Nanomaterial Synthesis Method

advertisement

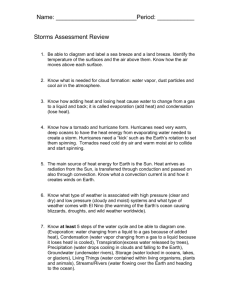

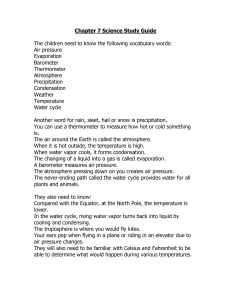

Nanomaterial Synthesis Method Ri-ichi Murakami Nanoscience and nanotechnology Nanomaterial Synthesis Method There's Plenty of Room at the Bottom By Richard Feyman in 1959 Nanotechnology application in nowadays Targeted drug delivery Super nano-capacitors CNT Transistor The University of Tokushima Outline Emergence and Challenges in Nanotechnology Bottom-Up and Top-Down Approaches Introduction to synthesis of nanoparticles Evaporation and Condensation growth Lithography technology Method to nano composite structure The University of Tokushima Emergence of Nano • Moore’s Law Original contact transistor 1947 ~cm Transistor in Integrated circuit Nowadays ~micrometer CNT Transistor Future ~nanometer Moore’s Law plot of transistor size versus year To meet the Moore’s Law, the size of transistor should be decreased The University of Tokushima Emergence of Nano • In our life 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. LED for display PV film Self-cleaning window Temperature control fabrics Health Monitoring clothes CNT chair Biocompatible materials Nano-particle paint Smart window Data memory CNT fuel cells Nano-engineered cochlear The nanotechnology is changing our life, but not enough. Energy crisis, environmental problem, health monitoring, Artifical joints The University of Tokushima Challenges in Nano • Atomic scale imaging TEM in biology LaSrMnO and SrTiO superlattice Understand and manipulate the target in nano scale The University of Tokushima Challenges in Nano • Interdisciplinary Investigation Protein TEM image Biology & Medicine Nano drug delivery Nano Mechanics & Electronics Nano mechanics The University of Tokushima Physics & Chemistry & Materials Approaches Emergence and Challenges in Nanotechnology Bottom-Up and Top-Down Approaches Introduction to synthesis of nanoparticles Evaporation and Condensation growth Lithography technology Method to nano composite structure The University of Tokushima Approaches • Obviously there are two approaches to the synthesis of nanomaterials and the fabrication of nanostructures: • Top-down Lithography • Bottom-up Self-assembly The University of Tokushima Synthesis of Nanoparticles Emergence and Challenges in Nanotechnology Bottom-Up and Top-Down Approaches Introduction to synthesis of nanoparticles Evaporation and Condensation growth Lithography technology Method to nano composite structure The University of Tokushima Synthesis of Nanoparticles • Homogeneous nucleation A solution with solute exceeding the solubility or supersaturation possesses a high Gibbs free energy, the overall energy of the system would be reduced by segregating solute from the solution. G: Gibbs free energy △G: Driving force for solidication G △G GVS GVL △T T* Tm At any temperature below Tm there is a driving force fro solidification. The University of Tokushima Synthesis of Nanoparticles • Homogeneous nucleation For nucleus with a radius r > r*, the Gibbs free energy will decrease if the nucleus grow. r* is the critical nucleus size, △G* is the nucleation barrier. The University of Tokushima Synthesis of Nanoparticles • Synthesis of metallic nanoparticles Influences factors A Differenct reagents A:sodium citrate B: citric acid B A weak reduction reagent induces a slow reaction rate and favors relatively larger particles. Concentration A: 0.25M AgNO3 B: 0.125M AgNO3 A large precursor concentration induces a large critical radius and favors relarively larger particles. A Other factors: the surfactants, polymer stabilizer, temperature, ect The details about the synthesis of nanoparticles via chemical method would be introduced by other professors in this lecture. The University of Tokushima B Evaporation and Condensation Emergence and Challenges in Nanotechnology Bottom-Up and Top-Down Approaches Introduction to synthesis of nanoparticles Evaporation and Condensation growth Lithography technology Method to nano composite structure The University of Tokushima Evaporation and Condensation • The evaporation and condensation are the fundamental phenomena in preparing thin films with nano meters thickness. Substrate vapor If a condensible vapor is produced by physical means and subsequently deposited on a solid substrate, it is called physical vapor deposition. Condensation If a volatile compound of a material react, with or without other gases, to produce a nonvolatile solid film, it is called the chemical vapor deposition. Although both are nonequilibrium processes, the kinetics and transport phenomena are the fundamental theory. Evaporation energy Source The University of Tokushima Evaporation and Condensation • The Kinetic theory Let’ s start with the