Disaster & Business Continuity

advertisement

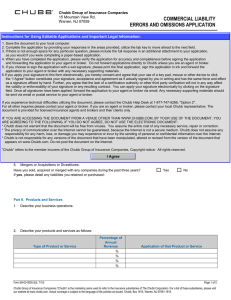

BIOTECH SUPPLY CHAIN ACADEMY October 8-9, 2012 Crowne Plaza, Foster City, CA Disaster Prevention and Business Recovery: Are You Ready? Russell Owens CSP, ABCP, AVP Senior Business Continuity Specialist The World Today • “Speed, agility, efficiency, responsiveness and innovation all remain critical, but equally important is a resilient supply chain.” – Research firm, Garner • “Everybody has moved to a leaner, single-sourcing, fewer-supplier approach. Hey presto, what’s going to happen? You are going to increase risk.” - Tim Lawrence, managing consultant at PA Consulting • The potential threat from natural disaster rose from 55% in 2010 to 81% in 2011 in a recent survey of 100 technology firms • We live in an interconnected world where geographical disasters and political unrest can impact businesses anytime, anywhere and any place Storage of API Fill & Finish Transit Supply Chain In-house QC Manufacturing of API Packaging & Labeling Customer Storage of finished goods & Distribution Supply Chain Solutions • Live with it • Improve it • Insure against it The Do Nothing Solution Solutions – Live with It • “Average fall in a share price following an announcement to the market of a supply disruption was 10 per cent. And it takes the price at least 60 days to recover from the fall.” • Stock price movement with and without a Contingency Plan Solutions – Improve It • If the Procurement Head is not part of the C-level suite, you need an ally there! • What does your BCP cover? – Were you part of its development? • Are you involved in testing the organization’s contingency plans? Solutions – Improve It • Split the sources/production up – This sounds like the simplest solution, but is it? • A diverse supply base is effective, but initially more expensive, strategy. • Where is the other source/production located? – Does this make the risk better or worse? • Just In Time – Vulnerable to supply chain shocks – What are the savings and what are the costs? Solutions – Improve It • Look at your top 3 products – Map It Out – What is the supply chain behind them – Where are the risk nodes behind that chain? • Supplier Relationship Management Program (SRM) – Do you have one? – Do you know what your suppliers SRM is for their suppliers? • You want to be at the front of the queue from your suppliers if you need them. When Looking at Suppliers • Do not look at their ability at a single point in time. Take a longer look at the chain (5 years?) • Map your exposures - Where are the pinch points that will effect the chain. 1. Location 2. Transportation 3. 2nd and 3rd level suppliers 4. Other areas of concern • Start the process when you are qualifying a supplier - Use of audits and detailed questionnaires Sourcing of Materials • Who will source goods? • Develop contingency plans for each element – Determine level of stock – consider single source items or items with extended lead times for delivery – Where are they being warehoused – Are there alternative materials or alternative vendors • Master Service Agreement should spell out roles/responsibilities • Pedigree Contingency Plans • Develop a plan with assigned responsibilities • Identify, qualify and select third party service providers • Negotiate contracts with each selected provider • Consider the Regulators and other Government requirements • Stress test the formal plan • Revisit your plan on a semi-annual or annual basis Training and Testing Update Plan Completed Plan Testing Training Training Update Plan Testing Solutions – Insure Against It • Insurance – Do you have enough ? – What does it actually cover ? – Have you discussed your needs with your Risk Manager or Insurance Buyer? – 30 per cent of US companies do not have any cover for supply chain disruption. • Most Business Interruption (BI) policies tend to cover – First-tier suppliers on a named or unnamed basis – Physical damage to that supplier (i.e. earthquake, flood or fire) – Does it cover Extra Expense? What are the limitations? Questions Thank You Chubb Group of Insurance Companies (“Chubb”) is the marketing name used to refer to the insurance subsidiaries of The Chubb Corporation. For a list of these subsidiaries, please visit our website at www.chubb.com. Actual coverage is subject to the language of the policies as issued. Chubb, Box 1615, Warren, NJ 07061-1615. This document is advisory in nature. The information provided should not be relied on as legal or insurance advice or a definitive statement of the law in any jurisdiction. For such advice, an applicant, insured, listener or reader should consult their own legal counsel or insurance consultant. No liability is assumed by reason of the information this document contains. Whether or to what extent a particular loss is covered depends on the facts and circumstances of the loss and the actual coverage of the policy as issued. 17 References & Additional Resources • • • • • • • Downey, E., Shea, T., & Kelleher, B. (2012). Beware the Weakest Link! Mitigating Supply Chain Risk: Best Practices Risk Management and Risk Transfer Strategies. What's Your BIO?, (p. 8). Evans, J. (2011, 02 06). 4. Retrieved 08 30, 2012, from WSJ.com: http://online.wsj.com/article/SB10001424052748703296604576005060742737534.html ? Gammelgard, A. (2011, 05 19). 8. Retrieved 08 30, 2012, from aws arena solutions: http://www-aws.arenasolutions.com/blog/post/managing-supply-chain-risk Hale, T., & Moberg, C. R. (2005). Improving supply chain disaster preparedness A decision process for secure site location. International Journal of Physical Distribution & Logistics Management, 195. Hookway, J., & Poon, A. (2011, 05). Crisis Tests Supply Chain's Weak Links. Retrieved 03 18, 2011, from The Wall Street Journal: http://online.wsj.com/article/ Snell, P. (2011, Summer). 10. Retrieved 06 28, 2012, from cpoagenda.com: http://www.cpoagenda.com/current-issue/features/chain-reaction/ Walch, D. (n.d.). Planning for Supply Chain Continuity. Retrieved 08 30, 2012, from disaster-resource.com: http://www.disaster-resource.com/articles/08exe_p24.shtml