Nunticha L. ID 5513961 Natcha K. ID 5513962 Rada C. ID 5514026

advertisement

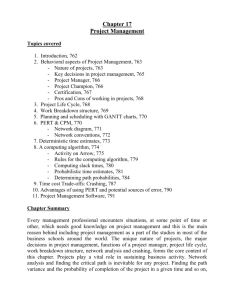

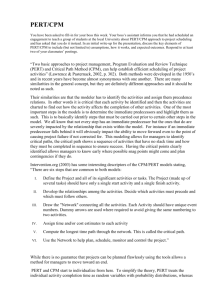

Nunticha L. ID 5513961 Natcha K. ID 5513962 Rada C. ID 5514026 IBM4715 Designing and Managing Global Operations Introduction+Chapter 1, 2,3,4,9 Summarize sheet Midterm 2/2014 Group M2N Introduction: Operations Strategy What is ‘Strategy’? Strategy is an elaborate and systematic plan of action Competitive Strategy: The Positioning View Cost leadership Differentiation Focus Levels of Strategy-Making Views to Develop Strategy 1. Best Product Classic competitive strategy: low-cost, unique set of features, or niche segment 2. Total Customer Solution Customer center and satisfy them is priority, close relationship to customer 3. System Lock-in Comprehends, company, customers, suppliers and its product & service to please customers Business Strategy: Dimensions along which Customers Assess Performance Cost Quality Availability Features/Innovativeness Environmental performance Strategy-Making in Context Operations Strategy: Goals Cost Quality Availability Features/Innovativeness Environmental Performance Strategy-Making: Step 1 Understand what position the firm wants to or can take in the marketplace by learning about: Competitors Suppliers Complementary product or service offerings and firms offering them Spaces outside the industry into which the firm might expand Customer needs Strategy-Making: Step 2 Understand what capabilities the firm has to offer, can or should develop both within and across the key functional areas of the firm: Operations Marketing Research and development Human resources Finance and accounting As well as outside the firm with supply chain partners Strategy-Making: Step 3 Integrate or synthesize the activities and capabilities of the functions to achieve: Coherent strategic fit in support of a desired strategic direction Development of a set of capabilities to pursue a new strategic direction ---------------------------------------------------------------------------------------------------------------Chapter 1: Operation and Competitiveness Operation is a function or system that transfer inputs into outputs of greater value Transformation process is a series of activities along a value chain extending from supplier to customers. To make transformation more efficiency Physical = manufacturing operations Locational = transportation operations Exchange = retail operations Physiological = health care Psychological = entertainment Informational = communication Operation management is a design operation and improvement of productive system. Evaluation of operations management Craft production = process of handcraft products Division of labours = divided job into series of small tasks and each performed by different workers Interchangeable parts = standardization of parts initially Scientific management = system analysis of work methods Mass production = high-volume production of a standardization for mass market Lean production = adaptation of mass production Historical events in operations management Industrial revolution = used machines Scientific management = do the same thing then you will become an expert (efficiency) Human relations = Hawthorne studies and Motivation theories Operations research = used technology to improve Quality revolution = JIT (just-in-time) = no area to keep stock then produce follow order Globalization = trade outside countries when goods are exceed local market Internet revolution Productivity increase by Become efficient = output increase only Expand = both input and output are increase Achieve breakthroughs = output increase while input decrease Downsize = input decrease only Retrench = both output and input are derease Competitive priorities Cost Quality Flexibility Speed Operation strategy: Products and Services Make-to-order = customization Make-to-stock = standardization Assemble- to-order = add options according to customer customized Production Strategy: Process and technology Project = do one at a time production of products Batch production =system process many different job at a same time Mass production Continuous production = use for very high volume commodity products Service Strategy: Process and technology Professional service = high customized, very labour intensive Service shop = customized, labour intensive Mass service = less customized, less labour intensive Service Factory = least customized, least labour intensive Element of strategy 1. Time S-T Intermediate L-T 2. Focus Process technology Market issues Volume Quality tasks 3. Evaluation Cost Quality Profitability Customer satisfaction 4. Consistency Professionalism Proliferation Change in task Explicit goals ---------------------------------------------------------------------------------------------------------------Chapter 2: Operation strategy Competitive Strategy: The positioning view Option for firm positioning: o Cost leadership = leader in term of lowest cost o o Based o o o Differentiate = unique products Focus = niche market Variety-based = satisfy some need but it is a majority need Needs-based = focus on market segmentation and satisfy all need Access-based = like needs-based but more specific access way to customers Level of strategy-making Corporate level Business level Functional level View to develop strategy 1. Best product = choose positioning 2. Total customer solution = customer center and satisfy them priority, close relationship to customer 3. System Lock-in = add additional services to make loyalty and satisfaction. Offer without customers need. Business Strategy: Dimension slang which customers access performance Cost Quality Availability Features/ innovativeness Environment performance Operations Strategy: Goals Cost Quality Availability Features/ innovativeness Environment performance ---------------------------------------------------------------------------------------------------------------Chapter 3: Project Management + Chapter 9: Project Scheduling The Elements of Project Scheduling Project Definition Statement of project, goals, and resources required. Activity Definition. Content and requirements of each activity Project Scheduling Specification of starting and ending times of all activities Project Monitoring Keeping track of the progress of the project Project Management Project Management is the management activities of planning, directing, and Controlling resources (people, equipment, material) to meet the technical, cost, and Time constraints of a project. Type of Project PURE PROJECT FUNCTIONAL PROJECT MATRIX Pure Project A pure project is where a self-contained team works full-time on the project Advantage The project manager