equilibrium process. Substrate Adsorption Supersaturation condition: Condensation ji, incident flux Tsub, temperature of substrate The impingement rate: the number of collisions per unit area per second that a gas makes with a surface, such as a chamber wall or a substrate P, the gas pressure;m, the particle mass; k, Boltzmann’s constant, 1.38×10-23 J/K; T, the temperature The substrate should be placed at relactively low temperature to meet the supersaturation condition. The impingement rate indicates the equilibrium process between evaporation and condensation. The University of Tokushima Evaporation and Condensation • The vapor source The vapor is usually produced from a effusion cell, rather than a open system, therefore, we can solve the flow density from the implingement rate. J A z On a certain angle J: flow density A: area of the leak z: implingement rate n cos vav J 4 The angle distribution is important for a co-sputtering condition. Source substrate Co-sputtering Tsource Peq The University of Tokushima Evaporation and Condensation • The vapor source If we use a beer can as source material, what vapor will we obtain? Consider the the implingement rate Al 97.7% Mg 1% Mn 1.3% Alloy source Al: 0.0001% Mn: 0.01% Mg:99.99% Al, Mg, Mn have different atomic mass. Mn atom It is not practical to use a congruent evaporation temperature to deposit a compound (or alloy) film from a compound beer can (or alloy ) film with a certain stoichiometric. Al atom Mg atom This result is obtained under consideringt the adsorption and desorption effect. Diffusion cell at 900 K The University of Tokushima Evaporation • How to get the stoichiometric vapor Flash Evaporation Flash evaporation utilizes very substrate rapid vaporization, typically by dropping powders or grains of the source material onto a hot surface. The vapor condenses rapidly onto a relatively cold substrate, usually with the same gross composition as that of the source material. The substrate was placed at a temperature that was a supersaturation temperature for each component. AC Heater Flash Evaporation The University of Tokushima Evaporation • How to get the stoichiometric vapor E-Gun substrate Molten End e- AC E-Gun Rod-Fed Source The University of Tokushima In a rod-fed source, typically an electron-beam-heated evaporator, the source material evaporators from the molten end of the rod. The rod advances as material is lost from the molten end. In steady state, the composition of the vapor stream must equal that of the rod. This requires that the molten end be enriched in the less volatile component. The adjustment is automatic, since diffusion in the liquid state is rapid. Evaporation • How to get the stoichiometric vapor Coevaporation The covaporation with the three-temperature method has been an effective technique for the compositionally accurate deposition of compound semiconductor films whose components’ vapor pressure differ greatly. It was the forerunner of molecular beam epitaxy (MBE). substrate T3 T1 A Effusion T2 Cells B Co-evaporation The University of Tokushima Evaporation • How to get the stoichiometric vapor Sputtering Sputtering of certain materials, whose ejected particles are molecules, was utilized to obtain a stoichiometric vapor. •Direct current sputtering •Direct current reactive sputtering •Radio-frequency sputtering The University of Tokushima Evaporation • The evaporation source The simplest sources to produce vapors of materials may be thermal sources. These are sources where thermal energy is utilized to produce the vapor of the evaporant material. Even when the energy that is supplied to the evaporant may come from electrons or photons, the vaporizing mechanism may still be thermal in nature. quasiequilibrium Evaporation Sources Effusion cell Effusion cell nonequilibrium The University of Tokushima Evaporation source • Ideal Effusion Cell aorifice δA L How to design a effusion cell Lbody Gas, Peq Liquid The University of Tokushima 1. The liquid and vapor are in equilibrium within the cell. Pliq=Pvap, Tliq=Tvap, Gliq=Gvap 2. The mean free path inside the cell is much greater than the orifice diameter.λ>>aorifice 3. The orifice is flat. 4. The orifice diameter is much less than the distance to the receiving surface. 