Analog Devices, Inc. - Willamette University

advertisement

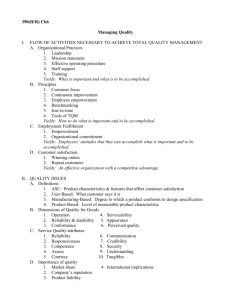

Analog Devices, Inc. Presented by: Joyce K. Fred and Darnell Price ADI Overview Who is ADI? 1996 Operations Company Goal 1996 Company Strategy ADI’s Successes 1965 to early 1980’s Growth at 27% per year 1984 to 1986 Revenues grew by 46% ($313 M) Profits grew by 105% 1988 Goal Revenue Growth of $1 Billion Warning Signs 1984 – 1986 Sales grew only 6.7% Profits fell by 38% Operational Problems Process yields less than 15% Defect Level > 20,000 PPM (Motorola @ 1,000 PPM) On-time delivery was missed 40% of time Customers complaining about quality 1986 Revenues Stagnant & Profits Declining Sales declined by 5% - Industry sales up by 25% Income Statement Looking for Solutions Half Life (QIP) Scorecard TQM Hoshin Kanri Hoshin Kanri Planning Principles Identify important areas of opportunity for the organization to change or improve Determine the most cost effective actions throughout the organization to achieve these changes Create a detailed implementation plan; and Provide a review mechanism to identify corrective actions and learning. Vision 2000 Build leadership positions in seven critical areas for signal processing Grow sales & profits more than 20% Develop employee’s skills and competencies ADI’s Plan Four Business Drivers Customer Satisfaction New Product Development Organizational Capabilities Financial Expectations See Exhibit 8 (in case) Group Discussion Questions Given the solutions in the case, what strategy should ADI employ to accomplish its Vision 2000? What organizational changes need to occur to implement the strategy and how will it be done? Why? Groups for Discussion Group Members Lisa, Ken, George Group Members David, Yasu, Bea, Van Group Members Amy, Elvira, Jeff Michael Beer Graduate School of Business Administration Harvard University “I view TQM as the continuous improvement of work processes to enhance the organization’s ability to deliver high-quality products or services in a cost-effective manner.” Why TQM Failed at ADI ! Lack of commitment by senior teams to TQM, in adopting TQM, and agreement on implementing TQM Lack of commitment to organizational and cultural changes for TQM Lack of company wide two way (vertically and horizontally) communication for TQM Lack of managerial capabilities in all sub-units with commitment to TQM How to Implement TQM Insist that: Leadership teams discuss the appropriateness of TQM to their sub-unit’s business model and problems. The senior team conduct a diagnosis of organizational and management barriers to TQM and develop a comprehensive action plan for change. The data collection and discussion process allow important, often threatening, issues to get raised and “publicly” discussed without negative repercussions. New plans be stress-tested by those who implement them to determine their validity and the organization’s willingness and capacity to implement them. Critical Success Factors for Employee Involvement (EI) Customer and Market Focused Strategy and Action Plans Marketing Research/R&D Leadership Steering Committee Strategic Planning Management Support Rewards Employee Involvement Training Teamwork Quality Results Innovation Wrap Up-ADI: Dying Giant or Smart Student ADI:2000 and Beyond TQM Infrastructure: 7 Elements for Success 2003 (3rd Q) Total Outgoing Electrical PPM = 25 2000 Revenues @ $2.5 Billion, EPS Rose 170% Struggling some since 2000 (dip to $1.7 Billion) 2003 Revenues @ $2 Billion WINS INTEL’S PREFERRED QUALITY SUPPLIER AWARD for the fourth consecutive year-2004 www.analog.com www.forbes.com/finance/mktguideapps/compinfo/Compan yTearsheet.jhtml?tkr=ADI