Company Background

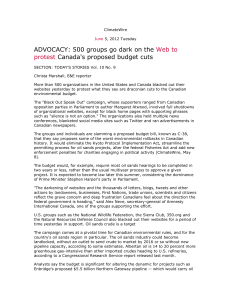

advertisement

Canadian Oil and Gas Presented by: Haosen Liang Sandy Sanjoto Alice Liang Yu Tai Ben Yee Presentation Overview Industry Analysis Imperial Oil Suncor Energy Encana Corporation Agenda Canada’s Place in the World Underlying Product Industry Components Importance of Technology SWOT Analysis Recommendation Top Ten World Natural Gas Producers in 2004 Top 10 World Crude Oil Producers in 2004 Oil and Gas Re-investment Cycle ($ Cdn for 2003-2005) What is the underlying product? Fossil sediments trapped in in the pores of rocks Hydrocarbons CH4 (methane), C3H8 (propane), C4H10 (butane) C7H16 through C11H24 (gasoline and diesel) Lubricating and Heavy gas oils Types and Uses Crude Oil and Natural Gas Uses: Products: Mobility, heat and cool our homes and provide electricity plastics, life-saving medications, clothing, cosmetics, and many other items you may use daily Barrel – a unit of measure for oil and petroleum products that is equivalent to 42 U.S. gallons ~ 159 Litres Proven Natural Gas Reserves Western Canadian Natural Gas Resources Canadian Oil Production Outlook Big Players’ Production Conventional Oil vs. Oil Sands Conventional Oil Petroleum found in liquid form, flowing naturally or capable of being pumped without further processing or dilution Light crude oil Cheaper to produce Oil Sands Synthetic Crude Oil Oil Sands is a thick mixture of sands, bitumen, mineral rich clays and water Synthetic crude oil is extracted from oil sands and it is often sold at a premium because of its high quality More costly to produce Types of Crude Oil Produced in Canada • Condensates: hydrocarbons recovered from a natural gas reservoir. • Light crude oil: liquid petroleum with a gravity of 28°API or higher • Heavy crude oil: liquid petroleum with a gravity below 28°API • Bitumen: petroleum in semi-solid or solid form that is found in bituminous sands. It is so heavy (gravity below 12°API) and viscous that it will not flow unless heated or diluted. • Synthetic crude oil: a product similar to a high-quality light crude oil. It is made by refining or upgrading heavy oil or bitumen. From 31-33°API • Pentanes: hydrocarbons containing molecules of 5 carbon atoms and 12 hydrogen atoms. Industry Components Upstream Exploration and Production Seismic Survey Midstream Pipeline, Transportation and Storage Downstream Refining, Marketing and Retailing Extraction 1.Natural Gas Wells are drilled and gas flows under its own pressure ~ 90% methane Needs processing to remove impurities 2. Drilling: Conventional crude oil that is near the surface can pumped up using traditional techniques Oil Sands Composition Synthetic Crude Production Process Ore Preparation Strip-Mining The pick and shovel method used to recover oil sands that are near surface 600,000 barrels per day 1.2m barrels per day in 2010 In Situ Includes various methods used to recover deeply buried bitumen deposits, including steam injection, solvent injection and firefloods 380,000 barrels per day 700,000 barrels per day in 2010 More than 80% of the Oil Sands reserve require this method Extraction Separates Bitumen from other molecules Upgrading Processes Bitumen into Synthetic Crude Oil and Vacuum Gas Oil In-situ Production SAGD: Steam Assisted Gravity Drainage Because of the rising prices of natural gas, crude producers are moving towards using bitumen or high sulphur fuels to generate steam 80% of bitumen extraction relies on this method Harvesting Bitumen Oil Refining 1. Fractional Distillation ~ boil and cool 2. Conversion ~ chemicals 3. Treatment ~ impurities 4. Recombination ~ octane ratings Importance of Technology Correlation between Oil and Natural Gas Prices Oil Sands Production Technologies Alternates to Natural Gas Toe-to-Heel Air Injection Oil Sands Supply Costs by Recovery Type Heavy Oil Economics (US$ per barrel) Strengths Canada is the world leader of Enhanced recovery techniques for mature reservoirs Cold climate and offshore production Gas processing, sulphur extraction and heavy oil upgrading Oil Sands reserve Development of Oil Sand projects Integrated with the world’s largest market for energy consumption, making it less costly to bring the products to market. Strong interest from China, the largest market for energy consumption in the future. Attractive crown royalty rate for oil sand projects Weakness - Regulatory Approval Weaknesses Limited natural gas reserves Capacity for natural gas is forecasted to decrease Canada is one of the high-cost places in the world to find and produce oil and gas Deep gas, natural gas from coal and developments offshore, in the oil sands and the North are large, complex and expensive and have long lead