MOE

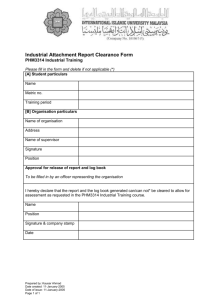

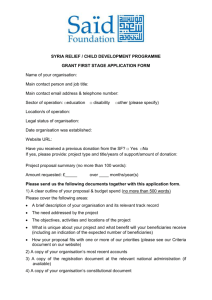

advertisement