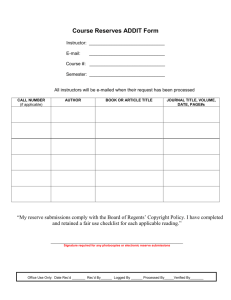

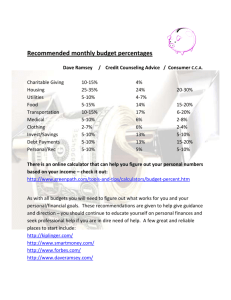

Summer Workshop, Veszprém 2009 RAW MATERIALS

advertisement

Faculty of Chemistry and Chemical Engineering

University of Maribor, Slovenia

Modeling and optimization of

processes of bioethanol

production with Mixed Integer

Process SYNthesizer

MIPSYN

Lidija Čuček, Zdravko Kravanja

Summer Workshop, Veszprém 2009

WHY BIOETHANOL ??

1. Fossil fuels are non-renewable

2. Growing concern about global warming

3. Possible disruption in oil supply

4. Alternative to gasoline, renewable energy

5. The most important long-term objectives of the European Union and United

States in the energy sector are:

- Achieving independence of fossil fuel energy supplies

- Achieving substantial improvement of energy efficiency of the whole supply

chain from production, distribution, to consumption, while minimizing emissions

and waste

- Achieving 20 % increase in the share of renewable energy (RES) by 2020

- The share of renewable energy in all modes of transport has to be at least 10 %

by 2020

Summer Workshop, Veszprém 2009

RAW MATERIALS

Bioethanol can be produced by fermentation of:

-Sugars (molasses),

-Starchy raw materials (corn, potato)

- Lignocellulose (wood, agricultural residues, municipal solid waste)

First-generation biofuels: produced by fermentation of plants containing starch or

sugar.

This production has a lot of downsides: plants are mainly food crops, affection of

the supply of population with food products, limited quantity, affecting

biodiversity, may cause more GHG than fossil fuels, using chemicals for plant

production, impact on drinking water supply,...

Second-generation biofuels: produced by fermentation of lignocelluloses

(agricultural residues, forestry waste, fast-growing energy crops...). Many technical

and economic issues related to their use before 2020.

Third-generation biofuels: produced from algae, sigle-celled aquatic organisms.

Summer Workshop, Veszprém 2009

OUR GOAL

Problems with using bioethanol:

- Usage requires modifications to the engines

- Consumption in engines is about 51 % higher compared to gasoline

- Costs for bioethanol production are very high (investment, costs of raw

materials , etc.)

Therefore it is necessary to develop effective, economical and environment

friendly technologies of bioethanol production.

Consumption of raw materials, energy and water should be very carefully

analyzed, planed and optimized.

Development and application of optimization methods are becoming necessary

in the technique.

Goal: Detailed synthesis and optimization of various production processes

of bioethanol production from different raw materials.

Summer Workshop, Veszprém 2009

GENERAL OVERVIEW OF WORK

Modeling and optimization was performed for ethanol

production from:

- starchy raw materials (corn, potato), dry milling process

- sugars (molasses), direct fermentation

- lignocelluloses:

i)

from corn stover, acid prehydrolysis and enzymatic hydrolysis

ii) from wheat straw, ammonia fiber explosion (AFEX) and

iii) from wood chips, gasification and subsequent fermentation of the

produced syngas

Superstructures of the processes are modeled as MINLP problems, which include

both discrete (topology) and continuous variables (operating conditions,

dimensions of the process units).

Synthesis was caried out with and without heat integration.

Different alternatives with respect to the separation of solids and liquids and

alternatives to the dehydration of ethanol.

Summer Workshop, Veszprém 2009

STARCH-BASED PROCESS

Summer Workshop, Veszprém 2009

SUGAR-BASED PROCESS

Summer Workshop, Veszprém 2009

ACID PREHYDROLYSIS PROCESS

Summer Workshop, Veszprém 2009

AFEX PROCESS

Summer Workshop, Veszprém 2009

THERMOCHEMICAL PROCESS

Summer Workshop, Veszprém 2009

MIPSYN

Optimization was performed with equation-oriented process synthesizer MIPSYN.

• package performs MINLP optimization on superstructures for process flowsheet

• enables automated execution of simultaneous topology and parameter

optimization of processes

Modified OA/ER algorithm and modeling and decomposititon (M/D) strategy

• The computer package MIPSYN enabled us to optimize the chemical

processes

Processes producing fuel ethanol from biomass are biochemical processes.

