Systems and Control

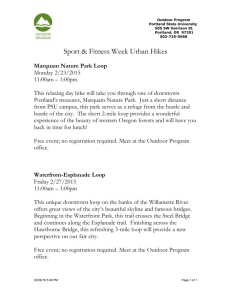

Systems Approach

Universal System

All systems can be analysed and simplified in terms of their

inputs, process and outputs

The UNIVERSAL SYSTEMS DIAGRAM consists of these three basic elements.

This process is known as the “BLACK BOX” approach to technology

We use a systems diagram to analyse technology.

INPUT PROCESS OUTPUT

Systems Diagrams

To analyse a system more fully, we can list the inputs and outputs from the system.

As an example, consider an electric kettle,

INPUTS:

Water and

Electricity.

OUTPUTS: Hot water, noise, steam.

Water and

Electricity

KETTLE

Hot water,

Noise and

Steam

Pupil Problems

Here are some problems for you to try,

1) Battery powered torch

Chemical energy

Torch

2) Vacuum cleaner

Electrical energy

Dirt

Vacuum

Light energy

Heat energy

Noise, Heat,

Clean carpets

Pupil Problems

3) Washing machine

Water, Dirty clothes,

Electrical energy

Washing M/C

4) Television

Electrical energy,

Digital signal

TV

Hot water,

Noise,

Steam,

Clean clothes

Picture,

Sound,

Heat

Sub-Systems

Sometimes it is necessary to break the PROCESS down into smaller pieces.

To enable this we consider the system’s

SUB SYSTEMS

System

Boundary

Example: A battery powered torch

Chemical energy

Switch Bulb

Light and

Heat energy

Pupil Problems

1) A microwave oven

1 st Inputs

Set time

Timer

2 nd Subsystems

5 th outputs

Magnetron

Electrical energy

On/Off Turntable

3 rd Boundary

Food

4 th Flow of information arrows

Heat,

Light,

Hot food

Pupil Problems

2) Washing machine

Electrical energy

Water

Set Cycle

Control

Heater Motor

Drum

Pump

Hot water,e tc.

Clean

Clothes

Dirty clothes

Control Systems

All types of system need some form of control to operate

There are 2 main types of control,

OPEN LOOP and CLOSED LOOP

In an OPEN LOOP system the input causes the output

The output operates independently of the input

Open loop system are cheap but not very accurate

Action Light switch Bulb Light

Control Systems

In a CLOSED LOOP system, the output is compared with a reference value

Closed loop systems are more accurate, but also more expensive

The self monitoring action of closed loop is achieved through a FEEDBACK loop

Set temp

Thermostat

On/Off Motor Fan Heater

Elect

Heat

Control Systems

Manual Open Loop

Water

Person

Tap

Handle

Valve Water level

Flood

Control Systems

Manual Closed Loop

Water

Tap

Handle

Valve

Correct level

Water level

Hand

Eyes /

Brain

Control Systems

Press

Automatic Closed Loop

Water

Start

Switch

Valve

Correct level

Water level

Control

Unit

Level

Sensor

•

•

•

Pupil Problems

State three examples of manual open-loop control. Draw a system diagram for each one and show the system boundary.

State three examples of manual closed-loop control. Draw a system diagram and show the system boundary.

State three examples of automatic closed-loop control. Draw a system diagram and show the system boundary.

Control Diagrams

Example: Temperature control in a gas oven

We could draw a systems diagram for the gas oven, but it is sometimes necessary to draw a more accurate control diagram

Gas Valve Burner Set value

+

-

Temperature sensor

Oven

Actual value

Correct temperature

Error Detector Symbol

How the error detector works:

If SET VALUE (+) is bigger than the ACTUAL VALUE

(-) the ERROR SIGNAL is ON (Raising the oven temperature)

Set value

+

If the SET VALUE (+) is less than the ACTUAL VALUE (-) the

ERROR SIGNAL is OFF (Cooling the oven temperature)

-

Actual value

Error

Pupil Problems

(1) Explain the following terms when applied to control systems:

• Open loop

• Closed loop

•

Error detector

Pupil Problems

(1) Draw a control diagram showing the manual closed-loop control system for a cyclist steering a bicycle.

(1) Draw a control diagram showing the automatic closed-loop control system for the cruise-control in a car.