環境檢測機構管理策略分析

advertisement

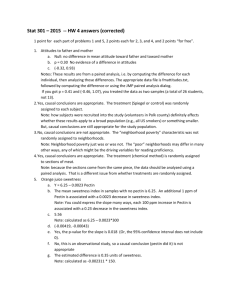

Chapter 1 Pectin 1-1 1-2 1-3 1-4 1-5 1-6 1-7 1-8 Structure and Terminology Production Characterization of pectin gel Factors affecting gelation Chemical properties Pectic enzymes Structure and mechanisms of gel formation Application 1-1 Structure and Terminology Pectin is heterogeneous complex polysaccharide Its composition varies with the source and the conditions applied during isolation All pectin molecules contain linear segments of (14)-linked a-D-galactopyranosyluronic acid with some of the carboxyl groups esterified with methanol. Some of the hydroxyl groups of the galacturonosyl unit (O-2 and O-3) are esterified with acetic acid. Pectin molecule with methyl esterified or nonesterified carboxyl groups Amidated pectin has commercial importance Terminology Protopectin Pectinic acids Pectic acids Pectins Degree of esterification (DE) > 50 High-methoxyl pectins (HM-pectins) High concentration of soluble solids, low pH DE < 50 LM-pectins Divalent cations 1-2 Production 1-2-1 Raw materials Citrus peel (20-30%), apple pomace(10-15%) Sugarbeet waste, sunflower heads, mango waste Sugarbeet pectin is inferior to citrus or apple pectin Presence of acetate esterification A relatively low molecular mass Presence of large amount of neutral sugar side chain 1-2-2 Extration, Purification, Modification Two general processes 1. Separating the pectin from most other water-soluble material by precipitation with an alcohol 2.Precipitating pectin as an insoluble salt with suitable multivalent metal ions 1-2-2 Extration, Purification, Modification Extraction: 50-90 , pH 1-3, Time 0.5-24h 1-2-3 Standardization Uncontrolled variations in the raw materials will affect their functional properties. Reproducible performance from batch to batch of the final products is a must. Unstandardized HM-pectins are usually ‘diluted’ to a uniform pectin grade (150 grade USA-SAG) The grade USA-SAG is the number of parts of sucrose which, under standard conditions, can be turn into a gel of standard gel strength by one part of the pectin. Standard conditions: refractometer soluble solids, 65%; pH 2.20-2.40; gel strength, 23.5% SAG in 2 min measured by Cox and Higby (1944) 1-3 Characterization of pectin gel 1-3-1 gel strength and breaking strength Some methods measure the gel strength within the elastic limits of the gel Other methods measure breaking strength SAG determination method The gel to be tested is prepared in a glass of standardized dimensions After curing, the gel is carefully removed from the glass and allowed to stand without support The height of the gel deformation by its own weight is measured after a specified time % SAG = 100 x (loss of height/original height) Plunger methods Strain is applied to the gel by means of a plunger--compression strain Corresponding values of deformation are measured Strain-versus-distance curve can be obtained while the plunger is forced into the gel at a constant speed Plunger methods are well suited for use in the jam and jelly industry 1-3-2 Gelling time and temperature Commercial high-ester pectins are usually standardized to a certain gelling time or temperature under specified conditions Gelation of high-ester pectins may begin later than instant when the gelling system was colled below the gelling temperature Gelling time is often measured rather than the gelling temperature Gelling time measurement The test gel is prepared in exactly the same way as for the SAG determination The still liquid preparation is adjusted to 95 and poured into a standard glass in a 30 water bath The setting time is then taken as the time span from the filling until visual signs of gelation appear Setting time values are 50 sec for commercial ‘rapid-set’ pectins and 225 sec for ‘slow-set’ pectins 1-3-3 Factors affecting gelation Temperature Concentration of pectin pH Concentration of cosolutes Concentration of ions Molecular weight Degree of esterification Degree of amidation Presence of acetyl groups Heterogeneity and presence of neutral sugar residues Temperature A pectin gel is in most cases prepared hot and then solidified by