Biochar Concrete Roofing Sheets for Nicaragua

advertisement

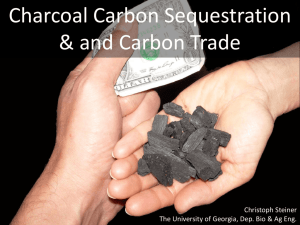

Biochar Concrete Roofing Sheets for Nicaragua Design Review 1 Agenda Team Introduction Project Background Problem Statement Additional Deliverables Use Scenarios Customer Requirements Benchmarking Engineering Requirements HOQ Risks Project Plan Concerns Next Steps Team Intro and Roles Peter Chynoweth - Mechanical Design Lead Jamiya Cook - External Project Manager Adrian Izbicki - Materials Design Lead Cindy Widergren - Internal Project Manager Project Background: Nicaragua and 4 Walls El Sauce, Nicaragua Largest country of South America Rural “cowboy” small-town atmosphere High unemployment, primarily agricultural, has growing opportunities for economic development 4 Walls Help families obtain their homes Build a potential small business for some people in Nicaragua Project Background: Biochar Made from many types of biomass including agricultural wastes Being tested as a component in building materials and are starting to test biochar amended with concrete Used to improve humidity control and could potentially have many other benefits Ithaka Institute - non-profit foundation that researches biochar teamed up with 4 Walls to see if roofs could be made from biochar Project Background: Biochar http://www.terralogix.net/biochar Problem Statement Current State Desired State Create roofs that are less expensive, made of local products, quieter in the rain and do not create a large solar gain by utilizing biochar Project Goals 4 Walls builds homes in Nicaragua but the roof construction is not optimal Analyze current roofing design Design a biochar roofing that can be made and repaired locally Constraints Roof must be able to be built with local materials and tools for less than $400 Deliverables Working Roof Prototype Test Documentation Molds for Manufacturing Material Mix (Biochar/Concrete) Instructions for Installation Schematics/Design Models Use Scenario: Construction of the Roof Customer Requirements / Interview Insights Benchmarking Cost ($/sqft) Weight (lbs) Installed Cost per sqft ($) Lifespan (years) Modularity (sqft) Wind Resistance (mph) Metal Sheets 1 1.5 7 50 42 140 Tar Tiles 1 2 1.20 20 3 110 Clay Tiles 2.50 10 4 45 1.5 110 *Benchmarks are in America Engineering Requirements House of Quality ● Compared customer requirements to engineering requirements HOQ Insights Most important ER: Total Cost Takeaways: Keep cost down Number of Skilled operators Keep installation simple Time to install roof Tradeoffs: Add more desired features, increase cost Keep in mind roof weight, dimensions, ability to hold a person, decreases install time Risks Current Project Plan and WBS Concerns Having our first meeting with one of our main customers today Will have to ensure that all of the previous work aligns with their requirements Future Plan As a team, where do you want to be in three weeks at your next review? a. Developing Alternatives b. Concept Selection c. Functional Analysis d. Feasibility Analysis e. Risk Assessment f. Test Plan Each individual team member has certain action items before the next review Questions?