elps5053-sup-0001-FigureS1

advertisement

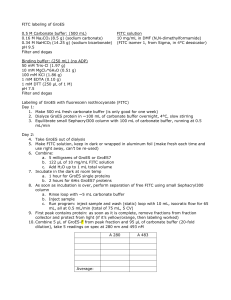

Determination of amino acids by microemulsion electrokinetic chromatography-laser-induced fluorescence method Wei-Cheng Lina‡, Wan-Ling Liua‡, Wei-Ying Tanga‡, Chin-Ping Huangb, Hsi-Ya Huanga*, Ting-Yu Chinc* a Department of Chemistry, Chung Yuan Christian University, 200 Chung Pei Road, Chung-Li, 320, Taiwan b Nanotechnology Research Center at Nano-instrumentation and Application Division, Industrial Technology Research Institute, Hsinchu, Taiwan. c Department of Bioscience Technology at CYCU, Chung Yuan Christian University, Chung-Li, Taiwan. Table of Contents 1. Material and method: 2. Figure S1 Effect of microwave energy. 3. Figure S2 Comparison of different microwave-assisted irradiation time 4. Figure S3 Effect of FITC concentration 5. Figure S4 Effect of various pH values running buffer with CZE method 6. Figure S5 Determination of 20 kinds of amino acid on CZE or MEKC system 7. Figure S6 Effect of co-surfactant concentration on MEEKC system 8. Figure S7 Effect of oil type on MEEKC system 9. Figure S8 Effect of surfactant concentration on MEEKC system 10. Figure S9 Electropherograms of amino acids by MEEKC with different pH running buffer. 11. Figure S10 Effect of ACN content on MEEKC system 12. Figure S11 Effect of column length on MEEKC system 13. Table S1 Table S1 Recovery of real samples 14. References 1. Material and method: Chemicals and reagents All amino acid standards were purchased from Sigma (Steinheim, Germany). Boric acid and borax were purchased from Merck (Darmstadt, Germany). Fluorescein isothiocyanate (FITC) was purchased from Fluka (Steinheim, Germany). All other chemicals used were of analytical grade and used without further purification. Apparatus and operating conditions for CE and FASS method All experiments were performed in a Beckman Coulter MDQ capillary electrophoresis system equipped with a LIF detection system (Fullerton, CA, USA). Beckman Coulter MDQ 32 Karat software was used for instrumental control and data analysis. The excitation light from an argon ion laser (3 mW) was focused on the capillary window by means of a fiber-optic connection. The 488 and 520 nm band-pass filters were used as excitation and emission filters, respectively. Separations were performed in a 50 cm effective length (inlet to detector) of a 60.3 cm total length with 50 μm I.D. uncoated fused-silica capillaries (Polymicro Technologies, Phoenix, AZ, USA) and the temperature of the capillary was maintained at 25 oC. The new capillary was conditioned in sequence with 1.0 M NaOH solution (20 min, 20 psi), deionized water (20 min, 20 psi), 0.1 M NaOH solution (10 min, 20 psi) and deionized water (10 min, 20 psi). The temperature of the capillary was maintained at 25 oC and the LIF detection wavelength was fixed at 488 nm during the entire experiment. Solutions and sample preparation Standard stock solution of amino acid with a concentration of 200 mg mL-1 was prepared by dissolving the analyte in 0.1M HCl. Stock solution of 30 mM FITC was prepared by dissolving 11.6 mg of FITC in 1mL acetone. The 63 mM borate stock derivatization buffer was prepared and its pH was 10.0 (unadjusted) and the microemulsion solution was prepared by mixing cyclohexane (0.6 %, w/w), sodium dodecyl sulphate (SDS; 2.16%, w/w),1-butanol (6%, w/w) ,acetonitrile (2%, w/w), 30 mM phosphate buffers (87.24% , w/w ,pH 6 unadjusted) were prepared by mixing for 30 minutes and standing for 1 hour. Derivatization