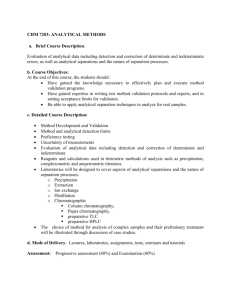

Validation

advertisement

Validation by Dr. Michael Scheutwinkel International Federation for Consulting GmbH IFC 1 • Governmental regulations • Books …. • Recommendations of associations 2 References EURACHEM Guide The Fitness for Purpose of Analytical Methods A Laboratory Guide to Method Validation and Related Topics (12/1998) www.eurachem.com CITAC / EURACHEM Guide Guide to Quality in Analytical Chemistry An Aid to Accreditation (2002) www.eurachem.com 3 4 Which chapter of ISO/IEC 17025 is dedicated to validation? 5 Do not ask me, I am only a simple guy from Alemania! 6 Definition in clause 5.4.5.1 of ISO/IEC 17025 Validation (ISO/IEC 17025) Validation is the confirmation by examination and the provision of objective evidence that the particular requirements for a specific intended use are fulfilled. ….fit for purpose 7 Validation of an analytical test method Validation is the process of establishing the • Performance characteristics • Limitations of a method • Identification of the influences which may change these characteristics and to what extent. Which analytes can be determined in which matrix in the presence of which interferences? Within these conditions what levels of precision and accuracy can be achieved? 8 Equipment and method valdiation Equipment validation DQ IQ Soft and hardware OQ PQ Method validation … different items 9 Validation in order to analytical method Standardized-methods Verification Modified standardized and in-house methods Validation 10 Verification of an analytical test method Verification is the process to demonstrate the competence in test performance of an already validated standardized test method. The tools are the same as for validation, the laboratory needs only to verify that the documented performance characteristics can be met (e.g. accuracy). 11 When should be validated? • Changes in established methods • New method developed for a particular problem • Established method used in different laboratories, different equipment or different staff • Out-of-control situations within internal quality assurance • Non-successful participation in PTs • Demonstration of equivalence between two methods (e.g. a rapid new test against a standard method) 12 Validation Strategy A Specific test requirements defined by customer or market B C D Characterization of the test method Comparison of method charcacteristics with requirements Verification to give proof that the requirements are fulfilled 13 Description of test method (clause 5.4.4) Identification / Scope Parameters in which matrix Reagents and materials, CRMs Equipment and environmental conditions Calibration Sampling and sample preparation Test performance including safety instructions Quality assurance Documentation , reporting evaluation criteria Uncertainty or procedure for its estimation 14 Please show us the way… 15 Tools Determination of method characteristics Characteristics of the range Characteristics of calibration Characteristics of accuracy Robustness / Ruggedness Selectivity or Specifity 16 Tools Determination of method characteristics Perform more point calibration Characteristics of calibration Linearity Sensitivity Correlation coefficient: r² > 0.99 ?? Linearity is defined by the correlation coefficient Sensitivity is defined by the slope of the calibration graph 17 Commission Decision 2002/657/EC 18 Validation of testing methods Calibration • Calibration values should be applied within the working range. • Lowest point should be the limit of quantification. • For calibration certified standard solutions shall be used. • In addition, also standard solutions have to be added to blank materials, analysed over all process steps. • For linear calibration functions at least five concentrations are necessary. • Test calibration functions for linearity and highlight failing linearity. 19 Validation of testing methods Sensitivity (resolution) What is sensitivity? It is the difference in an analytical concentration that corresponds to the smallest difference of a signal in a method which is still detectable. Sensitivity can be extracted from the calibration curve or defined by using samples with different concentrations. 20 Validation of testing methods Linearity Definition based on samples with varying concentrations and the calculation of the regression of results. Signal and concentration do not have to be fully related. Five standards suffice to produce a calibration curve if linearity is o.k. More standards are necessary once the linearity is unsatisfactory. Examine repeat samples and standards over a particular working range to experience whether a reliable line can be drawn between proof and detection limit. 21 Homogeneity of variances Characteristic values for the comparison of standard variations for differing concentration. In case of great differences between standard deviations (in-homogeneity of variances), the working range needs to be split. 22 Tools Determination of method characteristics Characteristics of calibration Characteristics of the range Limit of detection Limit of quantification Characteristics of accuracy Robustness / Ruggedness Selectivity or Specifity 23 Validation of testing methods Working range Finding out the appropriate working range using • different matrices • varying concentrations. Concentration range within the achievement of acceptable • accuracy and • precision is possible. In general the working range is broader than the linear range. 24 Validation of testing methods Prerequisites for calibration Standards must be faultless. Precision has to be similar throughout the entire working range. The model function is applicable: either linear or curved. Errors only may occur randomly within signals. Errors have to follow the normal distribution. 