chapter 3 linear measurements

advertisement

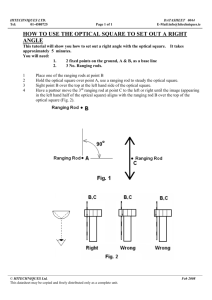

CHAPTER 3 LINEAR MEASUREMENTS By, VANSHIKA MUCHHARA ASSISTANT PROFESSOR CIVIL DEPT-PIET DEG 1ST SHIFT PARUL UNIVERSITY RANGING OUT SURVEY LINES 1. 2. In measuring the length of a survey line called chain line, it is necessary that the chain should be laid out on the ground in a straight line between the end stations. “The process of establishing intermediate point on a straight line between two end points is known as ranging”. Ranging must be done before a survey line is chained. It may be necessary to establish a number of intermediate points prior to chaining when chain line is much longer. Ranging may be done by direct observation by the naked eye or by line ranger or by theodolite. Generally, ranging is done by naked eye with the help of three ranging rods. Ranging is of two kinds: Direct Ranging Indirect or reciprocal ranging DIRECT RANGING When intermediate ranging rods are fixed on a straight line by direct observation from end stations, the process is known as direct ranging. Direct ranging is possible when the end stations are intervisible. Two methods are used for Direct Ranging a) b) Ranging by eye Ranging by line ranger RANGING BY EYE Two points A and B are at the ends of survey line. Distance AB is greater than one chain length. Ranging rods are fixed at stations A and B It is require to fix a intermediate point C between A and B. The surveyor stands about half meter behind the ranging rod at A by looking towards line AB. The assistant holds ranging rod at C vertically at arms length the rod should be held tightly by the thumb and forefinger. Now the surveyor direct the assistant to move the ranging rod to the left or right until the three ranging rods come exactly the same straight line. The ranging will be perfect, when the three ranging rods coincide and appear as a single rod. When the surveyor is satisfied that the ranging is prefect, he signals the assistant to fix the ranging rod on the ground. By following the same procedure, the other ranging rods may be fixed on the line. . Line ranger is a light and easy to use instrument which can be used for ranging. It consists of 2 plane mirrors or 2 right-angled isosceles prism places one above the another. Diagonals of two prism are silvered so as to reflect light. Lower prism is fixed while the upper prism is moveable. Instrument is provided with handle at bottom which gives ease to the user for using the instrument. Suppose Point L is to be located between points A and B. Observer stands in line and place the instrument on a rod or holds it at eye level until the image of rod at A is seen in field view. Then surveyor moves with the line ranger. The point where two images A and B coincide in line ranger is the point in line with two fixed ranging rods. At this point a pebble is dropped from the handle of line ranger and point L is traced on ground. INDIRECT RANGING OR RECIPROCAL RANGING End stations are not intervisible due to rising ground between them. End stations not visible due to long distances. For such above cases, intermediate points can be fixed on line by process known as reciprocal ranging. Consider two points A & B as in figure Chainmans should stand at P1 and R1 such that P1 is able to see R1 and B & chainman at R1 can see P1 and A R1 will direct P1 to move to P2 such that R1P2, A are in line. P2 will direct R1 to move to R2 such that P2, R2, B are in line. By successive directing each other, the two chainmen proceed such that A, P, R & B lies in a line. P and R are the intermediate points between A and B. TYPES OF OFFSETS Offsets are the lateral measurements from the base line to fix the positions of the different objects of the work with respect to base line. These are generally set at right angle offsets. It can also be drawn with the help of a tape. There are two kinds of offsets: 1. Perpendicular offsets 2. Oblique offsets. INSTRUMENTS USED FOR LAYING OFFSETS Figure shows three different types of cross staffs used for setting perpendicular offsets. All cross staffs are having two perpendicular lines of sights. The cross staffs are mounted on stand. One pair of vertical slit is to bisect ranging rod at the end of the given chain line by standing on chain line & other pair of vertical slit is required to be in line with ranging rod at object for perpendicular offset. First line of sight is set along the chain line and without disturbing setting right angle line of sight is checked to locate the object. With open cross staff (Fig a) it is possible to set perpendicular only, while with french cross staff (Fig. b), even 45º angle can be set. Adjustable cross staff (Fig c) can be used to set any angle also, since there are graduations and upper drum can be rotated over lower drum. Optical square Instrument used for perpendicular offsets only. Consists of circular box 50 mm in diameter & 12.5 mm in depth. Three silts at E, G, F. In line EG a glass B is provided silvered at top, plain at bottom. Opposite of C, silver painted glass A called index glass is fixed so that the inclined edge of glass A & inclined face of glass B makes angle 45 deg. Opening F, when faced towards object P, image will strike at A and reflected to horizon B which will be seen at E. Thus he can set the ranging rod at Q by object image seen at B. If observer finds that the ranging rod Q and image of object P do not concide ,then he should move forward or backward along chain line until ranging rod Q and image of P exactly coincide. Indian Optical Square Brass wedge shaped hollow box of 5 cm sides & 3 cm deep with handle about 8 cm long fixed undeneath. m1, m2 are two mirrors fixed to inclined sides of box at 45 deg. ab, cd are two rectangular openings above mirrors. PQRS is open face turned towards object to which the offset is taken. Principle is same as that of Optical square. Prism Square Same principle of optical square. Instead of two mirrors, prism is used which has two reflecting surfaces I and H fixed at 45 deg. Procedure is same as that of Optical square. ERRORS IN CHAINING Instrumental: Surveying error may arise due to imperfection or faulty adjustment of the instrument with which measurement is being taken. For example, a tape may be too long or an angle measuring instrument may be out of adjustment. Such errors are known as instrumental errors. Personal: Error may also arise due to want of perfection of human sight in observing and of touch in manipulating instruments. Such errors are known as personal errors. Natural: Error in surveying may also be due to variations in natural phenomena such as temperature, humidity, gravity, wind, refraction and magnetic declination. If they are not properly observed while taking measurements, the results will be incorrect. For example, a tape may be 20 meters at 200 deg celcius but its length may change if the field temperature is different. Systematic or Cumulative Errors: A systematic or cumulative error is an error that, under the same conditions, will always be of the same size and sign. A systematic error always follows some definite mathematical or physical law and correction can be determined and applied. Such errors are of constant character and are regarded as positive or negative according as they make the result great or small. Their effect is, therefore, cumulative. For example, if a tape is P cm short and if it is stretched N times, the total error in the measurement of the length will be P´N cm. The systematic errors may arise due to (i) variations of temperature, humidity, pressure, current velocity, curvature, refraction, etc. and (ii) faulty setting or improper levelling of any instrument and personal vision of an individual. The following are the examples: If undetected, systematic errors are very serious. Therefore, (1) all surveying equipment must be designed and used so that, whenever possible, systematic errors will be automatically eliminated, (2) all systematic errors that cannot be surely eliminated by this means must be evaluated and their relationship to the conditions that cause them must be determined. Compensating Errors: This type or surveying error tends to occur in both directions, i.e. the error may sometimes tend to be positive and sometimes negative thereby compensating each other. They tend sometimes in on direction and sometimes in the other, i.e. they are equally likely to make the apparent result large or small. The following are a few examples: Incorrect holding of chain Displacement of arrows Adding or omitting a full length of chain Reading wrongly Booking wrongly So we can say that errors in chaining may arise from 1. 2. 3. 4. 5. 6. 7. 8. Incorrect length of chain or tape. Bad Ranging Careless holding and marking. Bad straightening Non –horizontality. Sag in chain Variation in temperature. Variation in pull, etc.