Decision Making and Relevant Information

advertisement

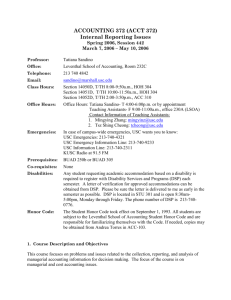

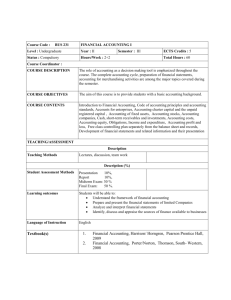

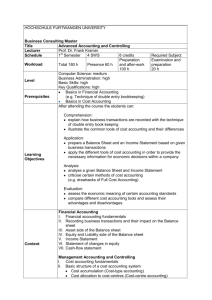

Decision Making and Relevant Information Chapter 11 ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 1 Learning Objective 1 Differentiate relevant from irrelevant costs and revenues in decision situations. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 2 The Meaning of Relevance Relevant costs and relevant revenues are expected future costs and revenues that differ among alternative courses of action. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 3 Learning Objective 2 Analyse a One-Time-Only Special Order ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 4 One-Time-Only Special Order Example The Bismark Co. manufacturing plant has a production capacity of 44,000 towels each month. Current monthly production is 30,000 towels. Costs can be classified as either variable or fixed with respect to units of output. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 5 One-Time-Only Special Order Example Variable Costs Per Unit Direct materials $6.50 Direct labor .50 Manufacturing overhead 1.50 Total $8.50 Fixed Costs Per Unit $ 0 1.50 3.50 $5.00 ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 6 One-Time-Only Special Order Example Total fixed direct manufacturing labor is $45,000. Total fixed overhead is $105,000. Marketing costs per unit are $7 ($5 of which is variable). What is the full cost per towel? ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 7 One-Time-Only Special Order Example Manufacturing ($8.50 + $5.00): $13.50 Marketing 7.00 Total 20.50 A hotel in San Juan has offered to buy 5,000 towels from Bismark Co. at $11.50/towel for a total of $57,500. No marketing costs will be incurred. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 8 One-Time-Only Special Order Example What are the relevant costs of making the towels ? $8.50 × 5,000 = $42,500 incremental costs What are the incremental revenues ? $11.5 x 5,000 = 57,000 Solution: Accept Special Order ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 9 Learning Objective 3 Analyse an insourcing versus outsourcing decision ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 10 Outsourcing versus Insourcing Outsourcing is purchasing goods and services from outside vendors. Insourcing is producing goods or providing services within the organization. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 11 Make-or-Buy Decisions Example Bismark Co. also manufactures bath accessories. Management is considering producing a part it needs (#2) or buying the same part produced by Towson Co. for $0.55. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 12 Make-or-Buy Decisions Example Bismark Co. has the following costs for 150,000 units of Part #2: Direct materials $ 28,000 Direct labor 18,500 Mixed overhead 29,000 Variable overhead 15,000 Fixed overhead 30,000 Total $120,500 ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 13 Make-or-Buy Decisions Example Mixed overhead consists of material handling and setup costs. Bismark Co. produces the 150,000 units in 100 batches of 1,500 units each. Total material handling and setup costs Consists of a fixed portion of $9,000 plus a Variable portion of $200 per batch. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 14 Make-or-Buy Decisions Example What is the cost per unit for Part #2? $120,500 ÷ 150,000 units = $0.8033/unit ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 15 Make-or-Buy Decisions Example Bismark Co. anticipates that next year the 150,000 units of Part #2 expected to be sold will be manufactured in 150 batches of 1,000 units each. Variable costs per batch are expected to decrease to $100. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 16 Make-or-Buy Decisions Example Bismark Co. plans to continue to produce 150,000 next year at the same variable manufacturing costs per unit as this year. Fixed costs are expected to remain the same as this year. Should Bismark Co. manufacture the part or buy it from Towson Co.? ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 17 Make-or-Buy Decisions Example What is the variable manufacturing cost per unit? Direct material Direct labor Variable overhead Total $28,000 18,500 15,000 $61,500 $61,500 ÷ 150,000 = $0.41 per unit ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 18 Make-or-Buy Decisions Example Expected relevant cost to make Part #2: Manufacturing Material handling and setups Total relevant cost to make *150 × $100 = $15,000 $61,500 15,000* $76,500 Cost to buy: (150,000 × $0.55) $82,500 Bismark Co. will save $6,000 by making the part. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 19 Make-or-Buy Decisions Example Now assume that the $9,000 in fixed clerical salaries to support material handling and setup will not be incurred if Part #2 is purchased from Towson Co.. Should Bismark Co. buy the part or make the part? ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 20 Make-or-Buy Decisions Example Relevant cost to make: Variable Fixed Total Cost to buy: $76,500 9,000 $85,500 $82,500 Bismark would save $3,000 by buying the part. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 21 Learning Objective 4 Explain the opportunity-cost concept and why it is used in decision making. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 22 Opportunity Costs, Outsourcing, and Constraints Assume that if Bismark buys the part from Towson, it can use the facilities previously used to manufacture Part #2 to produce Part #3 for Krysta Company. The expected additional future operating income is $18,000. What should Bismark Co. do? ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 23 Opportunity Costs, Outsourcing, and Constraints Bismark Co. has three options regarding Krysta: 1. Make Part #2 and do not make Part #3. 2. Buy Part #2 and do not make Part #3. 3. Buy the part and use the facilities to produce Part #3. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 24 Opportunity Costs, Outsourcing, and Constraints Expected cost of obtaining 150,000 parts: Buy Part #2 and do not make Part #3: $82,500 Buy Part #2 and make Part #3: $82,500 – $18,000 = Make Part #2: $64,500 $76,500 ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 25 Opportunity Costs, Outsourcing, and Constraints Opportunity cost is the contribution to income that is forgone (rejected) by not using a limited resource in its next-best alternative use. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 26 Opportunity Costs, Outsourcing, and Constraints Assume that annual estimated Part #2 requirements for next year is 150,000. Cost per purchase order is $40. Cost per unit when each purchase is 1,500 units = $0.55. Cost per unit when each purchase is equal to or greater than 150,000 = $0.54. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 27 Opportunity Costs, Outsourcing, and Constraints Average investment in inventory is either: (1,500 × .55) ÷ 2 = $412.50 or (150,000 × $0.54) ÷ 2 = $40,500 Annual interest rate for investment in government bonds is 6%. $412.50 × .06 = $24.75 $40,500 × .06 = $2,430 ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 28 Opportunity Costs, Outsourcing, and Constraints Option A: Make 100 purchases of 1,500 units: Purchase order costs: (100 × $40) $ 4,000.00 Purchase costs: (150,000 × $0.55) $82,500.00 Annual interest income: $ Relevant costs: $86,524.75 ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 24.75 11 - 29 Opportunity Costs, Outsourcing, and Constraints Option B: Make 1 purchase of 150,000 units: Purchase order costs: (1 × $40) $ Purchase costs: (150,000 × $0.54) $81,000 Annual interest income: $ 2,430 Relevant costs: $83,470 ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 40 11 - 30 Learning Objective 5 Know how to choose which products to produce when there are capacity constraints. Video Clip ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 31 Product-Mix Decisions Under Capacity Constraints Per unit Product #2 Product #3 Sales price $2.11 $14.50 Variable expenses 0.41 13.90 Contribution margin $1.70 $ 0.60 Contribution margin ratio 81% 4% Bismark Co. has 3,000 machine-hours available. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 32 Product-Mix Decisions Under Capacity Constraints One unit of Prod. #2 requires 7 machine-hours. One unit of Prod. #3 requires 2 machine-hours. What is the contribution of each product per machine-hour? Product #2: $1.70 ÷ 7 = $0.24 Product #3: $0.60 ÷ 2 = $0.30 ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 33 Learning Objective 6 Discuss what managers must consider when adding or discontinuing customers and segments. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 34 Profitability, Activity-Based Costing, and Relevant Costs Mountain View Furniture supplies furniture to two local retailers – Stevens and Cohen. The company has a monthly capacity of 3,000 machine-hours. Fixed costs are allocated on the basis of revenues. ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 35 Profitability, Activity-Based Costing, and Relevant Costs Revenues Variable costs Fixed costs Total operating costs Operating income Machine-hours required Stevens Cohen $200,000 $100,000 70,000 60,000 100,000 50,000 $170,000 $110,000 $ 30,000 $(10,000) 2,000 1,000 ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 36 Profitability, Activity-Based Costing, and Relevant Costs Revenues Variable costs Fixed costs Total operating costs Operating income Machine-hours required Total $300,000 130,000 150,000 $280,000 $ 20,000 3,000 ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 37 Profitability, Activity-Based Costing, and Relevant Costs Should Mountain View Furniture drop the Cohen business, assuming that dropping Cohen would decrease its total fixed costs by 10%? New fixed costs would be: $150,000 – $15,000 = $135,000 ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 38 Profitability, Activity-Based Costing, and Relevant Costs Revenues Variable costs Fixed costs Total operating costs Operating income Machine-hours required Stevens Alone $200,000 70,000 135,000 $205,000 $ (5,000) 3,000 The answer is NO! ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Foster 11 - 39