Silanna Semiconductor (Word

advertisement

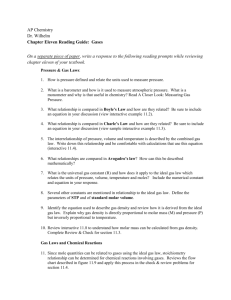

Silanna Semiconductor INTRODUCTION The Carbon Tax has increased the cost of operating in Australia by 10% that cannot be passed onto our customers as all our products are 100% exported. This now questions the viability of manufacturing in Australia. In addition to the energy increases, the carbon tax is wrongly applied to reacted gases in the manufacturing process with a burden of $160,000pa. COMPANY OVERVIEW Silanna Semiconductor is an Australian owned, very advanced semiconductor design and manufacturing facility that was incorporated in 1996 and now has over 15 years of experience in delivering high performance integrated circuits into the global space, defence, medical and consumer markets. Silanna has built a strong production team that maintains its manufacturing processes at high levels of yield and performance. Silanna has developed a strong development team, with systems in place that enable it to rapidly bring processes from concept to development and into production. Apart from being a commercially focussed organisation with almost all of the products being exported, we have considerable strategic value to research organisations including Universities, NICTA, CSIRO and DSTO. We support major research projects such as the CSIRO's Square Kilometre Array Radio Telescope, the UNSW Quantum Computing Project and many University Linkage projects. Silanna has a strong record of collaboration and engagement with Universities (Australian as well as USA, including Yale and Johns Hopkins). These engagements develop research ideas, address research problems, and harness complementary strengths and facilities. We have also collaborated successfully with other Australian research organizations, as well as private industry. We value these engagements and see them as a crucial element in the development of new approaches to harness our technology to solve important problems. Silanna Semiconductor has two facilities in Australia, one in Sydney Olympic Park and the other in Brisbane. The Sydney facility has an advanced fab with capabilities to produce both CMOS and Compound Semiconductors. We currently employee 100 highly trained operators, engineers and scientists. We have intellectual property in manufacturing processes that extends more than 30 years and our expertise is in commercialising R&D. Successes Manufactured 100’s of millions of parts and 100’s of designs. Manufactures 100% of Peregrine Semiconductor’s space and defence products Parts used on all 3 Mars Rovers Most US satellites launched use parts manufactured by Silanna Supplied in excess of one million chips per week to the mobile phone market, that feeds the supply chain of Nokia, Motorola, Apple (iPhone) and RIM (Blackberry) to name a few. MANUFACTURING CAPABILITY The CMOS manufacturing operation is performed in Fab 1 and Fab 2. Fab 1 has Class 10 cleanrooms and Fab 2 has Class 1 cleanrooms. Tooling is supplied by industry standard vendors such as ASML photolithography wafer scanner and steppers, SVG deep-UV photoresist tracks, Varian highangle ion-implanter, SVG vertical furnaces, Mattson Rapid Thermal S 8 Herb Elliott Avenue, Sydney Olympic Park, NSW, Australia 2127 Page 1 Silanna Semiconductor Processor, advanced metrology tools and other facilities support equipment. Silanna currently produces 150mm wafers in both UltraCMOS™ and bulk silicon. A recent investment of $30 million in a compound semiconductor facility focused around a Veeco dual-chamber molecular beam epitaxy tool (MBE). This facility manufactures very low defect density wafers of GaN (plus variants) with wafer sizes ranging from 50mm to 150mm. Gases Used in the Manufacturing Process. Gases There are three classes of gases we use; gases that are reacted and consumed in the manufacturing process, refrigeration gases that are not reacted and inert gases such as nitrogen and argon. Refrigeration Gases The following list is the refrigeration gases that are not used in the process but in manufacturing equipment that could be the subject of reclaim or destruction. Refrigeration Gases Stock # Chemical Formula CHClF2 Gas type R22 ChloroDiFluoroMethane R134a - Tetrafluoroethane C2H2F4(CH2FCF3) R402a (38% R-22, 60% R-125, 2% R-290) R404a (44% R-125, 52% R-143a, 4% R-134a) R409a (R-22, R-124, R-142b) R410a (R-32, R-125) TOTAL Amount ODP GWP (Kg)/yr 0.05 1700 40 0 0.02 0 0.047 0 1300 2600 3300 1585 2100 10 10 10 10 10 90 CO2 /yr (ton) 68 13 26 34 16 21 178 Carbon Tax Refrigerant Total CTax CTax per ($/kg) tax ($/kg) ($/kg) Bottle $ Total CTax/yr $39.10 $0.165 $39.265 $1,564.00 $1,570.60 $29.90 $59.80 $75.90 $36.46 $48.30 $0.165 $0.165 $1.165 $0.165 $0.165 $30.065 $59.965 $77.065 $36.620 $48.465 $299.00 $598.00 $759.00 $364.55 $483.00 $4,067.55 $300.65 $599.65 $770.65 $366.20 $484.65 $4,092.40 New Gas Bottle No. of Country Total Gas Price/bottle Price inc bottles Imported Price/yr AUD Cyl. kg Ctax used /yr From: $22 $22 40.0 $1,586 1 Australia $22 $25 $24 $25 $25 $143 $22 $25 $24 $25 $25 $143 10.0 10.0 10.0 10.0 10.0 $321 $623 $783 $390 $508 $4,211 1 1 1 1 1 6 Australia Australia Australia Australia Australia As shown the total gas price of the 6 bottles per year is $143 but when the carbon tax of $4092 is applied takes the gas price to $4235. This is a 28 times increase. The total CO2 equivalent mass is 178 tonnes. Reacted Gases The following list is the gases that are reacted (destroyed) in the manufacturing process. Manufacturing Gases Chemical Formula Stock # Gas type 8020 R116 - Hexafluoroethane Amount GWP (Kg)/yr 9200 517 ODP C2F6 CO2 /yr (ton) 4,762 Carbon Tax Refrigerant Total CTax CTax per ($/kg) tax ($/kg) ($/kg) Bottle $ Total CTax/yr $211.60 $0.165 $211.765 $9,119.96 $109,524.86 8029 Sulphur Hexafluoride SF6 23900 34 814 $549.70 $0.165 8026 Nitrous Oxide N2O 310 1633 506 $7.13 $0.000 $7.130 $194.01 8052 Nitrogen Trifluoride NF3 17200 20 344 $395.60 $0.000 $395.600 $7,912.00 $7,912.00 8038 R14 - Tetrafluoromethane CF4 6500 48 310 $149.50 $0.165 $149.665 $4,746.63 8021 R23 - Trifluoromethane CHF3 11700 16 186 $269.10 $0.165 $269.265 $8,543.93 3 8085 Methane (12.5m ) CH4 21 11 0 $0.48 $0.000 $0.483 8061 Carbon Monoxide (5.9m3) 8053 Carbon Dioxide CO CO2 3 1 6 9 0 0 $0.07 $0.023 $0.000 $0.000 $0.069 $0.023 2293 6,922 TOTAL 0 0 $549.865 $12,478.19 $18,722.90 New Gas Bottle No. of Country Total Gas Price/bottle Price inc bottles Imported Price/yr AUD Cyl. kg Ctax used /yr From: $96,280.20 $8,023 43.1 $17,143 12 USA $3,164.00 $2,109 22.7 $14,588 1.5 USA $11,640.44 $131,040.00 $2,184 27.2 $2,378 60 USA $14,434.00 $14,434 20.0 $22,346 1 USA $7,127.80 $6,119.24 $4,079 31.8 $8,826 1.5 USA $4,274.58 $2,908.15 $5,816 31.8 $14,360 0.5 USA $5.26 $5.26 $1,430.00 $1,430 10.9 $1,435 1 Singapore $1.32 $0.69 $0.40 $0.21 $472.30 $104.56 $1,574 $349 19.1 30.0 $1,576 $349 0.3 0.3 Singapore Singapore $43,001.98 $159,208.44 $255,952.44 $39,999 $83,001 78 The manufacturing gases in the table above are in order of the greatest impact from the carbon tax. As shown the total gas price of the 78 bottles per year is $255,952 but when the carbon tax of $159,208 is applied takes the gas price to $415,160. This is an increase of 162% in cost. The total CO2 equivalent mass is 6,922 tonnes. Since these gases are reacted in the process we are unfairly being taxed for gas byproducts that are non-polluting. Inert Gases The inert gases such as liquid nitrogen, liquid oxygen and argon do not have a carbon tax directly applied but because these gases are produced from high electricity consumption during the air separation process there are increases applied to them. For instances liquid nitrogen will increase by 14% and we use $1 million dollars of LN2 annually which means this gas alone has increased by $140,000. When oxygen and argon are taken into account this adds another $10,000 in carbon tax. S 8 Herb Elliott Avenue, Sydney Olympic Park, NSW, Australia 2127 Page 2 Silanna Semiconductor Detail of Gas Reaction Process The following text explains the reaction products of each of these gases used in the manufacturing process. R116 - Hexafluoroethane C2F6 C2F6 is used in the Novellus Plasma Enhanced Chemical Vapour Deposition system for a chamber clean. The main aim of this gas is to convert SiO2 and Si3N4 that is deposited on the heater block into gaseous SiF4 which leaves a carbon residue in the chamber. The C2F6 and O2 react to release F ions. The reaction components are: C2F6 + 2O2 =CO2 +6F_+ C SiO2 + 4F- = SiF4 (gas) + O2 Si3N4 + 12F- = 3SiF4 + 2N2 The by-products SiF4 and SFx are