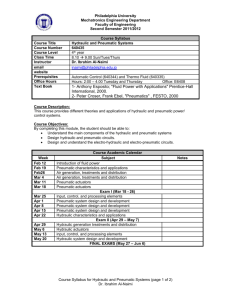

Document

advertisement

Hydraulic and Pneumatic Actuators and their Application Areas Elena Ponomareva JASS 2006 – St. Petersburg 1 06.04.2006 Introduction Figure A. Automatic Pneumatic Drive: UGM - units of gas networks and mains; PA - pneumatic amplifiers; PE - pneumatic engines; MT - the mechanism of transfer; CSD converting and summing device; ACE - amplifiers of capacity of electric signals; EMC - electromechanical converters; DF - devices of feedbacks; AC - adjusting circuits; IF - internal feedbacks; GG - a source of gas energy 2 Pneumatic Actuators 3 Gas Laws The combined gas law Boltzmann’s equation p1V1 p2V2 T1 T2 1 3 2 m c kT 2 2 The ideal gas law pV nRT 4 P is the pressure in atmospheres (atm) or kilopascals (kPa); V is the volume in liters n is the number of moles of gas R is the ideal gas constant in L atm/mol K or Pa m³/mol K T is the temperature in kelvins. 3 1 kT m c2 The strings 2 and 2 are the Kinetic Energy m refers to the mass of one atom < c2 > refers to the average of c2 k refers to the Boltzmann constant T refers to the temperature of the surroundings Classification Of Pneumatic Actuators All pneumatic actuators can be subdivided into the following types: diaphragm pneumatic actuators; pneumatic power cylinders; gas-engine pneumatic actuators; turbine pneumatic actuators; jet pneumatic actuators; pneumomuscles; combined pneumatic actuators. 5 Diaphragm Pneumatic Actuators Figure 1.1. The membrane pneumatic actuator: 1 - the connecting pipe of the second cavity; 2 the connecting pipe of the first cavity; 3 - the membrane; 4 - the case; 5 - the rod; G1 - the second charge of a gas stream in the first cavity; G2-the second charge of a gas stream in the second cavity; p1 - pressure of gas in the first cavity; р2 - pressure of gas in the second cavity; xr - moving of the rod 6 Figure 1.2. The sylphon pneumatic actuator: 1 - the connecting pipe of the second cavity; 2 the connecting pipe of the first cavity; 3 - the case; 4 — the rod with the piston of the first cavity; 5 - a sylphon of the first cavity; 6 – the closing up of the sylphon of the first cavity Pneumatic Power Cylinders 7 As compressed air moves into the cylinder, it pushes the piston along the length of the cylinder. Compressed air or the spring, located at the rod end of the cylinder, pushes the piston back. Pneumatic Power Cylinders A double acting pneumatic cylinder has twodirected powered motion, with pressure on both sides. 8 Pneumatic Power Cylinders 9 Pneumatic Power Cylinders 10 Optimal range •Good running performance and long service life thanks to smooth, hard cylinder bore •Piston rod and cylinder barrel made of stainless steel More than the standard •Round cylinders with piston diameters from 8 to 25 mm conform to ISO 6432, DIN ISO 6432. Variants are based on these standards. The series is not repairable. •The cap is swaged onto the barrel. Functional Three different end caps mean numerous functional and spacesaving designs Variants •Non-rotating •Through piston rod •With or without position sensing •Cushioning non-adjustable at either end or cushioning adjustable at both ends •Further piston rod variants Pneumatic Power Cylinders The piston rods are connected with the same piston. Double-rod cylinders provide equal force and speed in both directions. 11 Double-acting double-rod cylinder – doubleacting cylinder with a piston rod extending form each end. Pneumatic Power Cylinders 12 •Fast or slow valve actuation •Position sensing •Internal air channels eliminate protruding tubing and attachments, and thus also harmful accumulation of contaminants •Suitable for manual on-site use, as well as automatic operation •Opening and closing actuated via flange-mounted solenoid valve with port pattern to Namur, or via valve terminals with a choice of 30 different fieldbus protocols •Sturdy and reliable, even in aggressive environments •Highly corrosion resistant Festo Copac Linear Actuator