WHMIS Training Session

advertisement

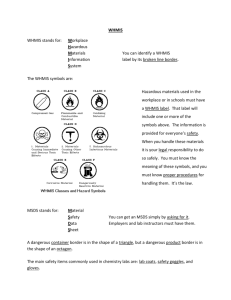

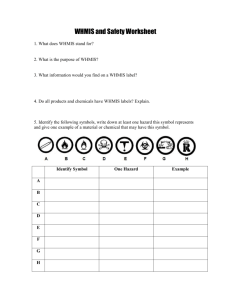

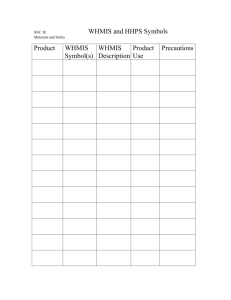

Overview of the Workplace Hazardous Materials Information System (WHMIS) Catherine Drum, BASc (OHS), CRSP Environmental Health & Safety Officer Ryerson University -- Wisdom Applied 2010 www.ryerson.ca/cehsm 1 Topics Overview Responsibilities under WHMIS (slide 11) WHMIS Classes & Symbols (slide 16) Supplier Label (slide 33) Workplace Label (slide 39) Material Safety Data Sheets (slide 48) 2 Topics continued… WHMIS and the Transportation of Dangerous Goods (TDG) – A Comparison (slide 68) Chemical Hazards (slide 77) Health Effects of Toxic Substances (slide 82) Protective Measures (slide 106) WHMIS in Laboratories (slide 134) WHMIS at Ryerson (slide 144) Summary (slide 151) 3 Overview What is WHMIS? Purpose of WHMIS What’s NOT Covered? Main Parts of WHMIS 4 Introduction -- Workplace Hazards What is an occupational health hazard? What is a risk and how is it different from hazard? How should workplace health and safety hazards be dealt with? Are there Ontario laws requiring the control of exposure to specific workplace hazards? 5 Introduction What is WHMIS? Workplace Hazardous Materials Information System Canada-wide legislation Information system designed to protect Canadian workers from hazardous materials used in the workplace Right to know about workplace hazards 6 Introduction Purpose of WHMIS? To provide information about hazardous materials used in the workplace To facilitate the process of hazard identification in the workplace To ensure consistency of hazard information in all Canadian workplaces 7 Introduction What’s NOT covered by WHMIS? Consumer restricted products (those products sold to people in regular stores that are already labeled following the rules of the Hazardous Products Act) Explosives (as defined by the Explosives Act) Cosmetics, drugs, food or devices (as defined by the Food and Drug Act) 8 Introduction Pest control products (pesticides, herbicides, insecticides, etc) (as defined by the Pest Control Products Act) Radioactive materials (as defined by the Atomic Energy Control Act) Wood and products made of wood A manufactured article Tobacco or products made of tobacco Hazardous wastes 9 Introduction What are the Main Parts of WHMIS? Labels Material Safety Data Sheets (MSDS) Worker Training & Education 10 Responsibilities Under WHMIS Supplier Employer Employee 11 Responsibilities under WHMIS Supplier Duties A supplier of a chemical product must compare the product's physical, chemical and toxic properties with a detailed set of WHMIS criteria If the product meets one or more of the criteria, the product becomes subject to WHMIS requirements 12 Responsibilities under WHMIS Classify products Label products with a WHMIS label Prepare and provide customers with MSDS's Update MSDS's at least every three years 13 Responsibilities under WHMIS Employer Duties Train employees in WHMIS Train employees in safe work practices Ensure products are labeled with supplier or workplace labels Provide employees with ready access to MSDS's 14 Responsibilities under WHMIS Employee Duties Participate in training Follow prescribed work practices Wear required protective equipment 15 WHMIS Classes & Symbols Compressed Gas Flammable & Combustible Materials Oxidizing Materials Poisonous and Infectious Materials Corrosive Materials Dangerously Reactive Materials 16 WHMIS Classes and Symbols What is the Classification System? Classifications are used to group chemicals with similar properties or hazards The Controlled Products Regulations specifies the criteria used to place materials within each classification There are six (6) classes with some having divisions and subdivisions Each class has a specific symbol to help people identify the hazard quickly 17 WHMIS Classes & Symbols Class A - Compressed Gas Materials which are normally gaseous kept in a pressurized container Risks: could explode due to pressure could explode if heated or dropped hazard from both the force of explosion and the release of contents Eg. Acetylene, Oxygen, Nitrogen 18 WHMIS Classes & Symbols Class B - Flammable & Combustible Material Materials which will continue to burn after being exposed to a flame or other ignition source Risks: may ignite spontaneously may be a material which will release flammable products if allowed to degrade or when exposed