cooling When cooled below the gelation temperature , systems containing LM-pectin will gel almost instantaneously whereas HM-pectin systems will gel after a time lag. HM-pectin gel cannot be remelted LM-pectin gel is thermoreversible It is often desirable to fill commercial containers at a temperature close to the gelation temperature to prevent flotation of particles (berries) Concentration of pectin Typical concentrations of pectin in jams and jellies range from 0.3% to 0.7% 0.3% HM-pectin gelling at about 65% soluble solids 0.7% amidated LM-pectin gelling at about 35% SS The pectin concentration used is inversely related to the concentration of soluble solids At fixed levels of all other parameters, increasing the amount of pectin causes the gel strength of the resulting gel to increase. pH A pH of about 3.0-3.1 is typical for high-sugar jams (HM-pectin, 65% SS) Low-sugar jams may be slightly less acidic for taste reasons. (pH 3.1-5.5) Low pH values tent to increase the strength of both HM- and LM-pectin gels Gels will generally not form above about pH 3.5 in the case of HM-pectin and about pH 6.5 in the case of LMpectin HM-pectin: lower DE need lower pH for gelation Concentration of cosolutes HM-pectins will gel only in the presence of large concentration of materials that lower water concentration /activity The soluble solids must be at least 55% (w/w) Increasing the soluble solids content causes the gelation temp. and the gel strength of the resulting gel to increase LM-pectins may be gelled at zero soluble solids, but increasing the soluble solids will also positively affect the gelation temp. and gel strength Concentration of ions Gelation of LM-pectin will only happen in the presence of divalent cations Except for pectates or very low ester pectins which may form gels with K inos under certain conditions Most divalent cations may be effective, but only Ca2+ is used in food application Increasing Ca2+ concentration results in increasing gel strength and gelling temp. Divalent cations are not necessary for the formation of an HM-pectin gel Molecular weight Gels made from either LM or HM-pectin with high molecular weights will be stronger than gels made with pectins of lower molecular weights Degree of esterification DE values for commercial LM-pectins range from 2040% Those with the lowest DE-values show the highest gelling temperatures and the highest sensitivity to Ca2+ In contrast, the highest gelling temp. and the fastest gelation of HM-pectins are found with those that have the higest DE Rapid-set (70-75% DE) > medium-rapid-set (65-70% DE) > Slow-set (55-65% DE) Gel strength: Slow-set + lower pH = rapid-set Gel strength: R > M > S (at same pH) Degree of amidation (DA) Most commercial LM-pectins are amidation DA values range from 15-20% Amidation causes the pectin to gel at higher temp. compared to a nonamidated pectin under the same conditions, and less Ca2+ is needed Amidation has a positive effect on gel strength Presence of acetyl groups If some of the galaturonic acid subunits contain acetyl group at O-2 or O-3, gelation will be hampered Every eight units is esterified this way The presence of acetyl esters may be a drawback to suggested alternative source of pectin such as sugar beet pulp and sunflower heads Heterogeneity and presence of neutral sugar residues Two pectin batches may behave differently, even if they are similar with respect to molecular weight and DE The distrubution of esterified and free carboxyl groups has received much attention because it is different in enzymicly deesterified pectins than it is in acid or alkali deesterified pectins. Gel strength: enzymicly deesterified pectins < acid or alkali deesterified pectins Heterogeneity has been reported to be advantageous to the gel-forming ability of a pectin Heterogeneity and presence of neutral sugar residues The rhamnose content has impact on the flexibility of the molecules (rhamonse insertions in the backbone) The side chains of neutral sugar may sterically hinder gelation or limit the size of junction zone 1-5 Chemical properties Pectins are polyanions at neutral pH and approach zero charge at low pH