has full authority over the project Team members report to one boss Shortened communication lines Team pride, motivation, and commitment are high Disadvantage Duplication of resources Organizational goals and policies are ignored Lack of technology transfer Team members have no functional area "home" Functional Project A functional project is housed within a functional division Advantage A team member can work on several projects Technical expertise is maintained within the functional area The functional area is a “home” after the project is completed Critical mass of specialized knowledge Matrix Project Organization Structure Disadvantage Aspects of the project that are not directly related to the functional area get short-changed Motivation of team members is often weak Needs of the client are secondary and are responded to slowly Advantage Disadvantage Enhanced communications between functional areas Too many bosses Pinpointed responsibility Depends on project manager’s negotiating skills Duplication of resources is minimized Potential for sub-optimization Functional “home” for team members Policies of the parent organization are followed Work Breakdown Structure A work breakdown structure defines the hierarchy of project tasks, subtasks, and work packages Network-Planning Models A project is made up of a sequence of activities that form a network representing a project The path taking longest time through this network of activities is called the “critical path” The critical path provides a wide range of scheduling information useful in managing a project Critical Path Method (CPM) helps to identify the critical path(s) in the project networks Network Representation Projects may be represented as networks with: Arrows representing activities. Nodes representing completion of a set of activities (milestones). Pseudo activities may be required to satisfy precedence relationships. Figure 9-4 shows a typical project network Figure 9-4 Critical Path Method An analytical tool that provides a schedule that completes the project in minimum time subject to the precedence constraints. In addition, CPM provides: Starting ending times for each activity Identification of the critical activities (i.e., the ones whose delay necessarily delay the project). Identification of the non-critical activities, and the amount of slack time available when scheduling these activities. Types of Critical Path Methods 1. CPM with a Single Time Estimate Used when activity times are known with certainty Used to determine timing estimates for the project, each activity in the project, and slack time for activities 2. CPM with Three Activity Time Estimates Used when activity times are uncertain Used to obtain the same information as the Single Time Estimate model and probability information 3. Time-Cost Models Used when trade-off information cost is a major consideration in planning Used to determine the least cost in reducing total project time CPM with a Single Time Estimate Steps in the CPM with Single Time Estimate 1. Activity Identification 2. Activity Sequencing and Network Construction 3. Determine the critical path - From the critical path all of the project and activity timing information can be Obtained The duration of each activity is listed above each node in the diagram. For each path, add the duration of each node to determine it's total duration. The critical path is the one with the longest duration. There are three paths through this project... CPM with Three Activity Time Estimates (PERT) PERT: Project Evaluation and Review Technique PERT is a generalization of CPM to allow for uncertain activity times. For each Activity the user must specify: a = minimum completion time b = maximum completion time m = most likely completion time The method assumes each activity time follows a beta distribution, which can be fit precisely with specification of a, b, and m. The mean and standard deviation of activity times are estimated from the following formulas (based on the beta distribution). In PERT one assumes that the path the with longest expected completion time is the true critical path (this is only an approximation, since true critical path is a random variable). Network Time-Cost Models Basic Assumption: Relationship between activity completion time and project cost Time Cost Models: Determine the optimum point in time-cost tradeoffs Activity direct costs Project indirect costs Activity completion times Suppose that projects can be expedited by reducing the time required for critical activities. Doing so results in an increase in some costs and a decrease in others. The goal is to determine the optimal number of days to schedule the project to minimize total cost. Maximum crashing with lowest cost Time-Cost Relationship Crashing costs increase as project duration decreases Indirect costs increase as project duration increases Reduce project length as long as crashing costs are less than indirect costs Chapter 4: Forecasting Method 1. Qualitative Methods (Judgment method) Executives/Managers, opinions, Expert opinions, Consumer Survey, Sales force estimate 2.Quantitative Methods Time series analysis (use past behavior of the variable to predict future) Causal method (added the TS with external data) Time Series Analysis Simple Moving Average Formula The simple moving average model assumes an average is a good estimator of future behavior The formula for the simple moving average is: Weighted Moving Average Formula While the moving average formula implies an equal weight being placed on each value that is being averaged, the weighted moving average permits an unequal weighting on prior time periods Exponential Smoothing Forecasts Forecast is the weighted average of of the forecast and the actual value from the prior period. ****The MAD Statistic to Determine Forecasting Error The ideal MAD is zero which would mean there is no forecasting error .The larger the MAD, the less the accurate the resulting model Simple Linear Regression Model Yt is the regressed forecast value or dependent variable in the model, a is the intercept value of the the regression line, and b is similar to the slope of the regression line. However, since it is calculated with the variability of the data in mind, its formulation is not as straight forward as our usual notion of slope. Econometric Models Single Equation Model of the Demand For Cereal (Good X) QX = a0 + a1PX + a2Y + a3N + a4PS + a5PC + a6A + e QX = Quantity of X PX = Price of Good X Y = Consumer Income N = Size of Population PS = Price of Muffins PC = Price of Milk A = Advertising e = Random Error Seasonal Variation -------------------------------------------------END--------------------------------------------------------