Coagulants for Water Treatment

advertisement

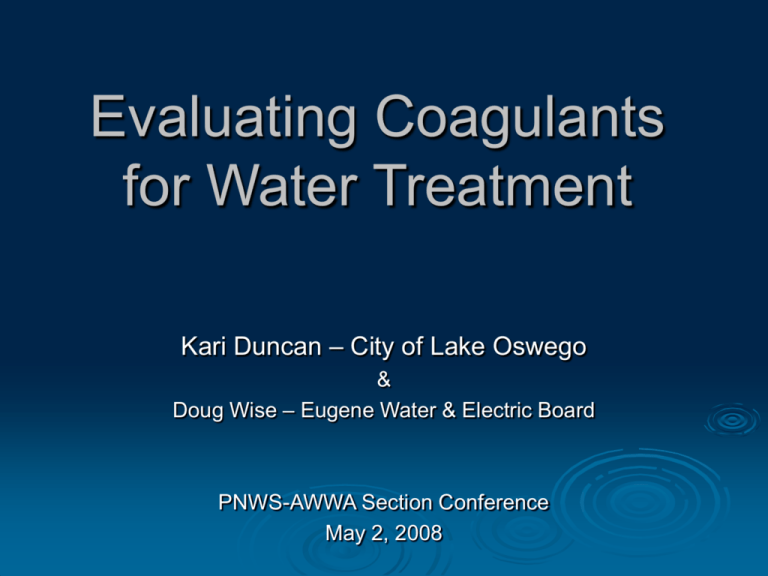

Evaluating Coagulants for Water Treatment Kari Duncan – City of Lake Oswego & Doug Wise – Eugene Water & Electric Board PNWS-AWWA Section Conference May 2, 2008 Overview Varieties of Coagulants: Inorganic – Organic Common Uses Case Studies: EWEB – City of Lake Oswego Entrance Strategy 1. 2. 3. 4. Jar Test Pilot Filter Evaluation Cost Evaluation ½ Plant Scale Test Entrance Strategy cont…. 5. Plant Scale Trial 6. Calculate “Real” Cost 7. Evaluation Step Operational Effectiveness Look for Unintended Consequences Aluminum Sulfate (Al2(SO4)3 · 14 H2O coagulants aluminum sulfate, aluminum chloride and ferric compounds Inorganic React with alkalinity to form positive ions which remove contaminants by adsorption. turbidity higher (sometimes dramatically higher) feed rates. Increasing PACL (Polymeric Inorganic Coagulants) “Generic” name that encompasses ACH, Sumaclear, Pass-C and others Product variables: Basicity 50% 80+% Al:Cl ratio Al2O3 content PACL A highly charged species that require little or no alkalinity to precipitate floc. Due to the high charge of the PACL’s dose may not increase as much during increasing contaminant loading PACL : ACH PACL formula: Al2(OH)(X)Cl(6-x) Al:Cl ratio increases as basicity increases ACH ‘special type of PACL’ Al:Cl ratio of 2:1 Basicity of 83% Al2O3 content of 23% Molecular Weight Comparison Alum : max MW of 1,000 PACL: ACH: MW of 500 – 2,500 4,000 – 5,000 (some up to 10,000) Floc Size Inorganic coagulants (Alum), and low basicity PACL form more voluminous, fragile floc. With increasing charge, PACL tend to form smaller floc with greater density ACH forms a very tight, dense floc Typical dosages Product sales advisors often quote an “Aluminum percentage ratio” For example, if the Al in the PACL is 4x that of Alum, they will cite an expected 25% of alum dosage. 50% basicity PACL; approx 80% of alum dosage ACH: approx 33% of alum dosage. Coagulation Control Jar Mix Pilot Filters Stream Zeta Current Monitors Potentiometers Coagulant Control: Jar Test Coagulant Control: Control Filters Coagulant Control: Current Monitor Coagulant Control Jar Test: Control Remember to look for smaller denser floc due to high basicity when using high molecular weight products Filters Streaming Current Monitor Benefits Increased filter runs Reduced sludge generation Sludge compacts / dewaters better Greater turbidity removal capacity Effective in low water temperatures PACL does not lower pH Check With Friends Drinking Water Program Bay Hills Water Association City of Creswell Garden Valley Water District City of Lowell City of Myrtle Point City of Waldport City of Yachats Cautions What is in the “magic” elixir? More Cautions! PACL products range in grade and composition; test product(s) extensively before committing to their use. Some products are sensitive to chlorine. Products which form a suspension or generate sludge after only six months of storage are very low grade. Case Study #1 Eugene Water & Electric Board’s Hayden Bridge Filtration Plant EWEB 72 MGD Raw Water Flow (108 MGD in 2009) McKenzie River Source Direct Filtration (summer) Conventional Filtration (winter) Alum coagulant Pre-chlorinate Cl2 gas 50% Caustic: corrosion control EWEB 7 month trial of “Sumaclear 1000” from Summit Research Lab Used Sumaclear predominantly through 2006. Trial examined cost and filter run times while maintaining existing filtered water turbidity goal of 0.035 NTU. EWEB Poly Alum vs. Alum 12.00 Alum 8.00 P/A 6.00 Linear (P/A) 4.00 Linear (Alum ) 2.00 0.00 0. 90 1. 04 1. 34 1. 35 1. 41 1. 