times before they turn a profit Challenges in meeting North America’s energy needs Opportunities Exporting to the US Oils Sands Exploration of Northern and Eastern Canada World population is currently around 6 billion people, but is expected to grow to approximately 7.6 billion by 2020. - a huge increase in the demand for transportation fuels, electricity, and many other consumer products made from oil and natural gas. Opportunities - Markets Expanding markets in U.S. and Asia Threats Tighter environmental and security regulations Kyoto Protocol Limited proven natural gas reserve Long run viability of oil sands project It is estimated that crude price has to be above $30 a barrel for oil sand projects to be profitable because of the high production costs Increasing Supply costs Important Trends Higher oil sands production/declining conventional oil production Share of gas production increasingly coming from sour and unconventional gas (e.g., coalbed methane) Average drilling density increasing and competition for the land base escalating Average finding and development costs spiraling upwards Greater North American market interdependence Recommended Strategy Selection Criteria for Long Term Investment Larger companies with strong financial resources Companies that have good access to resources and (potential) markets Companies that already demonstrate superior cost structure and lower production costs Imperial Oil Limited Agenda Company Background Management & Business Strategy Business Segments Risks and Challenges Financial Information by Segments Agenda (Cont) Financial Statements Valuation Ratios Stock Prices and Charts Discounted Cash Flow Model Conclusion & Recommendation Company Background Incorporated in 1880 with HQ in Calgary, Alberta Largest integrated oil company in Canada Stock Exchanges: AMEX (IMO-A), TSE (IMO-T) Market Cap: 37.187 Billion (As of March 10, 2006) Share Price: $111.80 CAD (As of March 10, 2006) Company Background (Cont) Proposed three-for-one stock split on Feb 2, 2006 Relationship with Exxon Mobil Corporation Exxon Mobil owns 69.6% of the company Abundant access to technologies, leverage, and research globally Imperial Oil and Exxon Mobil have agreed to operate their Western Canada production together as of April 1, 2005 Management & Business Strategy T.J. (Tim) Hearn: Chairman, president and CEO R.L. (Randy) Broiles: Senior VP, resources division P.A. (Paul) Smith: Controller and senior VP, finance and administration Enhances shareholder value through the Consistent Management Approach Management & Business Strategy Sustained emphasis on 4 corporate priorities: Operational Growing excellence profitable sales volume Achieving and maintaining a best-in-class cost structure Improving asset mix the productivity of the Business Segments Three business segments: Natural Resources (Upstream) Petroleum Chemicals Products (Downstream) Natural Resources Conventional Oil and Gas Norman Wells in Northwest Territories West Pembina in Alberta Wizard Lake Oil Sands - Cold Lake in Alberta Tar Sands - Syncrude in Alberta Exploration and Development Mackenzie Delta Major Oil Sands Deposits Oil Sands – Cold Lake Operations Imperial Oil owns 78,000 hectares of oil sands Cold Lake is the second largest thermal heavy-oil operations in the world Development drilling program and research Increasing royalties to be paid to government Oil Sands – Cold Lake Operations Oil Sands – Cold Lake Operations Tar Sands – Syncrude Operations Tar Sands – Syncrude Operations Located near Fort McMurray, Alberta The single largest crude oil producer in Canada Three main activities: recover shallow deposits of tar sands using open-pit mining methods, extraction of crude bitumen, and production of synthetic crude oil Recent investment in expansions (Aurora) Exploration and Development Mackenzie Delta Development of 3 natural gas fields: Taglu, Parsons Lake, and Niglintgak Shared project with ConocoPhillips, Shell Canada, Exxon Mobil, and the Aboriginal Pipeline Group Petroleum Products Four refineries: Sarnia, Strathcona, Darmouth, and Nanticoke Nation-wide distribution system with 30 primary terminals Petroleum Products Markets over 700 petroleum products throughout Canada Distributed and marketed through over 2000 Esso stations, 100 commercial facilities, and 3 urban home heating operations 650 Esso convenience and 400 sites with car washing facilities Chemicals Largest market share for rotational modeling polyethylene applications and second largest market share for injection modeling applications in North America Major operations located in Sarnia, Ontario Risks and Challenges Volatility of oil and natural gas prices Intense competition Environmental regulations