PETROLEUM ENGINEERING 405

advertisement

PETE 411

Well Drilling

Lesson 10

Drilling Hydraulics (cont’d)

1

10. Drilling Hydraulics (cont’d)

Effect of Buoyancy on Buckling

The Concept of Stability Force

Stability Analysis

Mass Balance

Energy Balance

Flow Through Nozzles

Hydraulic Horsepower

Hydraulic Impact Force

2

READ:

ADE, Ch. 4 to p. 135

HW #5:

ADE # 4.3, 4.4, 4.5, 4.6

due September 27, 2002

3

Fh

Buckling

of

Tubulars

Fh - Fb

l

Neutral Point

l

Slender pipe

suspended

in wellbore

Partially

buckled

slender

pipe

Neutral Point

Fb

4

Buckling of Tubulars

• Long slender columns, like DP,

l

Neutral

Point

have low resistance to

bending and tend to fail by

buckling if...

• Force at bottom (Fb) causes

neutral point to move up

• What is the effect of buoyancy

on buckling?

• What is NEUTRAL POINT?

Neutral

Point

Fb

5

What is NEUTRAL POINT?

• One definition of NEUTRAL

POINT is the point above

which there is no tendency

towards buckling

l

• Resistance to buckling is

indicated, in part, by:

Neutral

Point

The Moment of Inertia

Neutral

Point

I

d

64

4

n

d4

in

4

6

Consider the

following:

19.5 #/ft drillpipe

Depth = 10,000 ft.

Mud wt. = 15 #/gal.

DPHYD = 0.052 (MW) (Depth)

= 0.052 * 15 * 10,000

DPHYD = 7,800 psi

Axial tensile stress in pipe at bottom

= - 7,800 psi

What is the axial force at bottom?

7

What is the axial force at bottom?

Cross-sectional area of pipe

= (19.5 / 490) * (144/1) = 5.73 in2

Axial compressive force = pA

lbf

2

7,800

5

.

73

in

2

in

= 44,700 lbf.

Can this cause the pipe to buckle?

8

Axial Tension:

FT = W1 - F2

FT

FT = w x - P2 (AO - Ai )

At surface, FT = 19.5 * 10,000 - 7,800 (5.73)

= 195,000 - 44,694

= 150,306 lbf.

At bottom, FT = 19.5 * 0 - 7,800 (5.73)

= - 44,694 lbf

Same as before!

9

F2

Stability Force:

Ai

FS = Aipi - AO pO

FS = (Ai - AO) p

(if pi = pO)

At surface, FS = - 5.73 * 0 = 0

At bottom, FS = (-5.73) (7,800) = - 44,694 lbs

THE NEUTRAL POINT is where FS = FT

Therefore, Neutral point is at bottom!

PIPE WILL NOT BUCKLE!!

10

Compression

44,770

Tension

150,306

0

FS

FT

Zero Axial Stress

Neutral Point

Depth of Zero Axial Stress Point =

150,306

= 7,708

11 ft

19.5

Length

of

Drill

Collars

Neutral Point

Neutral Point

12

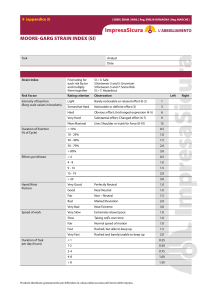

Length of Drill Collars

In Air:

In Liquid:

In Liquid

with S.F.:

(e.g., S.F =1.3)

LDC

FBIT

WDC

LDC

LDC

FBIT

f

WDC

1

s

lbf

lbf / ft

lbf

lbf / ft

FBIT * S.F.

f

WDC

1

s

13

State of stress in pipe at the neutral point?14

At the Neutral Point:

The axial stress is equal to the average

of the radial and tangential stresses.

r t

Z

2

15

Stability Force:

0

FT

FS

FT

FS = Ai Pi - Ao Po

If FS > axial tension then

the pipe may buckle.

If FS < axial tension then

the pipe will NOT buckle.

16

At the neutral point:

FS = axial load

To locate the neutral point:

Plot FS vs. depth on

“axial load (FT ) vs. depth plot”

The neutral point is located where the

lines intersect.