Completion of MIPSYN’s library PROSLIB with modules for

synthesis of the biochemical processes

Summer Workshop, Veszprém 2009

MODUL - WASHER

*

*

*

===========================

=

WASHING =

===========================

EQUATIONS

WASHWA(WASH,COMPON)

TOTAL STREAM OF WASHING WATER

WASHCB(WASH,COMPON)

COMPONENT BALANCE AT WASHING

WASHT(IN,WASH)

INLET TEMPERATURE RELATION AT WASHING

WASHP(IN,WASH)

INLET PRESSURE RELATION AT WASHING

WASHSIZE(WASH)

SIZE VARIABLE ;

WASHWA(WASH,COMPON)$EXIST(WASH)..

F('IN-2',WASH) =E= WASHMIN*WASHFRAC*F('IN-1',WASH);

WASHCB(WASH,COMPON)$EXIST(WASH)..

FC('OUT-1',WASH,COMPON) =E= SUM(IN$RELIOB(IN,WASH),FC(IN,WASH,COMPON));

WASHT(IN,WASH)$(RELIOB(IN,WASH)AND EXIST(WASH))..

T('OUT-1',WASH) =E= T(IN,WASH);

WASHP(IN,WASH)$(RELIOB(IN,WASH)AND EXIST(WASH))..

P('OUT-1',WASH) =E= P(IN,WASH);

WASHSIZE(WASH)$EXIST(WASH)..

sizes(wash)*SIZE(WASH) =E= AREA(WASH) ;

Summer Workshop, Veszprém 2009

MODUL – FLOTATION UNIT

*

*

*

===========================

= FLOTATION =

===========================

EQUATIONS

FLOTCBH(FLOT)

COMPONENT BALANCE FOR HYDROPHOBIC MOLECULE

FLOTCBM(FLOT)

COMPONENT BALANCE FOR WATER IN TOP

FLOTCB(FLOT,COMPON) COMPONENT BALANCE FOR FLOTATION

FLOTT(OUT,FLOT)

TEMPERATURE RELATION FOR OUT

FLOTP(OUT,FLOT)

PRESSURE RELATION FOR OUTLET

FLOTSIZE(FLOT)

SIZE VARIABLE ;

FLOTCBH(FLOT)$EXIST(FLOT)..

FC('OUT-1',FLOT,'PROT') =E= FLOTREC*FC('IN-1',FLOT,'PROT');

FLOTCBM(FLOT)$EXIST(FLOT)..

FC('OUT-1',FLOT,'WA') =E= FLOTREC*FLOTMOIST*FC('IN-1',FLOT,'PROT');

FLOTCB(FLOT,COMPON)$EXIST(FLOT)..

FC('OUT-2',FLOT,COMPON) =E= FC('IN-1',FLOT,COMPON)-FC('OUT-1',FLOT,COMPON);

FLOTT(OUT,FLOT)$(EXIST(FLOT) AND RELIOB(OUT,FLOT))..

T(OUT,FLOT) =E= T('IN-1',FLOT);

FLOTP(OUT,FLOT)$(EXIST(FLOT) AND RELIOB(OUT,FLOT))..

P(OUT,FLOT) =E= P('IN-1',FLOT);

FLOTSIZE(FLOT)$EXIST(FLOT)..

sizes(flot)*SIZE(FLOT) =E= F('IN-1',FLOT)*fs*3.6;

Summer Workshop, Veszprém 2009

MODUL – ADSORBER I

*

*

*

=============================

= ADSORPTION =

=============================

EQUATIONS

ADSSIZE(ADS)

REQUIRED BED SIZE

ADSMBETHO(ADS,COMPON) FLOW BALANCE FOR ETHANOL FOR OUTLET

ADSCBOUT(ADS,COMPON) COMPONENT BALANCE FOR OUTLET 2

ADSCBWA(ADS,COMPON) COMPONENT BALANCE FOR NON-ADSORBED WATER

ADSCBWAADS(ADS,COMPON) COMPONENT BALANCE FOR ADSORBED WATER

ADSTB(ADS)

TOTAL BALANCE FOR ADSORBENT

ADSCB(ADS,COMPON) ADDITIVE COMPONENT BALANCE IN ADSORBER

ADSFCPH(ADS,COMPON) evaluation of FCPH

QHPEQ(ADS)

ENTHALPY OF STREAM

ADSHB(ADS)

HEAT BALANCE

ADSP1(ADS)

PRESSURE RELATION FOR OUTLET 1

ADSP2(ADS)

PRESSURE RELATION FOR OUTLET 2

ADST(OUT,ADS)

TEMPERATURE RELATION ;

ADSSIZE(ADS)$(EXIST(ADS) AND (NOT MILP))..

