Company Presentation - The Alliance for Green Heat

advertisement

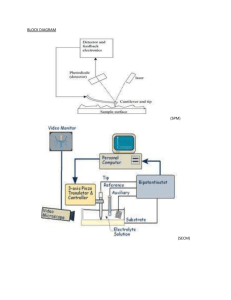

Peter Cullen, VP Sales, WUSA + COMPANY PROFILE „We are a family-run, technically oriented company with more than 80 years of experience. We operate on an international basis and employ more than 140 people. Our headquarters are based in Bad Wünnenberg, Germany, and we are the leading manufacturer of measuring, inspection and cleaning technology.“ 2 History 1932 1965 1978 Founding Wöhler A 66 Wilhelm Wöhler ran a registered brush making factory in Berlin Flue gas analyzer to determine CO2 content; the beginning of developing analyzers at Wöhler in Bad Wünnenberg Wöhler SM 78 – first Suspended Particulate Analyzer to determine the content of dust in flue gases resulting from household fires burning solid fuels 3 History 1986 1994 1995 1998 2001 Wöhler A 86 Wöhler DP 94 – the first electronic leakage detection device to examine exhaust ways Wöhler SK 95 – the flue camera opens the market for video inspection technology Wöhler E 98 – the world's first fully electronic flue gas analyzer for less than DM 800 Wöhler DC 2000 – first hand-held analyzer offering a measuring range of 1 : 200 000 Development of electronic flue gas analyzers begins 4 History 2005 2008 2010 2012 Wöhler VIS 220 Wöhler A 400 flue gas analyzer with heating check functionality and 4 Pa test Wöhler DC 430 – fully automatic leakage measurements Wöhler SM 500 At the time, the most favorably priced service camera on the market First TUV tested and approved suspended particulate analyzer on the market for measurements complying with the 1st German Federal Immission Control Act 5 Wöhler Group of Companies 6 Locations Deutschland Bad Wünnenberg Headquarters Sales and Service center Bochum West Sales and Service center Munich South Sales and Service center Field service staff 7 Locations Europe Hilversum Netherlands Pelhrimov Czech Republic Bolzano (Bozen) Italy Toulouse France St. Pölten Austria 8 Locations Asia/ North America Boston United States of America (U.S.A.) Shanghai China 9 Target group national 7% Construction 12% Industry 50% 31% Chimney Sweeps HVAC 10 Target group CHIMNEY SWEEPS HVAC INDUSTRY / CONSTRUCTION ... trust Wöhler, because Wöhler analyzers ... installers trust Wöhler, ...industrial/construction companies trust are easy to operate and provide the desired because precision and reliability Wöhler, because precision measurements information in a user-friendly format. top their list of priorities. provide an objective basis for factual assessments. 11 Top export countries according to turnover 7% 4% Netherlands Czech Republic 8% Austria 27% other countries 13% USA 19% 22% Italy France 12 + THE MEASURE OF TECHNOLOGY „In close cooperation with our customers we develop, produce and market inspection and cleaning technology that provide tailor-made solutions for heating, ventilation and building applications. “ 13 + DEVELOPMENT Our innovations set the standards the market follows. Our successful innovations are based on four rock-solid foundations: Our fascination with technology, all of our development engineers have a university degree, our many years of experience and we never stop talking with our customers. 14 + PRODUCTION Expert workmanship is required to implement innovative developments. The reason: Wöhler gives top priority to the reliability and high standards of quality of its products. Alone the precision and efficiency of working procedures during production ensure we are able to deliver "the measure of technology". 15 + CONSULTATION/SALES We offer customers planning investments all the support we can give based on our experience and technological know-how. Because development, production and marketing are all under the same roof at Wöhler we are able to call on a great deal of competence. This enables us to offer our customers the best possible solutions to support them during their work. 16 + SERVICE We focus on providing competent service, because professional equipment maintenance helps to safeguard customer investments. As the manufacturer Wöhler is able to offer absolutely reliable maintenance, inspection and calibration services at all times. 17 + FLUE GAS ANALYSIS Precision flue gas analyzers are indispensable to ensure compliance with statutory regulations and resolute environmental protection. Data processing functionality as well as interfaces to a PC and mobile terminal device support the user when evaluating and documenting measurement data. 18 + MEASURING PARTICULATE MATTER Innovative Wöhler products are causing a stir in the industry: Back in 2012 the Wöhler SM 500 was the first particulate matter analyzer to fulfill the more stringent requirements imposed by the first German Federal Immission Control Act (1. BImSchV) with regard to particulate matter limits. 19 + HEATING SYSTEMS Wöhler pressure measurement and leakage detection devices make it possible to reliably monitor systems critical to safety in accordance with (German) technical rules for gas installations; as a consequence, they help to detect and avert hazardous situations endangering the lives of residents. 