BigButton - New River Kinematics

advertisement

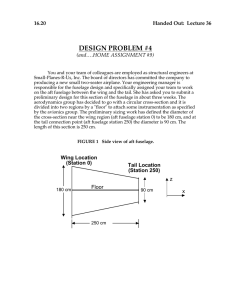

Big Button Model Based Assembly Jim Lind Boeing IDS Scott Sandwith New River Kinematics CMSC 2003 July 21-25 2003 Introduction: Model Based Assembly • Integrate engineering design, Measurement Plan Script with advanced metrology in an easy to use interface • Improve cost and quality by simplifying aerospace manufacturing • Simplify assembly and build processes by implementing and quickly delivering integrated production-ready solutions • Minimal operator learning curve Motivation: Produce Product • Move away from large assembly tooling – Less complex / lower cost – Mobility / smaller footprint • Engineering tolerances remain critical • Increasing production rates • Limited skill base • Technology learning curve Automation ROI • Existing Tool Routine – Subset average 34 hours – 110 hour average • Automating Tool routine – Subset demonstrated in 3 minutes – Overall projected within 1 shift • Time savings not enough – Multiplier for reduction in Production Disruption Embedding Metrology Solutions • Transparent to mechanic – Process not technology training – If done well, they may not realize they are operating precision metrology equipment • Simple interface – Work instructions displayed with big action buttons – Results displayed with big action buttons • Automatic reporting Benefits • Single person operation possible • Speeds up process • Improved repeatability • Quality check built into process • Consistent, traceable results Benefits • Optimize product performance • Cost savings and flow time reduction – Maintenance and time – Set/Inspect part features directly from CAD – Reduces measurement tolerance guess work • Part specific template and general measurement plan support custom configurations directly on the shop floor without reprogramming • Relationship between features are optimized directly! Build / Inspect • Integrate assembly configuration for design/tolerance improvements • CAMS Reaches High-Tech Milestone In Support of F/A-22 Aft Fuselage • The Computer Aided Measurement Systems (CAMS) organization recently demonstrated a new process improvement using a scripting program, which measures F/A-22 aft fuselage parts to ensure proper fit. The old process involved hand-guided measuring, which took up to six hours and time-consuming set-up. After months of research and testing, the CAMS organization is now able to program specific coordinates into a database that tells the laser tracker and computer exactly what, where and how to measure. Automating this process reduces the flow time by 87.5 percent from the old process and could yield approximately eight hours of processing time on future builds. “While this represents a very significant savings, we expect savings as great, or greater as we integrate Model Based Assembly – using the CATIA model as the authority to do the aircraft assembly – into our manufacturing processes,” said Ed Baker, Emergent Manufacturing & Tooling senior manager. CAMS Reaches High-Tech Milestone In Support of F/A-22 Aft Fuselage “…reduces the flow time by 87.5 percent…” CAMS Reaches High-Tech Milestone In Support of F/A-22 Aft Fuselage “…we expect savings as great, or greater as we integrate Model Based Assembly into our manufacturing processes.” Ed Baker, EM&T senior manager. Simulation of Application Direct Project Benefits (Overall) • OLD – 142,000 lbs. steel – $14 million fabrication – ~ 3150 sq. ft. footprint – Future – rate tools? • NEW – < 1 ton – < $ 1 million to fabricate – Assemble 3 or 4 sections in the same footprint – Flexibility – move assets to support need Summary • Big Button Model Based Assembly improves over traditional processes • Reduce the amount of tolerance information by working directly with the critical features • Preparation, Setup, and Flow time are minimized • Direct use of the CAD Geometry improves part and trend analysis • Using part tolerances instead of tooling tolerances enables significant cost savings Acknowledgements • Ed Baker, John Costello and Barry Cooke of Boeing • Dr. Robert Salerno, Dr. Joseph Calkins, Bruce Thomas, and Rick Cole of NRK