Chassis Systems A4 Tasks Part 4

advertisement

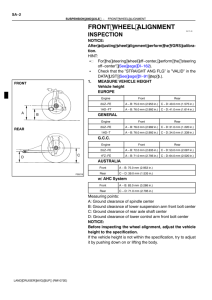

1 Service Power Steering Pump Meets NATEF Task: (A4-B-13 [P-1], A4-B-14 [P-2], and A4-B-15 [P-2]) Remove, inspect, replace, and adjust power steering pump belt and pump; press fit pump pulley. Name ____________________________________Date__________________________ Make/Model _____________________________ Year _________ Instructor’s OK _____ 1. Check service information for the specified procedures and specifications for removing, replacing, and adjusting the power steering pump and drive belt. Describe the recommended procedure. __________________________________________________________________ __________________________________________________________________ Specified belt tension = ____________________ _____ 2. Remove and reinstall power steering pump assembly. Instructor check __________ _____ 3. Check service information for the specified procedure to follow to remove and reinstall the power steering pump drive pulley. Describe the recommended procedure. __________________________________________________________________ __________________________________________________________________ List the tools required. _______________________________________________ Instructor check __________ 2 Diagnose Power Steering Fluid Leakage Meets NATEF Task: (A4-B-12) Diagnose power steering fluid leakage; determine necessary action. (P-2) Name ____________________________________Date__________________________ Make/Model _____________________________ Year _________ Instructor’s OK _____ 1. Check the service information for the specified power steering fluid. ____ Power steering fluid ____ Dexron III ATF ____ Type F ATF ____ Other (specify) _____________________________________________ _____ 2. Perform a visual inspection of the power steering system and determine the location of any leaks. Hoist the vehicle if necessary. Check each area listed below that is found to be leaking. ____ Pump shaft seal area ____ Reservoir cap ____ Reservoir ____ High-pressure line at the pump ____ High-pressure line between the pump and the gear ____ High-pressure line at the gear ____ Steering gear leak near the stub shaft ____ Steering gear leak at the inner tie rod end boots ____ Low-pressure hose leak (describe the location) _______________________ ____ Other (describe) _______________________________________________ ____ 3. What action is necessary to correct the leak(s)? ________________________________ __________________________________________________________________ __________________________________________________________________ _________________________________________________________________ 3 Inspect Power Steering Hoses and Fittings Meets NATEF Task: (A4-B-16) Inspect and replace power steering hoses and fittings. (P-2) Name ____________________________________Date__________________________ Make/Model _____________________________ Year _________ Instructor’s OK _____ 1. Check the service information for the specified procedures, precautions, and torque specifications. A. Specified procedure: _________________ __________________________________ B. Specified precautions: ________________ __________________________________ C. Specified torque specifications _________ __________________________________ _____ 2. Check the reason why the hoses and/or fittings are being replaced. ____ Leaking ____ Worn outside cover ____ Possible restriction as determined by testing ____ Recommended when replacing pump or gear assembly ____ Other (specify) ____________________ ________________________________ _____ 3. Which hose(s) or fitting(s) was replaced? ____ High-pressure hose and fitting ____ Low-pressure hose and fitting ____ Other (specify) ____________________ _________________________________ 4 Electronically Controlled Steering Systems Meets NATEF Task: (A4-B-19 [P-3], A4-D-4 [P-3], and A4-D-5 [P-3]) Diagnose, test and diagnose components of electronically controlled steering systems using a scan tool. Name ____________________________________Date__________________________ Make/Model _____________________________ Year _________ Instructor’s OK _____ 1. Check service information for the specified procedures to follow when using a scan tool to diagnose components of the electronically controlled steering system. Describe the recommended procedure. _________________________________________________________________ _________________________________________________________________ _____ 2. What components or sensors are displayed on the scan tool that are related to the electronically controlled steering system? _____________________________ _____________________________ _____________________________ _____________________________ _____ 3. Check service information for the specified procedures to follow when replacing components of the electronically controlled steering system. List the replaceable components and describe the specified procedures. Replaceable components: ________________________________________ _____________________________________________________________ Specified procedures: ___________________________________________ _____________________________________________________________ _____ 4. What is the purpose of the idle speed compensation switch used on some vehicles? _______________________________________________________________ 5 Electric Power Steering Meets NATEF Task: (A4-B-20) Inspect and test electric power assist steering. (P-3) Name ____________________________________Date__________________________ Make/Model _____________________________ Year _________ Instructor’s