5. The wall thickness is much less than the orifice diameter. L<<aorifice Evaporation source • Near-ideal Effusion cell It is impossible to design an ideal effusion cell Direct Re-emitted With a thick orifice lid, diffuse and specular reflection off the sidewalls are possible. L Lbody Lbody Gas, Peq Liquid The University of Tokushima It is the restriction due to the long cell body that cause a nonequilibrium behavior of vapor. Evaporation source • Open-Tube Effusion Cell The relative beam intensity of the open-tube effusion cell calculated for various tube length-to-tube radius ratios (L/a) a L A quasiequilibrium source The University of Tokushima An open-tube effusion cell Figure 2.56 Evaporation source • E-Gun A target anode is bombarded with an electron beam given off by a charged tungsten filament under high vacuum. The electron beam causes atoms from the target to transform into the gaseous phase. These atoms then precipitate into solid form, coating everything in the vacuum chamber (within line of sight) with a thin layer of the anode material. The University of Tokushima Evaporation source • Pulsed Laser Deposition A high power pulsed laser beam is focused inside a vacuum chamber to strike a target of the material that is to be deposited. This material is vaporized from the target (in a plasma plume) which deposits it as a thin film on a substrate. The University of Tokushima Evaporation source • Sputtering • The University of Tokushima In sputtering, energetic ions from the plasma of a gaseous discharge bombard a target that is the cathode of the discharge. Target atoms are ejected and impinge on a substrate, forming a coating. Evaporation source • Plasma-enhanced chemical vapor deposition Plasma-enhanced chemical vapor depostion is a process used to deposit thin films from a gas state (vapor) to a solid state on a substrate. Chemical reactions are involved in the process, which occur after creation of a plasma of the reacting gases. The plasma is generally created by RF (AC) frequency or DC discharge between twoelectrodes, the space between which is filled with the reacting gases. A plasma is any gas in which a significant percentage of the atoms or molecules are ionized. Fractional ionization in plasmas used for deposition and related materials processing varies from about 10−4 in typical capacitive discharges to as high as 5–10% in high density inductive plasmas. The University of Tokushima Condensation • Condendation is the change of the physical state of matter from gaseous phase into liquid phase or solid phase, and the reverse is vaporization. condensation re-evaporation film growth film adsorption at special sit surface diffusion nucleation Inter diffusion Adsorption of atoms from gaseous phase Cluster formation Critical size islands growth Coalescence of neighboring islands Percolation of islands network Continuous film growth The University of Tokushima Condensation • Adsorption gas It is defined as chemisorption coefficient that he fraction of adsorbated atoms transferred from physisorption into chemisorption but not re-evaporated. physisorption transition Van der Waals force chemical bond chemisorption re-evaporation An critical condition is that the adsorption is equall to the reevaporation. Only the atoms adsorpted on the substrate and condensed, grow bigger the critical radius, then the film would be deposited. substrate The University of Tokushima Condensation • Condensation coefficient incident flux The fraction of the incident flux that actually condenses jc ac ji re-evaporation condensation substrate The University of Tokushima ji: the incident flux density ac: the condensation coefficient jc: the condensation flux Condensation • Deposition Rate Growth speed Si The deposition rate, or the growth speed jc vn nf jc, the condensation flux nf, the particle density, how many particles per volume An example 8 atoms per conventional unit cell The volume per unit cell, (5.430 A)3=160.10 A3 The particle density, 8/(160.10 A3)=0.05 A-3 The growth speed a 5.430A cubic lattice parameter, 5.430 A The University of Tokushima jc 0.703 A2 / s vn 14.06 / s 3 nf 0.05 A Condensation • Growth mode The University of Tokushima Condensation • Non-epitaxial growth For most film-substrate material combinations, film grow in the VolmerWeber (VW) mode which leads to a polycrystalline microstructure. The University of Tokushima Condensation • Epitaxial growth---molecular beam epitaxy Molecular beam epitaxy is a technique for epitaxial growth via the interaction of one or several molecular or atomic beams that occurs on a surface of a heated crystalline substrate. The University of Tokushima Condensation • Epitaxial growth-Atomic layer deposition based on the sequential use of a gas phase chemical process. The University of Tokushima Condensation • Monolayer monitoring---RHEED Reflection high energy electron diffraction, an extremely popular technique for monitoring the growth of thin films. In RHEED, electrons beam strikes a single crystal surface at a grazing incidence, forming a diffraction pattern on a screen. Electrons with tenth of KeV order energy are focused and incident onto the surface. Then, electrons are scattered by the periodic potential of the crystal surface, which results in a characteristic