procedures For standard solution derivatization, 10 μL of 200 mg L-1 standard stock solution was mixed with 20μL FITC and 20 μL derivatization buffer then the mixture was vortexed for 1 min. The sample was placed in a beaker containing RT water and then microwave heated in a domestic microwave oven (900 W, SAMPO RE-1002SM) while the other set-up was done in a 100 mL Teflon autoclave containing 12 mL deionized water placed in a microwave reactor (START D, Milestone, maximum power of 1200 W, 2.45 GHz) and heated for a predetermined time. The preparation of the samples for derivatization were the same for both water-bath and microwave methods. Beverage and food sample preparation The outer film tablet of food sample was removed and put 0.1g sample in centrifuged tube then adds 0.1 M HCl solution (1mL) and shakes 60 minutes for extracting amino acids. After extracted step, centrifuging at 5000 rpm for 30 minutes, taking the upper layer and filtered by 0.2μm filter. Rat brain sample preparation Rat brain was obtained from 5-month old rats. The extraction procedure was referred to previous papers [1-3] and briefly described herein. Cell metabolites extraction was performed by adding lysis buffer to release the metabolites of interest. Then the extract was centrifuged for 10 min and the supernatant containing the amino acids was used as the real sample to be derivatized using FITC. The microwave-assisted derivatization was performed in 600 µL microcentrifuge vial as follows: 5μL real sample, 19μL derivatization buffer and 1μL 30mM FITC solution. After mixed step, the microcentrifuge vial was sealed by heat tape and placed in a domestic microwave oven (900 W) together with a beaker containing 250mL water. 2. 1.5 FITC Arg (a) 900W 1.0 a 0.5 a a a RFU 0.0 1.5 (b) 729W FITC Arg 1.0 a 0.5 a a a 0.0 1.5 (c) 590W FITC 1.0 Arg 0.5 a a a a 0.0 4 5 6 7 8 Time (min) Figure S1 Effect of microwave energy The sample introduction was 0.5 psi for 3s, in which the concentration of Arg standards is 5 µgL-1. Derivatization condition: 25 mM boric acid +25 mM borax, pH 9 (derivatization buffer), reaction time, 2 min. CE conditions: capillary, 40 cm×50 m i.d,; separation voltage, 20 kV; running buffer, 50 mM boric acid was mixed with 40 mM borax (pH 9), detection, LIF, 488/520 nm. 3. Peak area 500000 400000 300000 0 1 2 3 4 Time (min) Figure S2 Comparison of different microwave-assisted irradiation time The sample introduction was 0.5 psi for 3s, in which the concentration of Arg standards is 5 µgL -1. Derivatization condition: 25 mM boric acid +25 mM borax, pH 9 (derivatization buffer), 15mM FITC. CE conditions: capillary, 40 cm×50 µm i.d,; separation voltage, 20 kV; running buffer, 50 mM boric acid was mixed with 40 mM borax (pH 9), detection, LIF, 488/520 nm. 4. Arg Ser Gly Glu Asp Area 1600000 1200000 800000 400000 10 15 20 30 FITC concentration (mM) Figure S3 Effect of FITC concentration The sample introduction was 0.5 psi for 3s, in which the concentration of standards is 2 µgL-1. Derivatization condition: 25 mM boric acid, 25 mM borax, pH 10 (derivatization buffer), reaction time, 3 min. CE conditions: capillary, 40 cm×50 m i.d,; separation voltage, 20 kV; running buffer, 50 mM boric acid was mixed with 40 mM borax (pH 9), detection, LIF, 488/520 nm. 5. 