Blank Panel Coating SEM: cross-section observation Energy Distribution Spectroscopy Linescan (EDS Linescan) Zn free (line 1) Panel Coating SEM: cross-section observation Energy Distribution Spectroscopy Linescan (EDS Linescan) Zn free (line 2) Panel Coating ADDITIONAL SYSTEMS TESTED SB Wash Primer Zinc Tetraoxychromate Zinc free •2K Etch/Wash primer: polyvinyl butyral epoxy modified •Substrate: Galvanized Panels, SG015 •20 (lower half – only primer) •50 (upper half – primer & intermediate) •300 h Neutral Salt Spray ASTM B117 •Formulated at same: •Anticorrosive Pigment Volume Content (9%) •PVC/CPVC ratio (same free binder volume) SB Wash Primer Cross cut test (ASTM D3359) Mild steel Cold rolled steel SB015D (Espancolor) S-46 (Q-Panel) Galvanized steel SG015 (Espancolor) Aluminum 3105H14 AA015D (Espancolor) Zinc Tetraoxychromate 5B 5B 4B 5B 5B 5B 3B 4B Zinc free SB Alkyd Blank 6% Zinc Phosphate 6% Zinc free •Solvent Based Alkyd •Substrate: CRS, S-46 •60 •641 h Neutral Salt Spray ASTM B117 •Formulated at same: •Anticorrosive Pigment Volume Content (6%) •PVC/CPVC ratio (same free binder volume) SB Alkyd Blank 6% Zinc Phosphate 3% Zinc free 6% Zinc free Zn free pigment shows better performance, even at lower dosage. SB Epoxy Blank 6% Zinc Phosphate 6% Zinc free •Solvent Based Epoxy •Substrate: CRS, S-46 •60 •1100 h Neutral Salt Spray ASTM B117 •Formulated at same: •Anticorrosive Pigment Volume Content (6%) •PVC/CPVC ratio (same free binder volume) SB Epoxy 10 % Zinc Phosphate 6% Zinc free 1100 h Blank 1320 h Blank 10 % Zinc Phosphate 8% Zinc free Zn free pigment shows better performance, even at lower dosage. SB 2K Polyurethane Blank 6% Zinc Phosphate 6% Zinc free •Solvent Based 2K Polyurethane (acryl/polyisocyanate) •Substrate: CRS, S-46 •60 •385 h Neutral Salt Spray ASTM B117 •Formulated at same: •Anticorrosive Pigment Volume Content (6%) •PVC/CPVC ratio (same free binder volume) SB 2K Polyurethane: pot-life Hours Blank Zinc Phosphate Zn free 2 1 Liquid Liquid Liquid 2 Liquid Thick liquid Liquid 3 Thick liquid Solid Thick liquid 4 Solid Solid Solid No effect on pot life / shelf life Powder coating •Powder Coating, Epoxy-Polyester •Powder Coating, Epoxy-Polyester •Substrate: Phosphated steel, Bonderite 1000 •90 •1000 h Neutral Salt Spray ASTM B117 •Formulated at same: •Substrate: Aluminium, 3105H14 •90 •4000 h Neutral Salt Spray ASTM B117 •Formulated at same: •Anticorrosive Pigment Volume Content (2,3%) •PVC/CPVC ratio (same free binder volume) •Anticorrosive Pigment Volume Content (2,3%) •PVC/CPVC ratio (same free binder volume) Blank Blank TESTED PANEL EVALUATION Rusting on the panel (ASTM D610) Zinc free Zinc free Blank Zinc free 1 8G (0.1%) 10 (none) TESTED PANEL EVALUATION Control Zinc free 1 Rusting at the scribe (ASTM D1654) 7 (1.5mm) 9 (0.5mm) Rusting on the panel (ASTM D610) 6G (1%) 9G (0.03%) WB Acrylic DTM Blank 4,5% Zinc Phosphate 4,5% Zinc free Gloss 85º = 69 Gloss 85º = 57 Gloss 85º = 71 •WB Acrylic DTM Zinc free: No gloss reduction Good anticorrosive activity •Substrate: CRS, S-46 •90 •310 h Neutral Salt Spray ASTM B117 •Formulated at same: •Anticorrosive Pigment Volume Content (4,5%) •PVC/CPVC ratio (same free binder volume) WB Alkyd Blank 4,5% Zinc Phosphate 4,5% Zinc free •WB Alkyd •Substrate: CRS, S-46 •90 •500 h Neutral Salt Spray ASTM B117 •Formulated at same: •Anticorrosive Pigment Volume Content (4,5%) •PVC/CPVC ratio (same free binder volume) WB Styrene Acrylic Blank 6% Zinc phosphate 6% Calcium phosphate 6% Zinc free •WB Styrene Acrylic •Substrate: CRS, S-46 •55 •478 h Neutral Salt Spray ASTM B117 •Formulated at same: •Anticorrosive Pigment Volume Content (6%) •PVC/CPVC ratio (same free binder volume) SUMMARY Summary •Zinc free pigments are an effective environmentally friendly option to zinc phosphate based products. •Compared to anticorrosive zinc phosphate based products, they show •an adhesion improvement on cold rolled steel. •a lower effect on gloss. •a lower reactivity in WB and SB polyurethane systems. •Accelerated evaluation have been used and correlated with results obtained in classic evaluation methods like Salt Spray test. •All these macroscopic facts are related to the chemical composition and physical properties of the pigment. •Proper adjustment of paint formula variables is a complex procedure. The expertise and skill of a reputable paint company and their staff of paint chemists is invaluable for the long term performance of a coating system Thank you for your attention