Mega Food Park - The Associated Chambers of Commerce and

advertisement

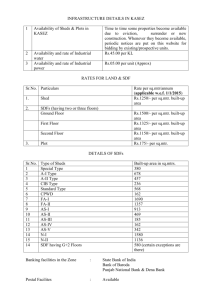

MINISTRY OF FOOD PROCESSING INDUSTRY BY :RAVINDRA CHAUDHARY (CEO) PATANJALI FOOD & HERBAL PARK LTD. VOICE - +91 -9760076644 Special Purpose Vehicle (SPV) in Public Private Participation (Mode) (PPP) TYPICAL TOTAL PROJECT Rs. 100 Cr. (US $ 16 Million. Approx.) GRANT BY GOVT. OF INDIA Rs. 50 Cr. (US $ 8 Million) (50%) PRIVATE EQUITY Rs. 25 Cr. (US $ 4 Million) (25%) BANK / INSTITUTIONAL FUND Rs. 25 Cr. (US $ 4 Million) (25%) Patanjali Food and Herbal Park is a Special Purpose Vehicle (SPV), created under the Mega Food Parks Scheme (MFPS) by the Ministry of Food Processing Industries, Government of India & Acharya Balkrishan ji. INTERNATIONAL MARKET CPC/FOOD PARK PPC FARMERS DOMESTIC MARKET CONSUMERS Offers complete business opportunity to a new or existing investor/entrepreneur in the field of Food Processing. Healthy environment and all necessary facilities. Generation of revenue in less time span. Infrastructure starting from electricity and water to labour and hi-speed broadband. Raw-Material supply setup, cold-rooms for material storage and loss prevention. Central Lab for testing of samples. 1.Compressors Integrated Cold chain facility with a capacity of 2500 MT . 2.Effluent Treatment Plant – Capacity 1550 MT per day. 3.Multi commodity automated washing and grading unit 4.In-house packaging units like Corrugated boxes, Blow & injection molding up to 1000 ml 5.Sewage Treatment Plant – Capacity 60 KLD . 6.Excellent drainage system 7.Computrised weigh system Capacity up to80 MT in 16 meter length. ADMINISTRATIVE BUILDING 8.Inhouse transport facility. 9. Centralized Canteen. 10.Wi-Fi and Leased-Line Broadband Connectivity 11. Common 33 kva sub station 12. In house engineering work shop 13. Well equipped testing laboratory 14.RCC road network PARTICULARS AREA IN SQ. METER OF FOOD PARK TOTAL AREA 1,95,601 ALLOTED AREA 1,72,716 VACANT AREA (Plot sizes available-1000,2000 ,3000and 8000 sq. mtr)Rent Rate – 225/sq. Mtr 22,885 Dehradun – Banana ripening chamber, cold storage , flour mill Devprayag- sorting and packing unit Nazibabad- wheat ware house Budhana ,Muzzafar Nagar-Jaggary production and packing Kotdwar- Potato cold storage, ripening chamber Baazpur—Frozen vegetables & Fruits, IQF,with packing facility. ADMINISTRATIVE BUILDING 11,000 Sq. Mtr. Area Conference Halls + 1 Board Room Cabins ,Workstations & Basement DRY & RAW MATERIAL WAREHOUSE 20,000 MT Capacity with Advanced Stacking System FINISHED GOODS WAREHOUSE •Capacity : 20,000 MT READY TO MOVE IN SHEDS •Area : 1,00,000 Sq. Ft. OVER HEAD WATER TANKS •Capacity – 3,50,000 KL WATER TREATMENT PLANT •Capacity – 3,50,000 Ltr. per hour R.O. WATER TREATMENT PLANT •Capacity : 45,000 Ltr. per hour BOILERS •4 Boilers of Total 27 MT Capacity (Wood fired) & 1 Boiler of 6 MT Capacity (Oil fired) TRANSPORTATION FACILITIES • Commercial Parking • Transportation Facilities to Employees. LOADING AREA Area: 200 Sq. Mtr. WEIGH-BRIDGE • Capacity – 80 MT DEDICATED INTERNAL SECURITY •Approx. 100 Security Personnel WELL CONNECTED METALLED ROADS •Total Area – 80,000 Sq. Mtr. BIO-GAS PLANT • Captive Power Generator Capacity – 1.5 MW PRIMARY PROCESSING CENTRE – LAL TAPPAR, DEHRADUN ROAD •Covered Area – 12,000 Sq. ft. BANANA RIPENING CHAMBER •Capacity - 5 MT per day PRIMARY PROCESSING CENTRE PRE – COOLING CHAMBERS • Refer Room Capacity – 20 MT per day •Capacity – 10 MT per day • Cold Storage Capacity – 20 MT per day • Flour Mill Capacity – 24 MT per day CHILLERS COMPRESSOR IQF 2000 KGS/HOUR COLD STORE- 2000 MT RIPENING CHAMBER POWER BACK -UP KOTDWAR- 2000 MT COLD STORAGE DEVPRAYAG - 6000 SQ FEET COVERED WITH SORTING AND PACKING FACILITY OF TRADITIONAL DAL,S LIKE GAUTH ETC BUDHANA – 100 MT/DAY SUGARCANCANE PRESSING PLANT CHEMICAL LABORATORY SOPHISTICATED INSTRUMENTS CLEAN ROOMS OTHER INSTRUMENTS Flour Mill - Over 100 TPD production Juice Plant - Capacity 6,000 liters per hour (final product/ juice) – up to 400 MTs of raw material can be consumed in a day. Candy Plant – Over 50 TPD production Extraction Plant - Over 10 TPD Processing of 500 kind of Herbs and vegetables. JUICE PLANT FLOUR MILL Corrugated Boxes line 50,000 Boxes per day Capacity – 250 MT per month PET and HDPE line Capacity – 5,00,000 Bottles/ day