Need to replace reserves Risks and Challenges Earnings Sensitivity Financial Information by Segments Financials - Income Statement Financials - Income Statement Financials - Balance Sheet Financials - Balance Sheet Financials - Cash Flow Statement Financials - Cash Flow Statement Valuation Ratios Imperial Oil 2005 2004 2003 Industry Price/Earnings 15.1 12.37 12.56 8.40 Price/Book 5.77 3.85 3.75 3.00 Net Profit Margin 9.22% 9.14% 8.88% 6.40% Dividend Yield 0.81% 1.24% 1.51% 2.46% ROE 39.20% 32.46% 30.75% 20.70% EPS 7.62 5.75 4.58 N/A 62.20% 23.67% 28.31% N/A Annual Growth 1 Year Stock Price vs. S&P Energy 5 Year Stock Price vs. S&P Energy Discounted Cash Flow Model Gordon Growth Model k = 0.0387 g = 0.0289 P = Div/(k-g) = 0.94/(0.0387-0.0289) = $95.92 IMO is overvalued slightly compared with its current stock price Conclusion & Recommendation Leader in market with low risk Sustainable growth High ROE Strong dividend and repurchase record Recommendation: BUY Suncor Energy Agenda Company Background Management Team Integrated Strategy Oil Sands Natural Gas Refining and Marketing – Canada Refining and Marketing – US Analysis on Suncor’s Consolidated Financial Statements Stock Information as of March 10, 2006 Recommendation About Suncor An integrated energy company Strategically focused on developing one of the world’s largest petroleum resource basins – Canada’s Athabasca oils sands Pioneering the industry in 1967 and became a publicly traded company in 1992 The core oil sands business is supported by conventional natural gas production in Western Canada and downstream refining, marketing and retail businesses in Ontario and Colorado Significant progress since 1992: Daily oil sands production has more than tripled One of the lowest cost producers in North America Growth in market capitalization ($1 billion to more than $19 billion at the end of 2004) Corporate Committee Richard George – President & CEO since 1991 Kenneth Alley – Senior VP & CFO since 2003 (join Suncor in 1984) Mike Ashar – Executive VP, Refining and Marketing since 2003 (join Suncor in 1987) David Byler – Executive VP, Natural Gas & Renewable Energy since 2000 (join Suncor in 1979) Terry Hopwood – Senior VP & General Council since 2002 (join Suncor in 1988) Sue Lee – Senior VP, HR & Communications since 1996 Jay Thornton – Senior VP, Business Integration Kevin Nabholz – Senior VP, Major projects since 2002 (join Suncor in 1986) Steven Williams – Executive VP Oil Sands since 2003 (join Suncor in 2002) Thomas Ryley – Executive VP, Energy Marketing & Refining (join Suncor in 1983) Integrated Strategy 4 major business divisions: 1. 2. 3. 4. Oil Sands Natural Gas and Renewable Energy – produce in Western Canada Energy Marketing and Refining – Ontario Refining and Marketing – Colorado Integrated Strategy With a high quality resource base that it is estimated to contain the raw materials to produce a potential 11 billion barrels of conventional crude oil, Suncor doesn’t need to look for new oil reservoirs. Instead it can focus on developing the technology and expertise to produce higher value crude oil products, increase production and improve operational flexibility. Integrated Strategy Oil Sands Located near Fort McMurray, Alberta Recovers bitumen through mining and in-situ development and upgrades it into refinery feedstock, diesel fuel and by products. The foundation of Suncor’s growth strategy and represents the most significant portion of the company’s assets. Suncor pioneered the world’s first commercially successful oil sands operation in 1967 and today, with total production nearing the one billion barrel mark and enough reserves to sustain production for the next 50 years, the company remains a leader in oil sands development. Oil Sands Natural Gas Primarily produces conventional natural gas in Western Canada Serves as a price hedge that provides the company with a degree of protection from volatile market prices of natural gas purchased for internal consumption. To ensure natural gas production keeps pace with company-wide natural gas purchases, NG is targeting production increases of 3% to 5% per year. Natural Gas Production Marketing and Refining - Cad Operates a 70,000 barrel per day (bpd) capacity refinery in Sarnia, Ontario Markets refined products to industrial, wholesale and commercial customers primarily in Ontario and Quebec Markets products to retail customers in Ontario through its Sunoco-branded and joint-venture operated service networks Encompasses third-party energy marketing and trading activities, as well as providing marketing services for the sale of crude oil and natural gas from the Oil Sands and NG operations. Outlook & Risk/Success Factors Outlook: Construction on a