A Design Approch for Radiation-hard Digital Electronics

advertisement

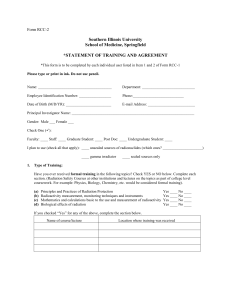

A Design Approach for Radiation-hard Digital Electronics Rajesh Garg Nikhil Jayakumar Sunil P Khatri Gwan Choi Department of Electrical and Computer Engineering, Texas A&M University, College Station, TX-77840 1 Outline Introduction Objective Previous Approaches Our Approach Results Conclusions 2 Introduction There has been significant interest in the radiation immunity of electronic circuits Historically mainly used for space and military electronics Higher levels of radiation in space and combat environments More recently, terrestrial electronics are also becoming vulnerable Shrinking feature size and supply voltages Reduced capacitances means less charge is required to flip node voltage This has led to a renewed interest in radiation tolerant circuit design 3 Introduction (contd.) Effects of radiation particle strike Neutron, proton and heavy cosmic ions Ions strike diffusion regions Deposit charge Results in a voltage spike What is Single Event Upset (SEU)? Interaction of a radiation particle with VLSI circuits can produce a charge deposition in critical regions of the circuit, leading to a bit reversal error, or single event upset. 4 Introduction (contd.) Charge deposited (Q) at a node is given by where: L is Linear Energy Transfer (MeV/cm2/mg) t is the depth of the collection volume (mm) Resulting current pulse is modeled as where: ta is the collection time constant tb is the ion track establishment constant 5 Objectives Radiation particles cause SEU Terrestrial electronics are also susceptible to SEU Therefore, need circuit level protection against SEU even for consumer electronics To make circuit radiation tolerant Delay and area overhead should be minimized 6 Previous Approaches Transistor sizing is done to improve the radiation tolerance of the design (Zhou et. al) Ensure that capacitance of any node is sufficient to make the circuit radiation tolerant. SEU event is detected using built in current sensor (BICS) (Gill et. al) Triple modulo redundancy based approach (Neumann et. al) Error correction codes (Gambles et. al) More detailed references can be found in the paper 7 Our Radiation Hardening Approach Part 1: Gate Level SEU protection Approach A: PN Junction Diode based SEU Clamping Circuits Approach B: Diode-connected Device based SEU Clamping Circuits Part 2: Logic Block Level Protection Radiation hardening for all gates Fixed depth protection Variable depth protection 8 Our Radiation Hardening Approach Approach A - PN Junction Diode based SEU Clamping Circuits V (out) Radiation Strike 1V in out G 0V D2 1.4V GP Shadow Gate 0.8 0.6 0.4 0.2 0 D1 V (outP) outP -0.4V time Higher VT device 0.8 0.6 0.4 0.2 0 -0.4 time 9 Our Radiation Hardening Approach Approach B - Diode-connected Device based SEU Clamping Circuits V (out) Radiation Strike 1V in 0.8 0.6 0.4 0.2 0 out G 0V D2 Ids 1.4V GP D1 V (outP) outP -0.4V time Higher VT device 0.8 0.6 0.4 0.2 0 -0.4 time 10 Our Radiation Hardening Approach Compared approaches A and B Performed layout and spice level simulation Approach A has higher area penalty than B But performance of approach A is slightly better than B Therefore, selected approach B 11 Simulating a Radiation Strike Circuit simulation is performed in SPICE 65nm BPTM model card is used VDD = 1V VTN = | VTP| = 0.22V The radiation strike was modeled as current source As commonly done in this field (Zhou et. al) Varied the value of Q and ta tb is chosen to be 5ps (Gill et. al) 12 Simulating a Radiation Strike Injected Current as a function of Q and ta 13 Protection Performance - Example Radiation strike at output node. Q = 4 fC ta = 10ps Approach B is used 14 Block Level Radiation Hardening Individual gate protection But our goal is to protect the entire logic circuit Approach B is selected Area overhead is more than 100% We call it as block level protection To understand block level protection Critical depth of a gate 15 Critical Depth of a Gate Consider 2 input AND gate Computed for each hardened cell Produces glitch Magnitude of Radiation glitch reduces Strike Glitch magnitude is 1 1 tolerable 1 1 1 Critical Depth =3 16 Critical Depth of a Gate Spice simulations were performed using Q = 5 fC, ta = 10ps, tb = 5ps Tolerable glitch magnitude is 0.35*VDD Gate Name Critical Depth (Δ) inv2AA 5 inv4AA 1 nand2AA 1 nand3AA 1 nand4AA 1 