Dissociations of the individual –COOH groups are not independent: pK = 2.9-3.3 The pH at 50% dissociation of the pectin ranges from 3.5 through 4.5 React with positively charged polymers, such as protein at pH values less than their pI Breaking strength of pectin gels as a function of pH Decomposed of pectins Dissolved pectins are decomposed spontaneously by deesterification as well as by depolymerization Factors: pH, Aw, Temperature HM-pectins: stable at about pH 3.5- 4, sugars or other agents that lower water activity reduces the rate of degradation LM-pectins: stable at about pH 4-5, In both acid- and base-catalyzed decomposition, the rate of DEster is faster than the rate of DPoly Highly esterified pectins are more prone to depolymerization than are LM-pectins or pectic acids Decomposed of pectins DPoly. At low pH-values is a hydrolysis reaction DPloy. At alkaline conditions is a beta-elimination reaction Glycosidic bonds to O-4 of an esterified galacturonic acid subunit eliminate much more easily than those to O-4 of an nonesteified subunit The rate of beta-elimination is almost proportional to the amount of remaining methyl ester groups and slow down as they are saponified Decomposed of pectins Powdered HM-pectins slowly lose their ability to form gels, especially if stored under humid or warm conditions Stored at < 20 C LM-pectins are more stable, loss should not be significant after 1 year storage at room temperature Analysis of pectins Degree of esterification (DE) Washing in 60% 2-propanol (isopropanol)/5% HCl Several washing with 60% 2-propanol (isopropanol) Titrate to the equivalence point with NaOH Saponification Analysis of pectins Degree of amidation Heating the sample with excess of NaOH and trapping the evolved ammonia in a known amount of HCL Acetyl content Alkaline saponification Acidification with dilute sulfuric acid and steam distillation The evolved acetic acid is trapped in a known amount of NaOH and titrated Analysis of pectins Average molecular weight Intrinsic viscosity method Membrane osmometry LC method 1-6 Pectic enzymes Pectin esterases (PEs) Polygalacturonases (PGs) EC 3.2.1.67 EC 3.2.1.15 Pectate lyases (PALs) Exo-PGs Endo-PGs EC 3.1.1.11 Exo-PALs Endo-PALs Pectin lyases (PLs) EC 4.2.2.9 EC 4.2.2.2 EC 4.2.2.10 Pectin esterases (PEs) Catalyze hydrolysis of methyl ester bonds Fungal PEs -- optimum pH about 4.5 Bacterial PEs -- pH 6-9 Attack prevailingly next to an unesterified galacturonic acid subunit Polygalacturonases (PGs) Catalyze hydrolysis of glycosidic bonds Exo-PGs The rate of reaction is inversely related to the DE Optimum pH 4.0-5.5 Release mono- or di-saccharides from the nonreducing end Endo-PGs Attact at random Pectate lyases (PALs) Catalyze depolymerization via b-elimination Fig 5 273 Only glycosidic bonds to O-4 of an unesterified galacturonic acid unit are attacked Optimum pH 8-9.5 Exo-PALs Endo-PALs Pectin lyases (PLs) Catalyze b-elimination at bonds to O-4 esterified galacturonic acid units Only endo-PLS are known Optimum pH 5-6 Presence of Ca2+: optimum pH 8 Pectin lyases (PLs) Catalyze b-elimination at bonds to O-4 esterified galacturonic acid units Only endo-PLS are known Optimum pH 5-6 Presence of Ca2+: optimum pH 8 1-7 Structure and mechanisms of gel formation To take part in gel formation, a pectin module must aggregate with one or more other pectin molecules The junction zones must be of limited size because the molecules would otherwise form a precipitate rather than a gel Citrus, apple and sunflower pectins preparations with acid under hydrolyzing conditions (Powell et al., 1982) DP is about 25 Because bonds to rhamnose were assumed to be more labile than ordinary glycosidic bonds in the galacturonan backbone One rhamnose unit for every 25 galacturonic acid units(regularly distributed) Apple pectins fractionated by DEAEcellulose Rhamnose insertions are very unevenly distributed along the galacturonan backbone (Vries et al., 1982) Pectin consists of smooth regions and hairy regions rich in neutral sugars predominantly present as side chain Neutral sugar content tends to be higher if mild conditions have been employed for extraction