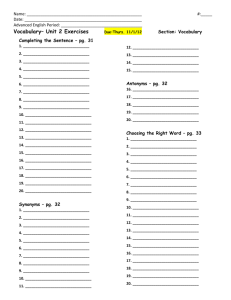

Port Development Technical Surveys & Design

advertisement

THE SCOPE OF DED :

I. TECHNICAL SURVEYS, CONSIST OF :

a. TOPOGRAPHIC AND BATHYMETRIC SURVEYS

b. HIDRO-OCEANOGRAPHIC SURVEY :

- Tidal observation

- Current observation

- Sediment and water sampling

- Wave observation

c. SOIL INVESTIGATION ON-SHORE AND OFF-SHORE 27 POINTS

II. WAVE CHARACTERISTIC ANALYSIS

III. SIMULATION OF SHIP MANOUVER AT PORT BASIN (by consultant from Netherlands)

IV. DESIGN OF CONTAINER WHARF STRUCTURE 1600 M LENGTH

V

DESIGN OF CONTAINER YARD STRUCTURE

1

I. TECHNICAL SURVEY

a. BATHYMETRIC SURVEY:

1.

Survey area is 2,297 Ha

2.

Equipment used for bathymetric survey: Echo Sounder (ES) Reson 210 which can

perform sounding -600 m water depth

AREA FOR BATHYMETRIC SURVEY

2

b.

TOPOGRAPHIC SURVEY:

1.

SURVEY AREA : 1200 Ha

2.

NUMBER OF BENCHMARK POINTS : 6 UNITS.

For horizontal position measurement of BM was carried out using GPS measurement Method

(DGPS Method), the device for this purpose is GPS Cnav with Singapore as base station.

3.

HORIZONTAL FRAME MEASUREMENT :

Horizontal base frame measurement was carried out using polygon measurement method and

the device which applied for it was Total Station Sokkia set 4B.

4. VERTIKAL BASE FRAME MEASUREMENT

This measurement has the objective to obtain elevation for every BM with the elevation

reference is the Mean Sea Level (MSL) from tidal observation for 30 days (0.91932 m from zero

datum).

5.

SITUATION MAPPING

•

This measurement has the objective to collect detail data of the site, including natures objects,

buildings, bridge, etc.

•

To help data collection, collecting detail data situation facilitated by Quickbird satellite vision

(April 2007)

•

Digitation all necessary object obtained from Quickbird satellite vision, field checks to ensure

the existence of the objects.

3

BM

Y (m)

X (m)

1

756358.097

651155.481

2

757130.196

650579.725

3

756272.000

649133.000

4

755664.028

649911.331

5

756088.923

645590.810

6

753308.533

646073.533

BM COORDINATES

BM

ELEVATIONS

(m)

ELEVASI (m)

BM01 BPKS

2.963

BM02 BPKS

2.784

BM03 BPKS

1.631

BM04 BPKS

3.556

BM05 BPKS

133.700

BM06 BPKS

6.024

BM ELEVATIONS

TOPOGRAPHIC AND

BATHYMETRIC RESULT

4

c. HYDRO-OCEANOGRAPHIC SURVEY

c.1. TIDAL OBSERVATION

Coordinate of tidal station : 5˚ 53' 15,8502” LU, 95˚ 18' 57,922” BT

The location of tidal station is at NAVY port of Sabang

Tidal observation was carried out for 30 days with observation time interval of 1 hour

starting from July 20, 2007 until August 18, 2007

The device for this purpose was Automatic Water Level Recorder (AWLR) type AOTT

resulting water elevation (tidal)

Water Surface Elevation

Datum

MSL

(m)

Datum

LWS

(m)

TIDAL STATION

LOCATION

5

c.2. CURRENT OBSERVATION

•

The location of this observation was at two stations, representative enough for current

condition in survey area. The position of the first station is (756926m; 651075m) with

40m depth and the other is (755660m; 649720m) with 20m depth.

•

The duration of observation in every station was for 25 hours with time interval of data

collection of 1 hour. The observation was arranged to get information on current of

neap period, at time between neap-spring (konda) and spring period.

•

Neap period observation was carried out in July 25, 2007. Observation konda time was

carried out in July 28, 2007. Spring period observation in August 1, 2007. Observation

at every station and every measurement was carried out at three depth (d) 0.2 d, 0.6 d,

and 0.8 d.

