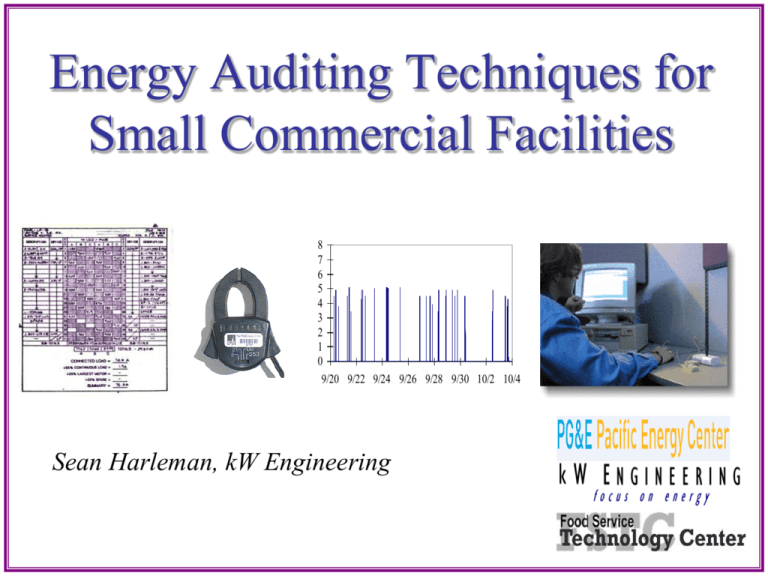

Energy Auditing Techniques for

Small Commercial Facilities

8

7

6

5

4

3

2

1

0

9/20 9/22 9/24 9/26 9/28 9/30 10/2 10/4

Sean Harleman, kW Engineering

HVAC Systems

Learning Objectives

•

•

•

•

•

Recognize common system types and controls

Understand economizers and outside air

Gather useful nameplate data

Provide recommendations for replacements

Do some simple energy savings calculations

Energy Auditing Techniques

Energy Auditor Role and Activities

Basic

• Inspect HVAC equipment

• Record nameplate information

• Review equipment operating schedules and controls

• Develop a list of energy efficiency measures (EEMs)

• Present EEMs, savings, incentives, and costs to the client

Advanced

• Above items plus:

• Log existing power use (status, amps, or kW)

• Log economizer operation (OAT, MAT, etc.)

Energy Auditing Techniques

HVAC Fundamentals

• Heating

– Offset heat that is lost to the environment

– Temper ventilation air

• Ventilating

– Provide fresh air to building occupants

• Air Conditioning (or Cooling)

–

–

–

–

Offset heat that gained from the environment

Offset heat generated internally

Control interior moisture (Relative Humidity)

Temper ventilation air

Energy Auditing Techniques

Why is HVAC Important?

CA Commercial Sector Electricity Use

California Commercial End Use Survey, Itron, CEC-400-2006-005.

Energy Auditing Techniques

Primary Purposes of HVAC

1. Comfort for occupants (ASHRAE 55)

– Temperature

– Humidity

– Air movement

2. Fresh air (ASHRAE 62.1 & T24)

– We need about 15 cfm per person (occupancy)

– Remove dust, pollutants, contaminants

& “bio-effluents”

Energy Auditing Techniques

Heat Sources, Sinks & Paths

• Envelope

– Solar

– Conduction

• Ventilation Air

– Required for IAQ

• Internal Loads

–

–

–

–

Lighting

Computers

Equipment

People

Energy Auditing Techniques

What is a HVAC Zone?

• A discreet physical area

that is conditioned by an

HVAC system

• Heat enters/leaves a zone

through Conduction,

Convection and Radiation

• Borders on zones are not

always clear, obvious, or

tangible

• Distinct zones in HVAC

system marked by

separate thermostats

Return

Air

Exhaust

Air

Outside

Air

Energy Auditing Techniques

COLD

HOT

Single Zone HVAC System

Return

Air

Exhaust

Air

Outside

Air

COLD

HOT

T

Energy Auditing Techniques

Primary Cooling Technologies

• Mechanical Cooling

– Unitary equipment uses a direct expansion (DX)

cooling coil

• accounts for ≈ 67% of all commercial and ≈ 90% of all

small commercial

• this will be our focus today

– Chilled water systems used in large buildings

en.wikipedia.org

Energy Auditing Techniques

Unitary HVAC Equipment

• Unitary refers to equipment where components are

matched and rated together. These components include

a compressor, condenser, evaporator and fan.