diesel desulphurization project at the Sarnia refinery to meet current and anticipated federal sulphur regulations. Construction of a planned ethanol plant is expected to begin in 2005 and be completed by 2006, subject to regulatory approvals. This facility is expected to produce ethanol at a for blending into Sunoco-branded and Suncor joint-venture retail gasolines. As a result of the fire incident, M&R may be required to purchase additional synthetic crude oil feedstock to meet demand, resulting in higher purchased product costs. Risk/Success Factors Affecting Performance: Fluctuations in demand and supply for refined products, margin and price volatility. The risk of cost overruns for the execution of capital projects. Numerous risks and uncertainties that could affect construction schedules of the diesel desulphurization project. Refining and Marketing - US Downstream assets based in Denver, Colorado (acquired in August 2003) This acquisition is part of an integration strategy aimed at improving access to the North American energy markets through acquisitions, long-term contracts and possible joint-ventures. Operates a 60,000 barrel per day (bpd) capacity refinery Markets refined products to customers primarily in Colorado, including retail marketing through 43 Phillips 66-branded retail stations in the Denver area. Outlook & Risk/Success Factors Outlook: Approximately $260m on new capital project Spend $29 million by 2006 to meet existing obligations between the refinery and the United States Environmental Protection Agency and the State of Colorado. 42-day scheduled maintenance is planned for pipeline and refinery equipment. R&M’s existing four-year contract with the local Paper, Allied-Industrial Chemical and Energy Workers International Union, which applies to hourly wage employees at the refinery, will expire in January 2006. Risk/Success Factors Affecting Performance: Fluctuations in demand for refined products, margin and price volatility and market competitiveness The risks associated with the execution of the fuels desulphurization project Numerous risks and uncertainties can affect construction schedules A weaker Canadian dollar would result in a higher funding requirement for U.S. capital programs. Outlook & Risk/Success Factors Outlook: Approximately $260m on new capital project Spend $29 million by 2006 to meet existing obligations between the refinery and the United States Environmental Protection Agency and the State of Colorado. 42-day scheduled maintenance is planned for pipeline and refinery equipment. R&M’s existing four-year contract with the local Paper, Allied-Industrial Chemical and Energy Workers International Union, which applies to hourly wage employees at the refinery, will expire in January 2006. Risk/Success Factors Affecting Performance: Fluctuations in demand for refined products, margin and price volatility and market competitiveness The risks associated with the execution of the fuels desulphurization project Numerous risks and uncertainties can affect construction schedules A weaker Canadian dollar would result in a higher funding requirement for U.S. capital programs. 2005 - Promised and Delivered Recovered from the challenging fire damage at the start of the year, which lowered production capacity from 225,000 to 171,000 hence higher production cost per barrel All recovery is on schedule and completed in September and full production capacity recovered. At the mean time able to control our net debt to cash flow ratio of only 1.2, despite a 2.9 billion recover expenditure on the fire recovery Commissioned a 450 million expansion, bringing production capacity up by 15% to 260,000 barrels per day Acquired Valero Energy Corporation, and became the largest refining operation in the U.S Rockies area Continued to improve energy efficiency, greenhouse effect offset and new, renewable energy projects. Risk/Success Factors Commodity prices Exchange rates Environmental regulations Stakeholder support for growth plans Extreme winter weather Regional labour issues Each business segment Risk/Success factors Subsequent Event Strong 4th Quarter results 1.214 billion earning , up from 1.020 billion Damage to fire last year recovered, fully functional Production capacity up to 260000 bpd from 225000 bpd However: Production is down: 206100 down from 263300 Average cost up as a result: 19.50 from 11.95 Net debt was 2.9 billion, compared to 2.2 billion from 2004 Outlook & Risk/Success Factors Outlook & Risk/Success Factors Control cost per barrel @ 16 to 16.75 Increase bitumen supply with proved supply and upgrader capacity to 350,000 bpd in 2008 Increase natural gas production to an average of 205 to 210 mmcf per day. Maintain a strong