50 1. 50 1. 60 1. 70 1. 77 2. 40 2. 50 4. 40 7. 74 Dose (mg/L) 10.00 Raw Turbidity EWEB Field Results Sumaclear 1000 dose was approximately 1/3 of Alum with low raw water turbidity. With raw water turbidity above 4 ntu, Sumaclear 1000 was approximately 1/2 of Alum dose. Experienced longer filter runs with Sumaclear. Sumaclear resulted in an overall economic benefit (chemicals, wash water, sludge management) of approximately 20%. EWEB Concerns Some changes in distribution water quality coincided with Summaclear 1000 trials. * Apparent DBP increase * Small Lead and Copper increase (may no longer be “optimized) EWEB Finds Fault A: We changed coagulant. B: Our system water quality changed. Therefore: the coagulant change made the system water quality change. EWEB Review of JAWWA Article on Cl- / SO4 Ratio Edwards & Triantafyllidou – July 2007 “…as the relative concentration of chloride to sulfate increased in a water supply, a utility was more likely to have a higher 90th-percentile lead concentration.” PACL : ACH PACL formula: Al2(OH)(X)Cl(6-x) Al:Cl ratio increases as basicity increases ACH ‘special type of PACL’ Al:Cl ratio of 2:1 Basicity of 83% Al2O3 content of 23% EWEB Not so fast…. There Are Other Considerations (EWEB) Multiple changes in treatment variables at the time of test: Added 15 MG Clearwell (May 2003) Changed chlorination practice (May 2004) Switched from Lime to Caustic (July 2004) Switched from Alum to Sumaclear 1000 (2005-2006) EWEB – Next Steps Continue Special Monitoring. Monitoring. Make Gradual Treatment Changes. Wait and Measure. Case Study #2 City of Lake Oswego Water Treatment Plant City of Lake Oswego Water Treatment Plant 16 MGD Clackamas Direct Alum River Source Filtration Plant (Coagulant) Pre-chlorinate Lime: with Hypochlorite corrosion control City of Lake Oswego Feeds Alum alone during low turbidity. Feeds a combination of Alum and Pass-C (Hydortech product) during high turbidity events. Pass-C: Al = 5/4 % ?? Al2O3: 10.3% Basicity: 55% Alum and Pass-C vs. Raw NTU 100 80 ALUM, mg/L 70 Pass-c mg/l dry 60 Raw NTU Avg 50 40 30 20 10 1/ 26 1/ 19 1/ 12 1/ 5 /2 9 12 /2 2 12 /1 5 12 /8 12 /1 0 12 Alum/Pass-C mg/L, Raw NTU 90 18 180 16 160 14 140 12 120 10 100 8 80 6 60 4 40 2 20 0 0 DATE 12/5 12/10 12/15 12/20 12/25 12/30 1/4 1/9 1/14 1/19 1/24 1/29 ALUM, mg/L Pass-c mg/l dry Raw NTU Avg Raw NTU Alum and PassC (mg/L) Alum and PassC vs. Raw NTU (2 axes) Alum mg/L vs. Raw NTU (without Pass-C) 50 ALUM, mg/L 40 ntu avg 35 30 25 20 15 10 5 1/13 1/6 12/30 12/23 12/16 12/9 12/2 11/25 11/18 0 11/11 Alum mg/L and Raw NTU 45 City of Lake Oswego Field Results The use of Pass-C at 3 to 11 mg/L decreases Alum use by up to (75%)* during periods of high raw water turbidity. The use of Pass-C at high turbidity prevents the need for Operators to add additional alkalinity. Improves ease of operation Cost differences appear to be nominal * Rough number City of Lake Oswego Summary Wide Trial variety of products available. runs are very important. Control your variables. Perform a cost analysis. Shop around and do your research. Lessons Learned From Coagulant Trials Intuitive expectations may be erroneous. Lessons Learned Changes in the distribution system may result from changes in treatment at the plant. Lessons Learned Unknown, unreported and / or undocumented consequences may be common. Lessons Learned Change only ONE thing at a time. Lessons Learned Wait Measure Interpret Acknowledgements Kari Duncan for her work in documenting these results. Randy Prock for developing the data at Hayden Bridge. The Operators at both plants for their patience and persistence. Questions?