25 LOD Characteristics of the range Limit of detection LOD by calculation xLOD = 3 . sL / b (Blank value method) xLOD = 4 . sxo (Calibration function method) xLd = Limit of detection sL = Standard deviation of the blanks Sxo = Standard deviation of the calibration function b = Slope of calibration function Various conventions XLOD = Mean of blanks + 3 x SL 26 LOQ Characteristics of the range Limit of quantification LOQ by calculation xLOQ = 9 . sL/ b (Blank value method) xLOQ = 11 . sxo (Calibration function method) xLOQ = Limit of quantification sL = Standard deviation of the blanks Sxo = Standard deviation of the calibration function b = Slope of calibration function Various conventions XLOQ = 5 or 6 or 10 x SL 27 Commission Decision 2002/657/EC 28 LOD Characteristics of the range Limit of detection From 2 : 1 to 5 : 1 by signal to noise ratio Limit of quantification From 5 : 1 to 10 : 1 29 Effect of peak shape on LOD / LOQ 30 Tools Determination of method characteristics Characteristics of the range Characteristics of calibration Characteristics of accuracy Robustness or Ruggedness Selectivity or Specifity 31 Selectivity / Specifity Selectivity Specifity Extent to which particular analytes can be determined in complex mixtures. A method which is selective for an analyte is said to be specific. Selective detectors in instrumental analysis Use of antibodies Cross-reactions ? Selective media in microbiology 32 The difference between selectivity and specificity Selectivity • A selective method gives correct results for all interesting analytes whereas a specific test method gives correct results for the interesting analyte whereas other analytes might interfere each other. Specifity • Outlines the analytical extent to which an analytical substance or substance group can be determined without interference from sample related components. No problem, usually both words are mixed … 33 Validation of testing methods Selectivity • Outlines the extent to which an analytical substance can be determined without interference from other components. • Method selective to one analytical substance specific. • Assess selectivity while application to pure solution up to complex matrices. • Document disturbances and restrictions of the method. 34 Tools Determination of method characteristics Characteristics of the range Characteristics of calibration Characteristics of accuracy Robustness / Ruggedness Selectivity or Specifity 35 Validation of testing methods Robustness Degree of proneness of a method to conscious and unconscious alterations of a working instruction. • Part of the routine. • Learn from other analytical institutes, as the method-establishing laboratory will have proved robustness before publishing a new method. 36 Robustness Sensitivity degree of the test method against small deviations in experimental conditions. Examples: • Times within process steps • Environmental conditions (e.g. temperatures) • Minor process changes (e.g. pH, flow rates in HPLC) 37 Ruggedness, according to USP Ruggedness is the degree of reproducibility obtained under a variety of conditions, expressed as relative SD, e.g.: • • • • different analysts, different equipment, different trade marks of reagents, etc. Internal reproducibility 38 Tools Determination of method characteristics Characteristics of the range Characteristics of accuracy: Correctness Uncertainty Precision (Repeatability/ Recovery) Reproducibility Characteristics of calibration Robustness or Ruggedness Selectivity or Specifity 39 Accuracy = Precision and correctness I Accuracy Exactness of an analytical method Degree of repeatability of an analytical method Precision Repeatability Reproducibility Correctness / Trueness Systematic error / Correct value Uncertainty Recovery / Bias 40 Random and systematic deviations precise and correct not precise but correct precise but wrong not precise and wrong 41 Accuracy = Precision and correctness II Characteristics of accuracy Correctness Precision Measure of correctness, covering systematic and non-systematic mistakes (use of CRM, comparison to a well characterized method) Measure of the degree of repeatability, covering systematic mistakes Repeatability: one laboratory; Better: internal reproducibility Reproducibility: more than one laboratory 42 Validation of testing methods Repeatability Use at least one of the following procedures for determination: Measurement of reference materials. Fortification of a blank sample with the analytical substance. Comparison to a reference procedure. Participation in a co-operative (interlaboratory) test in which the “true content” is known. 43 Validation of testing methods Precision Information on accuracy of two coinciding and independent analytical results. Precision depends on the concentration of the analyte. Repeatability is part of the precision with respect to repeated measurements: – same material, – same method, – same analyst, – same laboratory and – short time-span in-between the analyses. 44 Validation of testing methods Correctness / Trueness Use the one of the following methods to assure correctness: • Analysis of certified reference material. • Participation in interlaboratory comparisons. • Comparison to a known procedure. If not available: • • • • Document any data that prove correctness. Make an approximation as a first approach to correctness. Purchase reference material. Use a similar method in parallel. 45 Validation of testing methods Recovery • Performed by addition of the analytical substance to the matrix. • A matrix shall be free of the analytical substance. • If not the sample will be enriched with a weak concentration of the analytical sample. • Or a simulated matrix will be used. • Recovery can be determined only when the analytical sample is available in pure form. • List the recovery rate (in %) and the standard deviation when recovery rates are constant. • Otherwise issue recovery rate as a function. 46 Validation of testing methods Frame conditions for the determination of the recovery rate The analytical substance needs to be added in that form in which it occurs in nature. The samples requires good homogenisation. The native content shall be below the determination limit. 47 Validation of testing methods Reproducibility internally Prove reproducibility externally Statistically Comparative standard deviation Replicate standard deviation Through participation in proficiency testing schemes or participation in interlaboratory comparisons. 