20 + VENTILATION/BUILDING Objective assessments based on measurement results create transparency and provide a solid basis for making suggestions for improvements. Utilizing Wöhler measurement technology it is possible to set-up ventilation and air-conditioning systems to operate at the best-possible level of efficiency and to monitor their long-term performance. 21 + INSPECTION TECHNOLOGY When chimneys, waste water pipes, flue gas and ventilation systems or industrial facilities need inspecting video inspection systems from Wöhler keep you in the picture. High-quality technology, for example the pan&tilt color camera head, ensure you can see as clear as a bell even in the most inaccessible of places. 22 + CLEANING TECHNOLOGY We develop mechanical cleaning devices for tradespeople and industry to clean flue gas systems and ventilation lines. Cleaning heads made of different materials and strengths guarantee on-the-job satisfaction. 23 Quality- and environmental awareness CUSTOMER SATISFACTION ECO-PROFIT SERVICE-QUALITY At Wöhler we enjoy excellent Wöhler is a participant in the Beginning with the initial contact relationships with our project ECO-PROFIT run by the through to our after-sales customers. A fact confirmed by district of Paderborn with the customer care TUV NORD has TUV NORD. objective of pursuing ecological confirmed the quality of our and economical concepts. excellent service. 24 + WÖHLER INSTITUTE OF TECHNOLOGY As a manufacturer we are not only able to draw on many years of experience and offer high levels of expertise, we are always right up-todate with relevant laws and standards. At the Wöhler Institute of Technology we pass on our comprehensive knowledge to the customer. 25 + WÖHLER POWER PARTNER The idea behind the Wöhler Power Partner program is quite simple: We wish to support our market partners operating in the chimney sweep, sanitation, heating and climate control trades to the best of our ability as they go about their daily work. To achieve this objective, we have developed a well-thought through program to ensure our customers receive the best support possible. 26 + INNOVATIONS-FORUM Dialog with the customer forms the basis for planning, developing and optimizing our products. That´s why we not only take every available opportunity to talk with our customers, we also create the opportunities too: The innovations forum to be held in Fulda, from the 29-30th May 2015 not only offers customers unparalleled experiences, it also offers the place where essential knowledge is passed on. 27 + WÖHLER THE EMPLOYER We also strive for first class quality amongst ourselves. We wish to achieve the goals we set ourselves – and we do it by working in partnership with one another. A continuously increasing number of colleagues feel at ease at their place of work and in the Wöhler environment. 28 + LIVING & WORKING IN BAD WÜNNENBERG Bad Wünnenberg is a small, family-friendly town in the Paderborn region of Germany. Beautiful countryside offers an open invitation to relax. Nevertheless, with the university town of Paderborn just 20 minutes down the road it is possible to benefit from all of the advantages that a large town has to offer. 29 Welcome! Wohler SM 500 Suspended Particulate Matter (SPM) Analyzer WIT Product Training Seminar 30 Program Wohler SM 500 Suspended Particulate Matter Analyzer • Basics • Wöhler SM 500 • History Measurement Technology Features Advantages Accessories Measurement 15 min. test continuous measurement • Service and Maintenance • Final test 31 Basics Efforts to reduce greenhouse gas emissions and a significant rise in costs for fossil fuels lead to an increase of firing equipment for solid fuels (wood). Problem! Raise in Total Suspended Particulate Matter (SPM) Solution! Reduction and control of Total Suspended Particulate Matter (SPM) with new measurement Technology required with instant results and cost effectiveness 32 Basics German EPA Standard 2010 (1. BImSchV) • solid fuel appliances with output ≥ 4 kW (13,500 BTU/hr) requires annual emission measurement (except single room stoves) • SPM, dust 20 to 150 mg/m³ • CO 0.3 to 1.0 g/m³ • emission limits depending on fuel, size and date of construction • approx. 