L-rhamnose, L-arabinose, D-xylose, D-galactose, D-glucose Pectins from spinach and sugar-beet Ester-linked ferulic acid has been found in neutral sugar side chains Formation of a covalent bond between ferulic acid by the action of hydrogen peroxide or peroxidase Model of a function zone in a highsolids pectin gel Model of a calcium pectate junction zone Egg box model of a junction zone in a calcium pectate gel 1-8 Application Pectins are a constituent of all plants and is part of the natural diet of man Pectins are generally recognized as safe (GRAS) 1-8-1 Jams and Jellies Pectin has a dominant position as a gelling agent in jams and jellies because The natural pectin content in fruits used for jam making is responsible for the gelation of traditional jam that has been produced for centuries Pectin is compatible with a natural image of the product Pectin has good stability at the pH of jams and jellies, even when hot 1-8-1 Jams and Jellies The selection of suitable pectin for a particular application is dependent upon the desired texture and the desired gelling temperature HM-pectins: rapid-set, medium-rapid-set, slow-set The actural gelling rate is dependent on the application conditions LM-pectins are the possibility if the pH of the product is above approximately 3.5 and/or the soluble solids (SS) concentration is below approximately 55% Gelling temperature Which gelling temperature is desired is determined by the filling temp. and the presence or absence of suspended fruit particles in the product Jams should solidify as soon as possible after filling. Fruit flotation is then stopped before it lead to a too unenen distribution of the fruit particles in the product Delayed gelation is desirable in the case of jellies so that air bubbles will have time to escape Filling temperature The desirable filling temperature is in turn restricted by the size of the jars used Large jars cool more slowly than smaller jars, and holding at elevated temp. is detrimental to product quality A relatively low filling temperature is consequently necessary if the product is to be sold in large containers Which pectin type may be used? The container size puts an upper limit to the filling temperature The filling temp. and the desirability or undesirability of a lag before solidification determine the desired gelling temperature The desire gelling temp., together with composition of the product, determines which pectin type may be used Jams, Jellies and Confectionery Jellies Preparations 1-8-2 Acidified Milk Drinks Casein particles of unstabilized acidified milk systems tend to aggregate, especially during heat treatment A sandy texture may develop and whey formation separation may occur due to sedimentation of the casein 1-8-2 Acidified Milk Drinks A typical use level for pectin in acidic milk drinks is 0.5% The necessary dosage is dependent upon pH, titer, protein concentration, heat treatment and size of casein particles pH 3.5-4.2 Best stability is achieved at relatively high titer value Typical titers of fruit-flavored acid milk products are 100-120 (mL 0.1N NaOH per 100 mL) More casein or harsher the heat treatment more pectin is required Large casein particles can not be stabilized efficiently Very small particles require much pectin Theory of stabilization In unstabilized acidified milk, casein particles that are below their isoelectric pH are positively charged A repulsion that is not strong enough to prevent aggregation exists between these particles When pectin is added, it reacts with the casein and neutralizes the charge, increasing the tendency of particles to aggregate When even more pectin is added to the casein particles, a new repulsion between particles results from a surplus negative charge that is stronger than the original positive charge 1-8-3 Other application Different properties of pectin are utilized in application related to beverages such as orange juice, orangeades, and soft drinks HM-pectin may be used to increase the viscosity of soft drinks and improve the mouthfeel It may be used to prevent sedimentation of suspended material in orange juice concentrates with more than 45% SS. Oil-in-water