•

The device used for this observation was Valeport Type 2000, it was a mechanical

current device

6

CURRENT OBSERVATION RESULT

OBSERVATION STATION I

AT NEAP TIME

• Current Speed is Small

• Tidal Current is dominant

• Mean Current Speed ~ 0.05 m/s

• Dominant direction was NorthWest-SouthEast

• Maximum Current Speed ~ 0.08 m/s

• Current Layer tends to uniform

AT KONDA TIME

• Current Speed is Small

• Tidal Current is dominant

• Mean Current Speed ~ 0.082 m/s

• Dominant direction was NorthWest-SouthEast

• Maximum Current Speed ~ 0.154 m/s

AT SPRING TIME

• Current Speed is Weak

• Tidal Current is dominant

• Mean Current Speed ~ 0.086 m/s

• Dominant direction was NorthWest-

• Maximum Current Speed ~ 0.161 m/s

SouthEast

RESULT FOR SECOND OBSERVATION STATION WAS

NOT DIFFERENCE WITH THE FIRST OBSERVATION

STATION

7

CURRENT

SIMULATION

IN SABANG

HASIL

SIMULASI

ARAH

ARUSGULF

Direction vector and value of current

RMA2 model at Spring Condition Flood 1

Direction vector and value of current

RMA2 model at Spring Condition Flood 2

Direction vector and value of current

RMA2 model at Spring Condition Ebb. 1

Direction vector and value of current

RMA2 model at Spring Condition Ebb. 2

8

d.

SOIL INVESTIGATION

SOIL INVESTIGATION RESULT : Cross section of Soil Layer CT.3 Port area

9

RESULT OF SOIL INVESTIGATION

RESULT OF SOIL INVESTIGATION IN CT.2 AND CT.3 AREA IS AS FOLLOW :

Soil layers tend to follow soil surface profile

At 6m – 10m depth from seabed, soil is very hard with SPT value > 70

At few location was found a very hard layer at the depth of 1m from seabed of 1m thickness

BASED ON SOIL CONDITION AS EXPLAINED ABOVE, RECOMMENDATION FOR PILE

FOUNDATION IS AS FOLLOW:

• PILE SHOULD BE OF STEEL PIPE

• MINIMUM THICKNESS IS 16 MM

IN SOME LOCATION WHERE THIN HARD SOIL LENS WAS FOUND ON TOP SOIL, NEED TO

BE PREDRILLED (DESTRUCTION) FOR PILE DRIVING PURPOSE

10

DRIVEN PILE ALLOWABLE CAPACITY

ALLOWABLE CAPACITY

1. Pile f 914 mm :

Depth 10 m (from sea bed)

: Nall,compression

= 427 ton : Nall,tension =

Depth 12 m (from sea bed)

: Nall,compression

= 914 ton : Nall,tension = 227 ton,

Depth 17,5 m (from sea bed) : Nall,compression

= 1351 ton : Nall,tension = 378 ton,

79 ton,

2. Pile f 1016 mm :

Depth 10 m (from sea bed)

: Nall,compression

= 518 ton : Nall,tension =

Depth 12 m (from sea bed)

: Nall,compression

= 1100 ton : Nall,tension = 2251 ton,

Depth 17,5 m (from sea bed) : Nall,compression

= 1623 ton : Nall,tension = 421 ton

86 ton,

ALLOWABLE CAPACITY FOR PERMANENT LOAD.

1. Pile f 914 mm :

Depth 10 m (from sea bed) :

Hijin

=

9,92 ton ( Permanent load SF = 2)

Hijin .

= 13,23 ton ( Temporary load SF = 1,5)

2. Pile f 1016 mm :

Depth 10 m (from sea bed)

Hijin

Hijin .

=

10,6 ton ( Permanent load SF = 1,5 )

= 14,11 ton ( Temporary load SF = 1,5)

11

II. WAVE ANALYSIS IN SABANG GULF

a.

WIND ANALYSIS

THE WIND ROSE WAS BASED ON

WIND DATA AVAILABLE FROM DATA

RECORDED

BMG

STATION

AT

SABANG FOR THE TIME RANGE OF

1992 - 2006

b. FETCH ON SABANG GULF

WIND ROSE

12

c. WAVE ROSE

GELOMBANG

DOMINANT

13

d. DESIGN WAVE

N

= North (Utara)

NNW

= North Northwest (Utara Barat Laut)

NW = North West (Timur Laut)

WNW

= West Northwest ( Barat Barat Laut)

W

WSW

= West Southwest (Barat Barat Daya)

SSW

= South Southwest (Selatan Barat Daya)

= West (Barat)

SW = South West (Barat Daya)

14

e.