200,000 appliances to be measured annually, (exact amount currently under determination ) • further decrease of limits in 2015 33 Basics Link: http://www.umweltbundesamt.de/uba-info-pressee/2010/pe10016_small_firing_installations_ordinance_enters_into_force _on_22_march_2010.htm 34 Wöhler SM 500 Wohler SM 500 SPM Analyzer - EVEN THE FINEST CANNOT ESCAPE - 35 Dust Measurement Technology by Wöhler • since 1970 • since 2007 • TÜV (authorized governmental test house) tested and certified compliance with BImSchV requirements for Wöhler SM 500 Autumn 2011- Spring 2012: • Research and Development of an online measurement technology for SPM (Wöhler SM 500) December 2011 • Wohler SM 78 and Wohler SM 96 Suspended Particulate Matter (SPM) Analyzer Stress and field testing together with the Institute of Combustion and Power Plant Technology (IFK), Stuttgart, Germany August 2012 Start of serial production of the Wöhler SM 500, 36 Measurement Technology Wöhler SM 500 Flue gas analysis and suspended particulate matter (SPM) analysis (fine dust mass concentration) for firing equipment for solid fuels Measurement of: • SPM mass concentration • Oxygen level • Carbon monoxide 37 Design an Function 3 Wöhler SM 500 1. Particulate-matter-sampling-probe 4 2. Telescopic stand with clamps 3. Heated sample intake hose 4. Control unit housing the high precision digital mass scale unit 2 5. Flue gas condenser 5 6. Probe TA / Pd 7. Condensate trap module, O2 and CO gas sensors 6 1 7 38 Measurement Technology - Probe Heated system up to 167 °F • • Heated hose Heated mass scale modul heated hose heated digital mass scale modul probe 39 Measurement Technology – gravimetric analysis Wohler SM 500 SPM Analyzer • Measurement of fine dust mass concentration with the Wohler digital mass scale module High precision digital mass scale unit: • Gravimetric analysis • 0.0 mg/m³ to 1000.0 mg/m³ dust mass concentration in flue gas 40 Measurement Technology – Filter Cartridge Characteristics • Hydrophob material, temperature resistant up to 210 °F (100°C), chemically inert • Filter characteristics identical to standard filter technology used in VDI 2066 • Low tare weight combined with high filter capacity and low pressure drop 41 Accuracy – Test Results Accuracy test result (ifk) mg/m3SM Staubkonzentration (Prüflinge 500 3 test1,2,3) Dust mass concentrationin[mg/m³], samples 300 Reference 927,9 mg/m³ S1 S2 S3 1200 mg/m³ 1000 mg/m³ 1142 mg/m³ 275 250 225 200 175 150 125 100 75 50 25 0 0 25 50 75 100 125 150 175 200 225 250 275 300 Staubkonzentration in [mg/m³], mg/m3 Referenz Spülung Dust mass concentration referencemit system Quelle: Institution for Fire- and power plant engineering ifk 42 Advantages In field measurement with instant results Simple and user friendly design: • Adjustable display unit height • Measurement • Integrated O2- and CO- measurement • Full featured unit • Complete analysis and verification onsite including probe for stack temperature and draft Take readings and print report Realtime graphic function display • Simple and intuitive menu • Brilliant full color LED display • All readings on one screen 43 Advantages Data transfer • The Wohler SM 500 computer software package allows extensive data analysis and display. • Integrated USB port • IR port for onsite portable printer 44 Advantages Cost effective and transparent calibration procedure • Two significant measurements 1. Mass reading of scale module: Reference weight e.g. filter cartridge max. tolerance ±5% of reference weight carat scale (digital carat scale $150) 2. Flowrate: 3.0 SL/min or 4.5 SL/min max. tolerance ±5% of reference flowrate (e.g. gas utility meter) Gas utility meter 45 Summary Wohler SM 500 SPM Analyzer • Simple use • Ergonomic Design • Adjustable display unit height All in one unit • Switch ON - Measure – Take Readings - Verification - Done! SPM, Stack temperature, draft, O2 and CO measurement Maintenance friendly cleaning kit included 46 Break ! Wohler USA Inc. Danvers, MA www.wohlerusa.com Wohler Messgeräte Kehrgeräte GmbH Germany www.woehler.de 47 How I do a measurement with the Wöhler SM 500? Wohler SM 500 Suspended Particulate Matter (SPM) Analyzer WIT Product Training Seminar 48 Measurement procedure Preparation for field testing of firing equipment for solid fuels to comply with German EPA standard. • Water temperature: ≥ 60°C (140°F) • Start of measurement: 5 minutes after applying the maximum amount of fuel (see manufacturers handbook) • Presuppose: Basic firebed for ignition available Simultaneous measurement of - SPM - O2 - CO Source: 1.BImSchV Anlage 2 49 Pre-Test Checklist 1. 2. 3. 4. check all filter check if all hoses are connected check if the silica beads have a orange color connect the exhaust hose Measurement procedure 2 options to measure with the Wöhler SM 500 15 min. with SM 500 continuous measurement 15 min. test Wohler SM 500 52 using the Wöhler SM 500 turn on and let´s go OK / Start / Stop Scroll / Zoom ESC / Menü using the Wöhler SM 500 switch on, self-test immediately after it is switch on leak tightness test, seal the probe orifice using your thumb and then press the "OK" button selecting a threshold value to 60mg/m³ - lower pump load - longer measurement time and slower dust entrainment using the Wöhler SM 500 Online results over the whole measurement period numeric display graphic display 55 using the Wöhler SM 500 using the Wöhler SM 500 to switch to the numeric display of measurement readings from one of the graphic displays press the "Numer" button after the 15-minute measurement process has been completed Results display Measurement results Measurement results • mass concentration and all combustion values on one screen • automatically