diffraction pattern on the screen. The diffracted intensity is displayed directly on a screen, so the information is available instantly, i.e, real-time analysis is possible. Further, RHEED arrangement in UHV chamber allows it to be used for in-situ observation of MBE thin film growing process. The University of Tokushima Methods for deposition Method ALD MBE CVD Sputtering Evapor PLD Thickness Uniformity good fair good good fair fair Film Density good good good good fair good Step Coverage good poor varies poor poor poor Interface Quality good good varies poor good varies Low Temp. Depostion good good varies good good Good Deposition Rate fair fair good good good Good Industrial Application varies varies good good good poor The University of Tokushima Lithography Emergence and Challenges in Nanotechnology Bottom-Up and Top-Down Approaches Introduction to synthesis of nanoparticles Evaporation and Condensation growth Lithography technology Method to nano composite structure The University of Tokushima Lithography • We have discussed various routes for the synthesis and fabrication of variety of nanomaterials; however, the synthesis routes applied have been focused mainly on the chemical methods approaches, or the physical vapor deposition. Now, we will discuss a different approach: top-down approach, fabrication of nanoscale structures with various physical techniques--lithography. The University of Tokushima Lithography Lithographic techniques (a)Photolithography (b)Phase shifting opitcal lithography (c)Electron beam lithography (e)Focused ion beam lithography (f) Neutral atomic beam lithography Nanomanipulation and nanolithography (a)Scanning tunneling microscopy (b)Atomic force microscopy (c)Near-field scnning optical microscopy (d)Nanomanipulation (e)Nanolithography The University of Tokushima Photolithography • Typical photolithographic process consists of producing a mask carrying the requisite pattern information and subsequently transferring that pattern, using some optical technique into a photoactive polymer or photoresist. The University of Tokushima Photolithography • Wafer preparation---cleaning Typical contaminants that must be removed prior to photoresist coating: •dust from scribing or cleaving (minimized by laser scribing) •atmospheric dust (minimized by good clean room practice) •abrasive particles (from lapping or CMP) •lint from wipers (minimized by using lint-free wipers) •photoresist residue from previous photolithography (minimized byperforming oxygen plasma ashing) •bacteria (minimized by good DI water system) •films from other sources: –solvent residue –H2O residue –photoresist or developer residue –oil –silicone Standard degrease: – 2-5 min. soak in acetone with ultrasonic agitation – 2-5 min. soak in methanol with ultrasonic agitation – 2-5 min. soak in DI H2O with ultrasonic agitation – 30 sec. rinse under free flowing DI H2O – spin rinse dry for wafers; N2 blow off dry for tools and chucks • For particularly troublesome grease, oil, or wax stains: – Start with 2-5 min. soak in 1,1,1-trichloroethane (TCA) or trichloroethylene (TCE) with ultrasonic agitation prior to acetone The University of Tokushima Photolithography • Wafer preparation---primers Adhesion promoters are used to assist resist coating. Resist adhesion factors: •moisture content on surface •wetting characteristics of resist •type of primer •delay in exposure and prebake •resist chemistry •surface smoothness •stress from coating process •surface contamination Ideally want no H2O on wafer surface – Wafers are given a “singe” step prior to priming and coating •15 minutes in 80-90°C convection oven Used for silicon: – primers form bonds with surface and produce a polar (electrostatic) surface – most are based upon siloxane linkages (Si-O-Si) •1,1,1,3,3,3-hexamethyldisilazane (HMDS), (CH3)3SiNHSi(CH3)3 •trichlorophenylsilane (TCPS), C6H5SiCl3 •bistrimethylsilylacetamide (BSA), (CH3)3SiNCH3COSi(CH3)3 The University of Tokushima Photolithography • Photoresist Spin Coating • Wafer is held on a spinner chuck by vacuum and resist is coated to uniform thickness by spin coating. • Typically 3000-6000 rpm for 15-30 seconds. • Resist thickness is set by: – primarily resist viscosity – secondarily spinner rotational speed • Resist thickness is given by t = kp2/w1/2, where – k = spinner constant, typically 80-100 – p = resist solids content in percent – w = spinner rotational speed in rpm/1000 • Most resist thicknesses are 1-2 mm for commercial Si processes The University of Tokushima Photolithography • Prebake Used to evaporate the coating solvent and to densify the resist after spin coating. • Typical thermal cycles: – 90-100°C for 20 min. in a convection oven – 75-85°C for 45 sec. on a hot plate • Commercially, microwave