Introduction to Materials Technology

advertisement

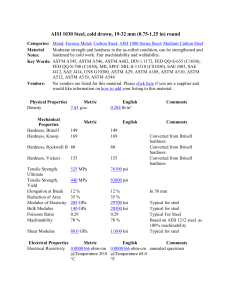

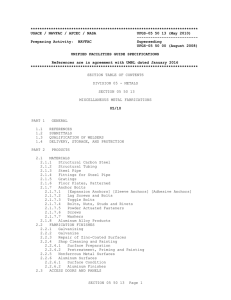

Introduction to Materials Technology Text Chapter 1 Charles W. Smith, PhD Department of Construction Management Colorado State University Fort Collins, Co 1 • Elements…Molecules of same types of atoms; cannot be broken down into chemically simpler substances…Periodic Chart • Metals: generally solid at room temperature -Tend to be good conductors. • Nonmetals: may be solids, liquids, or gases at room temp. -Tend to be good insulators 2 Compounds…Molecules of different types of atoms…may have properties substantially different from the constituent elements… - salt- NaCl: sodium and chlorine, water- H2O: Hydrogen and Oxygen. (molecularly bonded) • Alloys: metals combined with one or more other elements - Steel alloys, copper alloys, aluminum alloys and others • a mixture containing two or more metallic elements or metallic and nonmetallic elements usually fused together or dissolving into each other when molten; "brass is an alloy of zinc and copper" • Mixtures…mechanically mixed together, but still chemically separate…the mixed substances may be elements or compounds…oil and water, smoke in air, 3 muddy water. 4 Materials can be: • Natural vs. Manufactured Elements can be either Naturally occurring or can be Synthetically manufactured. • Organic vs. Inorganic Compounds can be either Organic or Inorganic (Organic compounds contain carbon) 5 Bonding of Materials • Material properties are affected by ability to combine/react with other materials, which is related to the chemical structure, especially electrons in the outer shell (valence electrons) • Types of bonding • Ionic: In compounds, where one atom gives up electrons (becoming a positive ion) to another different atom (which, gaining an electron, becomes a negative ion) Example: sodium chloride NaCl (salt)…these bonds are very tight, strong, very stable. • Covalent: In diatomic gases, like oxygen (O2), nitrogen (N2), hydrogen (H2) where two atoms share electrons to complete each other’s outer shells…these bonds are very strong. All organic compounds are also covalently bonded. • Metallic: localized exchange of electrons between small number of atoms via an “electron cloud” 6 • Physical state (solid, liquid, gas) depends on type and strength of bonding: • Liquids & gases: loosely bound atoms and molecules, free to move independently of each other • Solids: atoms are tightly bound together …rigidly held in place by other atoms -Turning into a solid: As bonds become stronger, atoms begin to form ordered patterns called lattices, which form larger patterns called crystals, which become solids 7 • Molecular Structure • Solid materials are usually Amorphous or Crystalline in structure. • Amorphous materials (like glass): No patterns, lattices, or crystals…random order and do not exhibit a regular patter or order. • Crystalline Structures Lattice structures: Imaginary lines connecting the centers of atoms in a pattern. Form true repeatable boundaries or patterns. - Metals crystallize into one of seven types of lattice structures (see Fig. 1-5, pg.13). - Material properties (primary physical and mechanical) depend on the crystal structure. 8 Basic Metal Crystal Formations 9 • Material Specifications • A Specification is basically a statement of the minimum quality of a desired product. **Items typically included in a specification: Method of manufacture or processing Forms, dimensions, and finishes desired properties (See Table 1-1, pg. 21): -General -Chemical -Physiochemical -Thermal -Electrical/Magnetic -Optical -Mechanical 10 • Mechanical (focus of this course): Tensile Strength Compressive Strength Shear Strength Flexural Strength Stiffness Toughness Hardness Elasticity Plasticity Ductility **See pg. 281 of Text 11 • Standards - Standards are the culmination of the efforts of experts in particular materials, manufacturing and construction methods, testing procedures, etc., to define commonly accepted minimum requirements for those materials, methods, and procedures. - Organizations involved in developing standards