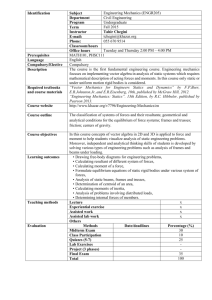

Chapter 1 Introducti..

advertisement

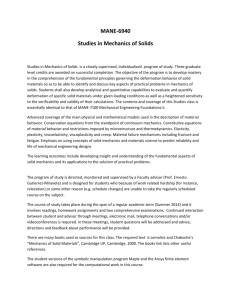

Chapter 1 Introduction Concept of Stress Road Map: Statics Mechanics of Materials Elasticity Plasticity Fracture Mechanics Fatigue Creep Mechanics of Materials is important foundation for: 1. Machine Design I & II 2. Advanced Mechanics Courses 3. Elasticity & Plasticity 4. Finite Element Methods Statics: main concern: Equilibrium Fx 0 Fy 0 M o 0 Mechanics of Materials: 1. Equilibrium Stress Strain 2. Deflection (Deformation) 3. Yielding or Failure Forces “Mechanics of Materials” is a branch of Mechanics that develops relationships between : The external Intensity of internal forces loads (stress / strain / deformation) 1.3 Stresses in the Members of a Structure P A (1.5) Assumptions: 1. Uniform distribution of stress 2. Uniform material properties Units: SI Units: English Units: (1.5) psi = lb/in2 ksi = 103 psi 1.5 Axial Loading: Normal Stress The normal stress: P average stress A The more general definition of normal stress is: F lim A0 A (1.6) (1.5) If the stress distribution is not uniform: dF dA External force internal force 1. In engineering practice we assume the stress is uniform This is only true: If the line of action of the concentrated loads P and P’ passes through the centroid of the section considered. 2. The distribution of the internal stress cannot be uniform if the load is eccentric. 1.6 Shearing Stress ave P A (1.7) ave 1.7 P F /2 F A A 2A Bearing Stress in Connections P P b A td (1.10) 1.9 Method of Problem Solution To solve a problem, use the following procedures: 1. Draw FBDs 2. Apply Equations of Equilibrium 3. Determine , , and deformation (deflections) 4. Check your answers. 1.10 Numerical Accuracy Accuracy Criteria: 1. the accuracy of the given data 2. the accuracy of the computations performed. For eng. practice, an accuracy of 0.2% is acceptable. 1. Use 4 important figures to record numbers with a “1” 2. Use 3 important figures in all other cases. Examples: A force of 40 lb. should be read 40.0 lb, and A force of 15 lb. should be read 15.00 lb. beginnings 1.11 Stress on an Oblique Plan under Axial Loading F P cos F A V P sin V A (1.13) (1.12) Since Ao = Acos, or A = Ao/cos The max normal stress occurs at = 0o The max shear stress occurs at = 45o At = 45o the normal stress is 1.12 Stress under General Loading Conditions: Components of Stress F x lim A 0 A Notation: Vxz xy lim A 0 V yx A xz Vzx lim A 0 A The plane is ┹ to x-axis The vector is // to z-direction (1.18) Notation: The surface is ┹ to x-axis xy The direction of the component: shear stress is // to y-direction All the forces in a system must fulfill the equation of equilibrium: Fx 0 Fy 0 M x ' 0 M y ' 0 Fz 0 Mz ' 0 (1.19) (1.20) Applying equation of equilibrium M z 0 xy yx yz zy (1.21) zx xz 1 (1.22) xy yx Therefore, only six components are required to uniquely define the stress state of a material. x , y , z , xy , yz , and zx . Max normal stress occurs at = 0o Max shear stress occurs at = 45o The cube at = 45o is subjected to the same magnitude of normal and shear stresses at all four sides 1.13 Design Considerations Concept of Factor of Safety: Factor of Safety = F.S. = ultimate load allowable load Factor of Safety = F.S. = ultimate stress allowable stress End D PD L PL PU ij Pij A