Compact Annubar Customer Presentation

advertisement

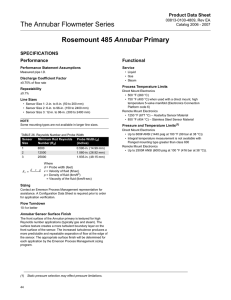

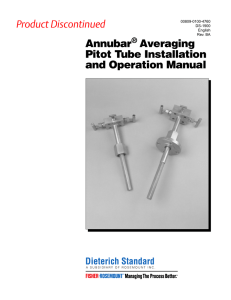

Save Time and Energy with the Compact Annubar™ Flowmeter Name Date Rosemount Invented the Averaging Pitot Tube and Continues to Innovate 1970 1978 Innovative upstream slot for comprehensive averaging 1984 1998 2002 Integral thermowell available T-shaped sensor creates large stagnation zones on backside to reduce noise Slide 4 Basic Principle of Annubar Primary Element Impact Pressure (40%) Total DP Blockage / Suction Pressure (60%) Static Pressure (40/60 relationship not the same for all APT’s) HIGH Velocity Profile DP(hw) = PH(avg.) - PL(avg.) Flow Impact area Slide 5 LOW Key Messages The 405A Compact Annubar Flowmeters allow for unparalleled ease of installation The 405A Compact Annubar sensor provides accurate measurements while keeping energy costs low through reduced permanent pressure loss Standardize DP Flow Installations with the 405 Compact Platform Slide 6 Are Difficult Installations Slowing Down Projects? Impulse piping Welding and additional pipe penetrations Extra time = $$$, labor for a welder, instrument tech, etc Slide 7 How Much Does a Flowmeter Really Cost? Installed Cost Traditional Installation 65% Engineering Costs Select Technology Size Create Spec Sheets & Drawings Material Costs Price of Components Installation Costs Piping Preparation Installation Commissioning Procurement Costs Generate Purchase Orders Manage Delivery Dates Vendor Relationships Purchase Price ≠ Total Installed Cost Source: Slide 4 Inch 8 line size per Aspen Richardson Process Plant Construction Estimating Standards, 2003 Edition, Process Equipment Cambridge: Aspen technology Inc., 2003. 405A Compact Flowmeters Eliminate Impulse Piping and Leak Points Traditional DP Flowmeter Assembly Installation Compact Flowmeter Installation Potential Leak Points = 6 + Factory Leak Tested Reduce Leak Points by 80% + Potential Leak Points = 29 + Slide 9 Installed using standard impulse lines Only 2 leak points to check in the field during installation! Eliminates troublesome impulse lines, reducing fugitive emissions and improving reliability 405A Integrated Flowmeters Arrive Fully Assembled and Factory Leak Checked Provides Easy Transmitter Connection Direct Mount Manifold Lowers Permanent Pressure Loss Averaging Pitot Tube Technology Eliminates Impulse Piping and Reduces Potential Leak Points All-Welded Design Easily Installs Between Raised Face Flanges 405 Compact Design Ensures Proper Alignment within the Pipe Integral Centering Ring Slide 10 Eliminate Additional Pipe Penetrations Integral RTD Decreases Measurement Error Annubar T-Shape’s higher signal with less noise and frontal slot design Annubar Technology Reduces Straight Run Requirements ■ ■ ■ ■ 2 3 4 5 6 7 8 9 1011121314151617181920212223242526272829303132333435363738394041424344 1 ■ ■ .67 Beta Orifice Rosemount Compact Annubar .67 Beta Orifice with 19-Tube Bundle Elbow Mounted Annubar Slide 11 Are High Utility Costs Hurting Your Bottom Line? “The biggest issue is the surging cost of energy, which now makes up 30% of operating costs for the average company.” *Control Global How much energy could you save? $$$ Slide 12 Sometimes Less is More When It Comes to PPL The amount of pressure lost is a function of 3 factors: •density of the fluid (f), •velocity of the fluid (Vf) •the amount obstruction (Kmeter) created by the flowmeter PPL = Kmeter x f x (Vf)2 The following is a guideline for Kmeter, in order from highest to lowest V-Cone Averaging Pitot Tube Orifice/ Nozzle Turbine Slide 14 Venturi Wedge Note: The Kmeter factor for a technology is dependent on the model selected. The 405A Allows You to Minimize Pressure Loss Throughout the Process FT4 FT2 PL4 Machine #1 FT5 FT1 Source PL2 Compressor PL5 FT 6 PL1 FT3 PL6 Machine #2 Destination Machine #3 FT7 PL3 Energy In PL7 Machine #4 Lowering Pressure Loss 1. 3. Reduces pumping/compressing costs 2. Increases capacity Minimizes compressor, pump or boiler size Pressure at Source > Pressure at Destination Slide 16 Annubar Technology Reduces PPL and Energy Costs • Minimizing pumping and compression costs • Increases throughput in existing lines • Maximize capacity of gravity-fed systems Slide 17 Has Valuable Experience in your plant “Gone Fishing?” “40% of the existing workforce will retire in the next 10 years.” *Society of Petroleum Engineers What will happen when your experienced personnel retire? Slide 18 Achieve a Perfect Installation Every Time for Every DP Flow Measurement Point Standardize installation procedures with the 405 Compact Platform Eliminate extra time, mis-installations, and training Annubar Conditioning Orifice Slide 20 Orifice Important 405A Specifications Accuracy 1.5% of flow coefficient (0.75% Calibrated) Repeatability ± 0.1% Pressure Rating ANSI 600# or DIN PN100 Line Sizes 2-8” (50-200 mm) Coming Soon! 10 & 12” (250 & 300mm) Slide 22 The Annubar T-Shape Creates a Higher Signal with Less Noise Slide 23 The Annubar T-Shape: No Wear, No Tear, No Worries The Compact Annubar sensor provides better wear resistance than orifice plates No sharp leading edges to wear Slide 24 Utilize the 405A for Applications with Medium to High Flow Rates 2-in. H2O 5-mbar 100-in. H2O 250-mbar 405C/P 0.40 β 405 C/P 100-in. H O 250-mbar 0.65 β 2-in. H2O 5-mbar 2 405A / 485 Sensor Size 1 2-in. H2O 5-mbar 5,000 – lb/hr 2,250 – kg/hr Slide 27 10,000 – lb/hr 4,500 – kg/hr 150# Steam - 4” (100mm) line size, sized 100” H2O 15,000- lb/hr 6,750 – kg/hr 100-in. H2O 250-mbar 20,000- lb/hr 9,000 – kg/hr Annubar Products Reach Beyond Flanges Pak-Lok • Patented compression design firmly secures the Annubar sensor to the opposite wall of the pipe • Rated up to 600# ANSI Flange-Lok • Combines Pak-Lok compression mechanism with a mounting flange Slide 28 Flanged With Opposite Side Support • Meets the requirement of high pressure applications • Available up to 2500# ANSI Flo-Tap • Can be hot-tapped without interruption of the flow • Easily removed for cleaning or line pigging • Available up to 600# ANSI Better Measurement is the Key to Better Control 3 in 1 measurement including differential pressure, static pressure, and temperature The result is better control of raw materials, combustion, reactions, blending and product quality Slide 29 Summary 405A Compact Annubar products provide unparalleled ease of installation The 405A Compact Annubar sensor provides accurate measurements while keeping energy costs low through a low permanent pressure loss Standardize DP Flow Installations with the Compact 405 Platform Slide 31 Thank you for your time and attention!