calculates of all results • immediate readings of measurement results Continuous measuremet PC Program Wohler SM 500 59 PC-Software - Application • transmit measurement data from the Wöhler SM 500 to a PC for evaluation • transmit data from a PC to the analyzer • process data in XML format to facilitate data exchange with external programs • recording logs and long-term measurements PC-Software Structure and functions on the main screen 1 2 3 45 6 7 8 9 10 1 Menu bar 2 Numerical representation of measurement values 3 Grafical representation of measurement values 4 Frequency 5 Hose temperature (TS) 6 Filter temperature (TF) 7 Flow 8 Absolute pressure 9 Name of log file when logging data 10 Serialnumber of SM 500 PC-Software - Start and Stop the measurement - measuring mode selection - Log, save the data - Info, Update information - Right-click mSt change the display from Total dust concentration to Momentary dust concentration ( which indicates changes to the dust concentration value in the last 30 seconds) - Measurement screen - Customers settings - Program settings - Right-click the measurement values TA and PD incorporate the values into the measurement results displayed in the Customer screen Customers Create a new customer Delete a new customer Save data aktive customer Settings - log file created automatically in CSV format - each time a measurement is carried out and saved to the path and location specified in this dialog box Data stored as company information is displayed in the report Test Sequence - Continuous Measurement 1. 2. 3. 4. Installing the Wöhler SM 500 PC software from the CD Start the Wöhler SM 500 PC-Program Connect Wöher SM 500 to the PC, using the USB calbe Switch on the Wöhler SM 500 USB connection Test Sequence - Continuous Measurement 5. start measurement switch on, self-test immediately after it is switch on leak tightness test, seal the probe orifice using your thumb and then press the "OK" button selecting a threshold value to 60mg/m³ - lower pump load - longer measurement time and slower dust entrainment Test Sequence - Continuous Measurement SIMULTANEOUS • Select measurement – continuous • Start • Log – select save location Measurement starts automatically 67 Test Sequence - Continuous Measurement 6. measurement mode Test Sequence - Continuous Measurement 7. stop measurement, click stop PC-Program Save the data under a customer and press cancel at SM 500 device 8. remove dust probe and start the tightness test for fresh air flush for 3 min 9. open your log – data under your selected log directory as CSV- file, open with f.ex. Word Exel Break ! Wohler USA Inc. Danvers, MA www.wohlerusa.com Wohler Messgeräte Kehrgeräte GmbH Germany www.woehler.de 70 How to maintain the Wöhler SM 500 Wohler SM 500 Suspended Particulate Matter (SPM) Analyzer WIT Product Training Seminar 71 Service and Maintenance Checklist After each measurement Check or replace filter cartridge Check and drain sample conditioner Check or replace cotton filters (humidity and deposits) After each day of use Cleaning of probe and digital mass scale modul After 50 measurements or once a month Check and clean the hose temperature sensor Semi annual Check and calibration according to German EPA 72 Service and Maintenance Checklist After each measurement Check or replace filter cartridge Check and drain sample conditioner Check condensators, replace cotton filters (humidity and deposits) and beads 73 Service and Maintenance Checklist After each day of use Cleaning of probe and digital mass scale modul 74 Service and Maintenance Checklist After 50 measurements or once a month Check and clean the hose temperature sensor, make sure that it is in the center, clean with acetone 75 Maintenance and inspection verification of the defining measurment values 76 validation of mass scale unit Equipment • • laboratory precision balance unused filter cartridge selecting the submenu "Mass„ – remove the unused filter Stabilization begins (around 3 minutes) weigh the filter cartridge on a laboratory precision balance, and write down the result Press "Next" when the mass drift progress bar is filled completely green to initiate the zeroing process Mass scale unit must be back in vertical position validation of mass scale unit When zeroing has been completed you are prompted to re-insert the filter cartridge – after zeroing! press “OK” When the lower progress bar is full after approx. 1minute, the graphic displaying the measurement readings is displayed Undo the screw cap, insert the weighed filter cartridge, and then screw the cap back on again It takes at least 2 minutes before the measurement reading can be read and compared with the target mass of the weighed filter cartridge. The maximum deviation from the target mass must not exceed ±5%. Online Test To apply for your certificate, please follow the link below and complete the online test Test: Wöhler SM 500 79 Break ! Wohler USA Inc. Danvers, MA www.wohlerusa.com Wohler Messgeräte Kehrgeräte GmbH Germany www.woehler.de 80