• Unitary equipment has two main classes: Packaged and

Split-System

– Packaged equipment houses all components in the same

enclosure

– Split-Systems have the compressor & condenser in one

enclosure and the evaporator and fan in another, connected by

refrigeration tubing

• Units can be cooling only or cooling with heating

• All units circulate air, most provide ventilation

Energy Auditing Techniques

Unitary Equipment Identification

• Packaged Unit

– All components contained in one location

– Ventilation is introduced through the unit

– Heating is supplied by a gas furnace, heat pump,

electric resistance or a hot water coil

http://www.carrier.com

Energy Auditing Techniques

Packaged Unit Components

Economizer

EA

OA

Cooling

Coils

SA

Filter

Condenser

Fan and

Coils

Heating

Supply Fan Coils

RA

Controls

T

Thermostat

Compressor

Packaged Unit

Energy Auditing Techniques

Building

Packaged With Horizontal Discharge

http://www.carrier.com

Energy Auditing Techniques

Packaged With Vertical Discharge

http://www.carrier.com

http://www.carrier.com

Energy Auditing Techniques

Unitary Equipment Identification

• Split-System

– Compressor Component Only

– No Ventilation provided by unit

– Only heating is heat pump

http://air-condition-units.com

Energy Auditing Techniques

Split-System

www.carrier.com

Energy Auditing Techniques

Split-System Examples

www.geo4va.vt.edu/A3/A3.htm

Energy Auditing Techniques

Split-System Examples

www.amvair.com/typesofac.html

www.letricharddoit.com/products.htm

Energy Auditing Techniques

Unclear on the concept

Energy Auditing Techniques

Primary Cooling Technologies

• Mechanical cooling (e.g. DX) energy use can be

reduced through the use of economizers and

evaporative cooling

• HVAC equipment is sized for design day loads,

but operates the majority of the time under part

load (~30-50% average is typical)

Energy Auditing Techniques

Economizers

• The economizer cycle refers to using controls and

dampers to make use of outside air for “free” cooling

when it makes sense

• Controls used to bring in outside air instead of return

air

• An “economizer” is generally not a single piece of

equipment, although people may refer to it as such

Return

Air

Exhaust

Air

Outside

Air

Energy Auditing Techniques

COLD

HOT

Economizer Offsetting All Cooling

Return Air

10,000 CFM, 75 deg F

Exhaust Air

8,000 CFM

2,000 CFM

Cooling Heating

Coil

Coil

Outside Air

8,000 CFM,

50 deg F

Discharge Air

10,000 CFM,

55 deg F

Mixed Air

10,000 CFM,

55 deg F

Energy Auditing Techniques

Reduced Mechanical Cooling

Return Air

10,000 CFM, 75 deg F

Exhaust Air

10,000 CFM

0 CFM

Cooling Heating

Coil

Coil

Outside Air

10,000 CFM,

60 deg F

Discharge Air

10,000 CFM,

55 deg F

Mixed Air

10,000 CFM,

60 deg F

Energy Auditing Techniques

Air Side Economizer

• Easy to show it’s not working, harder to show that it is

working

• Spot checks not conclusive; must trend data over time

– Is the economizer bringing in 100% outside air when

appropriate?

– Is the system always providing minimum ventilation air?

Energy Auditing Techniques

Economizer Expected Performance

Expected Economizer Operation

80

Minimum outside air

75

Outside Air Temperature

65

Return Air Temperature

60

55

Mixed Air Temperature

Supply Air Temperature

100% Outside air

50

45

40

Mixed return and outside air

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Temperature

70

Noon

Midnight

Time

Energy Auditing Techniques

Economizer Expected Performance

• Data taken from a

study in Southern

California

Average Compressor Loading

100%

90%

80%

Desert

• Building type is

Small Office

• Percent Loaded is

calculated as

Compressor Run

Hours / by Total

Cooling Hours

Percent Loaded

70%

60%

Inland Valley

50%

40%

Inland

30%

Coastal

20%

10%

0%

Energy Auditing Techniques

Climate

Economizer

No Economizer

Economizers: Implementation

• Assess economizer operation by observing damper

positions for various ambient conditions

• Use temperature data loggers to better estimate

economizer performance

• Consider add-on economizer kits for existing units

with failed economizers

• Check for adequate relief for outside air

Energy Auditing Techniques

Evaporative Cooling

• Cools air via evaporation of

water

• Direct evaporative coolers draw

air through evaporative media

lowering the temperature and

increasing humidity

• Indirect evaporative coolers use

a heat exchanger to reduce the

air temperature without

increasing humidity; less

effective

Energy Auditing Techniques

www.muntersamerica.com/

Direct Evaporative Cooling

www.wikipedia.com

This image has been (or is hereby) released into the public domain by its creator, Buster2058. This applies worldwide.