WAVE HEIGHT SIMULATION

TELUK

SABANG

Contour of depth for Wave Height

Simulation

Contour of Height and Wave Direction resulted from

Refraction and Diffraction Process for Wave from

NNW (T= 9s, H = 4 m)

Contour of Height and Wave Direction resulted

from Refraction and Diffraction Process caused by

wave from N (T=9s , H = 4,95 m )

Contour of Height and Wave Direction resulted

from Refraction and Diffraction Process for Wave

from NW ( T = 9s , H=3,3 m )

15

Contour of Height and Wave Direction resulted

from Refraction and Diffraction Process for

Wave from WNW (T = 9s, H = 4,6 m)

Contour of Height and Wave Direction resulted

from Refraction and Diffraction Process for

Wave from WSW ( T = 9s , H = 1,4 m )

Contour of Height and Wave Direction resulted from

Refraction and Diffraction Process for Wave from SW

( T = 9s , H = 1,4 m )

16

III. PORT PLANNING

CT1

CT2

CT3

CT5

CT4

CT6

CT7

CT8

LAYOUT of LONG TERM DEVELOPMENT (source Master Plan)

1. LAY OUT of CT1, CT 2 AND CT3 PORT (SHORT TERM PLANNING)

CT1

CT2

CT3

LAYOUT CT1, CT2, CT3

MAIN DATA FOR CONTAINER PORT :

1. CONTAINER PORT CT.1

Existing building : Pelindo Port, NAVAL Base (TNI-AL) and PERTAMINA

Wharf Size : L = 500 m, B = 45,5 m, basin depth : – 20,00 m LWS

Container Yard Size L = 500 m, B = 275 m

Need to remove existing onshore building and existing jetty or port

2. CONTAINER PORT CT.2

Existing building : Fishing Port, Dok Kodja, Passenger Port

Wharf size : L = 800 m, B = 45,5 m, basin depth : – 22,00 m LWS

Container Yard size : L = 800 m, B = 400 m

Need to remove existing building

3. CONTAINER PORT CT.3

Existing building : none

Wharf size : L = 800 m, B = 45,5 m , basin depth : - 22,00 m LWS

Container Yard size : L = 800 m, B = 400 m

20

2. PORT STRUCTURAL DESIGN

a. PRINCIPLES FOR PORT STRUCTURAL DESIGN

WHARF STRUCTURE IS DESIGNED BASED ON THE FOLLOWING ASPECTS :

1. STRUCTURAL RESPONSE TO RESIST DESIGN LOAD

2. STRUCTURAL STIFFENESS

3. NATURAL CONDITION OF PORT LOCATION

4. DESIGN LIFE

5. SIZE AND DIMENSION OF DESIGNATED SHIPS

6. VERTICAL AND HORIZONTAL LOADING

7. CONSTRUCTION MATERIAL

8. CONSTRUCTION SYSTEM THAT COULD BE CONSTRUCTED WITHOUT

SPECIAL EQUIPMENT AND COULD BE HANDLED BY NATIONAL CONTRACTOR

9. REFERENCES AND CODES

10. COST

11. CONSTRUCTION TIME

21

b. GENERAL CRITERION FOR WHARF STRUCTURE :

1. DESIGN LIFE OF THE STRUCTURE IS 100 YEARS

2. ELEVATION OF PORT DECK IS + 4,5 M LWS ( OR + 2,5 M FROM HWS )

3. MAXIMUM WAVE HEIGHT IN FRONT OF WHARF IS 0,5 M

4. SABANG HAS CLASSIFIED AS STRONG QUAKE ZONE, SO THAT THE PORT STRUCTURE

WAS DESIGNED FOLLOWING GENERAL CRITERION AS FOLLOW ( REFFERED TO CODE FOR

SEISMIC DESIGN OF NEW WHARVES )