emulsions in cosmetics may be stabilized with pectin Numerous patents, most of which related to uses of pectin is in food products Chapter 2 Cellulose and its derivatives 1. Methylcellulose and its derivatives 2. Hydroxyalkyl and ethyl ethers of cellulose 3. Sodium carboxymethylcellulose 1. Methylcellulose and its derivatives 1-1 Introduction 1-2 Manufacture 1-3 Properties 1-4 Application 1-1 Introduction Etherification of cellulose provides a broad spectrum of products that includes low-substituted alkyl ethers that are insoluble in water and organic solvents Alkyl ethers of intermediate substitution that are water soluble Highly substituted ethers that are soluble in organic solvents but not in water The methylcellulose and its derivative gums described here are those that are water soluble and classified as hydrophilic industrial gems 1-1 Introduction The term methylcellulose gums is used to refer to entire group of products including Methylcellulose (MC) Hydroxypropylmethylcellulose (HPMC) Hydroxyethylmethylcellulose (HEMC) Methylcellulose gums have broad commercial application in a wide variety of uses and a production of more than 76 x 10 exp 6 kg/year 1-2 Manufacture Cellulose sheet pulp obtained from cotton or wood is converted into alkali cellulose by reaction with sodium hydroxide Then, pressure reactors are used to etherify the alkali cellulose with methyl chloride and , in some cases, propylene oxide, ethylene oxide, or butylene oxide Reaction times of 2-10 h Purification takes advantage of the product’s thermal gelation properties 1-2 Manufacture The crude product is dispersed in hot water, in which it is insoluble, and is then separated by filtration or centrifugation Additional washes may be used to improve purity The wet methylcellulose is dried and milled Manufacturers of methylcellulose and modified methylcelluloses 1-3 Properties 1-3-1 solid Methylcellulose gum products are available in powder and granular forms The primary benefit of powder products is rapid dissolution Granular products have reduced dusting tendency and are more easily dispersed Both products may be treatment with dispersing agents to make dissolution easier, but these products can’t be used in foods or in contact with food products Physical properties of methylcellulose powder and granular products 1-3-2 To prepare solutions Insufficient dispersion may lead to lumping and incomplete dissolution Application of high-shear mixing devices to help promote dispersion can cause excessive foaming It is generally recommended that the gum first be mixed with a formulation ingredient, such as alcohol, glycol, or salt solution. Water is then added to the mixture The powder can be dispersed in water heated above the gel temperature of the gum 1-3-2 To prepare solutions Solution of methylcellulose gums are pseudoplastic Solution rheology is dependent upon the molecular weight of the gum its concentration presence of other solutes Relationship between molecular weight and aqueous solution viscosity Viscosity as a function of concentration for highviscosity types of Methocel Viscosity as a function of concentration for low-viscosity types of Methocel Gel strength as a function of molecular weight of Methocel products 1-4 Application 1-4-1 Salad Dressing 1-4-2 Dietetic Foods 1-4-3 Fried Foods 1-4-4 Bakery Products 1-4-5 Frozen Dessert 1-4-1 Salad dressing MC and HPMC are used in pourable salad dressings, such as French dressing, to stabilize the emulsion and prevent separation. Higher molecular weight versions of the gum are preferred for the formulation with the purpose of thicken and stabilize (0.3-1.0% gums) Higher concentration are used in low-calorie, reducedoil dressings and in oil-free salad dressings 1-4-2 Dietetic foods Bulking agent in low-calorie foods Partial replacements of digestible carbohydrates with low levels of nondigestible MC gums provides desirable organoleptic properties with reduced calorie content Reduced-calorie salad dressing: 0.3-1.0% gums Dietetic jellies and Preserves :0.5-1.0% gums, palatable Artificially sweetened syrups: 1% MC, smoothness and body Low-calorie beverages: 0.15-0.20% HPMC, mouthfeel