Energy Auditing Techniques

Evaporative Cooling: Implementation

• Best when high percentage of outside

air is required

• Supply air temperature limited by

ambient conditions

• Direct evaporative cooling is best

suited for areas where high humidity

won’t cause problems

• Indirect evaporative cooling can be

used when humidity needs to be

controlled or mechanical cooling will

also be used

Direct Evaporative Cooler

www.muntersamerica.com/

Energy Auditing Techniques

Primary Heating Technologies

• Gas Furnaces are the most common source for heat in small

commercial applications

– Range of efficiencies available

– Forced & Induced draft

• Electric Heat Pumps provide both heating and cooling

– Air source

– Water Source

– Ground Coupled

highperformancehvac.com

• Electric Resistance Heat Strips can be convenient if natural gas is

limited or combustion exhaust is an issue, but Heat pumps are

more energy efficient

• Hot water or Steam coils can also be used, but are generally found

in larger systems or systems with many zones

Energy Auditing Techniques

Air Source Heat Pump

Utilizes same vapor compression refrigeration cycle, only

now the condenser can be used to add heat to the space

Energy Auditing Techniques

Air Source Heat Pump

oee.nrcan.gc.ca/publications/infosource/pub/h.

..

Energy Auditing Techniques

Air Source Heat Pump

oee.nrcan.gc.ca/publications/infosource/pub/h.

..

Energy Auditing Techniques

Air Source Heat Pump

• Use air as heat sink

• Therefore:

Efficiency depends on air temperatures (minimum outside

operating temperature is ~ 17 °F)

• Typically smaller systems / single zone

• Best applicability: mild climates

• SEERs range from 8 to 16

• Title 20 Sets minimum

standards by size

• Also:

www.fmcs.coop/.../electrical_heat/air_source.htm

– Water Source

– Ground Coupled

Energy Auditing Techniques

Field Identification of HVAC Zones

• Ask facility staff/engineer

• Review as-built mechanical

drawings

• Inventory the number of

thermostats and HVAC units

• Observe placement of units to

thermostats

• Last resort: go after hours and

observe response to changed

setpoints

Energy Auditing Techniques

Unitary HVAC Nameplate

•

•

•

•

Brand/Model #

Age

Voltage/Amperage/kW

Other information:

–

–

–

–

–

–

Rated efficiency

Heating/cooling capacity

Air flow rate

Liquid flow rate

Pressure rise

Refrigerant

Energy Auditing Techniques

It’s not always easy to get the size

Energy Auditing Techniques

It’s not always easy to get the size

Energy Auditing Techniques

Reinforcement Activity

• HVAC system exercise…

Energy Auditing Techniques

Energy Efficiency Opportunities

• Retrofits

– High Efficiency Units

– Evaporative Cooling

• Controls

– Scheduling / reduce operating

hours

– Programmable thermostats

– Economizer operation

– Demand control ventilation

• Operations

– Reduce cooling loads

– Keep units maintained

Energy Auditing Techniques

www.carrier.com

High Efficiency Replacements

• Package unit replacement isn’t generally cost

effective on energy savings alone

• So where are the opportunities?

– Older units

– Early retirement

– New additions

• How do we promote it?

– Comfort

– Reliability

– Reduced O&M Costs

www.trane.com

Energy Auditing Techniques

What to specify: Unitary AC and HP

• For larger units, use

Consortium for Energy

Efficiency (CEE) guidelines

(www.cee1.org)

• Specify Tier 1 or 2

Efficiency level

www.trane.com

Energy Auditing Techniques

What to specify: Unitary AC

© 2009 Consortium for Energy Efficiency, Inc. All rights reserved. www.cee1.org

Energy Auditing Techniques

What to specify: Heat pumps

© 2009 Consortium for Energy Efficiency, Inc. All rights reserved. www.cee1.org

Energy Auditing Techniques

Unitary HVAC: Calculations

• Average Demand

– kW = (Cooling CapacitykBtu/h) / (SEER)