Pneumatic Power Cylinders 13 •Ball-bearing circulating guide system for a long service life when operated vertically •Double piston rod for a high level of force in spite of a flat design •Compact dimensions •Symmetric geometry •Low weight •Wide variety of mounting options Ideal for vertical use The ZSC series is available in five sizes with piston diameters of 6 to 25 mm and strokes from 10 to 100 mm (in 10 mm increments). The mini slides operate at a speed between 0.05 to 0.5 m/s (0.16 to 1.6 ft/s) at an operating pressure of 1.5 to 7 bar (22 to 102 psi). Pneumatic Power Cylinders 14 The GPC series is ideal for all applications that demand absolute precision and side load capacity. Compared to standard cylinders, cylinders from this series offer extremely precise movement, high side load capacities, and also torsion protection. This results in fewer outer guides to design and set up machines. Pneumatic Power Cylinders Tandem cylinders ADVUT 15 By connecting 2, 3 or 4 cylinders with the same piston diameter and stroke in series, the force in the advance stroke (thrust) can be doubled, tripled or quadrupled in comparison to a single cylinder. • A maximum of 4 cylinders can be combined. • The internal distribution of compressed air means that only 2 connections are required to pressurise all cylinders. • The force in the return stroke corresponds to that of a single cylinder with corresponding piston diameter. Pneumatic Power Cylinders Shock influence is required in a number of technological operations, such as punching, marking, punching of holes. In this case we use shot pneumocylinders. 16 Figure 1.3. The scheme of the shot pneumocylinder: A, b, c – cavities; 1, 3, 4 – channels; 2 - aperture Pneumatic Power Cylinders In technological operations when the executive mechanism is, for example, the cutting tool or a gearshift, it is necessary to establish two and more fixed positions, multiposition pneumocylinders or pneumatic positioners are used. 17 Figure 1.4. Threeposition pneumocylinder: A, B, C - control valves; 1, 2, 3 – channels; T1, T2 – pneumothrottles; a, b – cavities; Рip - pressure of compressed air in cavities a and b Pneumatic Power Cylinders 18 •Compact – fitting length relative to stroke •Loads and devices can be directly mounted on the slide •All settings accessible from one side: •Precision end-position adjustment •Position of proximity sensors •Mounting of drive •Speed regulation •Pneumatic endpositioncushioning •Sealing system Pneumatic Power Cylinders Figure 1.5. The hose pneumocylinder: 1 – hose; 2 - rollers of the carriage; 3 - control valve; B 19 Pneumatic Power Cylinders • Nominal swivel angles of 90°, 180°, 270° or 360° • Freely selectable swivel angle from 0 to 360° • With adjustable end-position cushioning at both ends and end-position adjustment for piston ∅ 16 to 100 mm • With adjustable end-position cushioning at both ends for piston ∅ 40 to 100 mm 20 Figure 1.6 Rotary pneumoactuator: 1, 2, 5 - channel; 3piston; 4 - chain transfer; A - cavity; Рip - pressure • For contactless position sensing • Backlash-free power transmission • Wide choice of mounting options Pneumatic Power Cylinders Figure 1.7 Chamber rotary pneumoactuator: 1 – channel; 2 - chamber; 3, 4 – levers; 5 - detail 21 Pneumatic Power Cylinders The pneumomotor with the limited angle of turn is applied to perform oscillating movements of the output shaft or its rotation on the definite angle. 22 Figure 1.8 The pneumomotor with the limited angle of turn: 1 - case; 2 - blade: 3 - target shaft; 4 compaction; 5, 6 - fittings; 7 - stops Pneumatic Power Cylinders Figure 1.9 Lateral force Fq as a function of stroke length l . 