to water 19 WHMIS Classes & Symbols Class B - Flammable & Combustible Material Division 1: Flammable Gas Division 2: Flammable Liquid Division 3: Combustible Liquid Division 4: Flammable Solid Division 5: Flammable Aerosol Division 6: Reactive Flammable Material 20 WHMIS Classes & Symbols Class B - Flammable & Combustible Material Flammable Gas: Hydrogen, Butane Flammable Liquid: Gasoline Combustible Liquid: Diesel Fuel, Organic solvents Flammable Solid: White Phosphorus, Magnesium 21 WHMIS Classes & Symbols Class B - Flammable & Combustible Material Flammable Aerosol: flammable propellants such as propane, butane and dimethyl ether Reactive Flammable Material: aluminum alkyls, metallic sodium and lithium aluminum hydride 22 WHMIS Classes & Symbols Class C – Oxidizing Material Materials which can cause other materials to burn or support combustion Risks: can cause skin or eye burns increase fire and explosion hazard may cause combustibles to explode or react violently Eg. Ozone, chlorine, & nitrogen dioxide 23 WHMIS Classes & Symbols Class D – Poisonous and Infectious Material Division 1: Materials Causing Immediate and Serious Toxic Effects Subdivision A: Very Toxic Material Subdivision B: Toxic Material Poisons/potentially fatal materials which cause immediate and severe harm 24 WHMIS Classes & Symbols Class D – Division 1 continued… Risks May be fatal if ingested or inhaled May be absorbed through the skin Small volumes have a toxic effect Eg. Styrene, hydrogen cyanide 25 WHMIS Classes & Symbols Class D – Poisonous and Infectious Material continued… Division 2: Materials Causing Other Toxic Effects Subdivision A: Very toxic material Subdivision B: Toxic material Materials which have harmful effects after repeated exposures or over long periods of time 26 WHMIS Classes & Symbols Class D – Division 2 continued… Risks: May cause death or permanent injury May cause birth defects or sterility May cause cancer May be sensitizer causing allergies Eg. Asbestos causes cancer, ammonia is an irritant 27 WHMIS Classes & Symbols Class D – Poisonous and Infectious Material continued… Division 3: Biohazardous Infection Material Infectious agents or a biological toxin causing a serious disease or death 28 WHMIS Classes & Symbols Class D – Division 3 continued… Risks: May cause anaphylactic shock Includes viruses, yeasts, moulds, bacteria and parasites which affect humans Includes fluids containing toxic products Includes cellular components Eg. Blood sample containing Hepatitis B virus 29 WHMIS Classes & Symbols Class E – Corrosive Material Materials which react with metals and living tissue Risks: Eye and skin irritation on exposure Severe burns/tissue damage on longer exposure Lung damage if inhaled May cause blindness if eyes contacted Environmental damage from fumes Eg. Ammonia, fluorine, & hydrochloric acid 30 WHMIS Classes & Symbols Class F – Dangerously Reactive Material Materials which may have unexpected reactions Risks: May react with water May be chemically unstable May explode if exposed to shock or heat May release toxic or flammable vapours 31 WHMIS Classes & Symbols May vigorously polymerize May burn unexpectedly Eg. Ozone, hydrazine, and benzoyl peroxide 32 Supplier Labels Requirements Examples 33 Supplier Labels Requirements Containers of controlled products that are sold for use in Canadian workplaces must carry a supplier label that contains 7 required items of information: 34 Supplier Labels Name of the product Supplier’s name Hazard Symbol(s) Risk phrases Precautionary measures First aid measures Reference to a Material Safety Data Sheet 35 36 37 Labels -- Rules for Labeling 38 Workplace Labels Requirements Examples 39 Workplace Labels Requirements If the supplier label is destroyed or chemicals are transferred from the supplier container to another, a workplace label is required Because it assumes that people in the workplace are familiar with the chemicals they are using, WHMIS sets less stringent requirements for an acceptable workplace label 40 Workplace Labels Name of the chemical Safe handling information Reference to the MSDS 41 Workplace Labels In some cases, the container size makes it impossible to affix a label that meets all the requirements for a workplace label In such cases, a system must be created that ensures that everyone who works in the laboratory can identify the contents and knows what precautions are needed to prevent injury or over-exposure, and