• Annual Energy Use

– kWh/yr = (kW) * (hours per year)

Energy Auditing Techniques

Evaporative Pre-cooling

• Lower head

pressure by precooling condenser

air by direct

evaporation

• New units use

microprocessor

controls to minimize

excess water

• Water off for

outside air temps

less than 70°F

• Evaporative pre-cooling is

available as add-on kit to fit

many unitary systems

Energy Auditing Techniques

Evaporative Pre-cooler Details

Energy Auditing Techniques

Evaporative Pre-cooler Details

Energy Auditing Techniques

Evaporative Pre-Cooling

Dining Unit 1 Evaporative Condenser Performance

85

Temperature exiting media (F)

80

75

70

65

60

55

55

60

65

70

75

80

Temperature entering media (F)

Energy Auditing Techniques

85

90

95

100

Evaporative Pre-cooler

Energy Auditing Techniques

Control Measures

• On/off

• Setbacks

• Demand Control Ventilation

Energy Auditing Techniques

The Opportunity: Controls

General Concepts

• Controls are generally the most cost

effective of EEMs

• Whatever doesn’t have controls

probably needs it

• Controls reduce opportunity for

human “enhancements”

• Limit hours of operation

• Use to maximize system

efficiencies

Energy Auditing Techniques

Scheduling

• Mechanical Time Clocks

http://www.moonlightinglls.com/

Energy Auditing Techniques

Commissioning is key

Even with simple equipment

Energy Auditing Techniques

Setbacks and Programmable Thermostats

• Install Programmable

Thermostats on all units

• Scroll through settings

during audit

www.white-rodgers.com

Energy Auditing Techniques

Where there’s a will…

Energy Auditing Techniques

Setback Thermostats / Scheduling

• Pitfalls

– Need to be set correctly, not in “hold”

mode

– Persistence: document with a system

manual how things are intended to work

• Savings

– Range widely depending on occupancy

and use. Typical is 5% to 50%.

– Demand savings are minimal

• Non-Energy Benefits

– Reduced wear on equipment

Energy Auditing Techniques

www.white-rodgers.com

Web-enabled Thermostats

• Web-based now

available

• About $170 to $300

each

• Include ability to

monitor remotely

www.proliphixstore.com

Energy Auditing Techniques

For Classroom Control

• Occupancy-based HVAC

controls e.g. Bard CS2000

Energy Monitor

• “Learns” occupancy patterns

• No programming required

• Can control lighting too

• Outside air off when unoccupied

www.proliphixstore.com

www.doersales.com

Energy Auditing Techniques

Demand Control Ventilation (DCV)

• Primary purpose of HVAC is to provide

adequate ventilation

• Basic method has been to provide

sufficient ventilation for design

conditions at all times

• DCV provides sufficient ventilation

based on actual occupancy, rather than

worst case

• Requires continuous monitoring of CO2

as proxy for occupancy

Energy Auditing Techniques

DCV: CO2 and Ventilation Rates

Energy Auditing Techniques

DCV: Implementation

• All major controls companies support

• Best practice is to measure outside air and indoor air CO2

concentrations

• If only indoor concentrations monitored, typical outside CO2

concentration is 400 ppm

• Controls typically set to introduce OA when indoor concentration

is about 500 ppm higher than outside (T-24 requires 600 or better)

• DCV should be overridden when system in economizer mode

• Commission to ensure ventilation rates are not compromised

• Select equipment that automates building purge for overnight

buildup of contaminants

Return

Air

Exhaust

Air

Outside

Air

Energy Auditing Techniques

COLD

HOT

Load Shifting for Small Commercial

• “Ice Bear” makes ice at

night for use the next day

• Thermal Energy Storage

• Capacity = 5 tons

• Storage = 30 tonhrs

• Primary savings are in

cost of energy due to load

shifting

• Peak kW cost savings

• May have small energy

savings too, depending…

Energy Auditing Techniques

www.ice-energy.com

Ice Bear Installations

www.ice-energy.com

Energy Auditing Techniques

Ice Bear Performance

www.ice-energy.com

Energy Auditing Techniques

Operations and Maintenance

•

•

•

•

Commissioning: check set points, schedules and resets

Check for controls overrides (e.g. bypassed time-clocks)

Filter changes for IAQ

Check fixed damper and minimum damper positions

• Adjust/tighten/replace belts

• Lubricate rotary equipment

Energy Auditing Techniques

Operations and Maintenance (cont.)