48 Tools Determination of method characteristics Characteristics of calibration Linearity Sensitivity Robustness or Ruggedness Characteristics of the range Limit of detection Limit of quantification Selectivity or Specifity Characteristics of accuracy Correctness Uncertainty Precision (Repeatability/ Recovery) Reproducibility 49 Validation of testing methods Classification of the test method Distinguish between • Analysis of contaminants (e.g. pesticides, heavy metals, food additives) • Analysis of food constituents (salt and minerals) • Methods which are determining true values • Test methods which have to be calibrated with instruments • Physical measurement (pH value, conductivity) • Qualitative determinations • Microbiological methods 50 Validation of testing methods Parameters for validation Parameter Analysis of Analysis of Conventional Methods not Physical Qualitative Bacteriological trace constituents methods necessary to methods methods methods X X X X X contaminants Description of calibrate X X X X Calibration X X X Working range X X X X Detection limit X X X Determination X X test method X X X limit Recovery X X Repeatability X X Correctness X Specificity Reproducibility X X X X X X X X X X if possible if possible if possible if possible if possible X X X if possible if possible 51 Validation of testing methods Common validation needs of known methods Method Accuracy Precision Specificity/ Selectivity Linearity Detection/ Determination limits Robustness (X) X X X X X AAS, AES, ICP, RF X X Polarography/ Voltametry X X X X X X X X X X X X X Spectroscopy X X X X X Release X X X X X Titration Water assay X X Chromatography/ Capillary Electrophoresis TOC Enzyme Immuno Assays X X X X X X X X X X 52 Procedures for method validation The Analysis of Standard Reference Materials • Generally accepted method for validation. • Such standards are provided with guarantee on the market. • It may be necessary to contract the preparation of a unique sample in particular matrix in order to utilise this procedure for method validation. • The analyst must demonstrate that the method provides accuracy and precision. 53 Procedures for method validation The participation in PT-schemes or in a laboratory Collaborative Study The most widely accepted procedure for method validation. Serious practical draw backs: Costly and time consuming Effort in co-ordination Shipping of samples and data Statistical analysis and interpretation of results. This method is rarely used for the first description of a method in the literature. 54 Procedures for method validation Comparison with a currently accepted method • Usually done by one analyst • or two using a split-sample. • using results from the currently accepted method for verification. Agreement suggests validation. Disagreement could also suggest that the currently accepted method is invalid. • In such case, another procedure has to be employed for the method validation. • The more samples are analysed and the wider the range of concentration the higher the credibility of the validation method. 55 Procedures for method validation The Zero-Blind Method • One analyst. • Using samples at known levels of analyte to demonstrate recovery, accuracy and precision. • Fast, simple and useful but it leads to subjective results. • Suitable for a first approximation requiring minimal time, manpower, samples and cost. • In general, a good start for the overall validation process. If this methods fails there is no reason to proceed with further validation of the method. 56 Procedures for method validation The Single-Blind Method • One analyst at the start. • Samples are given to a 2nd analyst to whom levels of analyte are unknown. • Results are compiled and compared by the 1st analyst. • Comparison by the first analyst makes objectivity questionable. • This method still is biased on behalf of the 1st analyst. • Suitable after the zero-blind method has been successful and before additional analysts or the management will be involved. 57 Procedures for method validation The Double-Blind Method • Three analysts. • 1st analyst prepares samples at known levels. • 2nd analyst does the actual analysis. • 3rd analyst (or administrator) compares both data from the first two analysts. • Only the 3rd analyst has access to these data. Most effective approach to objectiveness 58 Validation of testing methods Clearance of validated test procedures Quality Manager Validation results Customer requirements 59 Validation of testing methods Decision criteria for the extent of a validation Technical feasibility and staff disposition? Analytical viewpoints Measuring principle, method complexity? facts Occurrence of the sample, wide-spread? Risk potential for client/ company? Political decisions Actual aim of the validation? super-ordinated criteria Consideration of normative and other requirements? 60 Validation of testing methods Extent of validation in analytical sciences Purpose • Suitability of the method • „Marketability“ of the method Analytical sensibility Costs Requirements from the outside 61 ISO/IEC 17025 states: Validation is always a balance between costs, risks and technical possibilities. The validation shall be completed by a statement by the laboratory that the method is fit for the intended use. 62 Validation is always a balance betwee costs, risks and technical possibilities. 63 Do not forget: Self developed software or excel sheets have to be validated. Records for that must be available. 64 Muito obrigado! 65 66 Bring them together …. 67 68 69 70 Trabajo en grupos ”Humedada en Alimentos” Fuente de incertidumbre Símbolo Valor ± [Unidades] Calibración de la balance uEst + 0.003 g Calibración de la estufa uPip 0% Tiempo uBurInd 0% Repetibilidad uRep + 0.1 % Distribución de probabilidad Divisor Tipo B / rect 3 Incertidumbre estándar [unidades] 0.7% 0.4% 3 Tipo B / rect Tipo B 3 0.1% 3 ucombinada = 3.43 % Uexpandida = 7 % 71 IfEP Workshop: Proficiency Testing - Background and general aspects Why proficiency testing? PT schemes are just one important tool in quality control and quality management. Participating in Proficiency Tests Use of certified reference material Validation of methods QM 72