how to respond to an accident 42 43 44 45 46 Labels -- Rules for Labeling 47 Material Safety Data Sheet (MSDS) Requirements Examples 48 Material Safety Data Sheets Requirements Product/Material Information Hazardous Ingredients Physical Data Fire and Explosion Data Reactivity Data Health Hazard Data 49 Material Safety Data Sheets First Aid Measures Preventative Measures Storage and Handling Spill Clean-up and Waste Disposal Preparation Date 50 Material Safety Data Sheets Product/Material Information This section provides the basic information about the product and the supplier. Product name Supplier's name and address Emergency phone number Intended use 51 Material Safety Data Sheets Hazardous Ingredients The MSDS must identify all the ingredients that meet WHMIS criteria and provide some data on the short term toxicity of either the product or the ingredients. 52 Material Safety Data Sheets For Each Hazardous Ingredient : Name Concentration or concentration range Chemical Abstracts Registry Numbers LD50 (Lethal Dose 50% - the dose which kills half of the animals in a toxicity test) 53 Material Safety Data Sheets Physical Data The MSDS provides a range of technical data which allows people to assess how the chemical behaves under differing situations and plan safe work procedures. Physical state Appearance and odour 54 Material Safety Data Sheets Vapour density, per cent volatile and evaporation rate for products with volatile components Boiling and freezing points and PH (if appropriate) for liquids Specific gravity Coefficient of oil/water separation Water solubility 55 Material Safety Data Sheets Fire and Explosion Data The MSDS provides information on which the workplace can plan fire prevention and which emergency responders may need in the event that a fire occurs 56 Material Safety Data Sheets Fire Data: Indication of whether the product is flammable and the conditions under which a fire might occur Means of extinction Flash point (the temperature at which enough of the material evaporates to form an ignitable mixture with air) 57 Material Safety Data Sheets Flammable limits (concentration range over which the vapour/air mixture will burn) Auto ignition temperature Hazardous combustion products Explosion data Sensitivity to impact Sensitivity to static electric ignition 58 Material Safety Data Sheets Reactivity Data WHMIS requires that the supplier provide information about the possible hazardous chemical reactions that might occur Many laboratory chemicals are highly reactive Even some of the trades or custodial chemicals can react with other chemicals or can react if exposed to heat or mixed with catalysts or activators 59 Material Safety Data Sheets Stability Sensitivity to shock or temperature or pressure changes Reactivity Incompatibility - chemicals which, if allowed to contact the product, could create a reaction hazard Hazardous decomposition products 60 Material Safety Data Sheets Toxicological Properties WHMIS requires the supplier to describe how people might come into contact with the product and what the short and long term effects would be if someone was over-exposed Route of entry into the body Effects of acute (short term) exposure Effects of chronic (long term) exposure Legal exposure limit 61 Material Safety Data Sheets Preventive Measures One of the most useful sections of the MSDS Supplier lists suggestions for the precautions which should be taken in storing, handling, using and disposing of the product These suggestions need to be considered carefully 62 Material Safety Data Sheets The supplier cannot always know in detail how we are going to use the chemical You should review the information in this section with your supervisor and assess how appropriate the supplier's suggestions are in your particular work situation Engineering controls - equipment needed to prevent over-exposure 63 Material Safety Data Sheets Personal protective equipment - gloves, respirators, impervious clothing, etc. Use and handling procedures Storage requirements Leak and spill procedures Shipping information Disposal practices 64 Material Safety Data Sheets First Aid Measures The MSDS provides first aid information similar to that presented on the product label This information will allow people to help someone who has been made unwell by a chemical In all but the most minor cases, the affected person should be treated at the Ryerson Health Centre or the nearest hospital 