17

NOTE:

If pi = po = p,

then Fs =

or,

d

4

2

o

di

2

p

AS

Fs = - AS p

18

Axial Load with

FBIT = 68,000 lbf

19

Stability

Analysis with

FBIT = 68,00020 lbf

Nonstatic Well Conditions

FLUID FLOW

Physical Laws

Rheological Models

Equations of State

21

Physical Laws

Conservation of mass

Conservation of energy

Conservation of momentum

22

Rheological Models

Newtonian

Bingham Plastic

Power – Law

API Power-Law

23

Equations of State

Incompressible fluid

Slightly compressible fluid

Ideal gas

Real gas

24

Average Fluid Velocity

Pipe Flow

Annular Flow

q

v

2

2.448 d

q

v

2

2

2.448 d 2 d1

WHERE

v = average velocity, ft/s

q = flow rate, gal/min

d = internal diameter of pipe, in.

d2 = internal diameter of outer pipe or borehole, in.

d1 =external diameter of inner pipe, in.

25

26

Law of Conservation of Energy

States that as a fluid flows

from point 1 to point 2:

E 2 E1 p2V2

p1V1

1 2

2

g D2 D1

v 2 v1

2

W Q

In the wellbore, in many cases

{

Q = 0 (heat)

= constant27

In practical field units

this equation simplifies to:

p2 p1 0.052

D2 D1

8.074 *10 4 v22 v12 DPp Dp f

where

p1 and p2

v1 and v2

Dpp

Dpf

D1 and D2

are pressures in psi

is density in lbm/gal.

are velocities in ft/sec.

is pressure added by pump

between points 1 and 2 in psi

is frictional pressure loss in psi

are depths in ft.

28

Determine the pressure at the

bottom of the drill collars, if

Dp f 1,400 psi

400 gal/min.

12 lbm/gal.

D2

10,000 ft.

(bottom of drill collars)

D1

0

(mud pits)

q

IDDC 2.5 in.

Dp p 3,000 psi

29

Velocity in drill collars

q

v2

2

2.448 d

(gal/min)

2

(in )

400

v2

26 .14 ft/sec

2

2.448 * (2.5)

Velocity in mud pits, v1 0

30

p 2 p1 0.052 (D2 D1 )

8.074 * 10

-4

( v v ) DPp DPf

2

2

2

1

p 2 0 0.052 * 12 (10,000 - 0)

- 8.074 * 10 -4 * 12 (26.14 2 0 2 ) 3,000 1,400

0 6,240 6.6 3,000 1,400

Pressure at bottom of drill collars = 7,833 psig

NOTE: KE in collars

0

May be ignored in many cases31

p2 p1 0.052 ( D2 D1 )

8.074 *10

-4

(v v ) DPp DPf

2

2

2

1

32

Fluid Flow Through Nozzle

Assume:

D2 D1

DPp 0

v1

0

v 2 vn

DPf 0

4

p 2 p1 8.074 * 10 v

and

vn

2

n

Dp

4

8.074 * 10

33

If

DPf 0

Equation may be written as

vn c d

Dp

4

8.074 * 10

c d 0.95

This accounts for all the losses in the nozzle.

Example:

vn 0.95

1,000

305 ft/sec

4

8.074 * 10 * 12

34

35

For multiple nozzles in //

Vn is the same for each nozzle

even if the dn varies!

This follows since Dp is the same

across each nozzle.

vn c d

Dp

8.074 * 10 4

Δp bit

q

& vn

3.117 A t

8.311 * 10 -5 q2

2

d

C A

2

t

36

Hydraulic Horsepower

of pump putting out 400 gpm at 3,000 psi = ?

Power rate of doing work

F* s/t

Dp * A

q

A

PH qDp

In field units:

qDp

HHP

1714

400 * 3,000

700hp

1714

37

What is Hydraulic Impact Force

developed by bit?

Consider:

CD 0.95

q 400 gal/min

12 lb/gal

Δp n 1,169 psi

38

Impact = rate of change of momentum

q vn

Dmv m

Fj

Dv

Dt

32.17 * 60

Dt

CD 0.95

Fj 0.01823 c d q Dp

q 400 gal/min

12 lb/gal

Δp n 1,169 psi

Fj 0.01823 * 0.95 * 400 12 * 1,169 820 lbf

39