1.0 FITC pH10 3 1 0.5 2 a 0.0 1.0 pH9 2 3 FITC 1 5 4 0.5 4 5 a RFU 0.0 FITC 2 pH8 2 1 4 a 0 1.0 FITC pH7 5 3 2 1 0.5 4 a 0.0 0.2 3 1 FITC pH6 3 2 1 4 5 a 0.0 5 5 10 15 20 25 Time (min) Figure S4 Effect of various pH values running buffer with CZE method The sample introduction was 0.5 psi for 3s, in which the concentration of standards is 2 µgL-1. Derivatization condition: 25 mM boric acid, 25 mM borax, pH 10 (derivatization buffer), reaction time, 3 min. CE conditions: capillary, 40 cm×50 m i.d,; separation voltage, 20 kV; running buffer, 50 mM boric acid was mixed with 40 mM borax, detection, LIF, 488/520 nm. Arg (1), Ser (2), Gly (3), Glu (4), Asp (5) and FITC hydrolyzate (a). 6. 3 (b) MEKC 2 1 1,2 a aa 17 7,8,9,10,11 20 12,13,14 15 3,4 56 16 18,19 RFU 0 8 FITC 4,10,14,13,15,16 5,11,7,3,9 6 (a) CZE 12 4 8 17 6 2 2 19 20 a a 0 5 10 15 20 25 Time (min) Figure S5 Determination of 20 kinds of amino acid on CZE or MEKC system Derivatization condition: 25 mM boric acid +25 mM borax, pH 10 (derivatization buffer), reaction time, 3 min. (a) CE conditions: capillary, the concentration of standards is 2 µgL-1 (0.5 psi, 3s), running buffer, pH 9, 50 mM boric acid was mixed with 40 mM borax, (b) pH-8 borate buffer (59mM), 2% SDS, 6% 1-butanol, 40 cm×50 m i.d,; separation voltage, 20 kV; detection, LIF, 488/520 nm. Lys (1), Arg (2), His (3), Pro (4), Val (5), Leu (6), Ile (7), Phe (8), Trp (9), Tyr (10), Met (11), Thr (12), Gln (13), Ala (14), Asn (15), Cys (16), Ser (17), Gly (18), Glu (19), Asp (20) and FITC hydrolyzate or impurity (a). 7. 0.8 (a) 6% 0.6 9,10,11 12 8 0.4 467 3 5 0.2 14 13-2 15,16 1,2 13-1 a 18,19 20 a 17 RFU 0.0 2.0 9,10,11,12 (b) 3% 1.5 1.0 8 5,6 3,4 7 1,2 13-2 0.5 13-1 a 14 15,16 a 18,19 a 20 17 0.0 10 15 20 Time (min) Figure S6 Effect of co-surfactant concentration on MEEKC system Running buffer, SDS, 6 % 1-butanol, 4 % ACN, pH6 phosphate buffer (40 mM) and the sample concentration is 4 µgL-1 (0.5 psi, 3s). Other conditions are the same as Fig.1. His (1), Arg (2), Gln (3), Pro (4), Tyr (5), Asn (6), Thr (7), Ser (8), Ala (9), Val (10), Met (11), Gly (12), Ile (13), Leu (14), Phe (15), Trp (16), Cys (17), Glu (18), Lys (19), Asp (20), FITC hydrolyzate or impurity (a). 8. 0.6 0.4 0.2 1 2 0.0 0.4 9,10,11 12 5 8 4 7 14 3 6 13-2 15 a 13-1 16a 18,19 20 17 9,10,11 12 4 12 a RFU (a) heptane 5 3 67 8 13-214 13-1 (b) EA 18,19 15,16 a 20 17 0.0 (c) octane 1.2 0.8 9,10,11 12 8 6 4 7 18,19 13-2 14 3 15,16 5 13-1 20 a 17 1 2 0.4 a 0.0 0.8 9,10,11 12 0.4 1 2 a 0.0 10 46 7 3 5 (d) cyclohexane 8 14 13-2 15,16 18,19 13-1 20 a17 15 20 Time (min) Figure S7 Effect of oil type on MEEKC system Running buffer, 2.16 % SDS, 6 % 1-butanol, 4 % ACN, 87.24 %, pH6 phosphate buffer (40 mM) and the sample concentration is 4 µgL-1 (0.5 psi, 3s). Other conditions are the same as Fig.1. His (1), Arg (2), Gln (3), Pro (4), Tyr (5), Asn (6), Thr (7), Ser (8), Ala (9), Val (10), Met (11), Gly (12), Ile (13), Leu (14), Phe (15), Trp (16), Cys (17), Glu (18), Lys (19), Asp (20), FITC hydrolyze or impurity (a). 9. 0.4 4 8 9,10,11 (a) 2.88% 6 1 0.2 2 3 5 7 12 0.0 0.4 9,10,11,12 0.2 1 2 RFU 0.0 5 FITC 10,11,12 0.2 (c)1.43% 7,8,9 12 3,4 a 0.0 56 1415,16 18,19 20 17 13 0.8 FITC 3,4,5,6,7,8,9,10,11,12 13,14,15,16,17 0.4 12 0.0 (b) 2.16% 68 18,19 4 7 13-2 3 1415,16 20 a 13-1 a17 0.4 1.2 14 13-2 15,16 18,19 20 17 13-1 (d) 0.72% 18,19 20 a 10 15 20 25 Time (min) Figure S8 Effect of surfactant concentration on MEEKC system Running buffer, 2.16 % SDS, 6 % 1-butanol, 4 % ACN, pH6 phosphate buffer (40 mM) and the sample concentration is 4 µgL-1 (0.5 psi, 3s). Other conditions are the same as Fig.1. His (1), Arg (2), Gln (3), Pro (4), Tyr (5), Asn (6), Thr (7), Ser (8), Ala (9), Val (10), Met (11), Gly (12), Ile (13), Leu (14), Phe (15), Trp (16), Cys (17), Glu (18), Lys (19), Asp (20), FITC hydrolyzate or impurity (a). 