23 Pneumatic Power Cylinders Figure 1.10 Pneumomuscle: 1 - internal elastic tube; 2 - braid; 3, 4 – covers; 5 – feeding channel Figure 1.12 Geometrical parameters of reduced pneumomuscles: 1 - braid; 2 - internal elastic tube; 3 – pantograph’s cell Figure 1.11 Comparative characteristics of output efforts of the power cylinder and the pneumomuscle: 24 1 - power cylinder; 2 - pneumomuscle Pneumatic Power Cylinders Figure 1.13 The artificial muscle: 1 – casing; 2 - elastic tube; 3 – thermoelement; 4 – filler; 5 electric leading-out wires 25 Pneumatic Power Cylinders Figure 1.14 The electropneumatic actuator: 1 - amplifier of direct current; 2 - electromechanical converter; 3 - choker; 4 - nozzles, 5 throttles, 6, 7 - executive pneumocylinders, 8, 9 feedback sensors 10 - spring, 11 - flywheel 26 Directional Control Valves 27 The Stream Regulator 28 Advantages and disadvantages Advantages: •simplicity of realization relatively to small back and forth motions; •sophisticated transfer mechanisms are not required •low cost •high speed of moving •ease at reversion movements •tolerance to overloads, up to a full stop. •high reliability of work •explosion and fire safety •ecological purity •ability to accumulation and transportation 29 Disadvantages: •compressibility of the air •impossibility to receive uniform and constant speed of the working bodies movement •difficulties in performance at slow speed •limited conditions – use of compressed air is beneficial up to the definite values of pressure (the cost of compressed air productior increases sharply when the pressure in the system exceeds 8…10 bar) •compressed air requires good preparation (the air should be cleared of mechanical impurity and should be free of moisture) Hydraulic Actuators 30 Bernoulli's Equation The original form of Bernoulli's equation v2 p gh const 2 31 v = fluid velocity along the streamline g = acceleration due to gravity on Earth h = height from an arbitrary point in the direction of gravity p = pressure along the streamline ρ = fluid density The second, more general form of Bernoulli's equation v2 p const , 2 φ is the gravitational potential energy per unit mass ω is the fluid enthalpy per unit mass ε is the fluid thermodynamic energy per unit mass The Structure of Hydraulic Cylinders Figure 2.1. The hydraulic cylinder: a - one- sided action with a returnable spring; b — doublesided action controlled by the differential scheme; 1 — plunger; 2 — spring; 3 — basic sealant; 4 — antisplash sealant; 5 — piston; 6 — nternal sealant; 7 — rod; 8 — a basic external sealant; 9 — antisplash external sealant; 10 — rod’s cavity; 11 — supply circuit; I, II — positions of a control valve; F — external force; S — the full area of the piston; S' - the ring area of the piston; Q, q — submission and plums of a stream accordingly 32 The Structure of Hydraulic Cylinders Figure 2.2. The hydraulic cylinder with a double-sided rod: a - with the fixed rod; b — with the fixed hydraulic cylinder and a control valve; 1—internal consolidation; 2, 5 — antisplash external consolidations; 3, 4 — basic external consolidations; F external force; h — course of the piston; p1, р1' — low pressure; p2, р2' — high pressure; Q — the charge; v — speed of the piston 33 The Structure of Hydraulic Cylinders Figure 2.3. The threehigh-speed hydraulic cylinder: 1,3, 6 — hydrolines; 2 — the internal hydraulic cylinder; 4, 5 — cavities; F— external force; S1 - area of the hydraulic cylinder 2; S2, S3- area of cavities 5 and 4 accordingly 34 The Structure of Hydraulic Cylinders Figure 2.4. The telescopic hydraulic cylinder: 1,6-pistons; 2, 3 — cavities; 4 — sleeve; 5 — hydroline; 7 — supply; F- the external force; S1. S2 —the area of cylinders with pistons 1 and 6 accordingly; S3, S4- areas of cavities 2 and 3 accordingly 35 The Structure of Hydraulic Cylinders Figure 2.5. The hydraulic cylinder with trailer throttle brakes and the protected rod: 1 - throttle; 2,3 - sockets; 4 — rubber sylphon; 5 — return valves; 6,7- ledges of the piston; 8 — ring volume; other designations see on fig. 2.2 36 The Structure of Hydraulic Cylinders Figure 2.6. The piston of the hydraulic cylinder with fixing devices: 1 - sealant element; 2 — conic surface; 3 — ball; 4 — spring; 5, 7 — cavities of the hydraulic cylinder; 6 — piston 