and body 1-4-3 Fried foods In batters, dipping solution and sprayed-on coatings for meat, fish and French-fried potatoes The gum reduces oil absorption through film formation and thermal gelation MC gums hydrophilicity helps to retain moisture during the cooking process, preventing drying out of the food Batter formulation: 0.5-2.0% 1-4-4 Bakery products Including cake, doughnuts, breads, cookies, fruit pie fillings… Their thermal gelation is valuable in preventing boil-over of pastry filling and aids in gas retention in cakes during baking Low moisture migration due to their hydrophilic nature improves shelf life and prevents icing dry out Their surfactancy and thickening properties help assure uniform consistency by improving emulsification, air entrainment, and ingredient suspension In frozen baked goods, MC gums retard water migration during freezing and thawing and help inhibit phase separation during freezing 0.07-0.3% base on total ingredients 1-4-5 Frozen dessert MC gums are used in frozen desserts to control ice crystal size and improve emulsification during processing 0.2-0.5% 1-4-6 others Beer foam stabilizer-- 100ppm or less Barbecue sauce and relish formulations-- 0.31.5% Sausage casings 2.Hydroxyalkyl and ethyl ethers of cellulose 1-1 Introduction 1-2 Manufacture and Properties 1-3 Application 1-1 Introduction The principal, commercial, water-soluble hydroxyalkyl derivatives of cellulose are hydroxyethylcellulose (HEC) and hydroxypropylcellulose (HPC) The derivatives are readily soluble in water and are produced in a wide range of viscosity grades Their solutions are pseudoplastic, that is, they vary in viscosity depending upon the amount of stress applied HPC is cold water-soluble and is a true thermoplastic and can be extruded, injection molded or compression molded into flexible film HEC is insoluble in hot water (> 42 C) and soluble in a broad range of polar organic liquids. 1-2 Manufacture Water-soluble hydroxyalkylcellulose are manufactured by reacting alkali cellulose with alkylene oxides at elevated temperatures and pressure in a mixture of organic solvents and water Each unit in the cellulose molecule has three reactive OH groups. Reaction of ethylene oxide or propylene oxide with cellulose also leads to formation of new OH groups Molar substitution (MS) or degree of substitution (DS) Viscosity range of aqueous solutions of hydroxyalkyl-celluloses at 25 C and various concentrations 1-2 -1 Preparation of HEC HEC is produced from alkali cellulose by reacting cotton linters or high-alpha wood cellulose with aqueous sodium hydroxide to produce alkali cellulose (soda cellulose), which is reacted with ethylene oxide in the presence of a water-miscible diluent such as isopropanol or tertiary-butanol 52 parts wood pulp + 450 parts isopropanol + 126 parts 22% aqueous caustic for 1h + 51 parts ethylene oxide heated to 30 C for 1h increase to 35 C maintained for 3h filtered washed with methanol-acetone mixture neutralized with acetic acid dried 1-2 -2 Properties of HEC Solubility MS > 1.6 : readily soluble in either hot or cold water Low-viscosity types dissolve more rapidly than high-viscosity types Effect of temperature on viscosity -- HEC The viscosity increases when cooled and decreases when warmed A convenient nomograph If a solution has a viscosity of 60 cP at 25 C The viscosity at 42 C will be ?? cP Effect of concentration on viscosity -- HEC Effect of pH on viscosity -- HEC HEC is a nonionic polymer and therefore undergoes little viscosity change over a pH range of 2 to 12 Solutions show best viscosity stability in the pH range of 6.5 to 8.0 A drop in viscosity results from acid-catalyzed hydrolysis below a pH of 3.0 At very high pH, alkaline oxidation accelerated by heat and light may occur Rheology of HEC All solution of HEC are psuedoplastic Solutions of lowmolecular-weight types exhibit less pseudoplasticity FDA status of HEC For use in packaging adhesives and resinous and polymeric coatings employed on metal or paper for food packaging HEC is not cleared as a direct food additives 1-2 -3 Properties of HPC Solubility Commercial HPCs have MS > 2.0 Soluble in water