Chapter -9 WEB STIFFENERS

advertisement

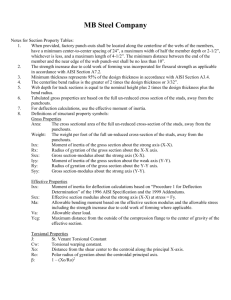

Chapter -9 WEB STIFFENERS contents Introduction Bearing stiffeners Intermediate stiffeners Horizontal stiffeners (Longitudinal stiffeners) Design of transverse stiffeners Design Longitudinal stiffeners 1-Introduction The web of plate girder is so thin that there is always tendency for diagonal buckling and vertical buckling. Therefore, stiffeners are provided. In welded plate girders, plates, angles, tees and closed sections are used as stiffeners (Fig. 7.1 p126). The outstand of the stiffener should not be less than that given in clause 7.4.1 (p124). (d/30 + 5 cm) or (d/30 + 10 cm) There are two kinds of transverse stiffeners:- 1-Bearing stiffeners. 2-Intermediate stiffeners. Back 2-Bearing stiffeners The function of these stiffeners is to distribute the load to the web. These are provided at the supports and at the points of concentrated loads. These stiffeners shall be symmetrical about the web and bear tightly against the flange plates. The bearing stiffeners shall be designed as a column assuming the section to consist of the pair of stiffeners together with a length of web equal to 12, 25 times the web thickness for end and intermediate stiffeners respectively. The radius of gyration shall be taken about the axis parallel to the web, and the working stress shall be in accordance with the appropriate allowable value for a compression member assuming an effective length equal to 0.80 of the length of stiffeners. From this, value of l/r is found. Allowable compression stress is found from clause 2.6.4 (p15). Where possible, specially at supports, the stiffeners should extend to the outer edges of the flange plates. Ends of all bearing stiffeners shall be machined or ground to fit tightly both at top and bottom and the stiffeners shall be provided with sufficient welds to transmit to the web the whole of the concentrated load (reaction). Back 3-Intermediate stiffeners Transverse intermediate stiffeners shall be provided throughout the length of the girder when the average calculate shear stress (qact= Q/Aw) is larger than the allowable buckling shear stress (qb) Clause 2.6.3.2, p. 14. The stiffeners may be pairs one on either side of the web or single. When the single stiffeners are used, these should be placed alternately on the opposite sides of the web. The stiffener shall extend from flange to flange. The intermediate stiffeners shall be designed as a compression member (with effective length = 0.80 the length of stiffener) to resist a force; 0.35 *F y Cs 0.65 * 1 * Qact. qb If q b 0.35 Fy (Eq. 7.8) C s 0.0 The connection between the transverse stiffeners and the web should be designed on the transverse stiffeners force. For intermediate stiffeners, this connection is designed in such a way that the fastener in either the upper or the lower thirds of the stiffeners should transfer the design force. Back 4- Horizontal stiffeners (Longitudinal stiffeners) When the thickness of the web is less than d Fy / 190 or d /120 (eq. 7.4& 7.5). horizontal stiffeners (with or without d d ) from transverse stiffeners) shall be provided at ( 5 4 the compression flange. The stiffeners shall be designed so that moment of inertia I is not less than ( 4d t 3w ). d Additional horizontal stiffeners at may be provided 2 and its moment of inertia is not less than ( d t 3w ). Back 5-Design of transverse stiffeners 1. Lb = 0.8 d 2. Intermediate 25 tw 3. End stiffener 4. Design as a compression member 5. Force on intermediate stiffener 0.35 *F y Cs 0.65 * 1 * Qact. qb If q b 0.35 Fy C s 0.0 6. Design end stiffener on R, intermediate on Cs 7. Weld for end stiffener (Force R, length d) 8. Weld for intermediate (Force Cs, length d/3) d/4 - d/5 d/4 - d/5 d/4 - d/5 d/4 - d/5 d/2 tw d d1 Back 6-Design Longitudinal stiffeners Iy for longitudinal stiffeners I y 4d t 3w d d at ( - ) 4 5 Iy d t d at ( ) 2 3 w Back