37 The Structure of Hydraulic Cylinders Figure 2.7. Consolidation of rods (a, b) and pistons (c, d) of hydrocylinders: a – with a round rubber ring; b,c – with V-look cuffs; d — with a bilateral cuff; 1 — aprotective ring; 2 — plastic persistent ring; 3 — rubber ring; 4 — nut; 5— dividing plastic cuff; 6 — consolidating rubber cuff; 7 — directing belt of a cuff; 8— cuff; 9 — bilateral cuff 38 Volumetric Hydraulic Actuator Figure 2.8. Hydraulic Jack In this system , a reservoir and a system of valves has been added to a simple hydraulic lever to stroke a small cylinder or pump continuously and raise a large piston or an actuator a notch with each stroke. 39 Volumetric Hydraulic Actuator Figure 2.9. Basic schemes of a hydraulic actuator: a - forward movement; b — rotary movement; c — hydromotor; 1 — hydraulic engine; 2 — hydraulic control valve; 3 — hydrotank; 4 — adjustable pump; 5 — safety valve; F — working force 40 Volumetric Hydraulic Actuator Figure 2.10. The scheme of a hydraulic actuator with the closed circulation of a liquid: 1 - adjustable pump; 2— auxiliary pump; 3 — downflow flap; 4 — return flap; 5— safety flaps; 6 — hydraulic engine (adjustable hydromotor); a, b — hydrolines 41 Volumetric Hydraulic Actuator Figure 2.11. The scheme of a hydraulic actuator with a regulator of a stream: 1— regulator; 2 — adjustable throttle; 3 — reducing valve; Рth pressure in a throttle upon an input; Рp - pressure of the pump 42 Volumetric Hydraulic Actuator Figure 2.12. The scheme of a hydraulic actuator with steady output rotation frequency: 1 - a pump; 2 — a hydromotor; 3 — the shaft of the hydromotor; 4 — a centrifugal regulator; 5 — the valve of the hydraulic control valve ; 6 — the hydrocylinder; 7 — a disk 43 Volumetric Hydraulic Actuator Figure 2.13 The scheme of a stream divider: 1 — throttles; 2, 3 — apertures; 4 — a piston; 5 — a sleeve; M — a point of division of stream Q on streams Q1, and Q2 44 Follower Hydraulic Actuator Figure 2.14 The scheme of a follower hydraulic actuator of cross-section submission of a support of the copy machine tool: 1 - piston; 2 — cavity; 3 — hydraulic control valve; 4 — bringing hydroline; 5 —probe; 6 — master cam; 7 — the case of the hydraulic cylinder; 8 — the case of the support; 9 — support Figure 2.15 The scheme of the hydraulic booster with a mechanical feedback:: 1 - point (hinge); 2—draft; 3 — piston; 4 — power cylinder; 5 — hydraulic control valve; 6 — rod (an output link); 7 — a point of an output link; 8 — differential lever; n, m – links of a doubleshouldered lever 45 Piston-type Hydraulic Actuator 46 Bag-Type Accumulator 47 Advantages and Disadvantages 48 Variable hydraulic actuators are widely used as drives of machine tools, rolling mills, pressing and the foundry equipment, road and building machines, transport and agricultural machines, etc. A number of advantages in comparison with mechanical and electric transfers explains such their wide application: •infinitely variable control of gear-ratio in a wide range and an opportunity to create the big reduction ratio; •small specific weight, i.e. the weight of a hydroactuator is in ratio to transmitted capacity (0,2...0,3 kg / kWt); •opportunity of simple and reliable protection of the engine from overloads; •small sluggishness of the rotating parts, providing fast change of operating modes (start-up, dispersal, a reverser, a stop); •simplicity of transformation of rotary movement into reciprocating one; •opportunity of positioning a hydraulic engine on removal(distance) from an energy source and freedom in making configuration. It is also necessary to reckon with disadvantages of hydraulic actuators: •Efficiency of a volumetric hydraulic actuator is a little bit lower, than efficiency of mechanical and electric transfers, and during regulation it is reduced; •conditions of operation of a hydraulic actuator (temperature) influence its characteristics; •Efficiency of a hydraulic actuator is a little reduced in the