•

•

•

•

•

Clean condenser coils

Clean evaporator coils

Insulate suction lines

Check refrigerant charge

Check thermostat/sensor

calibration

• Insulate/seal ductwork

Energy Auditing Techniques

O&M horrors from HVACfun.com

Energy Auditing Techniques

www.energy.ca.gov/pier

PIER Buildings Program Design Guide: Big Savings on Small HVAC Systems

Small HVAC: Frequent Issues

Energy Auditing Techniques

Reinforcement Activity

• HVAC calculation system exercise…

Energy Auditing Techniques

Key Points to Remember

• Economizers fail frequently and make a big difference in

CA climates

• HVAC units are sized for design-day conditions, but

typically operate at 40-50% load

• Calculating unitary HVAC annual energy use:

Energy (kWh/yr ) = [Capacity (kBtu/h) *hours (hr)] / SEER

• Evaporative pre-cooling can yield big savings in dry

climates

• Record the entire model number from HVAC units

• DCV provides savings for building with variable

occupancies

Energy Auditing Techniques

References and Resources

• PG&E http://www.pge.com/mybusiness/

• Database for Energy Efficiency Resources

http://www.deeresources.com

• CEC Guide to Preparing Feasibility Studies for Energy Efficiency

Projects www.energy.ca.gov/efficiency

• Consortium for Energy Efficiency(guidelines for specifying EERs

& rough costs/savings) www.cee1.org

• Energy Design Resources www.energydesignresources.com

• Washington State University (calculators & other resources)

www.energyexperts.org

Energy Auditing Techniques

Course Tracker

Please take a moment to fill out your

Course Tracker excel sheet.

Energy Auditing Techniques

What is that?

1. Split - condenser

2. Packaged unit

3. Exhaust fan

4. Split - evaporator

A.

C.

Exhaust fan

Split - evaporator

B.

Packaged Unit

D.

Split - condenser

Energy Auditing Techniques

Model number: DPS-007-AHCY3

1. Cooling capacity: 7.5 tons

3. Line voltage: 230

2. EER: High? Need more info 4. Heating type: None

Energy Auditing Techniques

Appendix

Energy Auditing Techniques

VFD’s for Fans

• Many systems use variable flow

air distribution

• Fan power laws dictate that

power is roughly proportional to

the flow rate cubed

• VFD quality/reliability have

improved greatly over time

• VFD costs have dropped

significantly with wider adoption

• Now required by code for many

applications in new construction

Energy Auditing Techniques

www.abb.com

Why Fans with VFD’s Save Energy

VFD

100%

Power

80%

60%

40%

20%

0%

0%

20%

40%

60%

80%

100%

Flow

This relationships between fan energy and fan flow are taken from the California Energy Commission Guide to

Preparing Feasibility Studies and the 1998 Nonresidential ACM Approval Manual. Note that a typical system curve,

DOE2 default, is assumed and these relationships are not applicable to all systems.

Energy Auditing Techniques

A Note on IPLV

• IPLV is being replaced by IEER

– Integrated Energy Efficiency Ratio (IEER)

– IEER Used for unitary equipment ≥ 65 kBtu/h

– AHRI is dropping use of IPLV because it did not

accurately represent efficiencies for units with multistage compressors

– AHRI Standard 340/360 2007 defines IEER as "a

single number figure of merit expressing cooling partload EER…”

– Incorporated by addendum into ASHRAE 90.1 2007

– Not yet adopted by CEE, but soon

Energy Auditing Techniques

A Note on IPLV

• Source: http://www.cee1.org/com/hecac/Prog_Guidance_IEER.pdf

Energy Auditing Techniques

DCV Savings

www.energy.ca.gov/pier

PIER Buildings Program Design Guide: Commercial Buildings Breathe Right with Demand-Controlled Ventilation

Energy Auditing Techniques

DCV Savings

Case studies

show real

energy savings

with payback

periods of 2

years or less

www.energy.ca.gov/pier

PIER Buildings Program Design Guide: Commercial Buildings Breathe Right with Demand-Controlled Ventilation