•

PORT STRUCTURE WAS DESIGNED AS A “DUCTILE MOMENT RESISTANCE FRAME“ , IT WAS

DECK ON PILE WITH DECK STRUCTURE CONSIST OF REINFORCED CONCRETE WHICH

SUPPORTED BY VERTICAL STEEL PIPE PILE, SINCE PORT STRUCTURE WITH VERTICAL

PILE HAS BETTER PERFORMANCE THAN BATTER PILES

•

MAXIMUM STRUCTURAL DISPLACEMENT CAUSED BY QUAKE IS 7,5 CM

•

THE CONCEPT “STRONG BEAM WEAK PILE” SHOULD BE APPLIED, THAT MAKES PLASTIC

HINGE OCCUR ON PILE

22

c. TECHNICAL CRITERION

c.1. SHIP SIZE

CONTAINER TERMINAL CT.1, CT.2 and CT.3 COULD BE BERTHED BY

FEDEER VESSEL CONTAINER MAX 2500 TEUS ( 45,000 DWT )

Length = 215 m , Width = 30m, Design draught = 12 m,

Berthing Velocity = 25cm/sec

SUEZMAX CONTAINER SHIP 12,000 TEUS ( 137,000 DWT )

Length = 400 m , Width = 55m, Design draught = 15 m,

Berthing Velocity = 15cm/sec

c.2.

PORT BASIN DEPTH – 22,00 m LWS

c.3.

LOADING

VERTICAL LOADING:

DEAD LOAD + SUPERIMPOSED DEAD LOAD

LIVE LOAD

AT WHARF, CONSIST OF :

Uniform distribution load 4 ton/m2

Truck T.45

Rubber tire/RB 40 ton

Mobile crane (outrigger load)

Forklift truck

Side loader

Quay crane (Rail Mounted)

23

Quay Crane Terminology (Twin – Lift Container Quay Crane)

30 ft = 33,3 m

24

Crane Load, with wheel load :

- Sea side

= 1300 kN/wheel

- Land side

= 1060 kN/wheel

LOAD ON JETTY BETWEEN 2

CRANE LEGS

25

•

LIVE LOAD ON CONTAINER YARD :

Uniform distribution load of 4 stack container

Rubber Tired/RB load with the following data (BS 6349-part1) :

- Tractor : Axle line load : front = 40 kN and rear 280 Kn

- Trailler : number of axle line = 2, max line load = 150 Kn

Side Loader : Payload capacity 40ton ; number of jack 4 ; jack spacing

= 2,5 m ; jack load 230 kN and contact pressure 500 kN/m2

Stradle carrier

HORIZONTAL LOAD

DOCKING IMPACT :

Force caused by ship berthing/Docking Impact calculate based on the following

formula:

E = 0.5 MD.CM.CS.CC.CE.V2 ,

MOORING LOAD:

For container ship, where ship area to receive wind load is bigger than other ships,

then pulling force on bollard is more accurate to be calculated as follow:

Wind pressure to the ships:

Rx = ½.ra.U2.AT.CX ( parallel to the ship )

Ry = ½.ra.U2.AL.CY ( perpendicular to the ship) and

RM = ½.ra.U2.AL.Lpp.CM (moment by wind forces to the midship)

26

Force caused by current to the ships :

Current pressure parallel to the ship :

Rf = 0,0014.S.V2

Current pressure perpendicular to the ship :

Rf = 0,5.ro.C.V2.B

EARTH QUAKE : Based on Indonesian Seismic Zone

(SNI.1726-2002), Sabang is located in seismic zone no 5.

SABANG

27

Response Spectrum Seismic Zone 5

Based on nominal static equivalent, the magnitude of horizontal earthquake force is :

V = C.I.Wt/R

where :

V = horizontal earthquake force

C = seismic coefficient, for natural period from wharf structure of 1.1 second,

thus C = 0,5 (medium soil)

I

= importance structural factor = 1,0

Wt = total weight structure

R = reduction factor = 6 ( steel frame resisting moment ),

from push over analysis to the wharf structure, the value of R = 7,349

28

PERFORMANCE BASE ANALYSIS :

Limitation on structural displacement of 7,5 cm, from performance base analysis, the structure

doesn’t have meaningful damage, where the strength and the stiffness before and after

earthquake are almost same.