VOLPAK PACKAGING UNIT TETRAPAK PLANT Co-packing facility-Tetrapak and Volpak. Proficient and Professional Team to manage Food Park Food Park has more than 100 technically qualified employees whose services can be availed by all the units. MANPOWER Easy availability of labours. Currently Food Park employee's thousand of labourers and about lakhs of labourers are available in the nearby Areas. GENERAL Increased economic benefits and potential of the region; Change in community demographics, employment, income, public services and qualities; Generation of employment; Generate tax revenues for the government; Creation of Value Chain, Employment and Income Generation. Enhancement in the relationship between direct, indirect and induced economic linkage. Encourage small and medium size of entrepreneurs. IN CRORES GROSS AREA DOMESTIC PRODUCT OF UTTARAKHAND 60000 50000 40000 30000 20000 10000 24786 28268 32260 38015 42837 47599 51107 55606 GROSS AREA DOMESTIC PRODUCT OF UTTARAKHAND 0 YEARS COMMODITY BEFORE ESTABLISHMENT OF FOOD PARK (Purchase price) AFTER ESTABLISHMENT OF FOOD PARK (Purchase price) Amla as example Rs.5.00/ - per kg Rs. 13.00/- per kg Aloevera Rs. 3.00/- per kg Rs. 8.00/- per kg Other Tropical Fruits & Vegetables Rs. 12.00/- per kg Rs. 25.00/- per kg SOCIAL AND ECONOMIC IMPACT COMMON PROCESSING FACILITY EMPLOYMENT GENERATION Employment Generation at PPC Units 1200 Employment Generation at CPC Units(Common Infrastructure Related) 1000 Employment Generation at CPC Units (Related to various tenants/ processing units) 12000 Total Employment generated through Vendors 15000 Total Employment generated through Production Distribution (Outlets) 120,000 No. of Farmers Covered 4,50,000 BEFORE 100 MT CONSUMPTION PER YEAR BEFORE FOOD PARK 500 MT CONSUMPTION PER YEAR BEFORE FOOD PARK AFTER 20,000 MT CONSUMPTION PER YEAR AFTER FOOD PARK 14,000 MT CONSUMPTION PER YEAR AFTER FOOD PARK B E F O R E BEFORE THE ESTABLISHMENT OF FOOD PARK A F T E R AFTER THE ESTABLISHMENT OF FOOD PARK A F T E R B E F O R E 400 MT CONSUMPTION OF SPICES & 20,000 MT OF HERBS BEFORE FOOD PARK 1200 MT CONSUMPTION OF SPICES & 1,20,000 MT OF HERBS AFTER FOOD PARK OTHER BENEFITS Long Term Effect Better Standard of Living Mid Term Effect Better Infrastructure and Amenities Immediate Effect Employment Generation NEW EMPLOYMENT OPPORTUNITIES Deployment of skilled and unskilled gradation; Regular source of income; Increased Wages to Labour; Increased Literacy Rate. Labour with skill Up BETTER INFRASTRUCTURE & LIVING CONDITION Enhancement in water supply facilities; Enhancement in Medical facilities. Improvement in Road Transport Facility. Enhancement in the value of Land. CONTRACT AND SUPPLY OPPORTUNITIES Income mobilization in the area; New Opportunities for service sector entrepreneurship; ALTERNATE MARKET CHANNEL FOR THE FARMERS •Stabilizethepricesof perishable commodities . •Helpinreducingthe“DistressSale”bytheproducers. •Reductionofintermediariesbydirect intervention withfarmers. IMPACT ON AGRICULTURE AND HORTICULTURE •Better price realization •Improvement in the quality produce. •Increase in demand of Agri & Horticulture produce. FRUIT & VEGATABLE BASED -Dehydrated Fruits, Pulps, Paste & Concentration, Juices & Beverages, Jam, Jelly, Candy, Sauce & Murabba, Fruit Extract & Aroma -Frozen Cut Vegetables, Dehydrated Vegetables, Pulp, Paste & Sauce, -Vegetable Extract & Aroma, Pickles, Heat ‘n’ Eat Packs, Chips & Wafers, Oils like Olive etc., Sauces, Chutneys, etc. CEREALS & GRAIN BASED -Flour, Pulses, Dalia, Ready to eat Extrude Foods, Papad, Pasta & Noodles, Breakfast Cereals like Cornflakes & Museli, Breads & Biscuits, High Protein Foods, Weaning Foods, Oils like Mustard etc. -Milk based, Ghee (ClarifiedButter), Paneer, Cheese, Butter, Khoya, Canned Sweetmeats, Ice-cream -Powdered and Herbal extracts -Amla Powder, Tulsi, Wheat Grass etc. -Herbal tea – Organic, Ginger, Masala etc. -Sugar cane based -Jaggery, Raab & Khand, Demurer Sugar, Crystal Sugar, Vinegar --others Rice Bran Oil, Rice Husk for Paper & Fuel, Spent Bran Cake as Cattle Feed. A HOLISTIC APPROACH by Grace of Swami Ram Dev ji FOR TOTAL AGRICULTURAL DEVELOPMENT… CONTINUED.. Phenol Solar Dying Bio-gas FAMILYEnergy Non Conventional Non Polluting Transport Animal Husbandry LOW COST SUSTAINABLE Village Level Processing DHANYAVAD !!!