OK _____ 1. Check service information on the specified factory inspection and testing procedure. __________________________________________________________________ __________________________________________________________________ _____ 2. Check all that apply: ___ Visual inspection was specified ___ Uses a scan tool to test ___ Uses a digital multimeter to test ___ Other (specify) _______________ __________________________ __________________________ _____ 3. Based on the inspection and testing of the electric assisted power steering assembly, what is the necessary action? __________________________________________________________________ __________________________________________________________________ __________________________________________________________________ 6 CV Joint Noise and Vibration Diagnosis Meets NATEF Task: (A3-D-1) Diagnose constant-velocity (CV) joint noise and vibration concerns; determine necessary action. (P-1) Name ____________________________________Date__________________________ Make/Model _____________________________ Year _________ Instructor’s OK _____ 1. Check service information for the specified procedure that should be followed when diagnosing CV joint noise and/or vibration concerns. __________________________________________________________________ __________________________________________________________________ _____ 2. Check all that were specified: ___ Drive backward while turning ___ Drive in a circle to the left and right ___ Drive forward while turning ___ Drive at highway speed ___ Drive forward straight ahead ___ Drive in reverse straight ahead ___ Other (specify) _______________________________________________ _____ 3. Most vehicle manufacturers specify that the engine and transmission/transaxle mounts be checked for damage or wear. What are the conditions of the mounts? __________________________________________________________________ _____ 4. Based on the inspection and testing, what is the necessary action? ________________ __________________________________________________________________ 7 CV Joint Service Meets NATEF Task: (A3-D-4) Inspect, service, and replace shafts, yokes, boots, and CV joints. (P-1) Name ____________________________________Date__________________________ Make/Model _____________________________ Year _________ Instructor’s OK _____ 1. Check service information and determine the specified procedures, tools, and torque specification needed to service CV joints. Specified procedure: ________________________________________________ ___________________________________________________________ Tools/equipment: ___________________________________________________ ___________________________________________________________ Torque specification: ________________________________________________ _____ 2. Following the specified procedure, remove the drive axle shaft assembly. Instructor’s check ____________ _____ 3. Following the specified installation procedure, check all that were replaced. ___ Drive axle shaft assembly ___ CV joint and boot ___ CV joint boot only ___ Other (specify) ___________________ _____ 4. Reinstall the drive axle shaft assembly. Instructor’s OK ______________ 8 Steering and Suspension Concerns Meets NATEF Task: (A4-E-1) Diagnose vehicle wander, drift, pull, hard steering, bump steer, memory steer, torque steer; determine necessary action. (P-1) Name ____________________________________Date__________________________ Make/Model _____________________________ Year _________ Instructor’s OK _____ 1. Check the service information to determine the alignment specifications. Camber = __________ Caster = __________ Toe = ___________ _____ 2. Hoist the vehicle on the alignment rack and install the wheel sensors. _____ 3. Compensate the wheel sensors. _____ 4. Lower the vehicle and jounce (bounce) to center the suspension. _____ 5. Read the rear camber and toe. Camber Toe LR RR _____ _____ _____ _____ Total rear toe = _______ _____ 6. Read the front camber and toe. LF Camber Toe _____ _____ RF _____ _____ Total front toe = _______ _____ 7. Perform a caster sweep to determine the front caster and SAI. LF Caster SAI _____ _____ RF _____ _____ Based on the alignment angles, what action is needed? _____________________ _____________________________________________________________ 9 Alignment Specification Meets NATEF Task: (A4-A-3) Research applicable vehicle and service information, such as suspension and steering system operation, vehicle history, and TSBs. (P-1) Name ____________________________________Date__________________________ Make/Model _____________________________ Year _________ Instructor’s OK _____ 1. Find the following alignment angle specifications for your vehicle: Camber (left) preferred = _______ minimum _______ maximum _______ Camber (right) preferred = _______ minimum _______ maximum _______ Caster (left) preferred = _______ minimum _______ maximum _______ Caster (right) preferred = _______ minimum _______ maximum _______ Front toe preferred = _______ minimum _______ maximum _______ Rear camber preferred = _______ minimum _______ maximum _______ Total rear toe preferred = _______ minimum _______ maximum _______ _____ 2. Determine the diagnostic angle specifications for your vehicle: Toe-out on turn (TOOT) inside wheel = _______ degrees outside wheel = _______ degrees Maximum allowable variation = _______ degrees Steering axis inclination (SAI) left = _______ right = _______ Maximum allowable difference = _______ 10 Pre-Alignment Inspection Meets NATEF Task: (A4-E-2) Perform prealignment inspection and measure vehicle ride height; perform necessary