balance sheet with debt and hedging management with 3.5 billion investment in 2006 Consolidated Financial Statements Sensitivity Analysis Consolidated Statement of Earnings Revenues Revenues INCREASE: $2421 millions (27.9% increase from 2004) The increase resulted primarily from: Higher average commodity price (offset by a 7% increase in the average CDN$/ US$ exchange rate) increased revenue by $1.2 billion Increase crude oil production increased revenue by approx $220 million Higher refined product wholesale and retail prices, increase in sales volumes, one full year of operations of the Refining and Marketing division increased revenue by approx $890 million These increased is partially offset by hedging losses reduced revenue by approx $380 million Expenses Purchases of crude oil and crude oil products INCREASE Higher benchmark crude oil feedstock prices, Higher volume and refined products feedstock required as a result of 1 full year of operations for R&M Operating, Selling and General INCREASE The effects of 12 months of operations at R&M - US Higher operating expense higher energy costs Higher cost for obtaining certification under the Sarbanes-Oxley Act, and higher stock-based compensation expense Increased maintenance activities Financing expense DECREASE Lower foreign exchange gains on the Suncor’s US$ denominated long-term debt Net Income Revenue increased by 27.9%, Expenses increased by 29.1% Earnings Before Income Taxes increased by 22.8% Income Tax expense INCREASED Net Income, EPS INCREASE by $0.33 Cash Dividend INCREASE by 4.3% Consolidated Net Income Net Income Analysis Balance Sheet Statements Analysis of Balance Sheet Increased in AR - due to higher sales volumes and higher price Increased in Property, Plant and Equipment – due to company’s expansion Increased in AP and accrued liabilities related to increased capital spending in the fourth quarter and higher accrued royalties payable Derivative Financial Instruments Commodity Hedging Activities To hedge against the potential adverse impact of changing market prices due to variations in underlying commodity indices Suncor did not enter into any new arrangements in 2004. The strength of the its financial position, combined with stable operating costs and a growing production base, reduces the company’s risk to crude oil price volatility. Prior to the suspension of the hedging program, Suncor had entered contracts to fix the price on 36,000 barrels of crude oil per day at an average price of US$23 per barrel, which resulted in decreased in net earnings by $397 million. Financial Hedging Risk management strategy to manage exposure to interest rate fluctuations The interest rate swap contracts involve an exchange of floating rate and fixed rate interest payments between the company and investment grade counterparties Energy Trading Activities Energy trading activities focus on the commodities the company produces. To gain market information and earn trading revenues Cash Flow Statements Cash Flow from Operations Cash Flow Analysis Return on Capital Employed (ROCE) Return on Capital Employed Capital Employed Return on Capital Employed Stock Information If $100 was invested in Suncor on December 31, 1992, it would have grown to $3,190 by the end of 2005. Stock Info as of March 10, 2005 Total Return on Investment Suncor’s return to shareholders has outperformed the TSX Integrated Oils and the S&P 500. Market Segment Analysis Recommendations BUY Encana Corporation Agenda History and Background Management Team Corporate Profile Business Strategy Financial Statement Analysis Risk Management Stock Information as of Wednesday, March 08, 2006 Recommendation History and Background In 2002, merger agreement was reached between two energy company: Alberta Energy (AEC) PanCanadian Energy (PCE) Alberta Energy is created by the government of Alberta in 1975 By 1993 Alberta government sold the entire ownership to make AEC as the public owned company By 1995, AEC put its growth strategy on oil and gas after selling off all other resource investment. By 2001, AEC has become the largest natural gas producer and also largest independent operator of gas storage. History and Background PanCanadian was created by Canadian Pacific and gas company in 1958 PanCanadian roots go back to the construction of the nation first transcontinental railways Canadian Pacific Railways made natural gas discovery in 1883 and later create Canadian Pacific and gas company in 1958 which later create PanCanadian in 1973 In 2000, PanCanadian launches one of the continent largest CO2 miscible flood project at Weybury, Saskatchewan In 2002, Gwyn Morgan and David O’Brien announced the merger agreement between AEC and PanCanadian Each AEC