65 Material Safety Data Sheets The medical personnel will need a copy of the MSDS, or at least label information, to effectively treat the victim 66 Material Safety Data Sheets Preparation The regulations require the supplier to indicate who prepared the MSDS when it was prepared a phone number to contact the person who prepared the document 67 WHMIS and the Transportation of Dangerous Goods A Comparison 68 WHMIS & TDG – A Comparison The requirements under WHMIS and under the TDG legislation are complementary information systems TDG legislation sets out information requirements for products being shipped to and from workplaces WHMIS applies to products inside workplaces No overlap is intended --- One system takes over where the other leaves off 69 WHMIS & TDG – A Comparison Worker exposure to dangerous goods that are IN TRANSIT is most likely to occur during an emergency such as a vehicle accident or spill. Therefore, information provided under TDG requirements addresses short-term exposures and uses symbols on labels and placards. Worker exposure to controlled products in the workplace can occur in a wider variety of circumstances and over longer periods of time. WHMIS requirements are more extensive than TDG and include the use of explicit labels and material safety data sheets. 70 WHMIS & TDG – A Comparison WHMIS and TDG Classification Systems The classification of products under WHMIS and TDG is similar but not identical WHMIS has 6 Classes, designated A to F and TDG has 9 Classes, designated 1 to 9 WHMIS Classes A to E have comparable Classes in TDG, but Class F has no equivalent in TDG TDG has 2 Classes that have no equivalent in WHMIS --- Class 1, Explosives and Class 7, Radioactive Materials 71 WHMIS & TDG – A Comparison WHMIS No Equivalent No Equivalent Class A Compressed Gases TDG Class 1 Explosives Class 7 Radioactive Materials Class 2 Compressed Gases 72 WHMIS & TDG – A Comparison WHMIS Class B Flammable and Combustible Material TDG Class 3 Flammable Liquids Class 4 Flammable Solids, Spontaneously Combustible, Dangerous When Wet 73 WHMIS & TDG – A Comparison WHMIS TDG Class C Oxidizing Material Class 5 Oxidizing Substances and Organic Peroxides Class D Class 6 Poisonous and Infectious Poisonous and Infectious Material Substances 74 WHMIS & TDG – A Comparison WHMIS Class E Corrosive Material Class F Dangerously Reactive Material TDG Class 8 Corrosives No Equivalent 75 WHMIS & TDG – A Comparison WHMIS No Equivalent TDG Class 9 Miscellaneous Products or Substances 76 Chemical Hazards Flammability Reactivity Health 77 Chemical Hazards Flammability readily catches fire and burns in air liquid does not burn - the vapours burn flash point, auto-ignition temperature, explosive limits, vapour density and ability to accumulate an electrostatic charge are important factors in determining the degree of fire hazard 78 Chemical Hazards Reactivity Involves the release of energy (heat) in relatively high quantities or at a rapid rate If the heat evolved in a reaction is not dissipated, the reaction rate can increase until an explosion results Some chemicals decompose rapidly when heated 79 Chemical Hazards Light or mechanical shock can also initiate explosive reactions Some compounds are inherently unstable and can detonate under certain conditions of pressure and temperature, while others react violently with water or when exposed to air 80 Chemical Hazards Health Contact with many chemicals can result in adverse health effects The nature and magnitude of toxic effects will depend on many factors including the nature of the substance, route of exposure, magnitude of the dose, duration of exposure, and individual susceptibility 81 Health Effects of Toxic Substances Toxicity vs. Hazard Routes of Entry Health Effects – Chronic vs. Acute Exposure – Chronic vs. Acute Physiological Classification of Materials 82 Health Effects of Toxic Substances Many materials used in the workplace can be hazardous In order for them to affect your health, they must contact the body or be absorbed into the body In order to assess the potential health effects from working with a particular material, it is necessary to understand the difference between “toxicity” and “hazard” 83 Health Effects of Toxic Substances TOXICITY is the ability of a substance to produce an unwanted effect when the chemical has reached a sufficient concentration at a certain site in the body The greater the toxicity = smaller absorption