heating or IR lamps are also used in production lines. • Hot plating the resist is usually faster, more controllable, and does not trap solvent like convection oven baking. The University of Tokushima Photolithography • Align/Expose/Develop The University of Tokushima Photolithography • Etching/remove photoresist photoresist has same polarity as final film; photoresist never touches the substrate wafer. The University of Tokushima Photolithography • Etching/remove photoresist photoresist has opposite polarity as final film; excess deposited film never touches the substrate wafer. The University of Tokushima Phase-shifting Photolithography • Photolithography has a resolution limit. In order to improve the resolution in photolithography, the phaseshifting method was developed. The University of Tokushima E-beam lithography • The theoretical resolution of photolithography is 2bmin d 3 (s ) 2 The wavelength of the exposing radiation s The gap width maintained between the masi and the photoresist surface d The photoresist thickness The wavelenght of electron beam is much smaller than UV light, electron beams can be focused to a few nanometers in diameter and can be deflected accurately and precisely over a surface. The University of Tokushima E-beam lithography • Resist film Negative resist: After development, the exposed structure is higher than the surrounding due to crosslinking of polymer chains. Positive resist: After development, the exposed structure is deeper than the surrounding due to chopping of polymer chains. PMMA (Poly-methyle-metacrylate) -one of the first e-beam resists (1968) -standard positive resist -resolution<10 nm -medium sensitivity (150-300μC/cm2 ) -available with high (950K) and low (50k) molecular weight -contrast: high for 950k-resist, low for 50k-resist The University of Tokushima E-beam lithography • Challenge Charging effect: Complicate exact focusing ofelectron-beam, displacement and distortion of exposed structures. Proximity effect: Scattering of electrons in resist film and substrate, unwanted additional exposure. The University of Tokushima Focused ion beam lithography • Advantages -Ions have heavy mass than electrons. -Less proximity effect than E-beam -Less scattering effect -High resolution patterning than UV, E-beam lithography -Even smaller wavelength than E-beam The University of Tokushima Neutral atomic beam lithography • In neutral atomic beams, no space charge effects make the beam divergent; therefore, high kinetic particle energies are not required. Diffraction is no severe limit for the resolution because the de Broglie wavelength of thermal atoms is less than 1 angstrom. The University of Tokushima Nanomanipulation and nanolithography (a)Scanning tunneling microscopy (b)Atomic force microscopy (c)Near-field scnning optical microscopy (d)Nanomanipulation (e)Nanolithography Nanomanipulation and nanolithography are based on scanning probe microscopy. The University of Tokushima Scanning tunneling microscopy • STM relies on electron tunneling, which is a phenomenon based on quantum mechanics. Principle A famous sample The University of Tokushima Atomic force microscopy • In spite of atomic resolution and other advantages, STM is limited to an electrically conductive surface since it is dependent on monitoring the tunneling current between the sample surface and the tip. AFM was developed as a modification of STM for dielectric materials. The University of Tokushima Atomic force microscopy • Local oxidation nanolithography Schematic diagram for the AFM based local oxidation lithography on both silicon and Ag monolayer. The University of Tokushima Atomic force microscopy • Effects of tip bias potentials on the lithography patterns. The University of Tokushima Atomic force microscopy • AFM and KPFM(Kelvin probe force microscopy) images of the patterned silver nanoparticle monolayer. Shaped patterns were written on to the monolayer. The University of Tokushima Nanomanipulation and nanolithography • Some examples The University of Tokushima Quiz • How to get the stoichiometric vapor ? The University of Tokushima Quiz • How to get the stoichiometric vapor ? 1. 2. 3. 4. Flash Evaporation E-Gun Covaporation Sputtering The University of Tokushima Quiz • Can we get the vapor with the same stoichimometric as the source materials? Why? The University of Tokushima Quiz • Can we get the vapor with the same stoichimometric as the source materials? Why? No Because of the different impingement rate for each element at the same vacuum condition The University of Tokushima Quiz • Describe a typical photolithographic process The University of Tokushima Quiz • Describe a typical photolithographic process The University of Tokushima Lecture by Ri-ichi Murakami The University of Tokushima