Share was converted to 1.472 PanCanadian Share On April 8, Encana begin trading on the TSX and NYSE under the symbol ECA. Its enterprise value now is around 52 billion History and Background Management Team Gwyn Morgan, President & CEO Served as Chief of Operating Officer before elected as CEO in January 01, 2006 Education : Northern Alberta Institute of Technology and University of Wyoming Key architect of the company North America’s resource play strategy More than 25 years of experience Brian Ferguson, Executive Vice President & CFO Education : University of Alberta and University of Western Ontario Member of CICA, CICA’s risk management and governance board More than 22 years of experience Management Team Roger Biemans, Executive Vice President and President of Canadian Plans Region Responsible for upstream exploration and production in the Alberta and Saskatchewan Education : University of Calgary and University of Western Ontario More than 10 years of experience John Brannan, Managing Director & Frontier and International New Ventures Responsible for leveraging Canadian frontier and international new venture Education : Texas A&M More than 26 years of experience Sherri Brillon, Vice President, Strategic Planning & Portfolio Management Responsible for the organization wide-coordination and critical analysis of the company’s strategic plan Education : University of Alberta More than 21 years of experience Management Team Bill Oliver, Executive Vice President & President, Midstream & Marketing Gerry Protti, Executive Vice President, Corporate Relations Responsible for marketing of North American resources play Education: Simon Fraser University, B.C and Cornell University, N.Y More than 20 years of experience Responsible for regulatory services and international, aboriginal, public and community relations Education: University of Alberta, University of Western Ontario, and University of Pennsylvania Michael M. Graham, Executive Vice President & President, Canadian Foothill Regions Responsible for all upstream operations in Northern Alberta, B.C, and southern Northwest Education: University of Wyoming More than 20 years of experience Management Team Hayward Walls, Executives Vice-President, Corporate Service & Chief Information Officer Responsible for Encana’s information system and technology and human resources Education: University of Brunswick More than 23 years of experience Don T. Swystun, Executive Vice-President, Corporate Development Responsible for Encana’s acquisitions, reserves assessment, and business inteligence More than 11 years of experience Jeff Wohajn, Executive Vice President and President Encana Oil and Gas (USA) Responsible for upstream exploration and production in the U.S Education: University of Calgary and Richard Ivery School of Business Company Overview Primary Goal Continue to increase net asset value per share by balancing capital investment between: Disciplined development of resources play Share buyback Target An average 10% annual sales growth per share Company Overview Strategic Focus North American natural gas Canadian in-situ oilsands Competitive Advantage Large land base with huge undeveloped resources Leading to technical competencies 30 years of experiences with unconventional reservoir development Low operating cost High working interest and infrastructure control Company Overview Mission Energy for People Vision EnCana will be the world's High Performance Benchmark independent oil and gas company Constitutional Meritocracy EnCana is a company where shared principles guide our behaviour and merit determines our reward Our Shared Principle Strong Character, Ethical Behaviour, high performance, great expectation, Dynamic and discipline Business Strategy 1) Focus on Resource Play Business Strategy Business Strategy 2. Divesture of conventional asset and International operation other than North America Asset to be divestured in 2005: - Gulf of Mexico 2.1 billion (closed) - Canadian conventional 326 million (closed) - Ecuador 1.42 billion will close at Q4 2005 Natural Gas Liquid Business Targeted for Q4 of 2005 Gas Storage Business Targeted for Q1 of 2006 Business Strategy 3. Acquisition Acquisition Tom Brown Inc to strengthen the asset position for $2.7 billion to increase Net Asset Value of share This acquisition align with the resource play strategy Tom Brown Inc appear to be undervalued by the appraisal compared to the potential resource calculated by unconventional way Business Strategy Acquisition and Capital Investment Since 2002: Has invested 6.3 billion in key resource development Invested 4.3 billion in property and corporate acquisition Business Strategy 4. Improving Technology - CO2 Miscible Flood Ex : Weyburn