Uses and Perception of Burnt Earth (clay)

advertisement

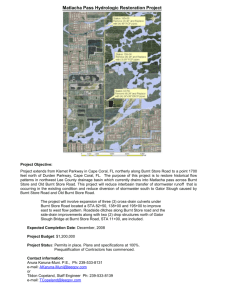

The Use of Burnt Earth (clay) in Guyana`s Road Construction Programme Presenters: Cecil Morrison and Lawrence Mentis Analytical Chemist Civil Engineer Consultant Head of Force Account Unit Serum Institute Ministry of Public Works Uses and Perception of Burnt Earth (clay) Introduction Burnt earth can be readily processed on the coast of Guyana , preferably in areas where the soil (clay) has a high percentage of salt. It must be noted that burnt clay was the foundation material of some of the inner city roads along with some highways constructed during the early and latter parts of the 20th century. However, in recent time, burnt earth has been regarded as old fashioned and replaced by mainly crusher run. This study is made up of photographs of usage, analytical tests results (compare/contrast with crush-run), engineering and mathematical model showing aggregate size/ distribution of burnt earth vs. crush-run, socioeconomic implications, and perception on barriers on the use of burnt earth for road construction as a surface and sub-base material. Perception The use of burnt earth (clay) in the construction of roadways has diminished mainly due to the perceived old fashioned methodology used in its production and lack of knowledge of its properties. With the advent of new technology in the quarry industry, the demand for burnt earth (clay) plummeted as a result of the main stakeholders educating their customers about the product(crusher – run). Further, the process by which crusher- run is derived is geological in nature compared with burnt earth (clay) which is man-made; hence the buy-in for the extensive use of crusher-run. However, based on the study conducted burnt earth (clay) has proven to be comparable with crusher-run and in some cases more suitable as a surface material due to aggregate and cost factor. The Findings The Findings revealed that the key factor inhibiting the use of burnt clay for road construction is low material demand due to a lack of knowledge. The findings provide a platform for stakeholders to address the barriers and thus enabling the extensive use of burnt clay/earth in road construction. Historical Perspective Historically, burnt earth (clay) has played a major role in the advancement of civilisation in the area of art and other aspects of human development which include but not limited to making cooking utensils and blocks used for building construction. Locally, burnt earth was widely used in the 1940s and 50s mainly as surface material for low volume roadways. This continued until about the 1980s where it was used in the construction of NDC roadways as well as in the maintenance of Guysuco and MMA all weather roads. Socioeconomic Impact Undoubtedly investment in the production of burnt earth (clay) would pay dividends to Guyana`s economy and by extension the society at large. The raw materials are easily accessible since they are ( with the exception of gasoline) a part of the country`s geographical structure. The process requires unskilled labour which would create jobs and increase the spending power of family units. Raw Materials The raw materials required in the production of burnt earth (clay) : • Wood (Courida logs)- these are the foundation for the heap and are stacked in a particular way; • Earth (clay)- Clay is the most important raw material used for processing burnt earth. Clay is the common name for earthy materials that become plastic when wet. Chemically, clays are hydrous aluminum silicates usually containing small amounts of impurities such as potassium, sodium, calcium, magnesium, or iron. One of the common process of clay formation is the chemical decomposition of feldspar. Essentially clay consist of interconnected silicates combined with a second sheet like grouping of metallic atoms, oxygen and hydroxyl, forming a two layer mineral such as kaolinite. Raw materials cont`d • Earth (Clay) cont`d Properties of clay minerals are plasticity, shrinkage under firing and air drying, fineness of grain, color after firing, hardness, cohesion, and capacity of the surface to take decoration. Generally, clay particles are smaller than 0.004 mm. Classes of clay: Residual clay Transported clay Groups of clay: Koalinite – are held together by fairly weak bonds Illite – strong bonding, presence of potassium Montmorillonite – presence of calcium and sodium + + + + + + - - - - - - Raw Materials Cont`d • Gasoline – the fuel used to light the mound. Gasoline is refined from crude oil. The generally accepted origin of crude oil is from plant and animal life from 100 to 600 million years ago. “Anaerobic digestion” of vegetable matter by bacteria, decomposing through heat and pressure .The result is the molecular structure of petroleum hydrocarbons and other compounds present in fossil fuels can be linked to the leaf waxes and other plant molecules of marine and terrestrial plants believed to exist during that era. Raw Materials cont`d Gasoline cont`d: Some properties of gasoline: It has a flash point of about -50° F (-65° C). Flash point is the temperature needed to produce sufficient vapour for combustion if an open ignition source is brought into contact with the vapour – i.e. an open flame or spark. The minimum auto-ignition temperature is about 495° F but usually it is between 232° C and 280°C. The flammability range of gasoline is between 1.4 and 7.6%. If the ratio of gasoline to air is less than 1.4%, by volume, then the mixture is “too thin or lean” to burn. Processing The production of the burnt earth(clay) takes approx. three (3) weeks. Courida logs is used as the foundation material for the heap (mound).The logs are approx. 