Earthquake direction :

The Structure was analyzed to the following combination of earthquake direction as

follow:

30%

100%

AND

100%

30%

IN THE SEISMIC ANALYSIS, THE EFFECT OF ECCENTRICITY TO THE CENTER OF STIFFNESS

IS INCLUDED IN THE CALCULATION

FROM STRUCTURAL ANALYSIS, THE MOST CRITICAL LATERAL

LOAD IS SEISMIC LOAD

29

c.4. MATERIAL

. CONCRETE

Every concrete (precast and cast in situ) designed with the strength of

fc’ = 36,0 Mpa ( K.400 )

• STEEL REINFORCEMENT :

Diameter < 12 mm BJTP.24

Diameter > 12 mm BJTD.39

• STEEL PIPE for pile : Referred to ASTM-A252 quality STK.41, with syield = 2400 kg/m2

• STEEL PIPE SHEET PILE, steel marine type, with syield = 3900 kg/m2

c.5. CORROTION PROTECTION FOR PILE

•

For splash zone, use HDPE system

•

Under splash zone, use cathodic protection, impressed current type

HDPE

Cathodic Protection

30

d. PORT STRUCTURAL SYSTEM

THE WHARF STRUCTURE WAS DESIGNED WITH SYSTEM “DECK ON PILE”

UPPER STRUCTURE :

THE UPPERSTRUCTURE WAS DESIGNED TO BE REINFORCED CONCRETE WITH fc’ = 36 Mpa/

K.400, CONSIDERING THE FOLLOWING CONSTRUCTION ASPECTS AS FOLLOW :

1. AT SABANG, IT’S NOT EASY TO FIND GOOD MATERIAL TO MAKE HIGH STRENGTH

CONCRETE, FOR THAT REASON THEN SOME PART OF ELEMENT (BEAM AND FLOOR SLAB)

CONSIST OF PRECAST SYSTEM AND MADE IN BANDA ACEH.

2. STRUCTURAL ELEMENTS WHICH COULD BE CAST IN SITU ARE : PILE CAP, CONCRETE

FILLER PILE, TOPPING FOR FLOOR SLAB. EVERY MATERIAL FOR CONCRETE CAST IN SITU

(SPLIT, SAND AND CEMENT) SHOULD BE SUPPLIED FROM BANDA ACEH.

3. COULD BE CONSTRUCTED BY NATIONAL CONTRACTOR

SUBSTRUCTURE :

SUBSTRUCTURE WAS DESIGNED TO BE STEEL PIPE PILE :

1. DIAMETER OF STEEL PIPE : 914 MM DAN 1016 MM, THIS LARGE DIAMETER IS NEEDED TO

RESIST BUCKLING AND TO REDUCE DISPLACEMENT DUE TO LATERAL LOAD.

2. MINIMUM THICKNESS OF STEEL PIPE IS 16 MM, DUE TO VERY HARD SOIL LAYER

> 65).

(SPT

31

CROSS SECTION OF PORT STRUCTURE

32

STRUCTURE DILATATION /GAP

DILATATION IN STRUCTURE IS NEEDED TO REDUCE THE EFFECTS OF TEMPERATURE

CHANGE IN STRUCTURE.

JETTY LENGTH BETWEEN DILATATION = Ld, CALCULATED BASED ON THE FOLLOWING

ASSUMPTION :

JETTY LENGTH BETWEEN DILATATION

= Ld =2.yo /c.Dt

Where :

yo = allowable pile displacement =

{L2.(SM)pile}/{3.(E.I)pile} = 2,975 cm

c = coefficient of thermal expansion of

deck material = 11,7

Δt = design temperature fluctuation = 20o

L = H + xo , xo = fixity point

= 20,0 m = 2000 cm

SM = pile section modulus

EI = pile stiffness

OBTAINED : Ld = 254 m,

Jetty length designed to be = 200 m,

and :

Dilatation width l = 2.yo + 0,5 cm = 6,45 cm

CONSTRUCTION OF DILATATION GAP

BETWEEN TWO PART OF JETTY WAS

DESIGNED USING SHEAR KEY SYSTEM

33

SHAPE OF THE UPPER STRUCTURE :

BEAM AND FLOOR SLAB WITH PRECAST SYSTEM

DECK LAY OUT

CROSS

SECTION

34

WHARF STRUCTURAL ANALYSIS :

A. LOADING COMBINATION FOR SUPER-STRUCTURE ANALYSIS :

a. ULTIMATE LOADING COMBINATION (BS 6349), for beam design :

