Class 6 - Marc Madou

advertisement

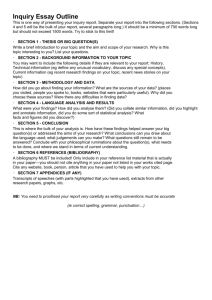

6. Wet Bulk Micromachining

Fundamentals of Microfabrication

Fall 2013

Prof. Marc Madou

MSTB 120

Table of Content

Single

crystal growth

Si lattice structure

Miller Indices

Wafer flats

Isotropic and anisotropic etching

Example

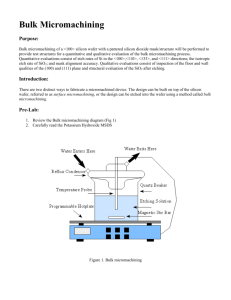

Bulk Micromachining

Semiconductor grade devices cannot be

fabricated directly from Poly-Si, first we

need to produce single crystal ingots,

also the mechanical properties of single

crystal Si are superior

Major methods are: Czochralski and

Float Zone method

Si crystal growthCzochralsky method

http://www.egg.or.jp/MSIL/english/msilhist0-e.html from

Mitsubishi Materials Silicon Corporation

Bulk Micromachining

Si crystal growth: float-zone

crystal growth

http://www.egg.or.jp/MSIL/english/msilhist0-e.html from Mitsubishi Materials Silicon Corporation

Bulk Micromachining

The Si diamond lattice is composed of two interpenetrating fcc lattices, one displaced 1/4 of

a lattice constant from the other. Each site is tetrahedrally coordinated with four other sites in

the other sublattice. When the two sublattices are of different atoms, then the diamond lattice

becomes the zincblende or sphalerite lattice. Examples of materials with the diamond crystal

structure are diamond, silicon and germanium.

Bulk Micromachining

Si crystal orientation

Each site is tetrahedrally coordinated

with four other sites in the other sublattice

More atoms per cm 2

(oxidizes faster than 100) but

etches much slower

Equivalent planes i.e. families {}

http://www.novagate.com/~ahines/rocks/vir_cris.htm

Bulk Micromachining

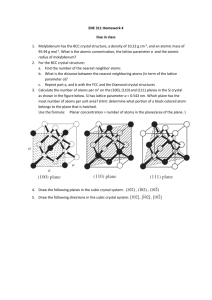

Miller indices

Miller Indices are a symbolic vector representation for the orientation of an

atomic plane in a crystal lattice and are defined as the reciprocals of the

fractional intercepts which the plane makes with the crystallographic axes

To determine Miller indices of a plane take the following steps: 1. Determine

the intercepts of the plane along each of the three crystallographic directions 2.

Take the reciprocals of the intercepts 3. If fractions result, multiply each by the

denominator of the smallest fraction

Bulk Micromachining

Miller indices

The first thing that must be ascertained is the

fractional intercepts that the plane/face makes

with the crystallographic axes, in other words,

how far along the unit cell lengths does the

plane intersect the axis? in the figure, the plane

intercepts each axis at exact one unit length (1)

Step two involves taking the reciprocal of the

fractional intercept of each unit length for each

axis, in the figure above, the values are all 1/1.

(2)

Finally the fractions are cleared (i.e., make 1 as

the common denominator) (3)

These integer numbers are then parenthetically

enclosed and designate that specific

crystallographic plane within the lattice. Since

the unit cell repeats in space, the notation

actually represents a family of planes, all with

the same orientation. In the figure above, the

Miller indices for the plane are (111)

Miller Indices http://www.gly.uga.edu/schroeder/

gly630/millerindices.html

Bulk Micromachining

This figure shows a 4 inch 100

plane crystal Silicon wafer,

typically between 250-600

microns thick

The current fab standards are up

to 12 inch wafers

For CMOS work (100) and

(111) (for bipolar) wafers are

most important but in MEMS

other orientations are used as

well (especially (110)

Wafer flats indicate orientation

(primary) and conductivity type

(secondary)