3-4 feet in length and are packed joining each other length wise. Large quantities of ploughed earth (clay) are packed onto the logs which is then set alight using gasoline and burns for three to five days. As many as two to three mounds can be operated simultaneously. After this period of burning all that remains is the hard lumpy red brick, ready for use as road building materials. Diagram of a Heap (mound) • Process Flow Burnt Earth Acquire Wood (Courida) Plough clay Heap (Mound) Add clay Pack Wood Low Volume Road Design Lawrence Mentis Civil Engineer Head of Force Account Unit Ministry of Public Works What is a low volume road? • This presentation covers the design of lowvolume roads for flexible pavement surface with the addition of burnt earth as a base material. The information is applicable to rural roads • A low volume road is commonly defined as a road that has an average daily traffic (ADT) of less than 400 vehicles per day, and usually has design speeds of less than 80 kmph (50 mph). Why a burnt earth designed road? • The objectives of the use of burnt earth designed road are to accomplish the following: • • • • Produce a safe, Cost effective, Environmentally friendly, Practical road design that is supported by and meets the needs of the users; Design Characteristics • Parameters of the design requirements or characteristics of the design • The maximum number of heavy vehicles over the design life in the design lane considered for low-volume pavement design is limited to 750,000 a year. Heavy vehicles which include buses, single-units (with six or more tires), and multitrailer trucks. This level represents approximately 70 trucks and/or buses per day in the initial year that grows 4% compounded annually over 20 years. • The range of Structural Number (SN) values for each condition is based on a specific range of 18-kip ESAL applications at each traffic level. Design Characteristics – Structural Number • What is the Structural Number in Pavement Design? • In designing and building pavements, we sometimes casually assume that making a pavement thicker also makes it stronger, but even to the extent this is true, how thick is thick enough? One of the key questions in the structural design of an asphalt pavement is how thick each layer of the structure should be. During design, these thicknesses are related to the Structural Number (SN), which is an abstract value that expresses the structural strength of the overall pavement. Design Characteristics – Structural Number • Function of a Structural Number • Formal pavement design relies on engineering calculations based on established design equations, such as the empirical equations found in the 1993 AASHTO Guide for Design of Pavement Structures. A critical element of the flexible pavement equation is the Structural Number, which represents the overall structural requirement needed to sustain the traffic loads anticipated in the design. The required Structural Number depends on a combination of existing soil support, total traffic loads, pavement serviceability, and environmental conditions. Design Characteristics – ESAL • What is ESAL? • ESAL is the acronym for Equivalent Single Axle Load. ESAL is a concept developed from data collected at the American Association of State Highway Officials (AASHO) Road Test to establish a damage relationship for comparing the effects of axles carrying different loads. The reference axle load is an 18,000-lb. single axle with dual tires. Results from using AASHTO 1993 for Burnt Earth (CBR 53%) Item ESALs SNreq Burnt Earth Thickness AC Thickness 1 0.1x10^6 2.788 18 Inches 2 Inches 2 0.2x10^6 3.00 20 Inches 2 Inches 3 0.3x10^6 3.211 21 Inches 2 Inches Results from using AASHTO 1993 for Crusher Run (CBR 70%), White Sand/ Sand Clay (CBR 30%) and White Sand (CBR 20%). Item ESALs SNreq CR Thickness WS/SC Thickness WS Thickness AC Thickness 1 0.1x10^6 2.788 6 Inches 6 Inches 8 Inches 2 Inches 2 0.2x10^6 3.00 6 Inches 7Inches 9 Inches 2 Inches 3 0.3x10^6 3.211 6 Inches 8 Inches 9 Inches 2 Inches Low Volume Roads Analysis • Data from charts from Low Volume roads using AASHTO 1993 • • • • • • • Reliability = 75% Standard Deviation = 0.45 Drainage condition = 1.0 Initial Serviceability = 3.5 Final Serviceability = 1.0 Design Serviceability Loss = 3.5-1.0 =2.5 Resilient Modulus (MR) = 4ksi Cost analysis of Burnt Earth vs. Crusher Run, White Sand/Sand Clay, White Sand Item ESALs SNreq AC Thickness Burnt Earth Thickness 1 0.1x10^6 2.788 2 Inches 18 Inches 2 0.2x10^6 3.00 2 Inches 20Inches 3 0.3x10^6 3.211 2 Inches 21 Inches Cost of Burnt Earth per Cubic Yard $5,500 Item ESALs SNreq CR Thickness WS/SC Thickness WS Thickness AC Thickness 1 0.1x10^6 2.788 6 Inches 6 Inches 8 Inches 2 Inches 2 0.2x10^6 3.00 6 Inches 7Inches 9 Inches 2 Inches 3 0.3x10^6 3.211 6 Inches 8 Inches 9 Inches 2 Inches $9,000 $3,000 $2,000 Cost per Cubic Yard Conclusion • In executing the community road in Georgetown (Area Q Turkeyen) Burnt Earth was used to expedite the conclusion of the road network since Crusher Run could not be obtained promptly. Burnt Earth was more cost effective and also met the design requirements based on AASHTO 1993. Photos of Finished Area Q Turkeyen Road Photos of Finished Area Q Turkeyen Road Recommendations • More studies should be done on burnt earth (clay) high volume roads/ highways; • The Ministry should make known to burnt earth (clay) producers estimated quantities required monthly/quarterly/annually with the necessary inhouse specifications; • The Ministry should provide the engineering data to all Regional Democratic Councils on burnt earth (clay) specifications and usage; and • Additional studies should be done on the use of burnt earth (clay) as a finished surface (wearing surface) Thank You