amount required to cause harmful effects The toxicity of a chemical is generally measured by experiments on animals (quite often rats) 84 Health Effects of Toxic Substances If it is measured in terms of the amounts of material necessary to cause death in 50% of the test animals These values are called LD50 (lethal dose) or LC50 (lethal concentration), and are usually given in weight of material per kg of body weight or airborne concentration of material per set time period respectively 85 Health Effects of Toxic Substances HAZARD is the probability that this concentration in the body will occur Toxicity is an inherent property of the material A material may be very toxic, but not hazardous, if it is handled properly and is not absorbed into the body On the other hand, a material may have a very low toxicity, but be very hazardous 86 Health Effects of Toxic Substances Examples: An open container of an acid is much more hazardous than a closed container of the same material 87 Health Effects of Toxic Substances Two liquids may possess the same degree of toxicity but present different degrees of hazard: One material may be non-irritating to the eyes and nose and odourless The other may be irritating to the eyes or respiratory system and possess a pungent odour 88 Health Effects of Toxic Substances Routes of Entry There are three primary routes of entry into the body: Ingestion Skin or eye absorption Inhalation 89 Health Effects of Toxic Substances Ingestion: Taking a material into the body by mouth (swallowing) Ingestion of toxic materials may occur as a result of eating in a contaminated work area 90 Health Effects of Toxic Substances Absorption Substances that contact the eye and the skin may be either absorbed into the body or cause local effects For the majority of organic compounds, the contribution from skin absorption to the total exposure should not be neglected 91 Health Effects of Toxic Substances Inhalation Taking a material into the body by breathing it in In the lungs, very tiny blood vessels are in constant contact with the air we breath in Airborne contaminants can be easily absorbed through this tissue Generally the most important route of entry 92 Health Effects of Toxic Substances Health Effects – Chronic vs. Acute Once a toxic substance has contacted the body it may have either acute (immediate) or chronic (long term) effects. Example: Spilling acid on your hand will cause immediate harm, i.e. a burn to the skin. Exposure to asbestos or tobacco smoke may result in lung cancer after as much as twenty years (this is a long term effect). 93 Health Effects of Toxic Substances Exposure - Chronic vs. Acute Exposure can be classified as chronic or acute In chronic exposures, the dose is delivered at some frequency (daily or weekly usually) over a period of time In acute exposures, the dose is delivered in a single event and absorption is rapid 94 Health Effects of Toxic Substances Usually, a chronic exposure occurs at low concentration and acute exposure at high concentration Some materials may only cause harm if given acutely, not having any effect in the long term Other materials may not exhibit an effect in the short term, but may cause problems after prolonged exposure 95 Health Effects of Toxic Substances Physiological Classification of Materials This classification identifies toxic materials on the basis of biologic action 96 Health Effects of Toxic Substances Irritants refers to some sort of aggravation of whatever tissue the material comes in contact with E.g. ammonia, nitrogen dioxide 97 Health Effects of Toxic Substances Asphyxiants exert their effects through a depletion of oxygen to the tissues E.g. simple asphyxiants - carbon dioxide, nitrogen, methane, hydrogen E.g. chemical asphyxiants - carbon monoxide, hydrogen cyanide, hydrogen sulphide 98 Health Effects of Toxic Substances Narcotics or Anaesthetics the main toxic action is the depressant effect upon the Central Nervous System E.g. - many organics, chloroform, xylene. 