Bulk Micromachining

The primary flat on (100) and (111)

wafers marks the <110> direction

(111)

Purpose and Function

(100)

Orientation for automatic equipment

Indicate type and orientation of crystal

Primary Flat = The flat of longest length located in the circumferen

Secondary Flat = Indicates the crystal orientation and doping of th

P type <111> No secondary Flat

P type <100> 90°±5° Clockwise from Primary Flat

N type <111> 45°±5° Clockwise from Primary Flat

N type <100> 180°±5° Clockwise from Primary Flat

m Prima

Bulk Micromachining

Chemical milling: using a maskant

and a scribe followed by acid to

etch the scribed area

–

–

Chemical milling (15 th century

decorating armor)

Chemical milling by the 1960’s

especially used by the aerospace

industry

Photosenstive masks instead of

scribing by hand (Niepce in 1822)

Printed circuit board (WW II)

Isotropic etching of Si (mid 1950’s)

IC’s (1961)

First Si micromechanical element

(1961-1962)

Anisotropic etching of Si (mid

1960’s)

Bulk Micromachining

Anisotropic etching: [100] Si

Proper alignment leads to {111}

sidewalls, (100) bottom, <110>

directed edges and <211> directed

ribs

Consider the unit cube and the offnormal angle of the intersection

of a (111) sidewall and a (110)

cross-secting plane

Flat [110]

tan =

L = a* 2

2

L

a

L = a* 2 = 35.26°or

=arctan

2

54.74° for the complementary angle

(111)

L

(110)

a

Bulk Micromachining

Anisotropic etching: [100] Si

The width of the square bottom cavity wo

is determined by the etch depth z, the

mask opening and the angle we just

calculated

W0 = Wm - 2 cotan (54.74°) z

W0 = Wm -

2

z

To create a dense array of vias the Si

wafer must be thinned

Bulk Micromachining

Anisotropic etching: [100] Si

(100) planes

Flat [110]

There are {100} planes perpendicular to

the wafer surface (at a 45° angle with

the wafer flat i.e.the {110} direction)

Bulk Micromachining

Isotropic etching (HF:Nitric Acid: Acetic Acid)

Anisotropic etching (KOH)

(110)

(100)

Bulk Micromachining

Isotropic etchants etch in all

crystallographic directions at the

same rate:

–

–

–

–

–

Stirring

Usually acidic (HNA i.e. HF,

HNO3 and CH3COOH)

Room temperature or slightly

above (< 50 °C)

Diffusion limited

Etching is very fast (e.g. up to 50

µm min-1)

Undercuts mask

No stirring

Masking very difficult e.g Au/Cr or

LPCVD Si3N4 is good, but SiO2 is

used because it is so simple

Bulk Micromachining

Anisotropic etchants etch at different

rates depending on the orientation of the

exposed crystal plane:

–

–

–

–

–

–

Usually alkaline (pH> 12 e.g. KOH)

Higher temperatures (> 50 °C e.g. 85 to

115 °C)

Reaction rate limited

Slower e.g 1 µm/min (for <100>

direction)

Does not undercut the mask

Not very agitation sensitive

Masking very difficult e.g. LPCVD

Si3N4

Bulk Micromachining

Example: electrochemical sensor array

A typical bulk micromachining

example: to make an array of

electrochemical sensors in a catheter

(e.g. to measure pH, O2 and CO2 in

blood)

The etch stop in this case is a sacrificial

oxide layer

Yet smaller structurs could be used to

experiment in picoliter microvials (e.g.

to investigate a single biological cell)go visit

http://pubs.acs.org/hotartcl/chemtech/98

/feb/exper.html

Bulk Micromachining

Example: electrochemical sensor array

As in most cases the packaging is

the more difficult and more

expensive part of the sensor

fabrication

Bulk Micromachining

The sensor array is mounted in a

catheter (750 µm diameter)

Biocompatible materials is still a

very big issue

CAD of the sensor array

Example: electrochemical sensor array