10. FITC 2 (a) pH10 1 0 3 FITC (b) pH9 2 1 0 RFU 3 FITC (c) pH8 2 1 0 3 FITC (d) pH7 2 1 0 1.0 0.5 0.0 FITC (e) pH6 9,10,11 12 8 14 5,6 7 13-2 15,16 1 2 3,4 18,19 a 20 17 13-1 10 20 30 Time (min) Figure S9 Electropherograms of amino acids by MEEKC with different pH running buffer. Running buffer, 2% SDS, 6 % co-surfactant, 0.6% cyclohexane, 91.4 %, pH6~10 phosphate buffer (40 mM) and the sample concentration is 4 µgL-1 (0.5 psi, 3s). Other conditions are the same as Fig. 1. His (1), Arg (2), Gln (3), Pro (4), Tyr (5), Asn (6), Thr (7), Ser (8), Ala (9), Val (10), Met (11), Gly (12), Ile (13), Leu (14), Phe (15), Trp (16), Cys (17), Glu (18), Lys (19), Asp (20), FITC hydrolyzate or impurity (a). 11. 1.2 (a) 6% 4,5,6 0.8 1,2 12 17,18,19,20 10,11 0.4 a a a 0.0 1.2 3 89 7 15,16 14 a 13 FITC RFU (b) 4% 0.8 9,10,1112 2 0.4 4 8 7 1 a a a 0.0 1.2 17,18,19,20 13-215 14 16 3 56 13-1 FITC (c) 2% 0.8 10,11 5,6 12 2 1 0.4 a 0.0 a a a 4 8 7 3 9 13-215 14 17,18,19,20 16 13-1 10 15 20 Time (min) Figure S10 Effect of ACN content on MEEKC system Running buffer, 1.43 % SDS, 6 % 1-butanol, ACN, pH6 phosphate buffer (40 mM) and the sample concentration is 4 µgL-1 (0.5 psi, 3s). Other conditions are the same as Fig.1. His (1), Arg (2), Gln (3), Pro (4), Tyr (5), Asn (6), Thr (7), Ser (8), Ala (9), Val (10), Met (11), Gly (12), Ile (13), Leu (14), Phe (15), Trp (16), Cys (17), Glu (18), Lys (19), Asp (20), FITC hydrolyzate or impurity (a). 12. 1.5 (a)50 cm 1.0 5,610,1112 17 9 8 13-2 47 18,19 20 a 14 15 3 12 16 a a a 0.5 RFU 0.0 13-1 2.5 FITC 2.0 (b) 40 cm 17 1.5 1.0 0.5 0.0 18,19 10,11 20 12 5,6 13-2 89 1415 47 12 3 a a a 16 a 13-1 10 15 20 25 Time (min) Figure S11 Effect of column length on MEEKC system Running buffer, 1.43 % SDS, 6 % 1-butanol, 4 % ACN, 87.24 %, pH6 phosphate buffer (40 mM) and the sample concentration is 4 µgL-1 (0.5 psi, 3s). Other conditions are the same as Fig.1. His (1), Arg (2), Gln (3), Pro (4), Tyr (5), Asn (6), Thr (7), Ser (8), Ala (9), Val (10), Met (11), Gly (12), Ile (13), Leu (14), Phe (15), Trp (16), Cys (17), Glu (18), Lys (19), Asp (20), FITC hydrolyzate or impurity (a). 13. Table S1 Recovery of real samples Recovery of real samples (%)a Concentration of real samples (mg/L) Analytes a Beverage Food Biological sample Beverage (spiked with 4ppb) Food (spiked with 4ppb) Biological sample (spiked with 2ppb) His (1) --b 106.1 1.82 87.5 100.2 87.6 Arg (2) Gln (3) Pro (4) Thr (7) Ser (8) Ala (9) Gly (12) 26.07 2.90 17.14 --b --b --b --b --b --b --b 156.8 24.28 --b --b 5.25 --b --b --b 28.49 --b --b 105.1 87.6 88.6 92.4 99.2 98.5 94.3 102.5 93.9 94.6 94.8 94.7 86.9 100.6 106.6 92.8 89.5 92.3 105.6 89.9 94.4 Ile (13) Leu (14) Phe (15) Trp (16) Cys (17) Asp (20) --b --b 49.94 57.53 --b --b 293.5 334.8 369.4 76.16 --b --b --b 0.68 0.77 --b 10.07 19.62 104.3 87.8 100.0 101.1 91.6 90.3 99.4 99.2 107.1 108.3 89.9 86.5 93.8 93.6 86.9 88.1 93.6 104.3 Recovery = (Found concentration of analyte standard obtained by the CE-LIF method / spiked concentration of analyte standard to real sample) × 100%. b non-detection 14 References [1] Ossola, B., Schendzielorz, N., Chen, S-H., Bird, G. S., Tuominen, R. K., Männistö, P. T., Hong, J-S., Neuropharmacology 2011, 61, 574-582. [2] Zhang, F., Qian, L., Flood, P. M., Shi, J.-S., Hong, J.-S., Gao, H.-M., J. Pharmacol. Exp. Ther. 2010, 333, 822-833. [3] Zhang, F., Shi, J.-S., Zhou, H., Wilson, B., Hong, J.-S., Gao, H.-M., Mol. Pharmacol 2010, 78, 466-477.