99 Health Effects of Toxic Substances Systemic Poisons the main toxic action includes the production of internal damage E.g. Hepatotoxic agents - toxic effects produce liver damage. eg. carbon tetrachloride E.g. Nephrotoxic agents - toxic effects produce kidney damage eg. some halogenated hydrocarbons 100 Health Effects of Toxic Substances Carcinogens agents/compounds that will induce cancer in humans E.g. benzene, arsenic, inorganic salts of chromium, nickel, beryllium 101 Health Effects of Toxic Substances Mutagens agents that affect the cells of the exposed people in such a way that it may cause cancer in the exposed individual or an undesirable mutation to occur in some later generation E.g. radiation, variety of chemical agents that alter the genetic message 102 Health Effects of Toxic Substances Teratogens Agents or compounds that a pregnant woman takes into her body that generate defects in the fetus E.g. Thalidomide, possibly steroids 103 Health Effects of Toxic Substances Sensitizers Agents that may cause allergic or allergiclike responses to occur After an initial exposure to a substance an individual may become sensitized to that substance Subsequent exposures to the same substance, often at a much lower concentration than before, produce an allergic response 104 Health Effects of Toxic Substances This response may be a skin rash (dermatitis) or an asthmatic-like attack, depending on the route of exposure E.g. cutting oils, isocyanates in polyurethane foam operations and paint spraying operations, some laboratory solvents 105 Protective Measures Elimination/Substitution Engineering Controls Work Practices Personal Protective Devices Other Safe Practices Emergency Provisions 106 Protective Measures Elimination/Substitution Ideally, the toxic substance used or generated should be eliminated Since this is not always possible, substituting a less hazardous substance can often be effective in reducing work exposure to toxic substances Eg. Is it necessary to use benzene for cleaning; usually, 1,1,1-trichloroethane will do the job just as well 107 Protective Measures Engineering Controls Isolation Design or Change of Process Local Suppression Ventilation 108 Protective Measures Isolation Hazardous processes or equipment can be segregated into separate rooms or areas or put in enclosures so as not to contaminate the whole workplace Eg. Operator booths are common in crusher operations (extremely dusty environments), crane cabs in hazardous areas, etc. 109 Protective Measures Design or Change of Process Often simple considerations can significantly improve conditions. Eg. packaging of exact amounts of material to add to a process rather than pouring, pumping, scooping, etc. from a bulk supply Eg. grouping of hazardous operations for better control. 110 Protective Measures Local Suppression Wetting or pelletizing of dusty materials or blanketing of toxic liquids. eg. Use of damp mopping in contaminated, dusty areas eg. Use of plastic balls or surface active agents in liquid tanks such as plating tanks. 111 Protective Measures Ventilation Ventilation is used to control airborne hazards in the form of dusts, fibres, mists, fumes, gases, and vapours The two methods of applying ventilation to provide contaminant control are general dilution ventilation local exhaust 112 Protective Measures Dilution Ventilation dilution of contaminated air with uncontaminated air in a general area, room, or building for the purpose of health hazard, nuisance control, and/or heating and cooling. 113 Protective Measures Local exhaust involves the capture of pollutants at the source Air movement is achieved by either natural or mechanical methods such as fans 114 Protective Measures the choice or type of ventilation depends on such factors as: • Toxicity or nuisance of the contaminant • Method and rate of generation • Physical state of the contaminant • Relative costs of different types of ventilation 115 Protective Measures Work and Hygiene Practices Work practices, procedures and hygiene practices supplement engineering controls These practices represent on the job activities that reduce the potential for exposure to toxic substances and include: 116 Protective Measures Posting warning signs and labeling hazardous materials Preventive maintenance of equipment Keeping records of employee exposure and making them available to employees Providing emergency facilities, such as eyewash fountains and deluge showers, where appropriate 117 Protective Measures Prohibiting eating, drinking or smoking in areas where materials in use are toxic by ingestion or may be inhaled through smoking Maintaining Good Housekeeping • good housekeeping provides for the removal of hazardous materials that might otherwise become airborne • a clean workplace tends to foster good work habits that probably reduce accumulations 118 Protective Measures Maintaining