SIZE(ADS)*sizes(ads) =E= ADSSATTIME*F('IN-2',ADS)*fs

$BATINCLUDE "P_LINEAR.INC" ADS ;

ADSMBETHO(ADS,COMPON)$(EXIST(ADS) AND (ORD(COMPON) EQ 6))..

FC('OUT-1',ADS,COMPON) =E= FC('IN-1',ADS,COMPON);

ADSCBOUT(ADS,COMPON)$(EXIST(ADS) AND (ORD(COMPON) NE 1) AND (ORD(COMPON) NE 6))..

FC('OUT-2',ADS,COMPON) =E= FC('IN-2',ADS,COMPON);

ADSCBWA(ADS,COMPON)$(EXIST(ADS) AND (ORD(COMPON) EQ 1) AND (NOT MILP))..

FC('OUT-1',ADS,COMPON) =E= (1.-ADSREMWA)*FC('IN-1',ADS,COMPON)

$BATINCLUDE "P_LINEAR.INC" ADS ;

Summer Workshop, Veszprém 2009

MODUL – ADSORBER II

ADSCBWAADS(ADS,COMPON)$(EXIST(ADS) AND (ORD(COMPON) EQ 1) AND (NOT MILP))..

FC('OUT-2',ADS,COMPON) =E= ADSREMWA*FC('IN-1',ADS,COMPON)+

FC('IN-2',ADS,COMPON)

$BATINCLUDE "P_LINEAR.INC" ADS ;

ADSTB(ADS)$(EXIST(ADS) AND (NOT MILP))..

F('IN-2',ADS)*fs =E= (1./ADSPOT)*ADSREMWA*FC('IN-1',ADS,'WA')*fcs('wa')

$BATINCLUDE "P_LINEAR.INC" ADS ;

ADSCB(ADS,COMPON)$EXIST(ADS)..

SUM(OUT$RELIOB(OUT,ADS), FC(OUT,ADS,COMPON)) =E=

SUM(IN$RELIOB(IN,ADS), FC(IN,ADS,COMPON));

ADSFCPH(ADS,COMPON)$(EXIST(ADS) AND (ORD(COMPON) EQ 1))..

FCPH(ADS)*fcphs(ads) =E= FC('IN-1',ADS,COMPON)*fcs(compon) * DHADS;

QHPEQ(ADS)$(EXIST(ADS) AND (NOT MILP))..

QHP(ADS)*qhps(ads) =E= ADSREMWA* FCPH(ADS)*fcphs(ads)

$BATINCLUDE "P_LINEAR.INC" ADS ;

ADSHB(ADS)$(EXIST(ADS) AND (NOT HIFL) AND (NOT HENFL))..

QC(ADS)*qcs(ads) =E= 3600. * NHOUR * 1.0E-9 * QHP(ADS)*qhps(ads);

ADSP1(ADS)$EXIST(ADS).. P('OUT-1',ADS) =E= P('IN-1',ADS);

ADSP2(ADS)$EXIST(ADS).. P('OUT-2',ADS) =E= P('IN-1',ADS);

ADST(OUT,ADS)$(EXIST(ADS) AND RELIOB(OUT,ADS))..

T(OUT,ADS) =E= T('IN-2',ADS);

Summer Workshop, Veszprém 2009

MODUL – RECTIFIER COLUMN I

*

*

*

=====================================

= RECTIFIER COLUMN =

=====================================

EQUATIONS

RECCB(REC,COMPON) ADDITIVE COMPONENT BALANCE IN RECTIFIER COLUMN

RECTOPH(REC,WE) COMPONENT BALANCE FOR HEAVY KEY - TOP

RECTOPL(REC,WE) COMPONENT BALANCE FOR LIGHT KEY - TOP

RECBOTH(REC,WE) COMPONENT BALANCE FOR HEAVY KEY - BOTTOM

RECBOTL(REC,WE) COMPONENT BALANCE FOR LIGHT KEY - BOTTOM

RECPT(REC)