nor2AA 1 nor3AA 1 nor4AA 1 and2AA 2 and3AA 1 and4AA 1 or2AA 1 or3AA 1 or4AA 1 17 Block Level Radiation Hardening Simple approach – radiation hardening for all gates Very inefficient approach Large delay and area overhead Primary Primary Inputs Outputs 18 Block Level Radiation Hardening Better approach – Fixed depth protection Let Δmax= maxC(Δ(C)) Assume Δmax = 2 then Radiation Strike Radiation Strike Primary Primary Inputs Outputs 19 Block Level Radiation Hardening Further improvement – Variable depth protection Primary Primary Inputs Outputs 20 Variable Depth Protection Let Δ(INV2AA) = 4, Δ(NAND2AA) = 1 and Δ(AND2AA) = 2 Maximum depth of protection required is 4 8 Primary 3 6 9 Inputs 1 4 Primary Outputs 7 10 5 2 More details of the algorithm can be found in the paper 21 Experiments Used our approach on some benchmark circuits. Used SIS for synthesis and technology mapping. Circuits were mapped for both delay and area. Used the “sense” package in SIS to find circuit delays. sense reports the largest sensitizeable delay. To get accurate area estimates, circuits were placed and routed using SEDSM from Cadence. QPLACE for placement, WROUTE for routing 22 Delay Characteristics of the Cells Cell Regular (ps) Hardened (ps) % Ovh Critical Depth inv2AA 24.614 28.012 3.4 5 inv4AA 23.914 23.576 -0.34 1 nand2AA 31.416 34.993 3.58 1 nand3AA 44.92 48.39 3.47 1 nand4AA 62.436 66.259 3.82 1 nor2AA 45.617 49.902 4.29 1 nor3AA 77.151 82.786 5.64 1 nor4AA 92.80364 95.38472 2.58 1 and2AA 57.476 61.911 4.44 2 and3AA 76.902 82.722 5.82 1 and4AA 98.752 107.329 8.58 1 or2AA 71.161 74.678 3.52 1 or3AA 112.871 116.304 3.43 1 or4AA 125.165 128.543 3.38 1 AVG 3.97 23 Block Level Delay Results Delay Overhead Area Mapped Ckt. Regular Delay Mapped Hardened % Ovh Regular Hardened %Ovh alu2 1057.99 1068.913 1.03 959.113 976.987 1.86 alu4 1318.652 1357.851 2.97 1247.762 1259.695 0.96 C1355 887.619 920.186 3.67 711.149 720.345 1.29 C1908 1301.522 1349.072 3.65 1085.28 1093.79 0.78 C3540 1546.819 1625.472 5.08 1414.443 1424.782 0.73 C499 887.619 920.186 3.67 711.149 720.345 1.29 C880 1489.53 1643.51 10.34 1405.322 1554.847 10.64 dalu 1167.817 1252.608 7.26 1056.534 1077.134 1.95 frg2 825.852 912.605 10.5 792.849 836.477 5.5 i2 451.879 463.949 2.67 363.611 382.298 5.14 i3 172.865 184.777 6.89 172.865 184.777 6.89 C7552 2012.924 2100.094 4.33 2005.371 2070.491 3.25 i10 1997.302 2253.81 12.84 1931.211 2002.74 3.7 AVG 5.76 Delay overhead primarily due to increased capacitive load from hardended cells. 3.38 24 Block Level Area Results Area Overhead Area Mapped Delay Mapped Ckt. Regular Hardened % Ovh alu2 1045.88 1728.9 65.31 alu4 2019.6 2830.24 C1355 1592.01 C1908 C3540 Hardened %Ovh 1439.44 1728.9 20.11 40.14 2470.09 3343.15 35.35 2252.45 41.48 1728.9 2279.11 31.82 1569.74 2252.45 43.49 1799.46 2279.11 26.66 3136 4763.76 51.91 4022.1 5077.99 26.25 C499 1569.74 2265.76 44.34 1728.9 2279.11 31.82 C880 1045.88 1883.56 80.09 1397.26 2252.45 61.2 dalu 2470.09 3540.25 43.32 3310.85 3986.66 20.41 frg2 1994.52 4725.19 136.91 2611.21 4057.69 55.4 i2 686.61 745.29 8.55 872.61 948.64 8.71 i3 495.51 586.61 18.39 495.51 566.44 14.32 C7552 7032.5 12638.26 79.71 7953.07 9576.58 20.41 i10 6845.9 9604 40.28 7705.32 11291.18 46.53 AVG 53.37 Regular Area overhead is larger for circuits mapped for minimum area Area overhead is also large for circuits with smaller logic depth (such as frg2) 30.68 25 Conclusions, Future Work We have presented a novel circuit design approach for radiation hardened circuit design. We use shadow gates and protecting diode-connected devices to protect the primary gate from a radiation strike. We presented techniques to replace fewer gates to help minimize the area and delay penalties. Only 30% area penalty and 4% delay penalty on average for circuits mapped for minimum delay. In the future we hope to be able to incorporate radiation hardening in the technology mapping step itself. 26 Thank You!! 27 Our Radiation Hardening Approach Radiation strike at the output of the shadow gate Output is protected upto 0.4+0.6+0.35 V glitch Radiation Strike 1V in out G 0V D2 1.4V GP Shadow Gate V (out) outP -0.4V D1 0.8 0.6 0.4 0.2 0 time V (outP) 0.8 0.6 0.4 0.2 0 -0.4 time 28 Our Radiation Hardening Approach Radiation strike at the output of the shadow gate Radiation Strike 1V in out G 0V D2 1.4V GP Shadow Gate V (out) outP -0.4V D1 0.8 0.6 0.4 0.2 0 V (outP) time 0.8 0.6 0.4 0.2 0 -0.4 time 29