1.1.265 DL

2.1.265 DL

3.1.265 DL

4.1.265 DL

5.1.265 DL

6.1.265 DL

7.1.265 DL

8.1.265 DL

9.1.265 DL

10.1.265 DL

11.1.265 DL

12.1.265 DL

13.1.265 DL

14.1.265 DL

+ 1.54 LL

+ 1.54 WIND

+ 1.54 LL

– 1.54 WIND

+ 1.54 LL

+ 1.54 Be.L + 1.54 Cu.L

+ 1.54 LL

+ 1.54 WIND

+ 1.54 LL

– 1.54 WIND

+ 0.462 LL + 1.54 Cu.L

+ 1.54 Mo.L

+ 0.462 LL + 1.54 Cu.L

+ 1.54 Mo.L

+ 0.462 LL + 1.54 Cu.L

+ 1.54 Mo.L

+ 0.462 LL + 1.54 Cu.L

+ 1.54 Mo.L

+ 0.462 LL + 1.54 Cu.L

+ 1.54 Mo.L

+ 0.462 LL + 1.54 Cu.L

+ 1.54 Mo.L

+ 0.462 LL + 1.54 Cu.L

+ 1.54 Mo.L

+ 0.462 LL + 1.54 Cu.L

+ 1.54 Mo.L

+ 1.54 LL

+ 1.54 WAVE

Where :

DL

LL

WIND

WAVE

Be.L

Mo.L

Cu.L

EQ-x

EQ-y

=

=

=

=

=

=

=

=

=

+1.54 Mo.L + 1.54 Cu.L

+ 1.54 Mo.L + 1.54 Cu.L

+ 1.54 Cu.L + 1.54 WAVE

+ 1.54 Cu.L + 1.54 WAVE

+ 1.54 Eqx + 0.462 Eqy

- 1.54 Eqx + 0.462 Eqy

+ 1.54 Eqx - 0.462 Eqy

- 1.54 Eqx - 0.462 Eqy

+ 0.462 Eqx

+ 1.54 Eqy

+ 0.462 Eqx

- 1.54 Eqy

- 0.462 Eqx + 1.54 Eqy

- 0.462 Eqx - 1.54 Eqy

Dead Load (Crane Load Included)

Live Load

Wind Load

Wave Load

Berthing Load

Mooring Load

Current Load

Seismic Load to x direction

Seismic Load to y direction

35

b. SERVICE LOADING COMBINATION ( BS 6349, Part 2, Section 6.11.4.3 ) used for pile capacity analysis :

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

1.0 DL + 1.0 LL + 1.0 WIND + 1.0 Mo.L + 1.0 Cu.L

1.0 DL + 1.0 LL – 1.0 WIND +1.0 Mo.L + 1.0 Cu.L

1.0 DL + 1.0 LL + 1.0 Be.L + 1.0 Cu.L

1.0 DL + 1.0 LL + 1.0 WIND + 1.0 Cu.L + WAVE

1.0 DL + 1.0 LL – 1.0 WIND + 1.0 Cu.L + WAVE

1.0 DL + 1.0 LL + 1.0 Cu.L + 1.0 Mo.L + 1.0 EQ-x

1.0 DL + 1.0 LL + 1.0 Cu.L + 1.0 Mo.L + 1.0 EQ-x

1.0 DL + 1.0 LL + 1.0 Cu.L + 1.0 Mo.L – 1.0 EQ-x

1.0 DL + 1.0 LL + 1.0 Cu.L + 1.0 Mo.L – 1.0 EQ-x

1.0 DL + 1.0 LL + 1.0 Cu.L + 1.0 Mo.L + 0.3 EQ-x

1.0 DL + 1.0 LL + 1.0 Cu.L + 1.0 Mo.L + 0.3 EQ-x

1.0 DL + 1.0 LL + 1.0 Cu.L + 1.0 Mo.L – 0.3 EQ-x

1.0 DL + 1.0 LL + 1.0 Cu.L + 1.0 Mo.L – 0.3 EQ-x

1.0 DL + 1.0 LL + 1.0 WAVE

+ 0.3 EQ-y

– 0.3 EQ-y

+ 0.3 EQ-y

– 0.3 EQ-y

+ 1.0 EQ-y

– 1.0 EQ-y

+ 1.0 EQ-y

– 1.0 EQ-y

B. BUCKLING ANALYSIS IN STEEL PIPE PILE (AISC - ASD 89) :

- Minimum thickness = 6,25 + D/100 ( D= pile diameter )

- Pile capacity to axial load is :

36

WHARF STRUCTURAL ANALYSIS RESULT :

Displacement (cm)