OUTLET PRESSURE RELATION (TOP)

RECPB(REC)

OUTLET PRESSURE RELATION (BOTTOM)

NTHEOREC(REC)

THEORETICAL NUMBER OF TRAYS

NACTREC(REC)

ACTUAL NUMBER OF TRAYS

RECMFTOP(REC,WE) RELATION OF MOL AND MASS FRACTIONS FOR OUT TOP

RECANTATOP(REC,WE) ANTOINE EQUATION FOR OUT TOP

RECMFBOT(REC,WE) RELATION OF MOL AND MASS FRACTIONS FOR OUT BOTTOM

RECANTABOT(REC,WE) ANTOINE EQUATION FOR OUTLET BOTTOM

RECMFCL(REC)

MOL FRAC IN THE CONDENSED VAPOR FOR LIGHT

RECMFCH(REC)

MOL FRAC IN THE CONDENSED VAPOR FOR HEAVY

RECXC(REC,WE)

RELATION OF MOL AND MASS FRACTION IN THE CONDENSER

CONDHVREC(REC,WE) HEAT OF VAPORIZATION OF COMPONENTS IN CONDENSER

FCPHREC(RECC)

evaluation of FCPH IN CONDENSER

QCONDREC(RECC) ENTHALPY OF HOT STREAM IN CONDENSER

RECCONDHB(RECC) HEAT BALANCE IN CONDENSER

REBHVREC(REC,WE) HEAT OF VAPORIZATION OF COMPONENTS IN REBOILER

FCPCREC(RECR)

evaluation of FCPC IN REBOILER

QREBREC(RECR)

ENTHALPY OF COLD STREAM IN REBOILER

RECREBHB(RECR) HEAT BALANCE IN REBOILER

RECSIZE(REC)

SIZE VARIABLE

;

Summer Workshop, Veszprém 2009

MODUL – RECTIFIER COLUMN II

RECCB(REC,COMPON)$EXIST(REC)..

SUM(OUT$RELIOB(OUT,REC), FC(OUT,REC,COMPON)) =E= FC('IN-1',REC,COMPON);

RECTOPH(REC,WE)$(EXIST(REC) AND DHKEY(REC,WE) AND (NOT MILP))..

FC('OUT-1',REC,WE) =E= DHREC(REC)*FC('IN-1',REC,WE)

$BATINCLUDE "P_LINEAR.INC" REC ;

RECTOPL(REC,WE)$(EXIST(REC) AND DLKEY(REC,WE))..

FC('OUT-1',REC,WE) =E= DLREC(REC)*FC('IN-1',REC,WE);

RECBOTH(REC,WE)$(EXIST(REC) AND DHKEY(REC,WE) AND (NOT MILP))..

FC('OUT-2',REC,WE) =E= (1.-DHREC(REC))*FC('IN-1',REC,WE)

$BATINCLUDE "P_LINEAR.INC" REC ;

RECBOTL(REC,WE)$(EXIST(REC) AND DLKEY(REC,WE))..

FC('OUT-2',REC,WE) =E= (1.-DLREC(REC))*FC('IN-1',REC,WE);

RECPT(REC)$EXIST(REC)..

P('OUT-1',REC) =E= P('IN-1',REC);

RECPB(REC)$EXIST(REC)..

P('OUT-2',REC) =E= P('IN-1',REC);

NTHEOREC(REC)$(EXIST(REC) AND (NOT MILP))..

NTHEO(REC) =E=

LOG((DLREC(REC)/(1.-DLREC(REC)))*((1-DHREC(REC))/DHREC(REC)))/LOG(AVEVLT)

$BATINCLUDE "P_LINEAR.INC" REC ;

NACTREC(REC)$(EXIST(REC) AND (NOT MILP))..

NACT(REC) =E= (NTHEO(REC)-1.)/TRAYEFF

$BATINCLUDE "P_LINEAR.INC" REC ;

Summer Workshop, Veszprém 2009

MODUL – RECTIFIER COLUMN III

RECMFTOP(REC,WE)$(EXIST(REC) AND (NOT MILP))..

MF('OUT-1',REC,WE)*SUM(WE1, FC('OUT-1',REC,WE1)/MOLWT(WE1))

=E= FC('OUT-1',REC,WE)/MOLWT(WE)

$BATINCLUDE "P_LINEAR.INC" REC ;

RECANTATOP(REC,WE)$(EXIST(REC) AND (NOT MILP) AND DLKEY(REC,WE))..