Personal Cleanliness • clean work clothes, regular showers and frequent washing will reduce skin contamination that may lead to skin absorption, dermatitis or ingestion • A further consideration for personal cleanliness is the possibility of an individual carrying toxic material home on work clothes or on the person and in turn placing the family at risk 119 Protective Measures Training • Individuals should be well aware of the hazards of the materials being used and the precautions to be observed • An informed worker can make a rational decision to accept such work and to wisely use the equipment provided for his/her protection 120 Protective Measures Personal Protective Devices These include protective glasses and goggles, face shields, protective clothing (laboratory coats and gloves), skin creams, and respirators It should be noted that respirators in particular, are not intended to be used as a primary means of control in lieu of other methods 121 Protective Measures Two essential elements of protective equipment use are: The choice of the proper type • For example, when choosing respirators and hearing protectors, the factors to be considered include: 122 Protective Measures type of hazard extent of exposure individual preference individual fit ease of supervision legislative requirements 123 Protective Measures The provision of an adequate maintenance program for the equipment • A maintenance program for the equipment must be in the care of a qualified person and will include, at regular intervals: – Inspection and Repair – Cleaning – Storage 124 Protective Measures Other Safe Practices and Emergency Provisions Leak and Chemical Spill Procedure Prompt action is necessary to reduce and eliminate hazards created by a chemical spill • Wear proper personal protective equipment (e.g. gloves, respirators) as specified in the MSDS • Absorb or neutralize liquids • Sweep solids into a container 125 Protective Measures • Ventilate area to dispel vapours if required • Wash affected area with soap and water or detergent • All materials used in cleanup, including absorbed liquids are to be disposed as hazardous waste - Label waste appropriately 126 Protective Measures If proper equipment is not available to safely contain and decontaminate a spill - evacuate the area and contact the appropriate personnel (a list of emergency contacts should be provided in each lab/work area) 127 Protective Measures Waste Disposal The disposal of hazardous chemicals is regulated by Ontario environmental legislation NOTHING GOES DOWN THE DRAIN in a laboratory (ask if you are not sure) Generators of hazardous wastes are responsible for properly packaging and labeling such wastes 128 Protective Measures Storage Requirements The hazard potential presented by flammable, reactive and toxic substances can also be reduced by adherence to safe storage procedures Quantities of these substances should be kept to a minimum 129 Protective Measures All containers must be labeled with the names of the contents and appropriate hazard warnings In laboratories or stockrooms, care should be taken to avoid exposure of chemicals to heat or direct sunlight 130 Protective Measures Always observe precautions regarding the proximity of incompatible substances (e.g. do not store alphabetically - store in compatible groups) Highly toxic chemicals should be stored in ventilated storage areas in unbreakable chemically resistant secondary containers 131 Protective Measures Properly labeled portable safety cans should be used for handling small quantities of flammable liquids When not in use these portable cans should be kept in enclosed fire-resistant cabinets 132 Protective Measures Larger quantities of solvents should be stored in correctly designed ventilated storage areas Flammable liquids should not be stored in laboratory refrigerators unless the unit is an approved, explosion-proof, or laboratorysafe type 133 WHMIS in Laboratories Topics Acute/Chronic Health Effects Symptoms Laboratory Equipment Personal Protective Equipment Storage Guidelines Chemical Spill/Fire Special Hazards 134 WHMIS in Laboratories -Acute Health Effects Acute Immediate Effect Powdered and liquid chemicals that contact the skin, the face or the eyes may be an ACUTE hazard Clothing that has become saturated may also present an ACUTE hazard for that part of the body Mists or fumes from some chemicals in high concentrations may be inhaled and may present an