below 38 C, insoluble in water above 45 C Soluble in many polar organic solvents Effect of temperature on viscosity -- HPC Viscosity decreases with increases in temp. The polymer reversibly precipitates from water at 40-50 C, causing a rapid loss in viscosity 5% NaCl reduced the ppt temp. to 30 C 40% sucrose 20C Effect of concentration and pH on viscosity -- HPC Viscosity increases rapidly with concentration HPC is nonionic and undergoes little viscosity change over the pH range of form 2-12 Thermoplasticity of HPC HPC can be processed by all plastic fabrication methods The low-molecular-weight types are preferred in injection and blow molding, where rigidity, hardness, and dimensional stability are important The medium- or high-molecular-weight types are recommended for most extrusion systems where greater flexibility and higher tensile properties are desired MW 50,000-1,250,000 FDA status of HPC Purified HPC is approved as a direct food additive Toxicity tests indicate that the polymer is physiologically inert 1-3 Application of HPC Organic solubility properties Thickener in solvent-based adhesives, alcohol-based hair dressings, perfumes, inks, HPC is widely used as a granulating agent for tablet and capsule mixes in the pharmaceutical industry HPC films– to coat nuts to prevent oxidative rancidity, coat candies and other confections Foaming aid and emulsion stabilizer in whipped toppings 3. Sodium carboxymethylcellulose 3-1 Introduction 3-2 Manufacture 3-3 Properties 3-4 Applications 3-1 Introduction of sodium CMC Sodium carboxymethylcellulose (CMC) is a watersoluble cellulose ether produced by reacting alkali cellulose with soldium monochloroacetate CMC was first used as a substitute for starch and natural gums The purified grade, known as cellulose gum, is used extensively in the food, pharmaceutical, and cosmetic industries A GRAS product 3-2 Manufacture The traditional process is accomplished in a sigma-blade mixer The cellulose is steeped in NaOH, pressed, and shredded Sodium monochloroacetate or chloroacetic acid can be mixed with the cellulose before or after alkali is added The reaction product is neutralized, dried, and packaged The crude product can be purified by the use of alcoholwater mixtures to extract salts without dissolving the gum 3-3 Properties 3-3-1 Degree of substitution (DS) Each D-glcopyranosyl unit has three reactive OH group It is possible to introduce three sodium carboxymethyl groups per unit DS = 3.0 Commercial CMC DS < 1.5 Most common 0.4 < DS < 0.8 Idealized structure of sodium CMC with a DH of 1.0 3-3-2 Uniformity of substitution The first element is the preparation of a uniform alkali cellulose The proper amount of caustic must be brought into contact with the cellulose fibers in a fashion that ensures uniform distribution Care in detailed distribution of the monochloroacetic acid is less critical NMR is used to determine the relative location of the carboxymethyl groups in CMC 3-3-2 Uniformity of substitution Derivatization of one OH group on the Dglucopyranosyl unit does not alter the relative reactivity of remaining OH group The relative rate constant: k2 = 2.14, k3 = 1.00, k6 = 1.58 3-3-2 Uniformity of substitution The unsubstituted regions tend to interact through hydrogen bonding and generate thixotropy (搖溶 性) in solutions Increase in thixotropy with increasing concentration is rough indicator of the relative uniformity of substitution of a given sample of CMC The longer the average chain length, the more viscous is the solution 3-3-3 Solubility Low-substituted types (DS 0.3 or less) are insoluble in water but soluble in alkali DS > 0.4 water soluble, DS < 0.4 with high uniformity of substitution water soluble Solubility of various sodium CMC-CMC films at various pH values 3-3-4 Rheology of CMC CMC is generally used to thicken, suspend, stabilize, gel, or otherwise modify the flow characteristics of aqueous solution or suspensions Pseudoplasticity: A CMC solution will vary in viscosity as different physical forces are applied to the solution (timeindependent shear-thinning) 3-3-4 Rheology of CMC Thixotropy: When long chain polymers associate