Loading

Combination

1

2

3

4

5

6

MAX

Stress Ratio

dx

dy

dz

0.500

1.465

0.000

MIN

-0.362

-2.611

-0.808

MAX

0.497

1.352

0.000

MIN

-0.360

-2.703

-0.808

MAX

0.397

3.220

0.000

MIN

-0.505

-1.048

-0.798

MAX

0.043

0.847

0.000

MIN

-0.018

0.000

-0.800

MAX

0.041

0.734

0.000

MIN

-0.016

0.000

-0.801

MAX

4.697

2.941

0.000

MIN

0.000

-1.708

D 1016

D 914.4

0.635

0.667

0.641

0.674

0.657

0.711

0.584

0.637

0.578

0.629

0.783

0.914

-0.804

37

WHARF STRUCTURAL ANALYSIS RESULT :

LOADING

Kombinasi

Pembebanan

COMBINATION

7

8

9

10

11

12

13

14

Stress Rasio pada Tiang

STRESS

RATIO

Pancang

Displacement (cm)

dx

dy

dz

MAX

4.707

0.529

0.000

MIN

0.000

-4.207

-0.813

MAX

0.000

2.287

0.000

MIN

-4.428

-1.107

-0.803

MAX

0.000

0.000

0.000

MIN

-4.436

-3.607

-0.812

MAX

1.742

5.525

0.000

MIN

0.000

0.000

-0.793

MAX

1.777

0.000

0.000

MIN

0.000

-6.913

-0.823

MAX

0.000

5.329

0.000

MIN

-1.569

0.000

-0.792

MAX

0.000

0.000

0.000

MIN

-1.596

-6.733

-0.823

MAX

0.033

0.503

0.000

MIN

-0.010

0.000

-0.801

D 1016

D 914.4

0.841

0.907

0.747

0.890

0.788

0.877

0.811

0.948

0,935

0,998

0.794

0.935

0.921

0.995

0.566

0.613

38

C. SUMMARY OF WHARF STRUCTURAL ANALYSIS

1. Max deflection : dx (longitudinal direction) = 4,707 cm (due to earthquake X direction)

dy (transversal direction) = 6,733 cm (due to earthquake Y direction)

2. PILE MAXIMUM STRESS RATIO = 0,998 ( crane beam pile d 1016 mm)

3. CHECKING THE PILE CAPACITY:

PILE f 914

Axial Load N max = 267,2 TON < N.allw (412 TON )

Horizontal H max = 13,4 TON (due to earthquake) < H.allw = 13,64 TON ( SF = 1,5 )

PILE f 1016

Axial Load N max = 230,7 TON < N.allw ( 518 TON )

Horizontal H max = 6,35 TON (due to earthquake) < H.allw = 14,41 TON ( SF = 1,5 )

FROM STRESS RATIO THAT OCCUR IN PILE AND FROM CHECKING PILE CAPACITY, PILE

DIMENSION IS DETERMINED BY STRESS IN PILE (DUE TO MOMENT AND AXIAL LOAD).

THIS IS BECAUSE THE LENGTH OF PILE ARE QUITE LONG (26 M), AND EVERY PILE IS

VERTICAL.

IF STRUCTURE IS DESIGNED USING BATTER PILE, THEN EARTHQUAKE FORCE WHICH

OCCUR IN STRUCTURE WILL BE BIGGER (COULD BE 3 TIMES OF THE STRUCTURE WITH

VERTICAL PILES) AND NEED MORE TENSION PILE BECAUSE OF LENGTH OF PILE UNDER

SEABED IS ONLY 10 M (DUE TO VERY HARD SOIL LAYER)

39

WHARF BACKFILL RETAINING WALL SYSTEM

(STRUCTURE BEHIND THE WHARF)

TWO ALTERNATIVES HAVE BEEN STUDIED. THESE ARE:

1. ARMORED ROCK SYSTEM

2. STEEL SHEET PILE SYSTEM

ARMORED ROCK COMBINED W/

L-SHAPE RETAINING WALL

STEEL PIPE SHEET PILE

RETAINING WALL

40

COST ESTIMATION FOR CT.3 ( Rupiah )

WORK ITEM

VOLUME

1. PREPARATION

2. WHARF STRUCTURE

CONSTRUCTION

3. RETAINING WALL BEHIND

WHARF

SUB TOTAL 1

PPN 10 % (TAX)

SUB TOTAL 2

SUPERVISION 1 %

TOTAL COST

ALTERNATIVE 2

(STEEL PIPE SHEET

PILE RETAINING

WALL)