Energy Auditing Techniques

Water-source Heat Pumps

•

•

•

•

•

•

•

•

•

AKA “California Heat Pump” system

Uses water loop as heat sink

Requires supplemental heat rejection/supply

Cooling mode: rejects heat water loop

Heating mode: absorbs heat from water loop

Efficiency depends water loop temperatures

Typically mid-sized commercial systems / multiple zone

Best applicability: mild climates

Title 20 Sets minimum

standards by size

McQuay Water Source Heat Pump Design Manual, C:330-1

Energy Auditing Techniques

McQuay Water Source Heat Pump Design Manual, C:330-1

Water-source Heat Pump Configuration

Energy Auditing Techniques

Equipment Efficiencies

• Efficiency: Ratios developed to represent equipment

ability to transfer or generate heat relative to the input

energy required by that equipment

• COP - Coefficient of Performance (unit less)

What you get divided by what you pay for (in same units)

• EER - Energy Efficiency Ratio (BTU/Watt-hrs)

Fully loaded unit output / electrical input

• SEER - Seasonal Energy Efficiency Ratio (BTU/Watt-hrs)

Average output over a range of conditions / Electrical

input

• IPLV - Integrated Part Load Value (units vary)

Weighted average at four part load conditions

• HSPF - Heating Seasonal Performance Factor

(BTU/Watt-hrs) Similar to SEER (same units) but for Heat

Pump heating

• AFUE - Annual Fuel Utilization Efficiency (%)

Efficiency of gas furnaces and small boilers measured as

the useful energy output divided by the input

Energy Auditing Techniques

Equipment Efficiencies

Equipment Type

Single Point Efficiency

Multi-Point or

"Seasonal" Efficiency

Chiller

Packaged AC

Furnace

Boiler

Heat Pump

kW/Ton

COP / EER

Thermal Efficiency

Combustion Efficiency

COP / EER

IPLV

SEER / IPLV

AFUE

AFUE (<300kBTUh)

HSPF

Energy Auditing Techniques

Units

• Energy

– Btu = Raises the temperature of 1 pound of

water 1 degree Fahrenheit under standard

conditions

– Watt-Hour = 3.413 Btu

– kilowatt-hr = 1000 Watt-hours = 1 kWh

– 100,000 Btu = 100 kBTU = 1 therm

• Rates (units of energy per time)

– Watt = 3.413 Btu/h (Btu’s per hour)

– kilowatt = 1000 Watts = 1 kW

Energy Auditing Techniques

Handy Equations

• Motor Draw

– kWh = (hp)(0.746 kW/hp)(%Loaded)(hours)/Efficiency

– kWh = (FLA)(Volts)(PF)(%Loaded)(hours)(Phase^½)

• Conduction

– Btu/h = (U-Value)(Area in sq ft)(Toutside-Tinside)

– Surface heat gain/loss due to Convection & Radiation

• Ventilation / Infiltration

– Btu/h = (1.085)(CFM)(Toutside-Tinside)

• Radiation

– Btu/h = Assess qualitatively

Energy Auditing Techniques

More Handy Equations

• Efficiency Conversions

– kW/ton = 12 / EER

– COP = EER / 3.412

– COP = 3.516 / (kW/ton)

• Heat Transfer in Water

– Capacity (kBTUh) = GPM * ΔT / 2

• Power from hp

– Power (kW) = 0.746 * Power (hp)

• Pump power

–

–

–

–

Water Power (hp) = (ft of head) * (GPM) / 3960

Pump Power = Water Power / [Pump eff * Motor eff]

Fan power

Fan Power (hp) = (cfm)*(SP) / [6354*ήfan* ήmotor]

Energy Auditing Techniques

Estimating Savings – Billing Data

• Estimate amount of bill dedicated to air

conditioning

• Estimate the average efficiency of the existing

equipment - SEER

• Select new efficiency based on available

equipment

• Estimate savings as:

SEERExist

NewBill OldBill

SEERproposed

SEERExist

or Savings OldBill 1

SEERproposed

Energy Auditing Techniques

Estimating Savings

• Simplified Full

Load Hour

Calculation

• Bin Simulation

• SPC Software

– PGE.COM/SPC

– Order CD

Single Zone Simulation (Constant Volume)

Supply Air

Flow rate

(CFM)

Fan kW

3

Supply Air

Average

Space

Temp (F)

Avg RAT

(F)

72

Bin Midpoint

10.00

OSA LO (F)