EXP(ANTA(WE)-ANTB(WE)/(ANTC(WE)+ T('OUT-1',REC)*100.)) =E=

(P('OUT-1',REC)-DP/2.)*7600.*

(MF('OUT-1',REC,'WA')*AVEVLT + MF('OUT-1',REC,'ETHO'))

$BATINCLUDE "P_LINEAR.INC" REC ;

RECMFBOT(REC,WE)$(EXIST(REC) AND (NOT MILP))..

MF('OUT-2',REC,WE)*SUM(WE1, FC('OUT-2',REC,WE1)/MOLWT(WE1))

=E= FC('OUT-2',REC,WE)/MOLWT(WE)

$BATINCLUDE "P_LINEAR.INC" REC ;

RECANTABOT(REC,WE)$(EXIST(REC) AND (NOT MILP) AND DHKEY(REC,WE))..

EXP(ANTA(WE)-ANTB(WE)/(ANTC(WE)+ T('OUT-2',REC)*100.))*

(MF('OUT-2',REC,'WA') + AVEVLT*MF('OUT-2',REC,'ETHO')) =E=

(P('OUT-2',REC)+DP/2.)*7600.

$BATINCLUDE "P_LINEAR.INC" REC ;

RECMFCL(REC)$(EXIST(REC) AND (NOT MILP))..

MFC(REC,'ETHO') =E= MF('OUT-1',REC,'ETHO')*(P('OUT-1',REC)-DP/2.)*7600./

EXP(ANTA('ETHO')-ANTB('ETHO')/(ANTC('ETHO')+T('OUT-1',REC)*100.))

$BATINCLUDE "P_LINEAR.INC" REC ;

RECMFCH(REC)$EXIST(REC)..

MFC(REC,'WA') =E= 1.- MFC(REC,'ETHO') ;

Summer Workshop, Veszprém 2009

MODUL – RECTIFIER COLUMN IV

RECXC(REC,WE)$(EXIST(REC) AND (NOT MILP))..

XC(REC,WE)*SUM(WE1,MFC(REC,WE1)*MOLWT(WE1)) =E= MFC(REC,WE)*MOLWT(WE)

$BATINCLUDE "P_LINEAR.INC" REC ;

CONDHVREC(REC,WE)$(EXIST(REC) AND (NOT MILP))..

DHV('OUT-1',REC,WE) =E= (HV(WE)/MOLWT(WE))*

((TC(WE)-T('OUT-1',REC)*100.)/(TC(WE)-TB(WE)))**NWATSON

$BATINCLUDE "P_LINEAR.INC" REC ;

FCPHREC(RECC)$SUM(REC$(ORD(REC) EQ ORD(RECC)), EXIST(REC) AND (NOT MILP))..

fcphs(recc)*FCPH(RECC) =E=

SUM(REC$(ORD(REC) EQ ORD(RECC)), F('OUT-1',REC)*fs*REFLUX*

SUM(WE, XC(REC,WE)*DHV('OUT-1',REC,WE)))

$BATINCLUDE "P_LINEAR.INC" RECC ;

QCONDREC(RECC)$SUM(REC$(ORD(REC) EQ ORD(RECC)), EXIST(REC) AND CONDFL(RECC))..

QHP(RECC)*qhps(recc) =E= fcphs(recc)*FCPH(RECC)*100.*0.01;

RECCONDHB(RECC)$SUM(REC$(ORD(REC) EQ ORD(RECC)), EXIST(REC))..

QC(RECC) =E= 3600.*NHOUR*1.0E-9 * QHP(RECC)*qhps(recc);

REBHVREC(REC,WE)$(EXIST(REC) AND DHKEY(REC,WE) AND (NOT MILP))..

DHV('OUT-2',REC,WE) =E= (HV(WE)/MOLWT(WE))*((TC(WE)-T('OUT-2',REC)*100.)/

(TC(WE)-TB(WE)))**NWATSON

$BATINCLUDE "p_linear.inc" REC ;

FCPCREC(RECR)$SUM(REC$(ORD(REC) EQ ORD(RECR)), EXIST(REC) AND (NOT MILP))..