are listed on pg. 20. Those which are especially pertinent to building construction include: 12 • For structural and architectural materials, components, and systems: ACI American Concrete Institute AISC American Institute of Steel Construction AISI American Iron and Steel Institute ASCE American Society of Civil Engineers ANSI American National Standards Institute ASTM American Society for Testing and Materials www.astm.org. 13 • For electrical materials, components, and systems: NEMA National Electrical Manufacturers Association IEEE Institute of Electrical and Electronic Engineers ASTM American Society for Testing and Materials For mechanical equipment: ASME American Society of Mechanical Engineers ASTM American Society for Testing and Materials 14 • We will focus in this course on general testing concepts, and will look at ASTM tests for such items as structural steel, concrete and rebar, glass, masonry, etc. In the lab, we will use selected typical test procedures from those presented in Appendix C of the text, which are simplified versions of actual ASTM tests. • The entire current set of ASTM standards constitutes a multivolume compendium which is kept in the Reference Dept. on the main floor of the library. The volumes are arranged in groups according to general categories (called “Sections”) of materials or procedures. Each volume contains standards which pertain to particular materials or procedures within a subgroup within the general category. 15 Professional Organizations • All of the previously listed professional organizations and others, work collectively to establish test standards in conjunction with the American Society of Testing Materials (ASTM). Individual organizations may have additional testing procedures or protocols that may differ from ASTM standard test. 16 • The general categories (“Sections”) include (we will focus on the first four sections): Section 1: Iron and Steel Products Section 2: Nonferrous Metal Products Section 3: Metals Test Methods and Analytical Procedures Section 4: Construction Section 5: Petroleum Products, Lubricants, and Fossil Fuels Section 6: Paints, Related Coatings, and Aromatics Section 7: Textiles Section 8: Plastics 17 Section 9: Rubber Section 10: Electrical Insulation and Electronics Section 11: Water and Environmental Technology Section 12: Nuclear, Solar, and Geothermal Energy Section 13: Medical Devices and Services Section 14: General Methods and Instrumentation Section 15: General Products, Chemical Specialties, End Use Products 18 • Each individual ASTM standard has a combination letter/number designation. The letter designates the general group under which the standard is contained; the number indicates the order in which the was adopted into the group. The letter groupings are: A. Ferrous metals B. Nonferrous metals C. Cement, concrete, ceramic, and masonry materials D. Miscellaneous materials E. Miscellaneous subjects F. Specific applications of materials C. Corrosion, deterioration, and degradation of materials ES. Emergency Standards 19 • Example: If we were looking for criteria regarding bolts for fastening structural steel, representative standards would be found in Volume 01.08 (Fasteners) of Section 1 (Iron and Steel Products), and would include standards A307, A325, and A490 for steel bolts. 20 • Section 1: Iron and Steel Products Volume 01.01 Volume 01.02 Volume 01.03 Volume 01.04 Volume 01.05 Volume 01.06 Volume 01.07 Volume 01.08 Steel-Piping, Tubing, Fittings Ferrous Castings, Ferroalloys Steel-Plate, Sheet, Strip, Wire Steel-Structural, Reinforcing, Pressure Vessel, Railway Steel- Bars, Forgings, Bearing, Chain, Springs Coated Steel Products Ships and Marine Technology Fasteners 21 • In Volume 01.08 (Fasteners), we would find: Standard A307: Standard Specification for Carbon Steel Bolts and Studs, 60,000 PSI Tensile Strength Standard A325: Standard Specification for Structural Bolts, Steel, Heat Treated, 120/105 ksi Minimum Tensile Strength Standard A490: Standard Specification for HeatTreated Steel Structural Bolts, 150 ksi Minimum Tensile Strength 22 American Society of Testing Materials. http://www.astm.org/ 23