intermolecularly, there tend to develop a three-dimensional structure and exhibit thixotropy (time-dependent shear-thinning) Solution of medium- and high-viscosity CMC 0.9 < DS < 1.2 pseudoplastic 0.4 < DS < 0.7 with slightly less uniformly substituted thixotropic Pseudoplastic vs Thixotropic Thixotropic solutions show hysteresis (遲滯現象) loops The increased shear stress required to break the thixotropic structure reduces the resistance to flow A pseudoplastic CMC solution instantly reverts to its at-rest viscosity after shear removal A thixotropic CMC solution requires time for return to its atrest state Left thixotropic and right nonthixotropic solution of CMC 3-3-5 Effect of trivalent metal ions Gelation of CMC solution can be controlled to form soft, pourable or very firm gels Gradual release of aluminum ions to a CMC solution results in uniform crosslinking The stiffness of gel depends on the amount of the crosslinking Concentration of polymer Metal cation to carboxylate anion ratio pH Polymer chain-length Aluminum-CMC gels Resistant to nonchelating acids but dissolve slowly in alkaline solutions High concentration of aluminum salts give more brittle gels Low-DS CMC solutions without salt addition also could form the gel More crystalline regions are present in low- than high-DS CMC Gel formation is probably the result of disaggregation of the fringed micelles in the crystalline regions, which provides more potential crosslinking points 3-3-6 Effect of temp. on viscosity Temp. variation has no permanent effect on viscosity However, long periods of heating at high temp. tend to depolymerize and degrade CMC 3-3-7 Effect of pH on viscosity CMC solutions exhibit maximum viscosity and best stability at pH 7-9 pH > 10 some decrease in viscosity pH < 4.0 less soluble, increase in viscosity 3-3-8 Effect of concentration on viscosity In concentrated solution There is little tendency for the counter ions (Na) to move out of the sphere of influence of the charges on the polymer molecules In dilution solution The cations tend to move away into the aqueous interpolymer regions, leaving a net charge on the molecules As dilution continue , the charge density on the chains increase, and the chains continue to uncoil 3-3-8 Effect of concentration on viscosity At higher concentration Viscosity increases as an exponential function of concentration A doubling of the concentration causes a tenfold increase in viscosity Because viscosity is determined in large part by the length of polymer molecules, a wide range of viscosity types of commercial CMC are available MW 40,000-1,000,000 3-3-9 Compatibility CMC is compatible in solution with most watersoluble nonionic and anionic polymers and gums, proteins, carbohydrates, salts, and solvents. Monovalent cations usually form soluble salts Generally, divalent cations will not form crosslinked gels with CMC Little effect on solution viscosity, clarity Forming hazy solutions with reduced viscosity Trivalent cations form insoluble salts Compatibility of CMC with inorganic salt solution Compatibility with water-soluble polymers CMC is compatible with most water-soluble gums over a wide range of concentration Low-viscosity types > high-viscosity types In non-ionic polymer Guar gum , hydroxyethylcellulose, HPC A synergistic effect on viscosity Synergistic effect on viscosity Compatibility with solvents Compatibility with others With carbohydrates CMC gum thoroughly dissolve in water and sugar is then added increase of viscosity Dry gum is added to the sugar solution decrease of viscosity With protein CMC helps to solubilize various proteins and to stabilize their solutions CMC inhibits precipitation of casein in its isoelectric pH region and produces high viscosities Interaction of sodium CMC (DS 0.7) and soy protein 3-4 Applications Food-grade CMC is widely used because of its ability to thicken water, act as a moisture binder, dissolve rapidly in both hot and cold aqueous systems And because it is tasteless, odorless, and forms clear solution without cloudiness or opacity And because it is physiologically inert and noncaloric Cellulose gum food applications and properties utilized