ACUTE hazard 135 WHMIS in Laboratories – Chronic Health Effects Chronic Delayed Effect Occasional moderate contact with liquid and powdered chemicals, over a period of time, may result in CHRONIC skin problems Rashes, blisters, cracking skin are known as “dermatitis” Excessive exposure to mists or vapours over a period of time may result in CHRONIC respiratory problems or in irritation of the eyes Some chemicals may also be SENSITIZERS 136 WHMIS in Laboratories – Symptoms If not used properly, the following health effects may be encountered, on the skin, in the eyes or in the lungs: Burning Irritation Permanent Damage 137 WHMIS in Laboratories – Laboratory Equipment Fumehoods Glassware, Syringes, Pipettes Machines Refrigerators & Freezers Heat sources Pumps Equipment for working at temperature extremes 138 WHMIS in Laboratories – Personal Protective Equipment Typical examples include: Goggles, face shields, respirators, gloves, boots, aprons, suits Refer to the Material Safety Data Sheet for a given chemical for the specific PPE that is required Such items MUST be worn during the entire process even if you are not doing anything! 139 WHMIS in Laboratories – Storage Guidelines Segregate chemical combinations that may be reactive Flammable chemicals (such as solvents) should be stored in approved cabinets Observe precautions regarding ignition sources Store pressurized containers according to the precautionary statements on the label General ventilation should be provided 140 WHMIS in Laboratories – Chemical Fire/Spill For a minor spill, contain, control and clean-up using proper equipment and safe procedures For a major spill, assess the situation Refer to the MSDS and container labels Evacuate if necessary In the event of fire, evacuate 141 WHMIS in Laboratories – Information YOU Need to Know YOU must be able to answer the following questions regarding the controlled products you are exposed to: What are the hazards of the controlled product? How do I protect myself and those I work with from these hazards? What do I do if a spill occurs? Where do I get more information about this controlled product? 142 WHMIS in Laboratories – Special Hazards Hazards of Compressed Gases Biological Hazards Radiation Non-ionizing Radiation Laboratory Waste Electrical Safety Ergonomics 143 WHMIS at Ryerson Training Material Safety Data Sheets WHMIS in Your Workplace 144 WHMIS at Ryerson - Training Employer Responsibilities The employer must provide a training program which includes instruction about: Labels and MSDS’s – their purpose and contents and the significance of each Procedures for safe handling, use, storage and disposal of hazardous materials specific to the workplace (Supervisor) Emergency procedures (Supervisor) 145 WHMIS at Ryerson - Training Worker Responsibilities The worker is required under the legislation to participate in the education program provided by the employer 146 WHMIS at Ryerson - Training Who Receives the Training? Anyone who WORKS with, or is in CLOSE proximity to hazardous products Anyone who USES, HANDLES, STORES or DISPOSES of the hazardous material Anyone who SUPERVISES the performance of the above duties 147 WHMIS at Ryerson - MSDS Material Safety Data Sheets Order them each time you purchase a chemical for the first time…reorder if there is not one available or find the closest one using the CAS# Read them PRIOR to using the product Everyone using hazardous materials must have easy access to the Material Safety Data Sheets Have a binder with MSDS’s for easy reference and in case of emergency 148 WHMIS at Ryerson – In Your Workplace How to Establish WHMIS at your Workplace (For Supervisors) Assign responsibility for the program implementation Establish an inventory of controlled products Ensure that WHMIS labeling and Material Safety Data Sheets are in place by a predetermined date Determine the hazards of the controlled products 149 WHMIS at Ryerson – In Your Workplace Establish protective precautions, e.g. what personal protective equipment needs to be used, work procedures Establish emergency procedures in case of spill or worker exposure Provide worker education Review the WHMIS program every year 150 Summary Perform a Risk Assessment on the work that you are doing Be familiar with the work that is going on in the same lab as you YOU must know the hazards, the associated risks and control measures in order to protect yourself, your colleagues and Ryerson 151