McFarland.Mon.Lab2.M..

advertisement

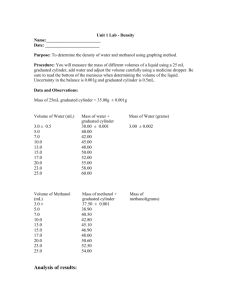

Date: September 22, 2010 To: Dr. Kline From: Ken McFarland Subject: CHEG 3810 Lab 2 Lab Overview This lab consisted of two parts. The first involved analyzing 4 different vapor liquid equilibriums using the IDEAL, NRTL, and UNIFAC property packages. This showed the differences that can result from changing the property package on a system. The second part involved creating a more complicated system that performed a number of unit operations on the product stream. Problem 1 For problem 1, a mixing point was created that created equal molar systems that were used to create T-x-y diagrams. There were four different systems to be created: Methanol – Water Ethanol – Water Chloroform – Tetrahydrofuran Ethanol – Toluene Three T-x-y diagrams had to be created for each of these 2 component systems, one using each of the three property packages listed above. These diagrams plot the liquid / vapor fractions by mole of a species in the system with respect to temperature. These can then be used to find the needed temperature for a desired phase fraction, or phase fraction for a given temperature. The 3 diagrams that were generated for the Methanol – Water system are included. Figure 1 shows the Vapor / Liquid equilibrium diagram generated using the IDEAL package. This uses the ideal gas law as the equation of state generating the data, which assumes no interaction between molecules of the gas. The next two figures, 2 and 3, show the same diagram generated using the NRTL and UNIFAC packages, respectively. These both use different equations of state or systems of equations to attempt to model the interactions between molecules as accurately as possible. Problem 2 The second problem required the addition of several more unit operations to the system that was created in problem 1. As in that problem, the Methanol – Water system was used. In order to set up the additional unit operations, a fourth T-x-y diagram had to be created, that was at 10 atm. This is attached as Figure 4. Due to the fact that gasses at 10 atm are not ideal, the UNIFAC package was used. This diagram was used to find the temperature 5 degrees below the saturation temperature for the .6 mol ratio methanol system, which was found to be 289°F. The mixture was compressed to 10 atm, with a power requirement of 1.24 kW. It was then heated to 289°F, bya heater with a heat duty of 500000 BTU/hr. This heated stream was then flashed back to 1 atm adiabatically. This resulted in two streams, T-Out, a vapor stream, and B-Out a liquid stream. The flow rates and composition of both of these streams are included in Table 1. As can be seen, the majority of the materials remain in the liquid stream with approximately 1/5 moles vaporizing in the flash. The final compositions of the flashed streams can be seen to correspond to Figure 3, the T-x-y diagram for 1 atm of pressure using the UNIFAC package, which was previously referenced. Lab Overview This lab allowed us to see the difference that can result from using just 2 of the many different properties packages that are available to use in Aspen. In problem 1 there are noticeable differences between the T-x-y charts made using the IDEAL equation of state, and the NRTL and UNIFAC equations of state. Problem 2 shows that at extreme temperatures and pressures, gasses behave in a very non-ideal manner, at which one of the packages that account for interactions between molecules of gasses must be used. Figure 1: T-x-y IDEAL for Methanol / Water system Figure 2: T-x-y NRTL for Methanol / Water system Figure 3: T-x-y UNIFAC for Methanol / Water system Figure 4: T-x-y UNIFAC for Methanol / Water system at 10 atm Table 1: Flow rates and Temperatures of T-Out and B-Out Mole Flow (lbmol/hr) B-OUT T-OUT METHANOL 43.36383 16.63617 WATER 36.01197 3.988032 Total Flow (lbmol/hr) 79.3758 20.6242 Temperature (F) 162.2001 162.2001