FCPC(RECR)*fcpcs(recr) =E=

SUM(REC$(ORD(REC) EQ ORD(RECR)),(F('OUT-1',REC)*fs*REFLUX-F('OUT-2',REC)*fs)*

SUM(WE$DHKEY(REC,WE), DHV('OUT-2',REC,WE)))

$BATINCLUDE "P_LINEAR.INC" RECR ;

Summer Workshop, Veszprém 2009

MODUL – RECTIFIER COLUMN IV

QREBREC(RECR)$SUM(REC$(ORD(REC) EQ ORD(RECR)), EXIST(REC) AND EVAPFL(RECR))..

QCP(RECR)*qcps(recr) =E= 100.*0.01*FCPC(RECR)*fcpcs(recr);

RECREBHB(RECR)$SUM(REC$(ORD(REC) EQ ORD(RECR)), EXIST(REC))..

QH(RECR) =E= 3600.*NHOUR*1.0E-9 * QCP(RECR)*qcps(recr);

RECSIZE(REC)$EXIST(REC)..

SIZE(REC)*sizes(rec) =E= VOLUME(REC);

Summer Workshop, Veszprém 2009

INPUT AND OUTPUT FILES

The high level language GAMS (General Algebraic Modeling System) is interface

for mathematical modeling with MIPSYN. Input and output files are written in

GAMS language.

User has to define (input files):

1.) the superstructure (p_struct)

2.) all data (datalib.gms)

3.) list of chemical components (p_compon)

4.) physical properties of components (if component is not defined) (compon)

5.) initialization scheme for non-existing modules in process flowsheet (initlib.gms)

6.) the additional modules equations (my_model.dat)

7.) components and their physical properties (p_dbase.lib).

Output files: p_w.lst (listing file)

optimum.res (optimal solution)

p_b.res (MINLP iterations)

Summer Workshop, Veszprém 2009

OPTIMIZATION

Raw material mass flow (corn, potato, molasses, etc.): 18 kg/s

Number of annual working hours: 8500

Objective: maximizing the profit

Product mass flow Price of product

max P

c

pprod

Profit

p

qp

c q

rreac

r

r

Need of utility

Depreciation

ch Qh cc Qc (a1 a2 S ) / n

Raw material Price of raw

material

mass flow

Utility price

Depreciation

period

Investment was estimated by programme Aspen Icarus 2006.5.

Solvers:

for NLP suboptimization: local optimizer CONOPT 3,

for MILP optimization: optimizer GAMS/CPLEX 10.1.

Summer Workshop, Veszprém 2009

RESULTS

Annual profit before taxes:

80000

70000

60000

50000

40000

30000

20000

10000

0

CORN

POTATOES

NHI: 1. structure

MOLASSES

NHI: 2. structure

CORN

STOVER

WHEAT

STRAW

HI: 1. structure

WOOD CHIPS

HI: 2. structure

Summer Workshop, Veszprém 2009

RESULTS

Optimal productivity of products:

WOOD CHIPS

WHEAT STRAW

CORN STOVER

MOLASSES

POTATOES

CORN

0

FLUE GAS

5

ACETIC ACID

10

15

DDGS

20

BIOGAS

25

30

BIOETHANOL

Mass flow rate /(kg/s)

Summer Workshop, Veszprém 2009

RESULTS

Annual profit per kg of bioethanol (k€/a):

14000

12000

10000

NHI: 1. structure

8000

NHI: 2. structure

HI: 1. structure

6000

HI: 2. structure

4000

2000

0

CORN

POTATOES

MOLASSES

CORN STOVER WHEAT STRAW

WOOD CHIPS

Summer Workshop, Veszprém 2009

RESULTS

Operating costs (k€/a):

100000

90000

80000

70000

60000

RAW MATERIAL

UTILITY - NHI

50000

UTILITY - HI

40000

INVESTMENT

30000

20000

10000

0

CORN

POTATOES

MOLASSES

CORN STOVER

WHEAT STRAW

WOOD CHIPS

Summer Workshop, Veszprém 2009

RESULTS

Payback period (a):

16

14

12

10

NHI: 1. structure

NHI: 2. structure

8

HI: 1. structure

HI: 2. structure

6

4

2

0

CORN

POTATOES

MOLASSES

CORN STOVER

WHEAT STRAW

WOOD CHIPS

Summer Workshop, Veszprém 2009

RESULTS

Efficiency (%):

50

45

40

35

30

25

20

15

10

5

0

CORN

POTATOES

MOLASSES

CORN STOVER

WHEAT STRAW

WOOD CHIPS

Summer Workshop, Veszprém 2009