eliminated by the scrubber. Sulphur Hexafluoride SF6 SF6 is used in the plasma etcher as a silicon etch. The reaction is: SF6 + e- → SF5 + F + eSi + F → SiF4 The by-products SiF4 and SFx are eliminated by the scrubber. Nitrous Oxide N2O N2O is used in the Novellus Plasma Enhanced Chemical Vapour Deposition system as the O2 source and the precursor used for NSG, BSG, PSG and BPSG oxide deposition. The reaction is: 3SiH4 + 6N2O → 3SiO2 + 4NH3 + 4N2 For doped oxides, B2H6 and PH3 are added in specific amount to maintain B% and P% in the glass. The by-product NH3 is eliminated by the scrubber Nitrogen Trifluoride NF3 NF3 is used in the plasma etcher as a silicon nitride etch. The reaction is: NF3 → NFx + F Si3N4 + F → SiF4 + N The by-product SiF4 is eliminated by the scrubber. R14 - Tetrafluoromethane CF4 CF4 is used in the plasma etcher as a silicon dioxide etch. The reaction is: CF4 + e- → CHF3+ + F + 2eSiO2 + F- → SiF4 + O S 8 Herb Elliott Avenue, Sydney Olympic Park, NSW, Australia 2127 Page 3 Silanna Semiconductor CF4 + e- → CHF3 + F + eCFx + O → CO + COF2 + CFy The by-product SiF4, CFx, CO, COF2 and CFy are eliminated by the scrubber. CF4 is also used in the plasma etcher as a silicon nitride etch. The reaction is: Si3N4 + F → SiF4 + N CFx + N → CN + CFy The by-products SiF4, CN and CFy are eliminated by the scrubber. R23 - Trifluoromethane CHF3 CHF3 is used in the plasma etcher as a silicon dioxide etch. The reaction is: CHF3 → CHF+ + F SiO2 + F → SiF4 + O CHFx + O → CO + COF2 + CHFy The by-products SiF4, CHFx, CO, COF2 and CHFy are eliminated by the scrubber. Methane CH4 N2O is the O2 source and the precursor used for NSG, BSG, PSG and BPSG oxide deposition. Chemistry NSG oxide: 3 SiH4 + 6 N2O → 3 SiO2 + 4 NH3 + 4 N2 For doped oxides, B2H6 and PH3 are added in specific amount to maintain B% and P% in the glass. Carbon Monoxide CO CO is used in the plasma etcher to help govern the silicon dioxide etch. The addition of CO reduces the amount of O available and slows down the reaction. The chemistry is the same as for CF 4 shown above. CO + O2 → CO2 + O The by-products are eliminated by the scrubber. Carbon Dioxide CO2 CO2 is used in the DI water rinse bath for post cleaning of wafers. It is bubbled into the water at a very low rate and reacts to form a very weak carbonic acid solution. CO2 + H2O → H2CO3 The wet scrubbers employed at Silanna Semiconductor is a simple method to clean exhaust air, exhaust gas and remove toxic or smelling compounds. In the flue gas scrubber, the gas gets in close contact with fine water drops in a co-current or counter current flow. This method is more effective when the water drop size gets smaller and the total surface between water or washing fluid and the S 8 Herb Elliott Avenue, Sydney Olympic Park, NSW, Australia 2127 Page 4 Silanna Semiconductor gas gets larger. The water or washing fluid is recirculated normally in order to save water and reduce the amount of waste water. The following components are removed from the exhaust gas: Water soluble substances will be dissolved. Dust will be precipitated. Chemicals that can be hydrolysed are decomposed. Steam will be condensed. The result is decontamination, detoxification, dedusting or dust removal, dehumidification, as well as removal of smelling for the benefit of our environment. Especially water soluble components can be removed very well from the gas. By dissolving those components, the water or washing liquid will be contaminated in many cases. The dissolved components are frequently acid or basic chemicals like hydrogen chloride (HCl), nitric / nitrogen oxide NO / NO2 or ammonia NH3. A neutralization unit is installed in the scrubber using caustic soda, to keep the pH value of the washing liquid and the waste water at a neutral level. Furthermore absorption of acid components is improved by using basic washing liquid and removal of basic chemicals is more effective by using acid washing liquid. Compounds which hydrolyse decompose in contact with water. During the chemical reaction new soluble compounds might be created which are then removed immediately by the spray water. Solid reaction products end up in the waste water as slurry and have to be filtered out and disposed. S 8 Herb Elliott Avenue, Sydney Olympic Park, NSW, Australia 2127 Page 5