0

107.5

102.5

97.5

92.5

87.5

82.5

77.5

72.5

67.5

62.5

57.5

52.5

47.5

42.5

37.5

32.5

27.5

22.5

4

10

38

74

114

163

219

263

318

436

558

483

330

226

105

38

8

1

TOTAL

3,388

450

Balance

Temp (F)

60

Hours/yr

COOLING

HEATING

VENTILATION

3,000

74

EER

Cooling

Minimum Minimum

OSA

OSA

% OSA

15%

Minimum

Supply Air

Flow

100%

N

32

Efficiency

Heating

15%

15%

15%

15%

15%

15%

15%

15%

15%

15%

15%

15%

15%

15%

15%

15%

15%

15%

79

78

78

77

76

75

75

74

73

72

72

71

70

69

69

68

67

66

3,846 kWh

366 Therms

10,163 kWh

Energy Auditing Techniques

55

Design Htg Design Clg Temp

Temp (F)

(F)

Econ

MAT (F)

Design SAT

SAT (F)

55

55

57

59

61

63

65

67

69

71

73

75

77

79

81

83

85

87

80%

Heating

(kBtu/yr)

102

OSA LO (F)

120

Cooling

(kBtu/yr)

0

0

0

0

0

0

0

0

0

0

1,807

6,264

7,478

7,310

4,082

1,836

469

49

278

759

2,576

4,338

5,546

6,353

7,093

5,976

4,125

1,412

0

0

0

0

0

0

0

0

29,295

38,456

Est Min

SAT (F)

55

Estimated

Max Zone

Load

100%

Example Calculation: The Problem

•

•

•

•

•

Existing 5 ton air conditioner is on 24/7

Site is Sunnyvale, CA

EER is 10.0

Furnace is 80% efficient

Office environment with fan in “on” position

(i.e. not “auto”)

• Propose to schedule M-F, 7 AM to 6 PM

Energy Auditing Techniques

Here’s the nameplate

Energy Auditing Techniques

Example Calculation: Scheduling RTUs

•

•

Energy Savings from scheduling RTUs off

consist primarily of two parts:

1. Reduced fan energy savings

2. Reduced ventilation loads

No simple way to take credit for transient effects

Energy Auditing Techniques

Example Calculation: Part 1 Fan Savings

• Fan draw:

– 208V * (1 phase)^½ * 5.7A * (0.9 PF) = 1.07 kW

• Hours reduced:

– Was 24*365 = 8760 hrs/yr

– Now 11 hrs per day * 365 days * 5/7 ≈ 2868 hrs/yr

– Savings: 5892 hrs/yr

• Savings = 1.07 kW * 5892 hrs = 6304 kWh

• Assuming $0.15/kWh → $945.60

Energy Auditing Techniques

Example Calc: Part 2 Ventilation Savings

• Use Sunnyvale bin weather data

• Ventilation load

Btu/h = (1.085)(CFM)(Toutside-Tinside)

• If positive, then cooling load

• If negative, then heating load

• Multiply by hours in bin

• Divide by equipment efficiency

Energy Auditing Techniques

Example bin method calc:

Calculating decrease in ventilation loads

Min OA

Outside

Air Temp

97

92

87

82

77

72

67

62

57

52

47

42

37

32

27

Total

5 tons

400 cfm/ton

2,000 cfm

15%

hrs

1

6

18

75

172

278

437

671

1,076

1,229

976

562

262

116

13

5,892

Room T

72

72

72

72

72

72

72

72

72

72

72

72

72

72

72

Ventilation Ventilation Ventilation Ventilation

Cooling

Cooling

Heating

Heating

Load

Load

Load

Load

(kBtu/h)

(kBtu)

(kBtu/h)

(kBtu)

8.0

7.0

5.0

3.0

2.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

8

42

90

225

344

0

0

0

0

0

0

0

0

0

0

709

0.0

0.0

0.0

0.0

0.0

0.0

2.0

3.0

5.0

7.0

8.0

10.0

11.0

13.0

15.0

0

0

0

0

0

0

874

2,013

5,380

8,603

7,808

5,620

2,882

1,508

195

34,883

Energy Auditing Techniques

Cooling

EER

$

$

709

10.0

71

0.15

10.64

kBtu

kBtu/kW

kWh

/kWh

Heating

Efficiency

34,883

80%

43,604

436

$

1.00

$

436

kBtu

kBtu

therms

/therm

Savings Summary

Energy Auditing Techniques