Project - Coalbed Methane Business Strategy 4. Technology (continued) - GL-Dhows allow to separate gas and liquid; oil and water - SAGD Upstream operation •Upstream income increase by 30% compared to increase of 87% from 2002 to 2003 •North Amercian Production and mineral taxes for produced gas increased 76% in 2004 compared to 2003 primarily due to increased in natural gas prices and volumes in US and higher effective tax rate on production growth in Colorado Midstream and Market Optimization • Revenues and purchased products expense in this sector increased in 2004 compared to 2003 result due to increases in commodity prices • operating cash flow increase 68 million in 2004 as a result of improved margin from natural gas liquids and gas storage optimization Corporate • Revenues happen to be losses since there is unrealized mark to market losses related to financial and commodity contract • While the interest expense increase drastically because of higher outstanding debt level during the purchase of TBI CAPEX Summaries •The CAPEX is increasing by 22% compared to 24 % from 2002 to 2003. • The increasing CAPEX in upstream and acquisition is offset by disposition some of the asset Corporate Value Drivers Increase production capacity from existing assets. Reduce operating costs of existing assets through economies of scale and by upgrading process technologies. Increase reserves (asset base) by pursuing new developments. Reserves Resource Play 10 Key Resource Play Proved Reserves Reserves Resource Play 1. Greater Sierra Reserves Resource Play 2. Cutbank Ridge Reserves Resource Play 3. Coalbed Methane Reserves Resource Play 4. Shallow Gas Reserves Resource Play 5. Jonah Reserves Resource Play 6. Piceance Reserves Resource Play 7. Fort Worth Reserves Resource Play 8. East Texas Reserves Resource Play 9. Foster Creek Reserves Resource Play 10. Pelican Lake Analysis of Income Statement Three sources of revenue; upstream, midstream and market optimization, and corporate Net earnings increased $1.1 billion in 2004 including $1.4 billion gain on sale of U.K discontinued operations Net earnings from Continued Operation is increased to $ 2.2 billion from $ 2.1 billion Maintain a steady based stock compensation 17 million and planning to reduce the number of stock of stock based compensation Analysis of Balance Sheet 50% of its asset were financed through Debt and the other 50% through shareholder Equity Its liquidity level to pay its current debt is high 1.18 compared to 1.26 in 2003 Number of debt outstanding increased by 1 billion caused of the purchase of TBI must be accommodated by borrowing Property, Plant and Equipment is increased by 30% from 17,770 to 23,140 million Analysis of Cash Flow Cash flow increased to $4,980 million in 2004, $521 million increase from 2003 Cash flow from continuing operations increased $ 470 million to $ 4,605 milllions from 2003 While Cash flow from operating is 4.5 billion compared to 4.3 billion (effect of discontinued operation, other change in asset and liabilities and non cash working capital) Free Cash Flow = 4.5 – 2.3 – 4.8 = -2.6 billion They Maintain a steady investment on CAPEX while buying Tom Brown Inc as their business combination. They are paying an increasing dividend by (32%) and purchase a number of shares Financing Activities Financial Instrument and Risk Management Financial (commodity price, foreign exchange, interest rate & credit risks) Operational Environmental, health, safety and security Reputational Financial Instrument and Risk Management Lock in near term ROI Downside protection for Cash flow Combination of fixed price swaps & put options Financial Instrument and Risk Management Financial Instrument and Risk Management Stock Information as of 8 March 2006 Ticker symbol : ECA Publicly traded in - New York Stock Exchange (NYSE) - Toronto Stock Exchange (TSE) Volume : 4,556,100 Price : CAD $49.44 : US $42.72 52 week High/Low: $59.82 / $31.31 Stock Information as of Wednesday, 8 March 2006 Shares Outstanding Market Capitalization Dividend Yield Annual Dividend Last Dividend Payout Last Dividend Amount P/E EPS : 1,765 million : 71,482.58 million : 0.70% : $ 0.30 : 12/13/2005 : $ 0.08 : 11.68 : 3.66 Stock Price Movement as of Mar 8,06 6 months 1 year 3 years 5 years Encana’s Direct Comparison with S&P 500 of 8 March 2006 6 months 1 year 3 years 5 year Fisher Approach Functional Factor Superior technology Leader in natural gas industry and natural gas storage People Factor Educated and experienced management Essential Investment Characteristic Strong competitive position Hedging The Price of the stock 28.6 % below 52 week high and 19.1 % above 52 week low High P/E ratio Recommendation BUY The End Any Questions?