action. (P-1) Name ____________________________________Date__________________________ Make/Model _____________________________ Year _________ Instructor’s OK _____ 1. Check tires. Both front tires and both rear tires should be checked for the following: A. Correct tire pressure B. Same size and brand C. Same tread depth OK _____ NOT OK _____ _____ 2. Perform a dry-park test to check for any looseness in the steering and suspension components such as: A. Tie rods B. Idler arms C. Ball-joints D. Control arm bushings E. Loose or defective wheel bearings OK _____ NOT OK _____ _____ 3. Check for proper ride height. A. Front and rear B. Left and right OK _____ NOT OK ____ 11 Alignment Angle Readings Meets NATEF Task: (A4-E-3) Prepare vehicle for wheel alignment on the alignment machine; perform four-wheel alignment by checking and adjusting wheel caster. (P-1) Name ____________________________________Date__________________________ Make/Model _____________________________ Year _________ Instructor’s OK _____ 1. Hoist the vehicle on the alignment rack and install the wheel sensors. _____ 2. Compensate the wheel sensors as per the alignment equipment manufacturer’s recommended procedure. _____ 3. Lower the vehicle and jounce (bounce) to center the suspension. _____ 4. Read the rear camber and toe. Camber Toe LR RR _____ _____ _____ _____ Total rear toe = _______ _____ 5. Read the front camber and toe. LF Camber Toe _____ _____ RF _____ _____ Total front toe = _______ _____ 6. Perform a caster sweep to determine the front caster and SAI. LF Caster SAI _____ _____ RF _____ _____ Describe what (if anything) is wrong with the present alignment. ___________________________________________________ 12 Four-Wheel Alignment Meets NATEF Tasks: (A4-E-3) Prepare vehicle for wheel alignment on the alignment machine; perform four-wheel alignment by checking and adjusting wheel caster. (P-1) Name ____________________________________Date__________________________ Make/Model _____________________________ Year _________ Instructor’s OK Specifications: Camber Caster Toe (Total) KPI/SAI Rear Camber Rear Toe Rear Toe (Total) Left __________ __________ Right __________ __________ __________ __________ __________ __________ __________ __________ __________ Methods of Adjustment: Camber Caster Toe Front ___________________ ___________________ ___________________ Rear ____________________ ____________________ Reading Before Alignment: (Record here and attach the print out.) Left Camber __________ Caster __________ Toe (Total) __________ KPI/SAI __________ Rear Camber __________ Rear Toe __________ Thrust __________ Set Back __________ Reading After Alignment: (Record here and attach the print out.) Left Camber __________ Caster __________ Toe (Total) __________ KPI/SAI __________ Rear Camber __________ Rear Toe __________ Thrust __________ Set Back __________ Right __________ __________ __________ Right __________ __________ __________ 13 TOOT and SAI Meets NATEF Task: (A4-E-4 [P-2]and A4-E-5 [P-2) Check toe-out-on-turns (turning radius) and SAI (steering axis inclination) and included angle; determine necessary action. Name ____________________________________Date__________________________ Make/Model _____________________________ Year _________ Instructor’s OK _____ 1. Check the alignment equipment instructions and measure the toe-out-on-turns. LEFT TOOT RIGHT TOOT ___________ _____________ _____ 2. Check service information for the specified toe-out-on-turns (TOOT). Specifications = ____________________________ _____ 3. Based on the TOOT readings, what is the necessary action? __________________________________________________________________ __________________________________________________________________ _____ 4. Check steering axis inclination (SAI) and compare to factory specifications. SAI LEFT SAI RIGHT _________ __________ Specification for SAI = ________________________________ _____ 5. Based on the SAI reading, what is the necessary action? __________________________________ __________________________________ __________________________________ __________________________________ 14 Diagnostic Alignment Angles Meets NATEF Task: (A4-E-6 [P-1], A4-E-7 [P-2]), and A4-E8 [P3]) Check angles that can detect collision damage; determine necessary action. Name ____________________________________Date__________________________ Make/Model _____________________________ Year _________ Instructor’s OK _____ 1. Measure the rear thrust angle and compare it to factory specifications. Measured rear thrust angle = __________________ Specified thrust angle = ___________________ _____ 2. Based on the results of the rear thrust angle measurement, what is the necessary action.? _________________________________________ _________________________________________ _____ 3. Measure the front wheel setback and compare it to factory specifications. Measured front wheel setback = __________________ Specified front wheel setback = ___________________ _____ 4. Based on the results of the front wheel setback measurement, what is the necessary action.? _________________________________________ _________________________________________ _____ 5. Check service information for the specified location and dimensions to check for the proper alignment of the front and/or rear cradle (subframe). __________________________________________________________________ __________________________________________________________________ _____ 6. Based on the results of the measurements, compared to factory specifications, what is the necessary action? __________________________________________________________________