process of exhaustion of its resource owing to the increase in backlashes and the increase of outflow of liquid (falling of volumetric efficiency); •sensitivity to pollution of working liquid and necessity of high culture service. Some More Cylinders Multi-position cylinder 49 Some More Cylinders Linear/swivel clamp CLR 50 Some More Cylinders Swivel/linear units DSL 51 Some More Cylinders Bellows cylinders 52 Some More Cylinders Fluidic Muscle 53 Some More Cylinders 54 Some More Cylinders Festo servopneumatic systems 55 Control Systems 56 Figure 4.1. Control Systems Let's consider a control system of a pneumatic or hydraulic drive with the use of PLC controller. The block diagram of system is specified in the following diagram. Logical scheme – electrical, pneumatic, hydraulic. Logical scheme Executive devices Sensors, controllers and operating control Sensors – contacts, inductive, capacitive, optical, hydraulic, pneumatic, PLC. 57 Executive devices – hydro- and pneumocylinders, hydroand pneumomotors and so on. Control Systems Figure 4.2 58 Figure 4.3. Control Systems Example Ìàíèïóëÿòîð.swf 59 Control Systems Датчики I0.0 a0 A+ O0.0 O0.1 I0.1 a1 A- Gripping device СХВАТ Датчики I0.2 b0 B+ O0.2 O0.3 ЦИЛИНДР 60 I0.3 b1 B- Cylinder Control Systems ЦИКЛОГРАММА РАБОТЫ СХВАТА a1 A- A+ Gripping device a0 ЦИКЛОГРАММА РАБОТЫ ЦИЛИНДРА b1 B- B+ b0 61 Шаг1 Step 1 Шаг2 Step 2 Шаг33 Step Шаг4 Step 4 Cylinder Control Systems Sensors A a 0 a1 b0 b1 Steps 1 2 3 4 a0 1 0 0 0 a1 0 1 1 0 A a 0 a1 b0 b1 b0 1 1 0 0 B a 0 a1 b0 b1 b1 0 0 1 1 Commands 62 B a 0 a1 b0 b1 A a0 b0 B a1 b0 A b0 B a1 0 A a1 b1 A b1 1 B a0 b1 B a0 A+ 1 0 0 0 A- 0 0 1 0 B+ 0 1 0 B- 0 0 0 Control Systems FST 4.10 63 Control Systems Sensors Inductive 64 Contact Capacitor Application Areas The right product for the right demands … 65 Application Areas Pneumatic processing centers 66 Figure. 5.1. The scheme of the pneumatic machining center Figure 5.2. The scheme of the pneumatic processing center for material’s sawing: 1 -work material; 2 -a power cylinder for a longitudinal motion; 3 - a power cylinder for a vertical motion; 4 – saw; 5 – supports; 6 – rotary actuator Application Areas Table: Scopes of systems with pneumatic muscles 67 Characteristics Platform positioning Good dynamics Large working efforts Accuracy of positioning Simplicity of a design Brake actuator Good controllability Absence of friction of rest Simplicity of a design and operation Tightening devices The big efforts of a clip Compactness Small weight Underwater Corrosion preventing Tightness Small consumption of working gas Sorting levers Big working efforts and acceleration Simplicity of a design Amortization of working loadings Walking Elevating devices Big working efforts and acceleration Amortization of working loadings Simplicity of a design Counterbal ancing Scheme Application Characteristics Application devices platforms devices Good dynamics Simplicity of a design Small weight Ease of positioning Adjustment of elasticity Adaptibility of characteristics Smoothness of job Small weight Scheme Application Areas Batching Figure 5.3. The scheme of batching: 1 – tank; 2 – fluid; 3 – a lever with a ladle; 4 - power cylinder; 5 – accepting chamber 68 Application Areas Robotics Figure 5.4. 69 Application Areas Robotics 70 Figure 5.6 Figure 5.5. The scheme of the mobile robot: 1,2 – longitudinal pneumatic cylinders; 3,4 – transversal pneumatic cylinders; 5 – lifting cylinder; 6 – pedipulator; 7 – metaldetector; 8 – infra-red sensor; 9 – the chemical sensor; 10 – sensor of longitudinal position movement; 11 - sensor of cross-section position movement; 12 - block of valves; 13 – block of rotation; 14 – electronic compass; 15 – onboard compass Application Areas Figure 5.7. The scheme of the mobile robot with vertical displacement: 1 - longitudinal movement module; 2 - rotating movement module; 3 – console; 4,5 - vacuum gripping devices; 6,7 - elevating cylinders; 8 –trajectory of turn 71 Questions? 72