21.545.000.000

21.545.000.000

800X45,5 M

741.325.000.000

741.325.000.000

1300 M

96.505.000.000

380.078.000.000

479.920.000.000

289.832.560.000

289.910.000.000

289.910.000.000

1.629.205.500.000

1.722.691.060.000

162.920.550.000

172.269.106.000

1.792.126.050.000

1.894.960.166.000

17.921.260.000

19.949.601.660

1.810.047.310.500

1.913.909.767.660

3. SAND AND ROCK BACKFILL

AND DREDGING

4. PAVEMENT

ALTERNATIVE 1

(ARMORED ROCK

RETAINING WALL)

800X400 M

41

COMPARISON BETWEEN THE TWO ALTERNATIVE

ALTERNATIVE 1 (ARMOURED

ROCK)

ALTERNATIVE 2 (STEEL PIPE

SHEET PILE)

INFRASTRUCTURE

COST

Rp. 1.810.047.310.500,-

Rp. 1.913.909.767.660,-

STRENGTH ASPECT

ROCKFILL IS EASILY

DEFORMED BY

EARTHQUAKE CAUSING FILL

BEHIND THE WALL TO

SETTLE

STRONGER AGAINST

EARTHQUAKE

CONSTRUCTION

TIME

LONG CONSTRUCTION TIME

SHORTER CONSTRUCTION TIME

MATERIAL

AVAILABILITY

HARD TO OBTAIN LARGE

QUANTITY ROCK

MARINE STEEL HAS TO BE

IMPORTED

- NEED HIGH ACCURACY IN

INSTALLING 1300 M LONG

PRECAST CONCRETE

- NEED HIGH ACCURACY IN

INSTALLING 1300 M LONG SHEET

PILE WALL

- NEED SPECIAL TREATMEN

IN INSTALLING FILTER

CONCRETE

- NEED SPECIAL PILE DRIVING

EQUIPMENT TO INSTALL 1 : 3

BATTER PILE

CONSTRUCTION

ASPECT

42

BASED ON COMPARISON TABLE ABOVE, IT CONCLUDED:

ALTHOUGH THE TOTAL COST IS RELATIVE MORE EXPENSIVE, BUT WITH

CONSIDER THAT SABANG IS AT REGION WITH STRONG AND HIGH

EARTHQUAKE INTENSITY AND LONG DESIGN LIFE TIME OF 100 YEARS, THEN

STEEL SHEET PILE IS CHOOSEN AS BACKFILL RETAINING WALL

SUGGESTION FOR CONSTRUCTION STAGE :

1. PREFERED FOR SHEET PILE CONSTRUCTION AT FIRST STAGE

2. BACKFILL COULD BE CONSTRUCTED IN AGREEMENT WITH STAGE OF WHARF LENGTH

CONSTRUCTION. CONSIDER THAT THE AREA OF THE PROJECT LOCATION IS VERY

LIMITED ESPECIALLY FOR MATERIAL STOCK PILING, IT WILL BE BETTER THAT ANY PART

OF LAND IN THE BACK OF SHEET PILE IS FILLED FIRST

3. STAGE CONSTRUCTION FOR WHARF IS PREFFERED TO BE 400 M/1 BERTH LENGTH, TO

GIVE POSSIBILITY TO OPERATE.

4. CONSTRUCTION SHOULD BE BY PROFESSIONAL CONTRACTOR THAT HAVE A

SUFFICIENT EXPERIENCES IN WHARF CONSTRUCTION

43

CONTAINER YARD STRUCTURE

STRUCTURAL DESIGN FOR PAVEMENT OF CONTAINER YARD WAS BASED ON THE

FOLLOWING SOME CONSIDERATION :

- Availability of material

- Work volume that is very large

- Simplicity of construction

- Soil condition in the location is sand with N SPT > 10

- Deck of container yard is supposed on sand fill, then the settlement which will occur is

relatively small

- Construction cost

TWO ALTERNATIVES THAT COULD BE USED FOR PAVEMENT DECK OF CONTAINER YARD

ARE :

1. PAVEMENT CONTAINER YARD USING RIGID CONCRETE PAVEMENT LARGE VOLUME OF

CONCRETE REQUIREMENT

2. PAVEMENT OF CONTAINER YARD USING PAVING BLOCK, REQUIRED LARGE VOLUME OF

PAVING BLOCK THAT MUST BE IMPORTED FROM JAVA (P. JAWA)

CONSIDERING SIMPLICITY IN CONSTRUCTION, CONCRETE PAVING BLOCK IS THE

CHOOSEN ALTERNATIVE

44